Patents

Literature

36results about How to "Eliminate magnetic flux leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

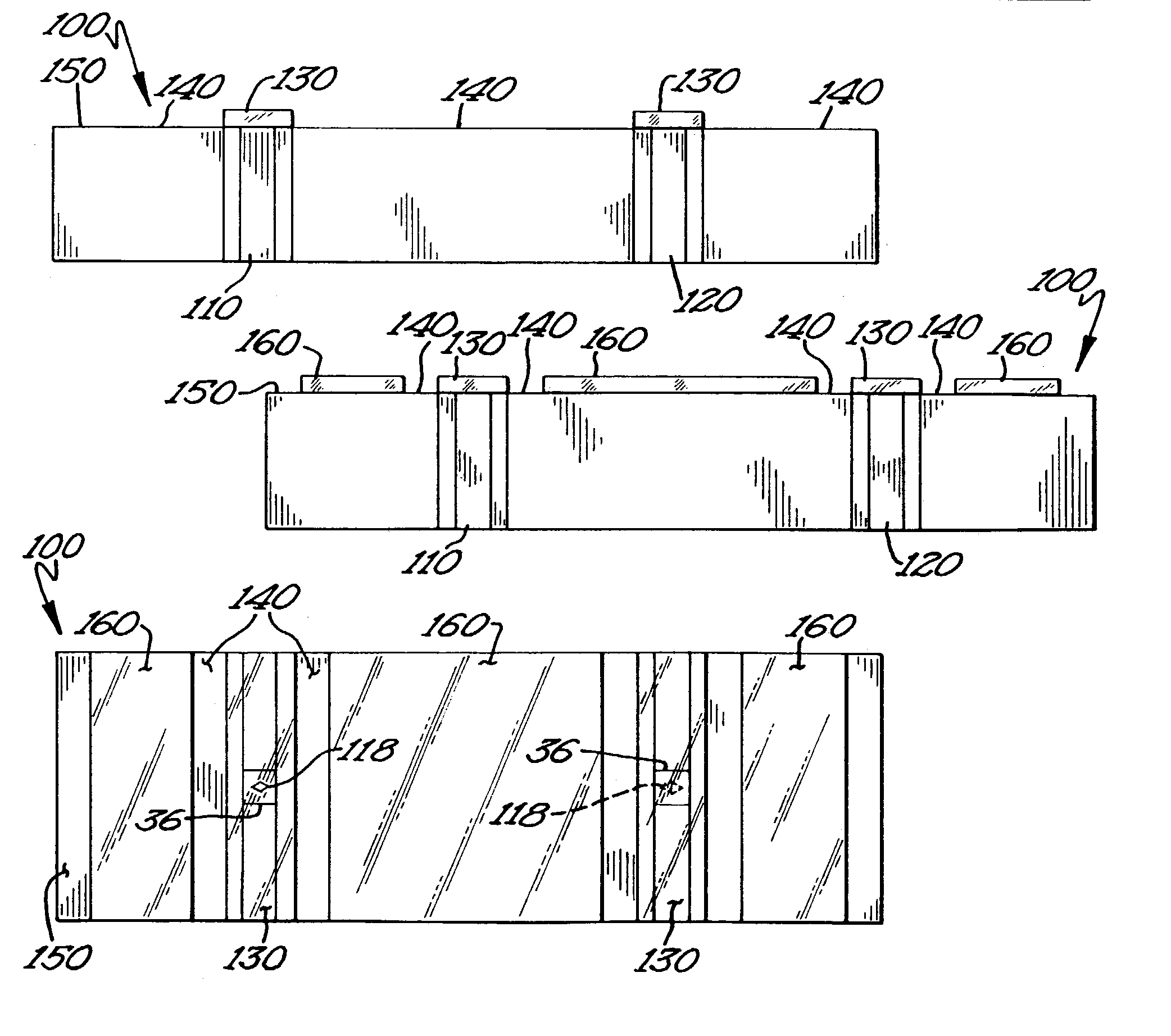

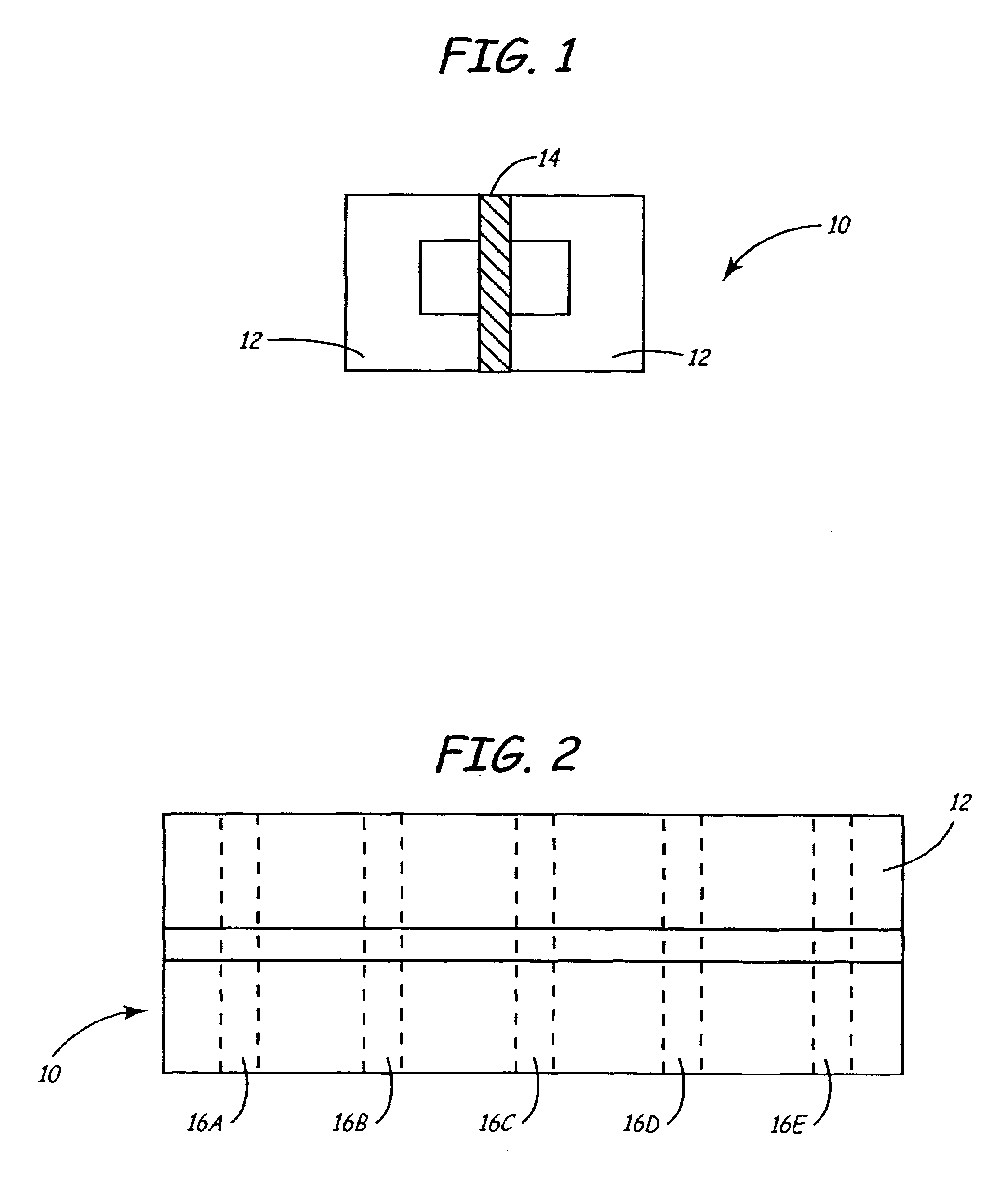

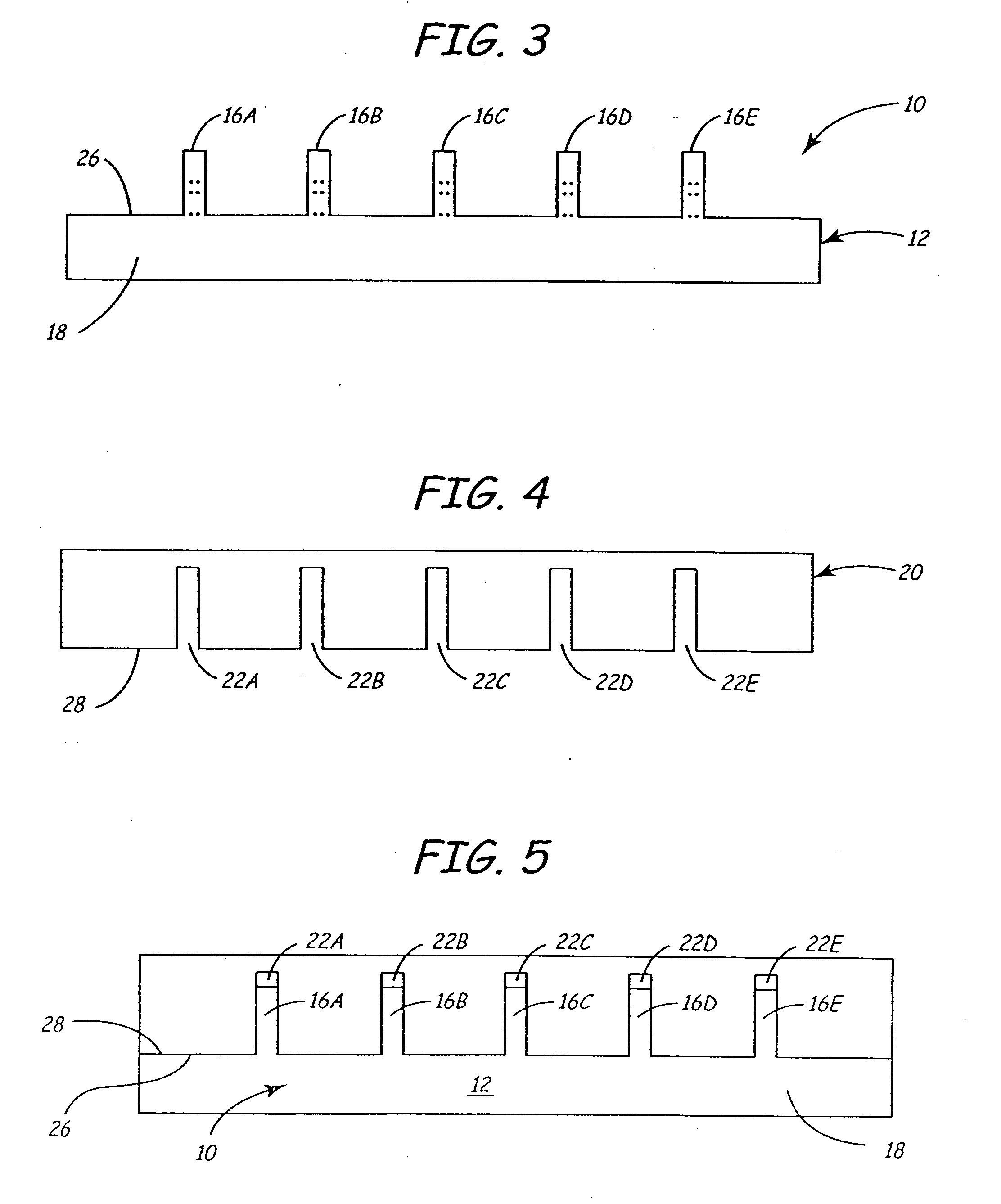

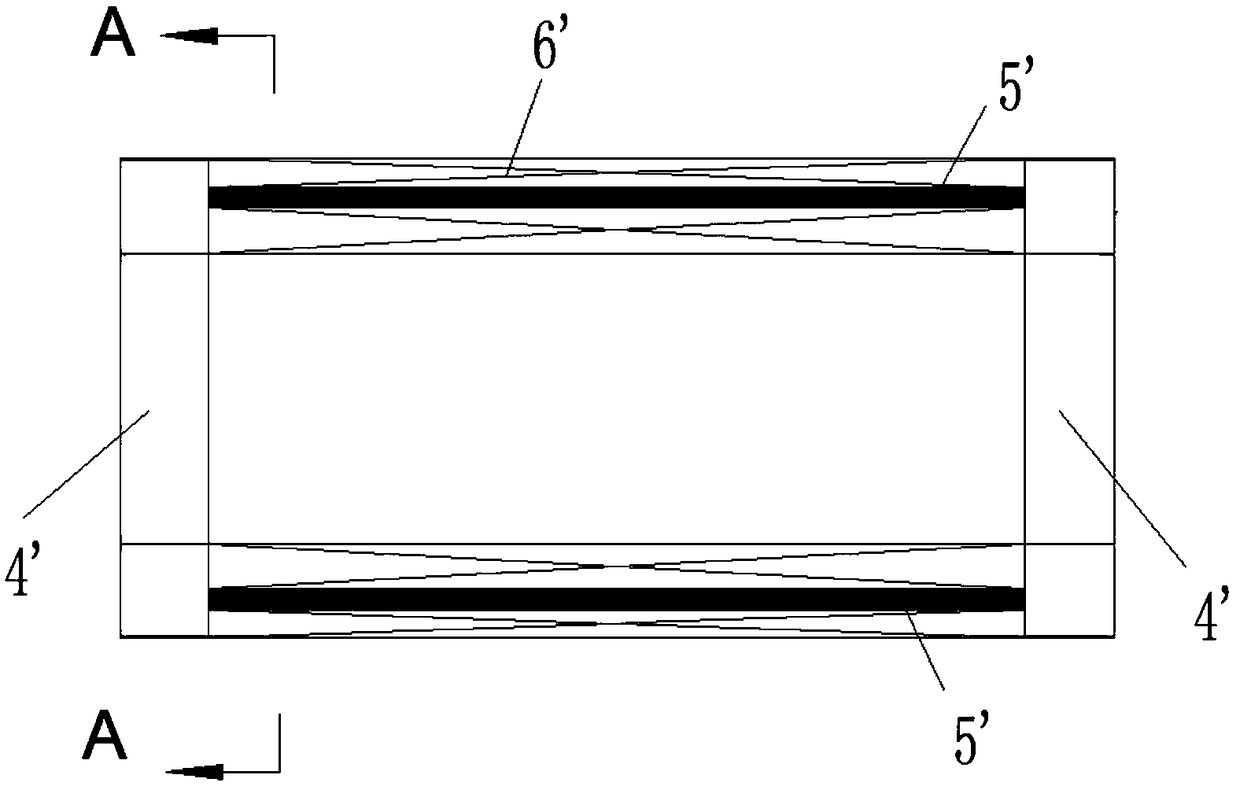

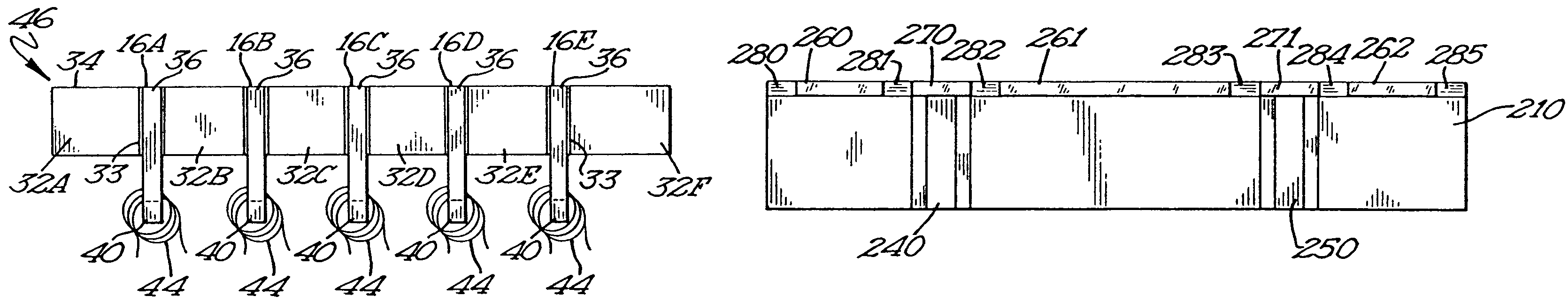

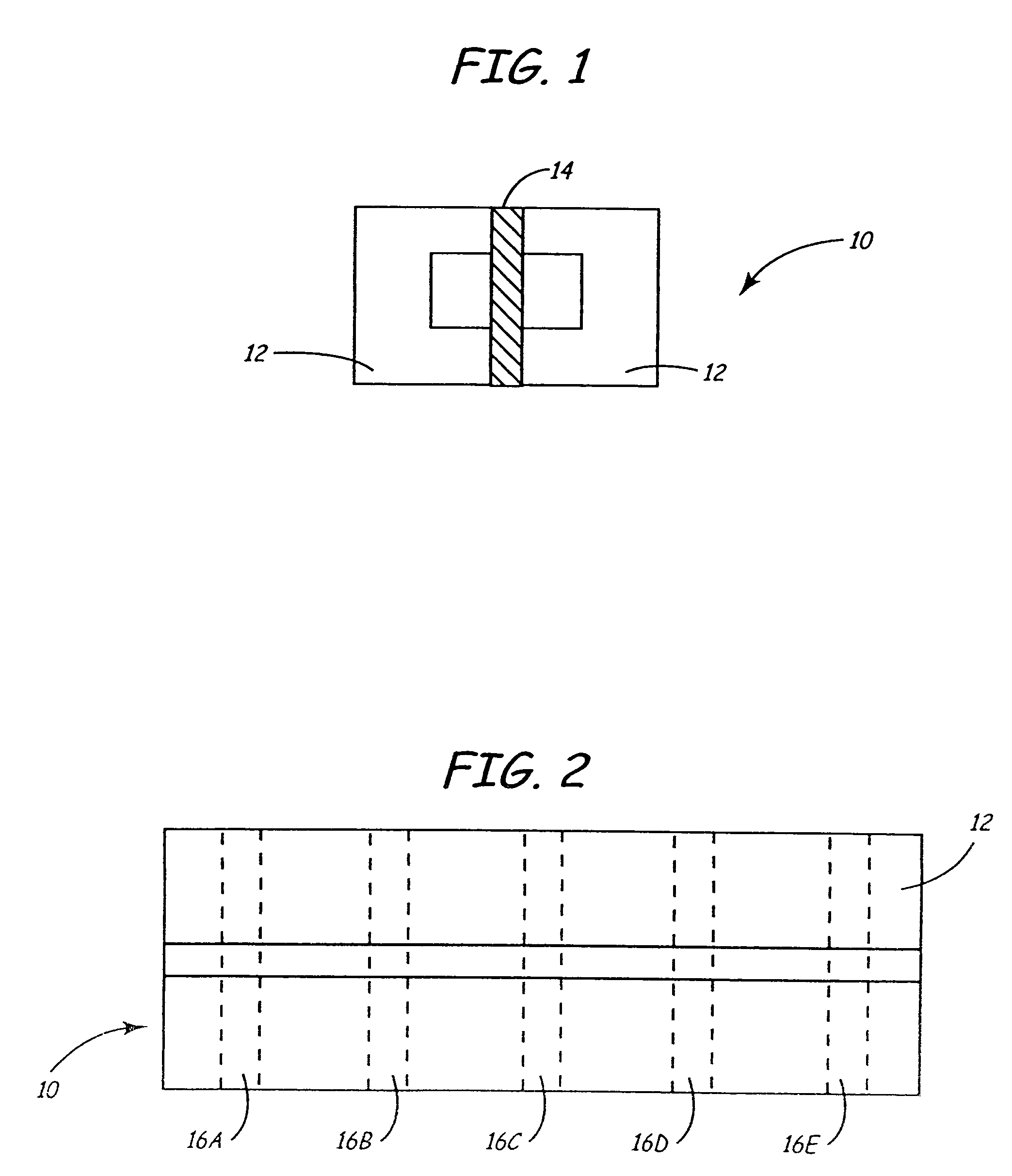

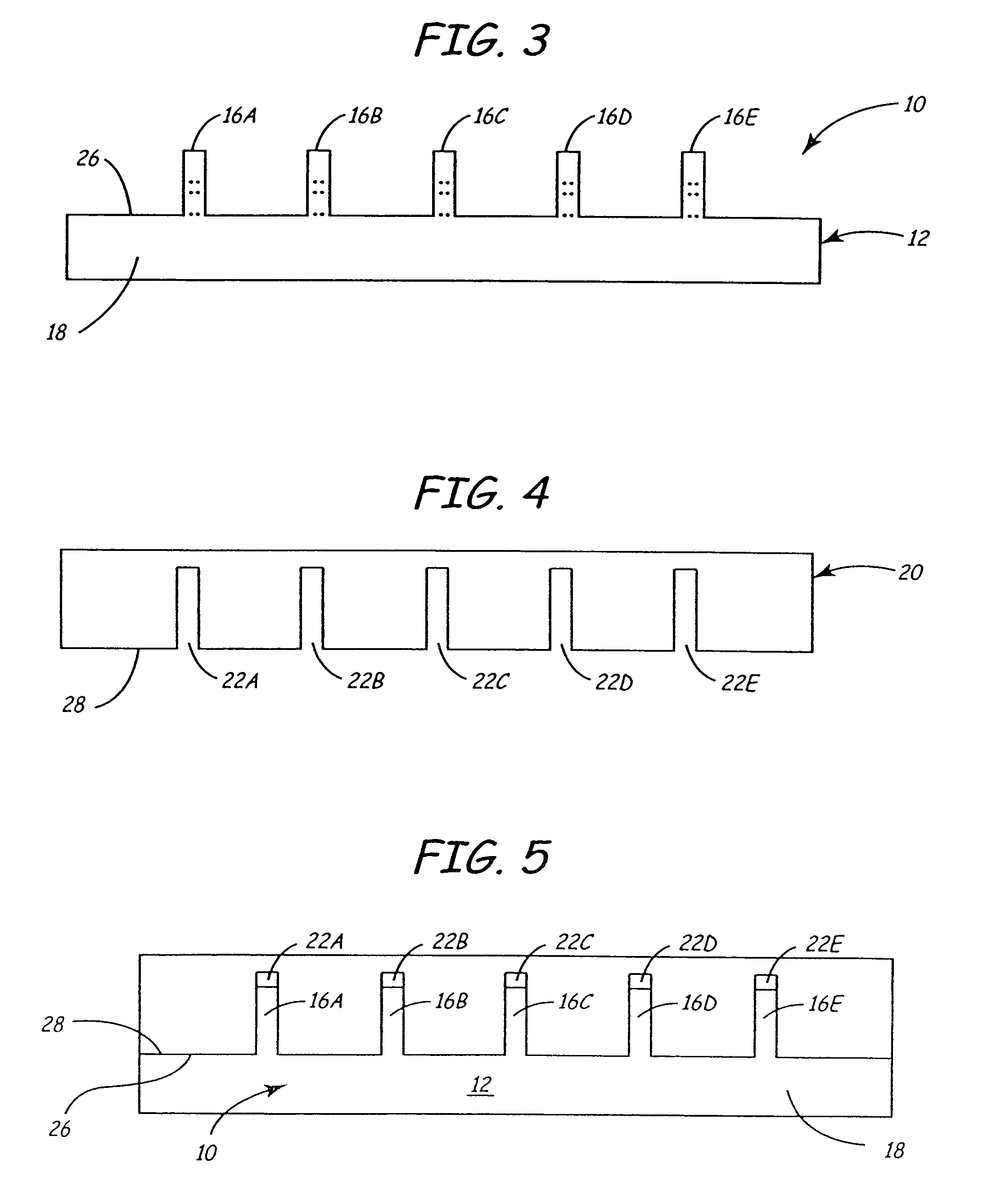

Wear pads for timing-based surface film servo heads

InactiveUS6989960B2Avoid negative effectsQuick wearElectrical transducersManufacture head surfaceEngineeringBearing surface

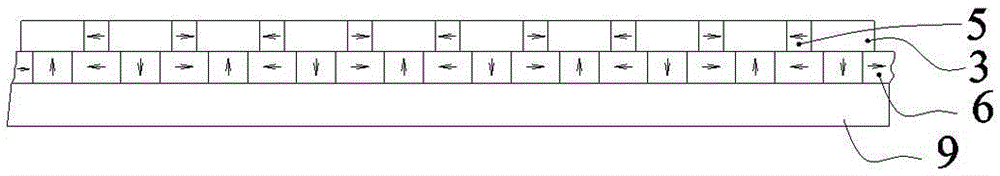

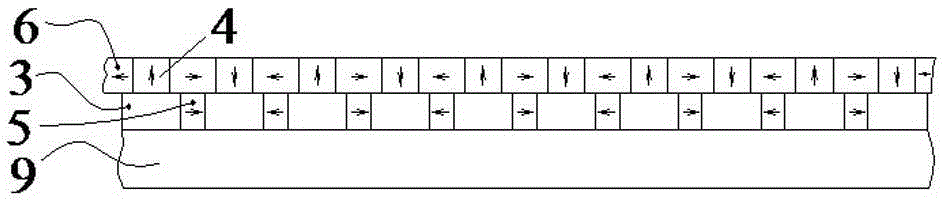

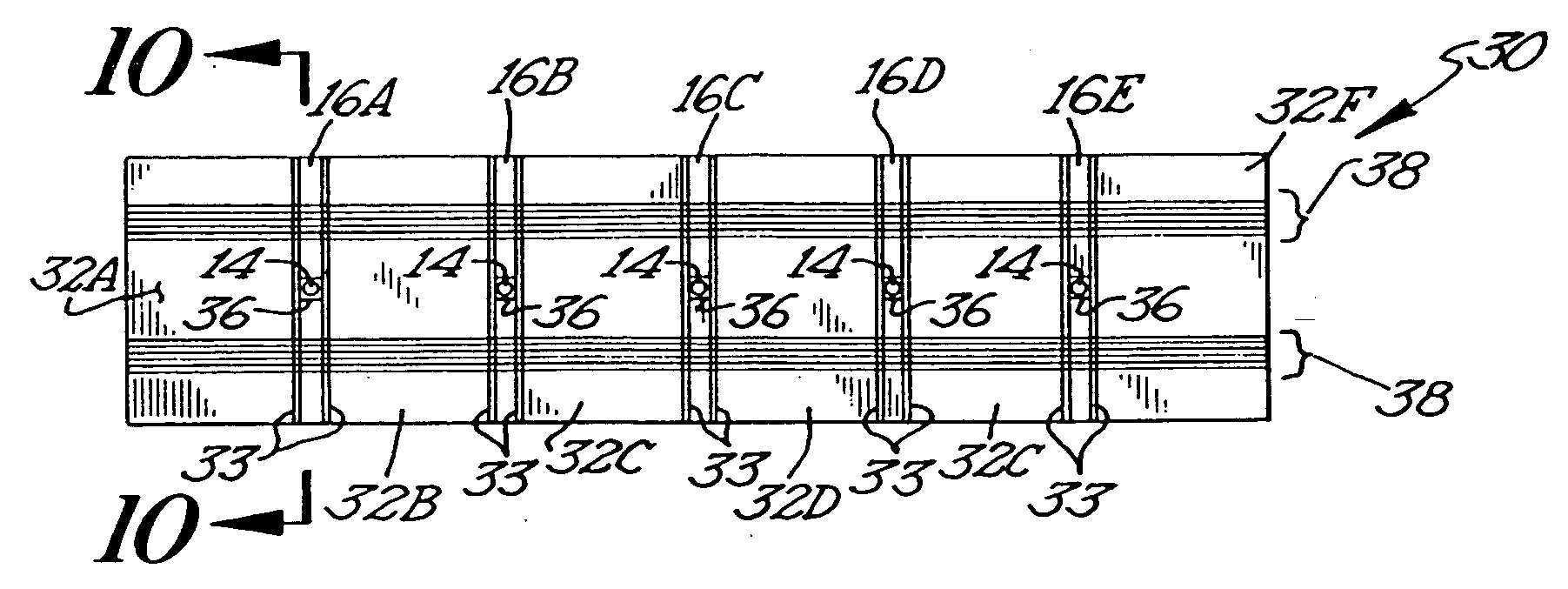

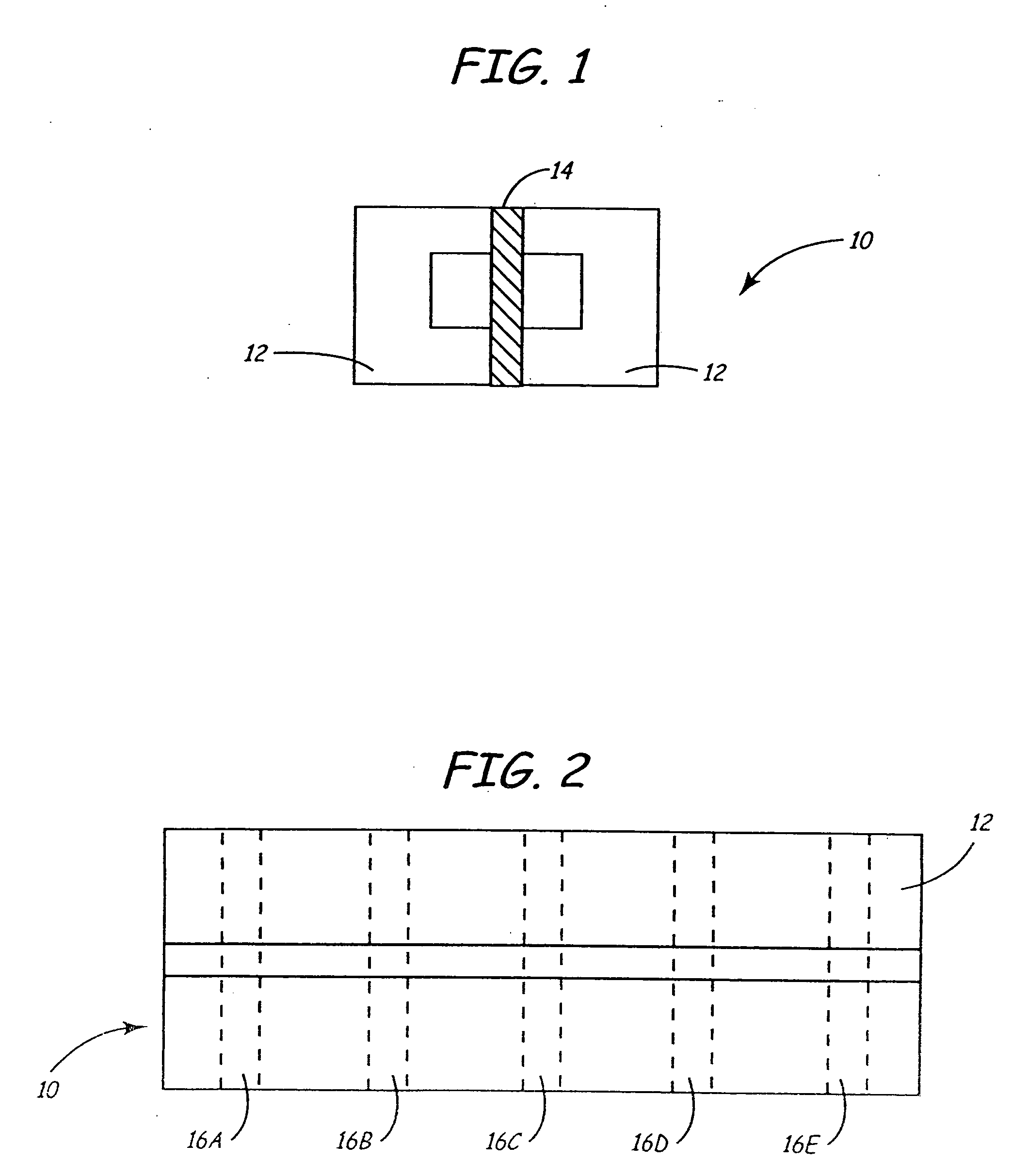

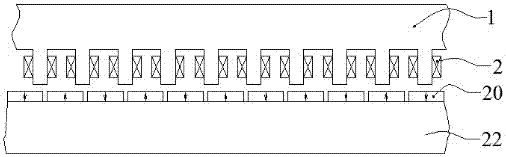

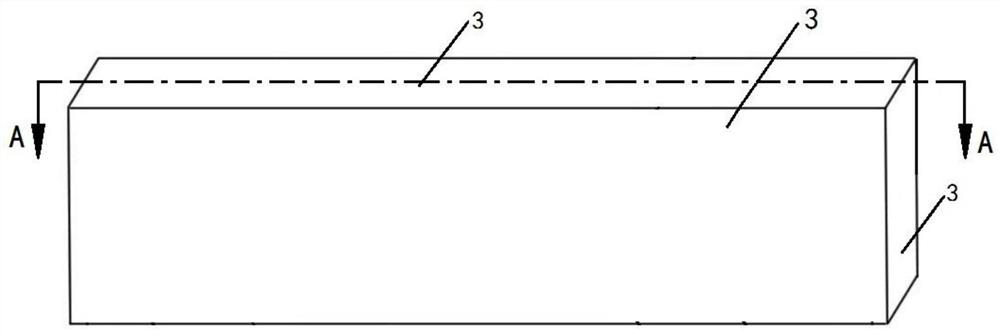

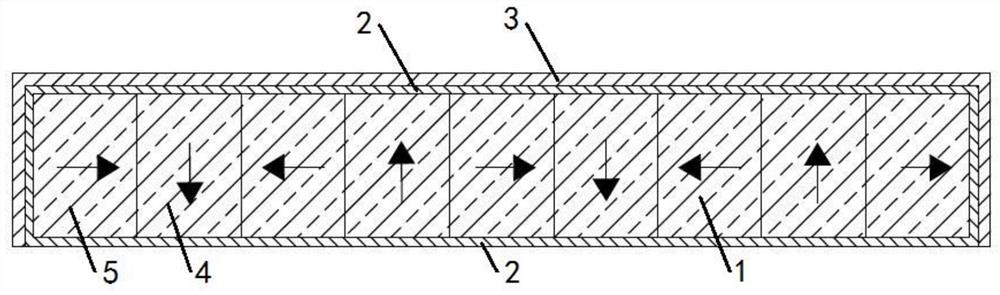

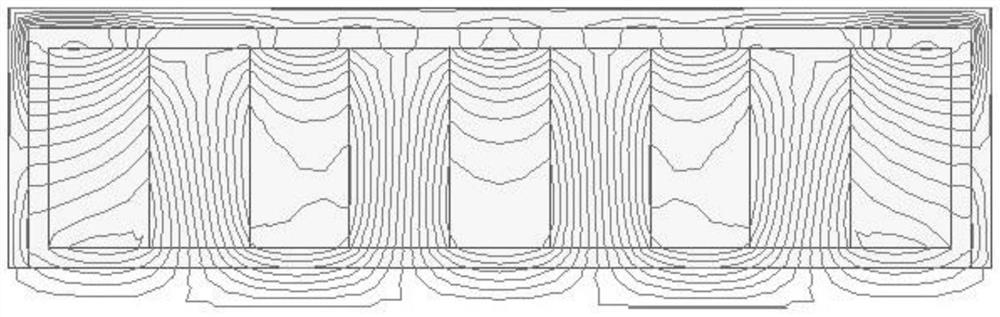

A thin film magnetic recording head is provided with a tape bearing surface that has magnetically isolated channels while still providing a maximum continuous surface area with which to engage the media. This can be accomplished by providing spaces in the magnetically permeable thin film that are large enough to prevent cross-talk between the channels, but small enough to prevent significant interference with the moving media. Alternatively, magnetically impermeable thin film spacers can be provided to magnetically isolate each of the channels. The spacers are generally even with the magnetically permeable thin film so as to provide a continuous media-bearing surface.

Owner:ADVANCED RES

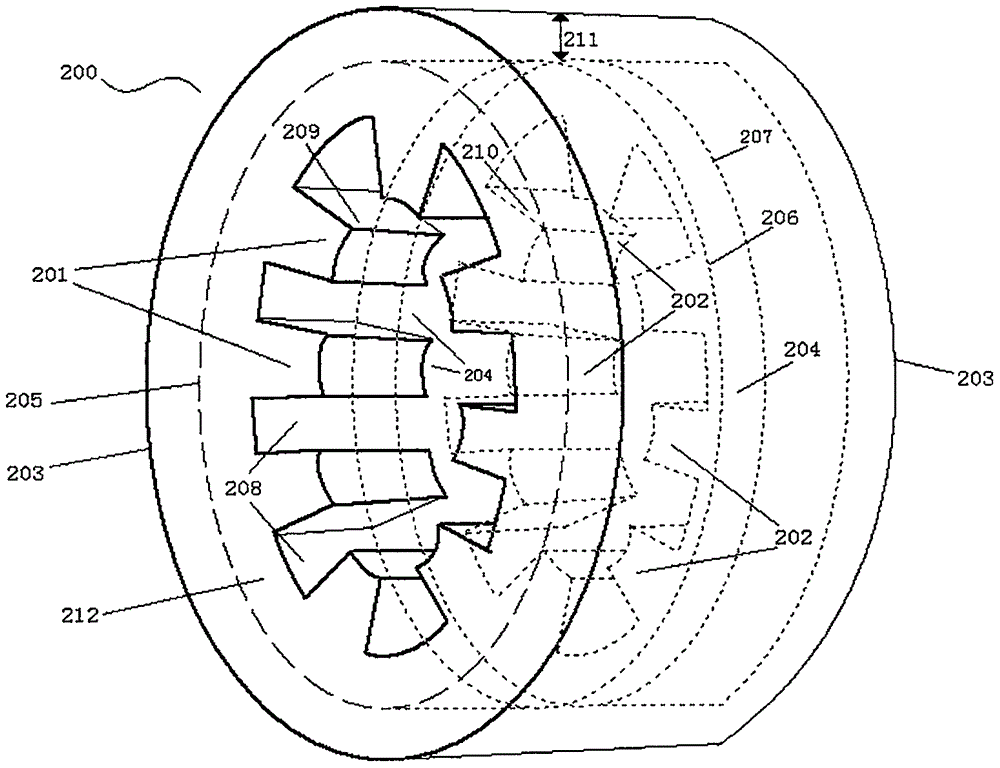

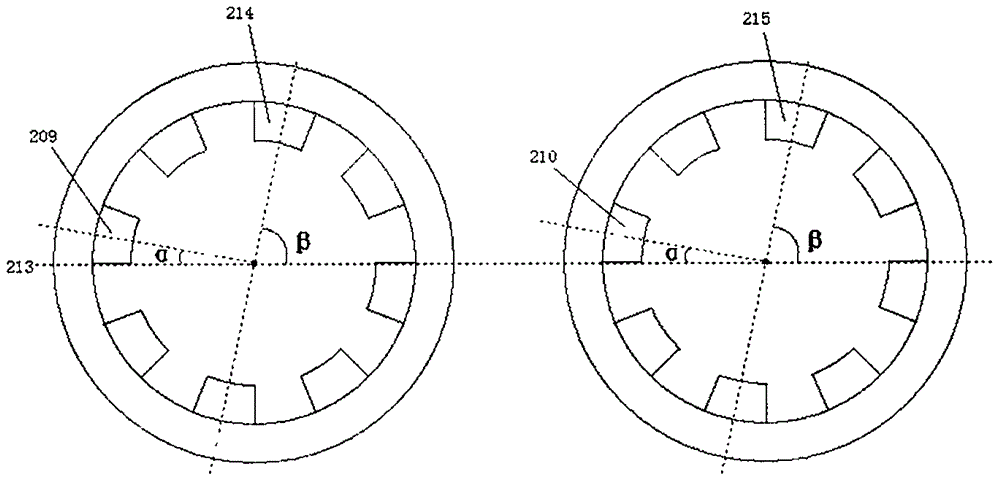

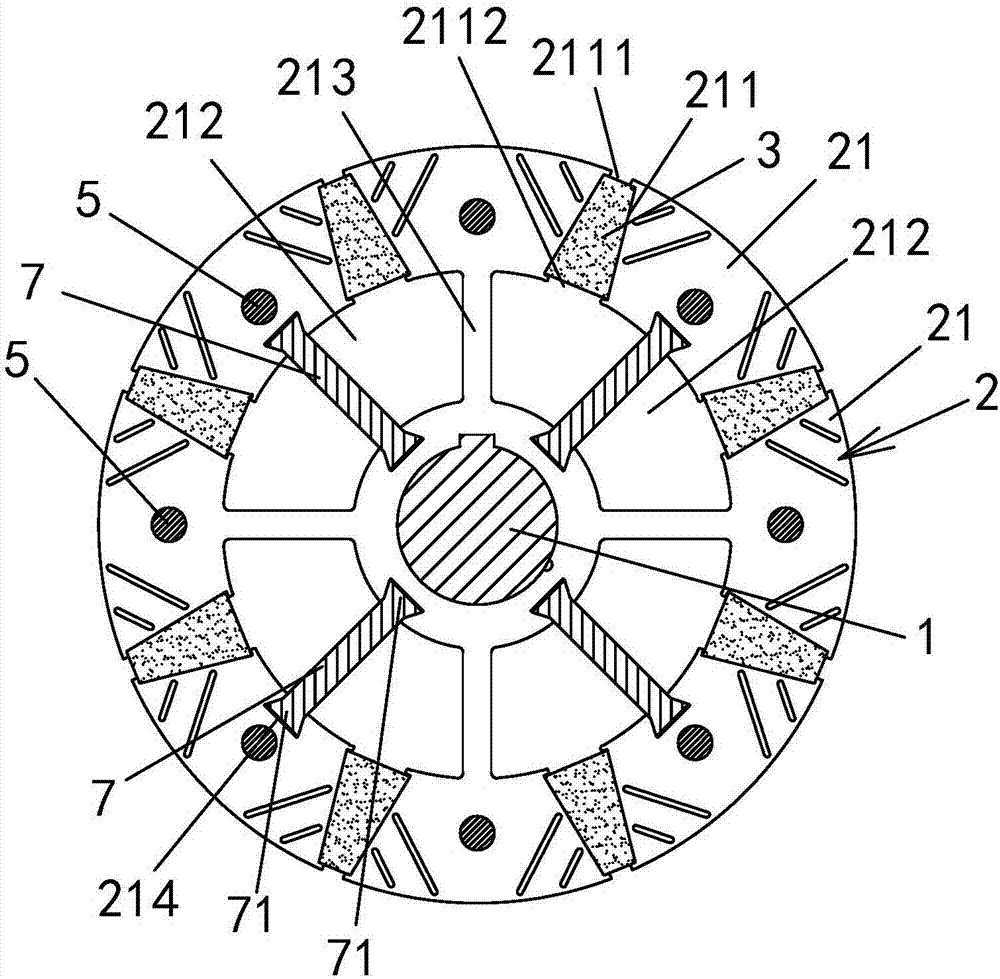

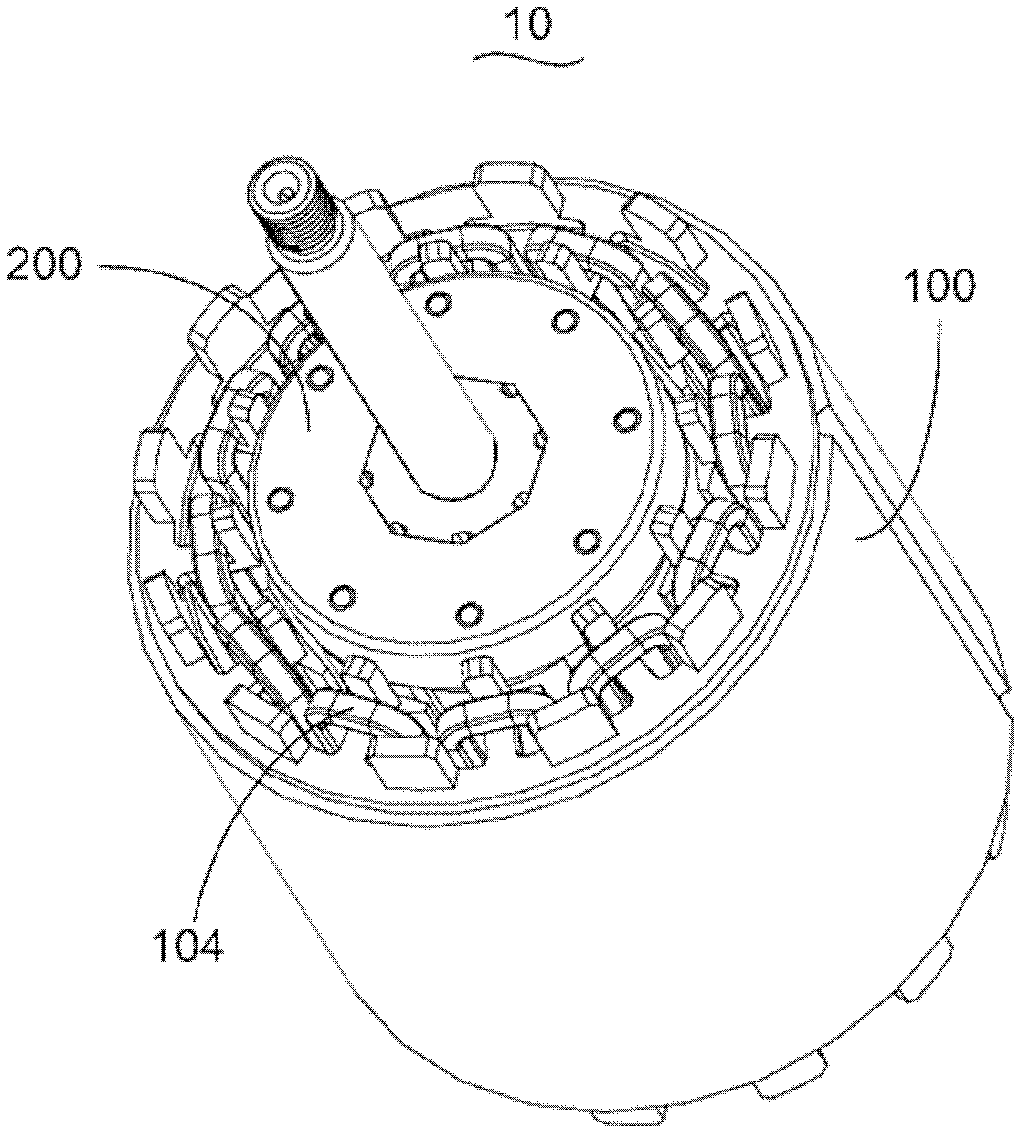

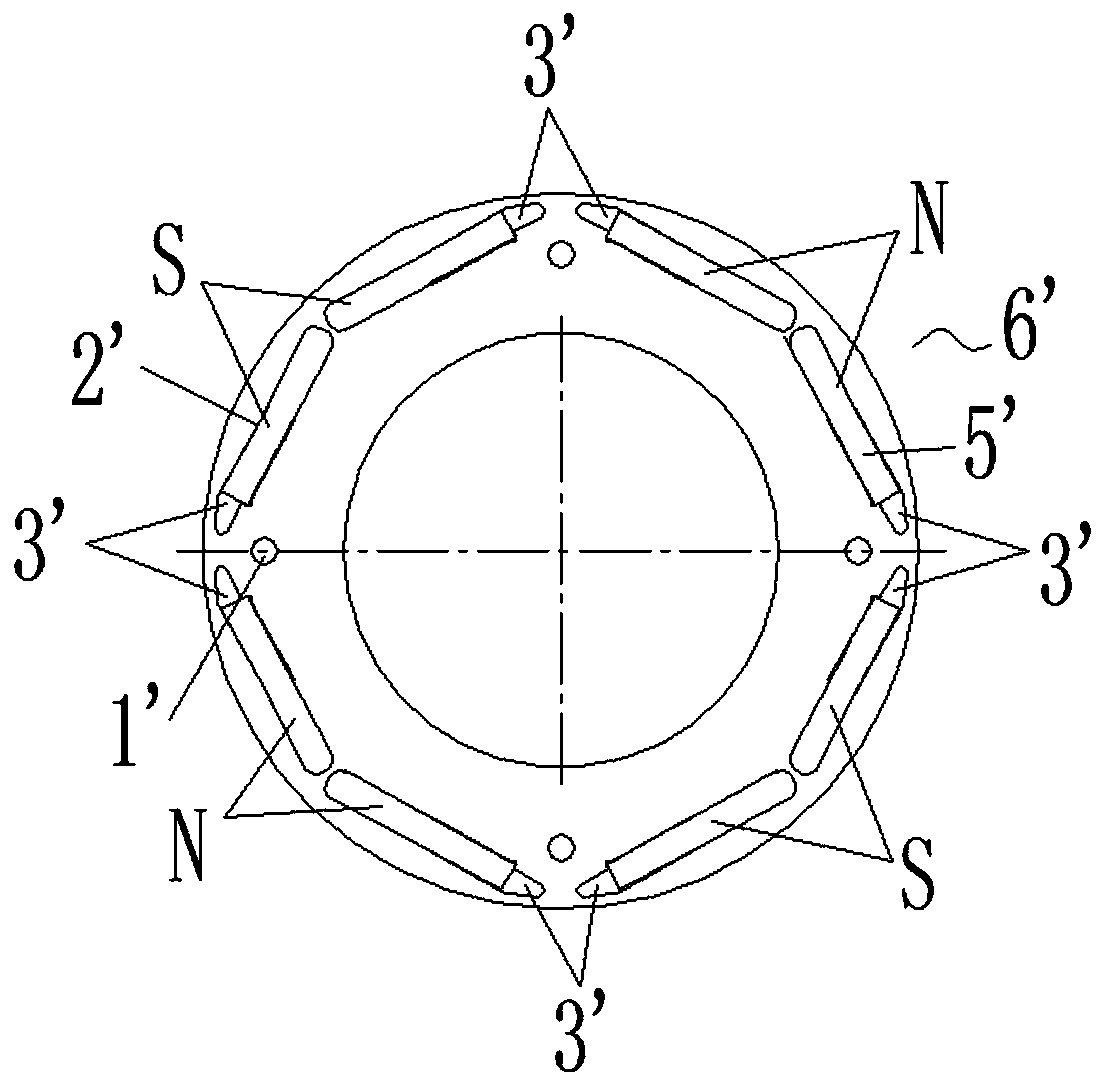

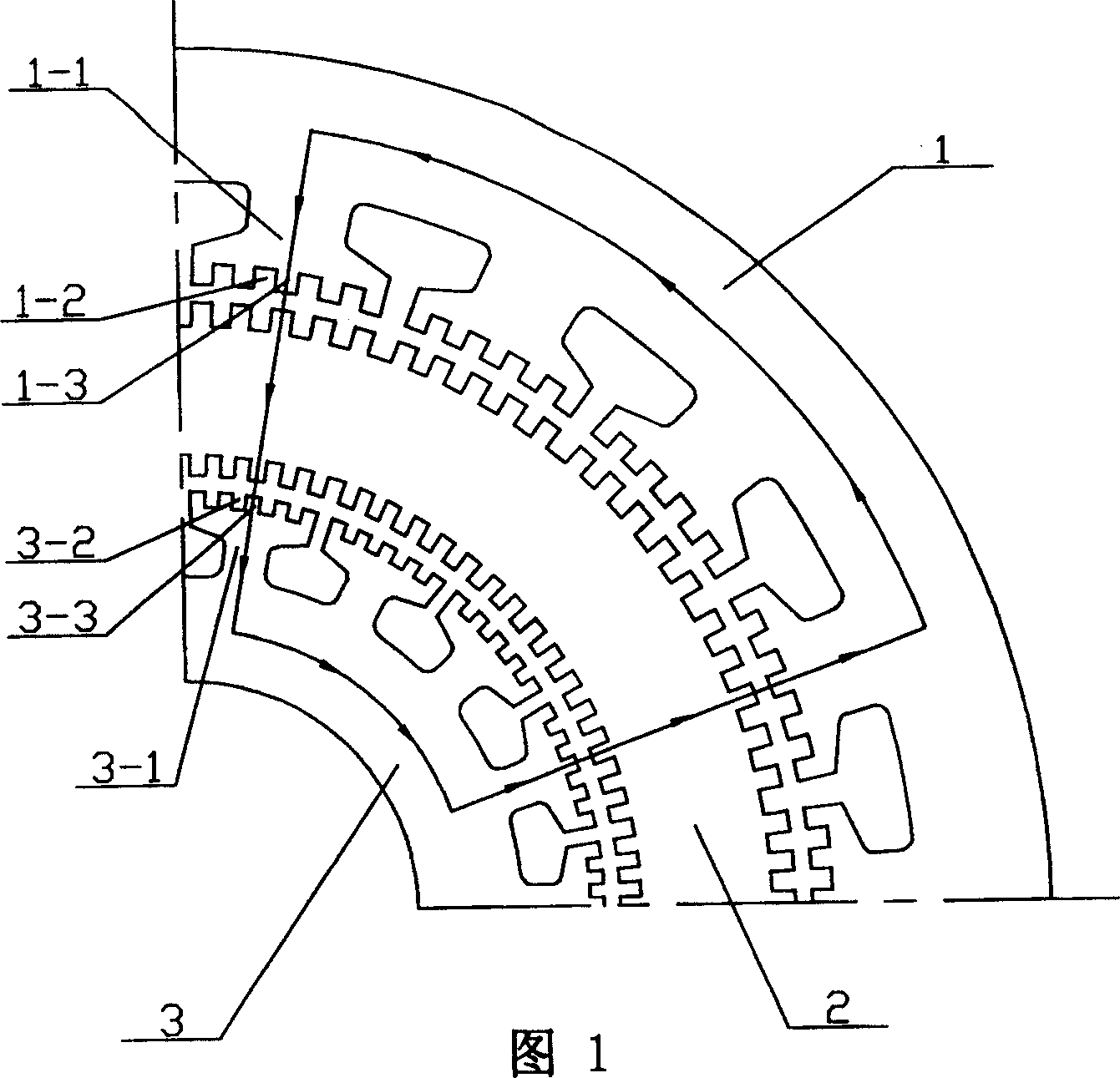

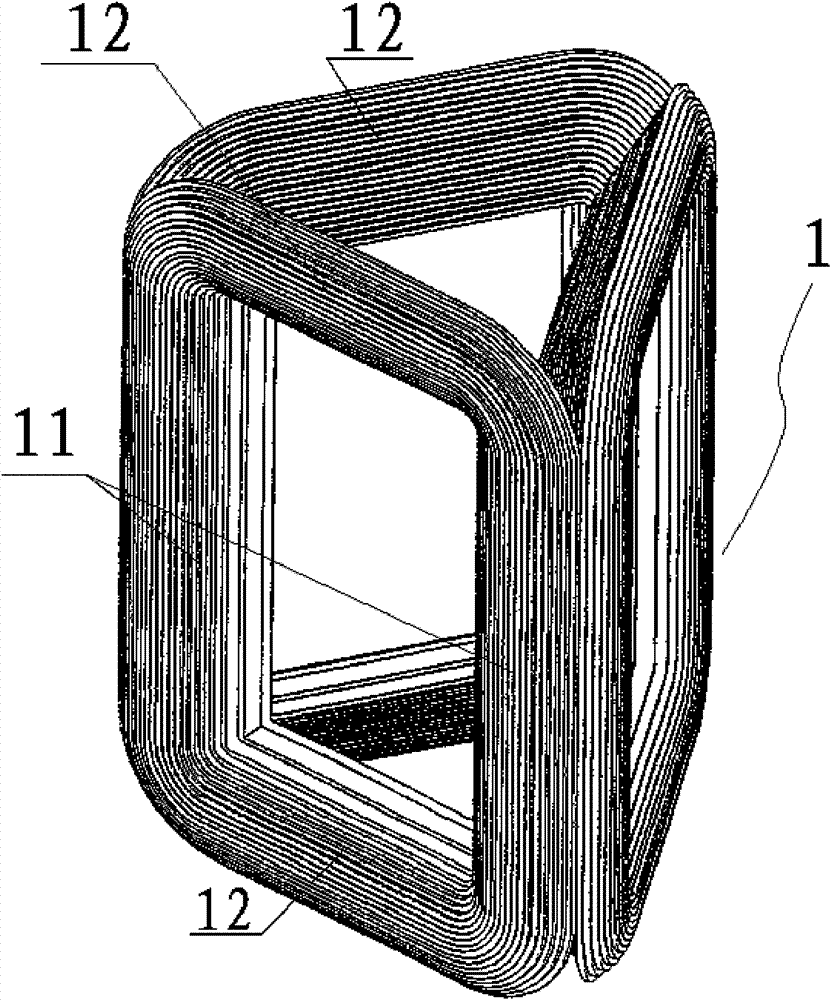

Salient-pole halbach composite permanent magnet rotation motor

InactiveCN105305756AEliminate magnetic flux leakageIncrease powerMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet motorConductor Coil

The invention belongs to the field of motors and electrical appliances, and specifically relates to a salient-pole halbach composite permanent magnet rotation motor. The salient-pole halbach composite permanent magnet rotation motor comprises a rotor and a stator corresponding to the rotor, the rotor is formed by a salient-pole halbach composite array, the salient-pole halbach composite array comprises a single-layer salient-pole halbach composite array and / or a double-layer halbach composite layer, the surface of a salient-pole magnet array is tightly attached to a halbach magnet array to form the single-layer salient-pole halbach composite array, and surfaces at two sides of the salient-pole magnet array are respectively and tightly attached to at least one group of halbach magnet arrays to form the double-layer salient-pole halbach composite layer. According to the salient-pole halbach composite permanent magnet rotation motor, the characteristics of the halbach magnet array are employed, the salient-pole magnet array is arranged in a strong-magnetism area or a weak-magnetism area of the halbach magnet array, the salient-pole halbach permanent magnet motor is formed by the cooperation of the salient-pole magnet array and a stator winding, magnetism leakage of the salient-pole magnet array is greatly reduced or even completely eliminated, the power and output of the motor can be greatly increased with same size and manufacturing cost, or the size and the manufacturing usage cost of the motor can be greatly reduced with the same power, and the salient-pole halbach composite permanent magnet rotation motor is especially applicable to occasions of high-power permanent magnet motor engineering application.

Owner:HENAN POLYTECHNIC UNIV +1

Wear pads for timing-based surface film servo heads

InactiveUS20060061906A1Improve linearityEliminate magnetic flux leakageManufacture head surfaceManufacturing heads with multiple gapsEngineeringBearing surface

Owner:ADVANCED RES

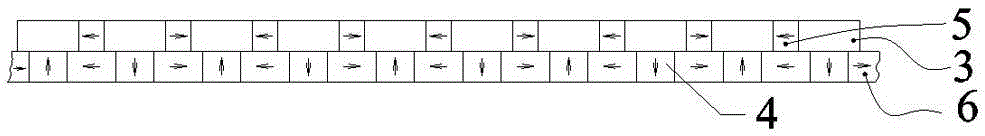

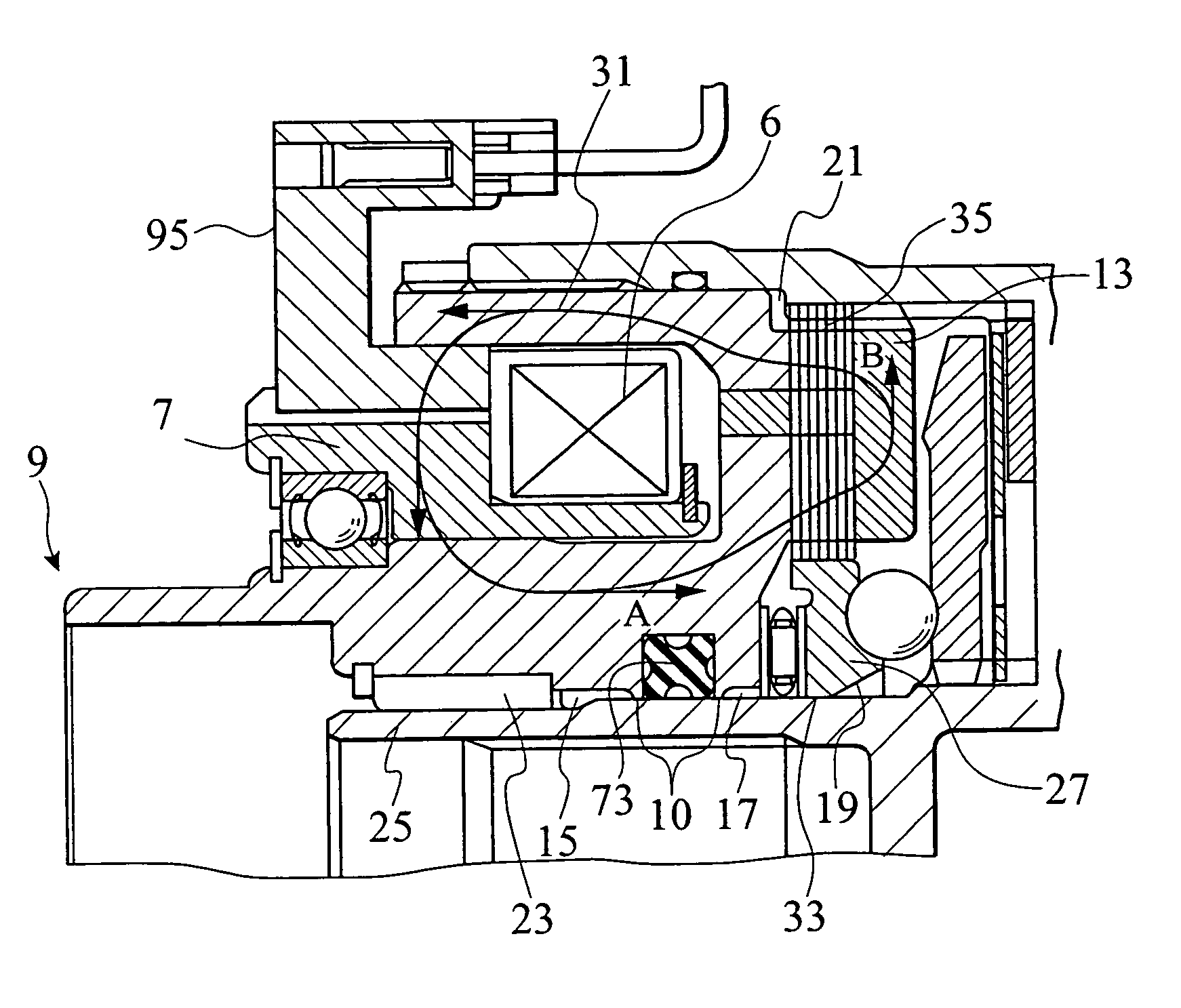

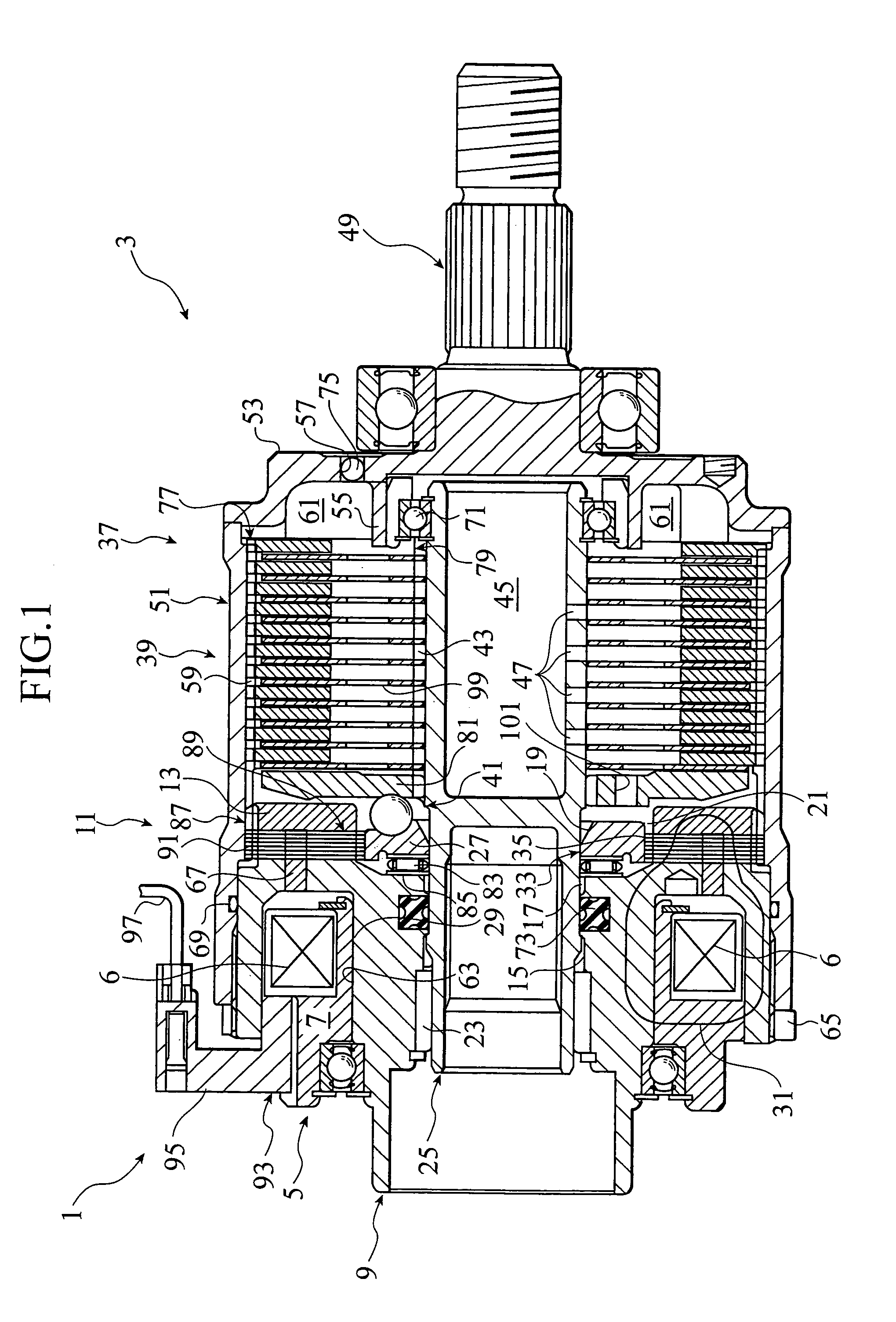

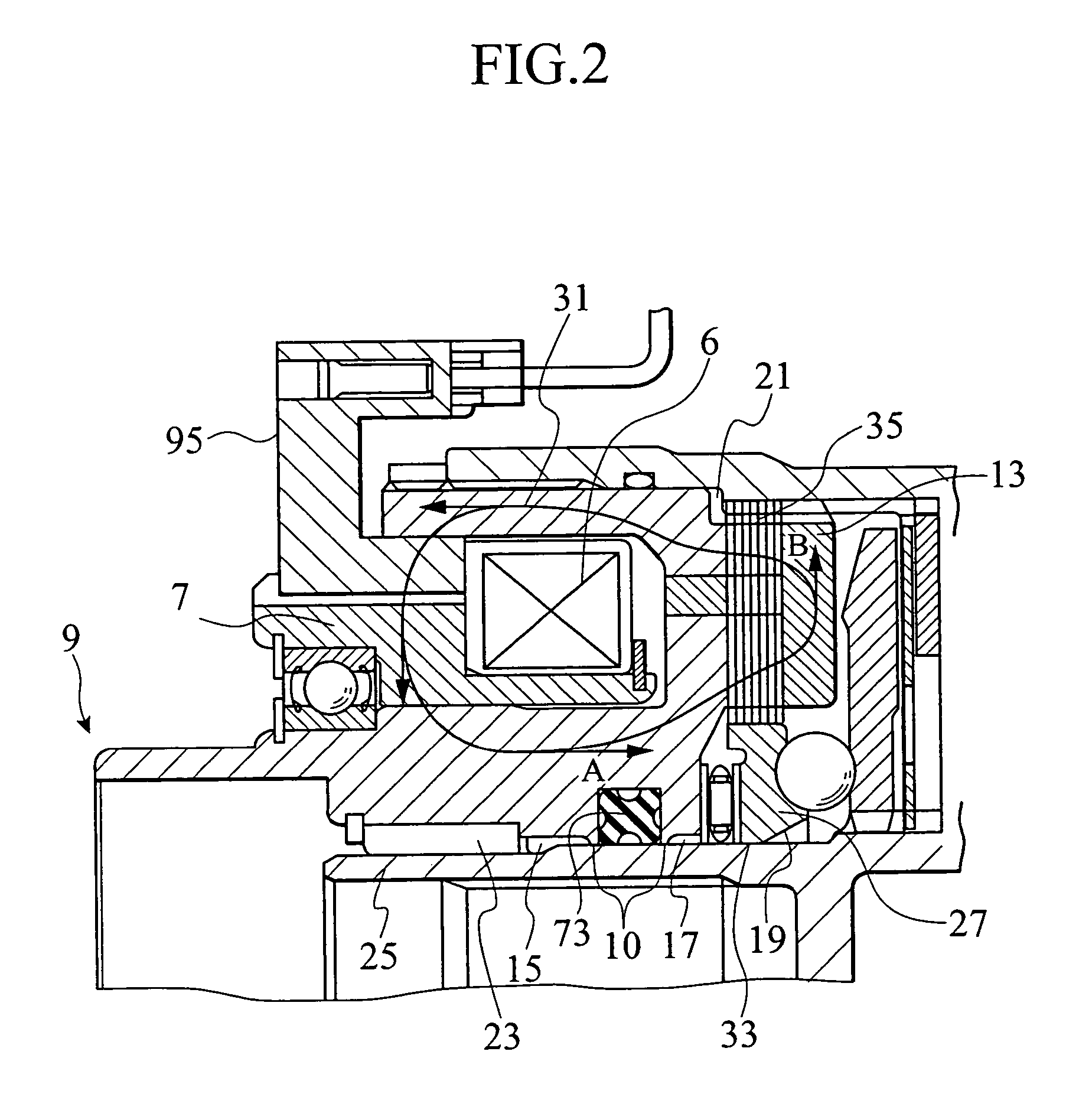

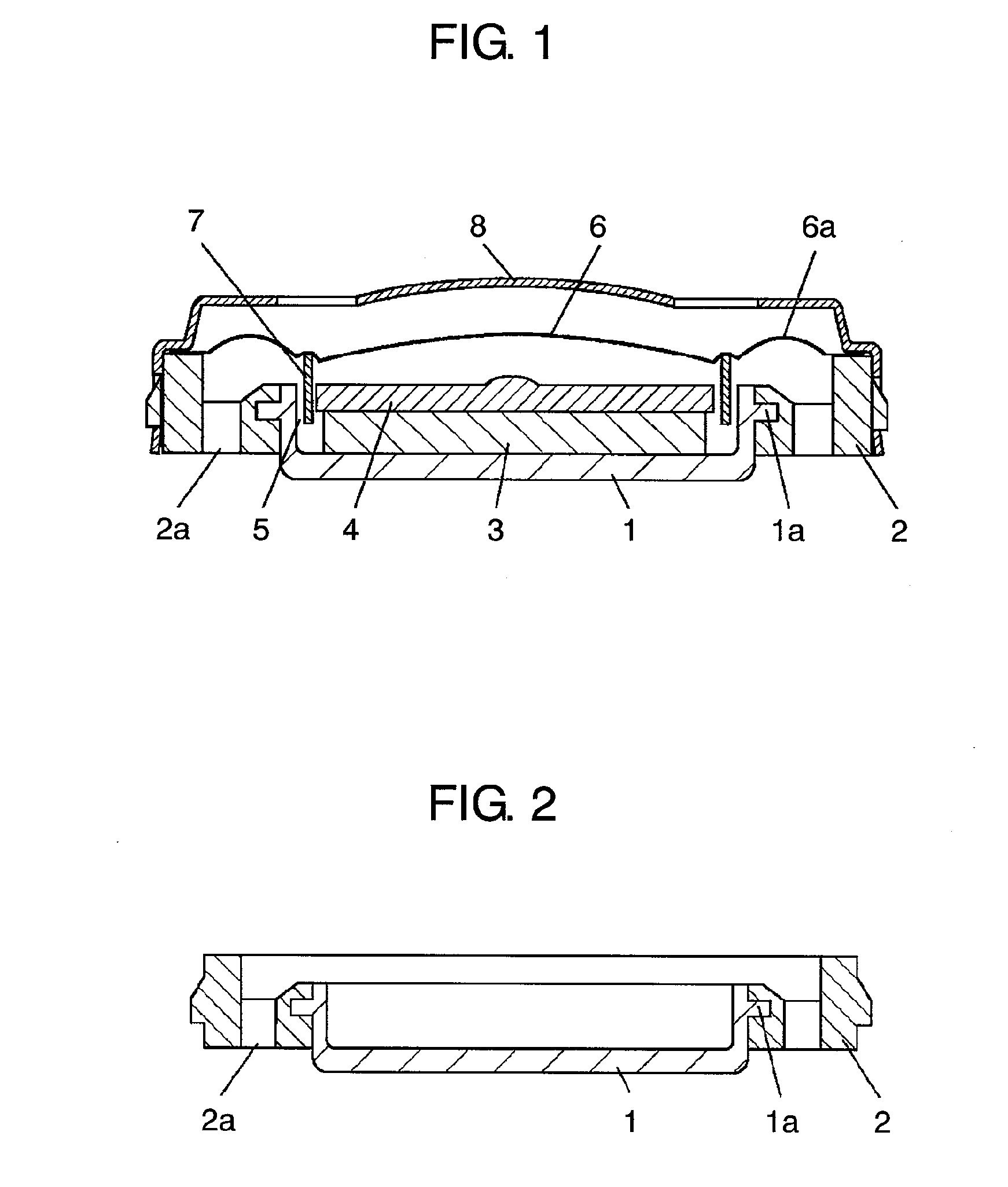

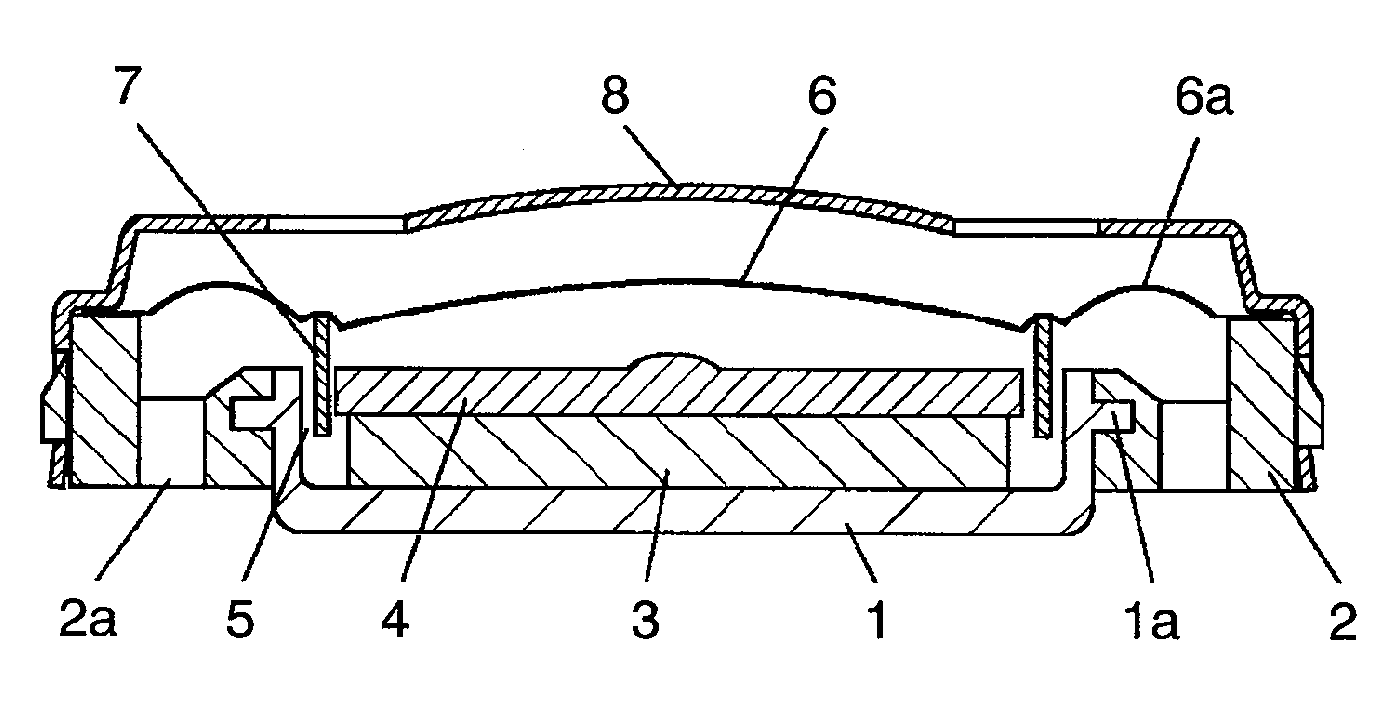

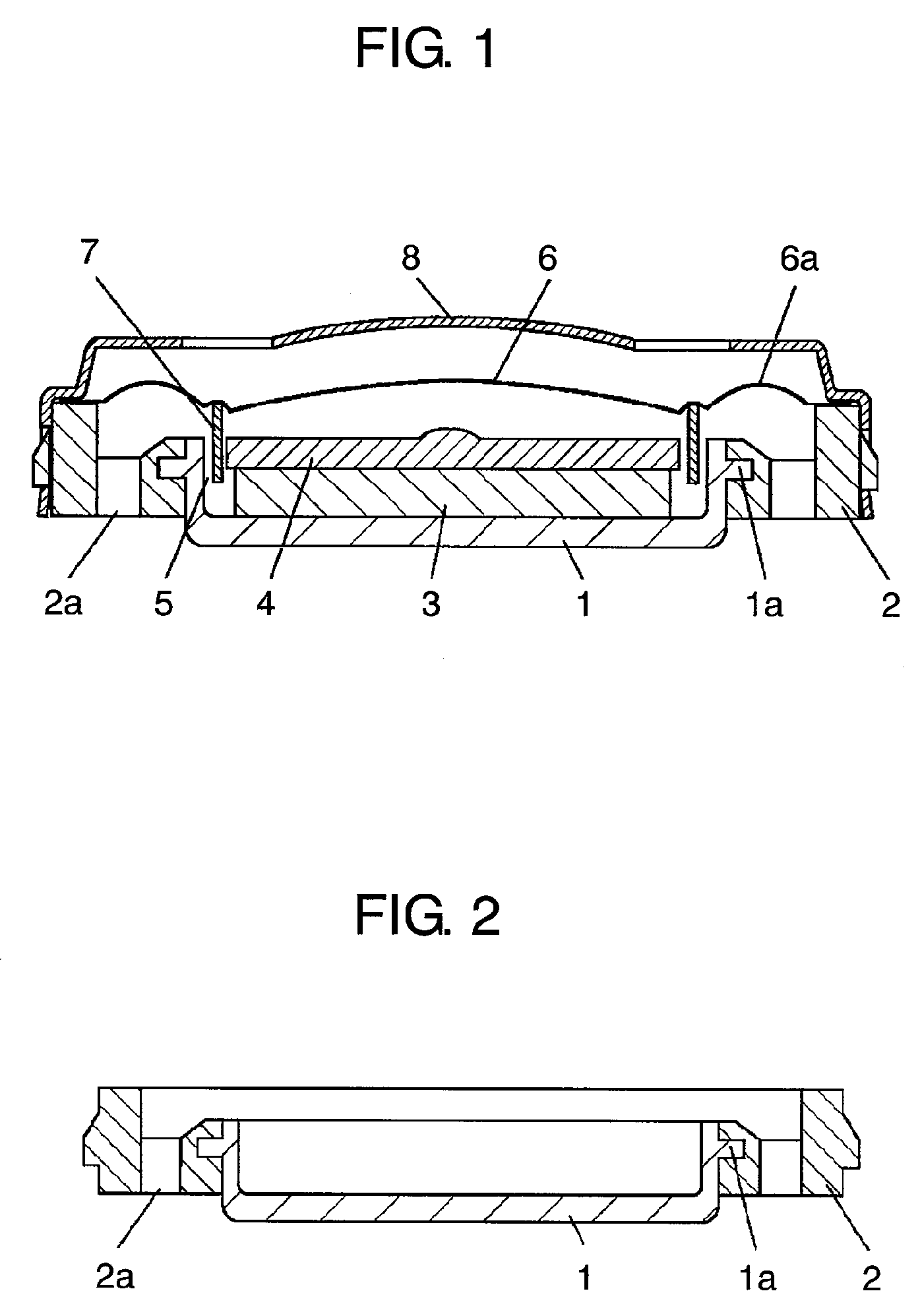

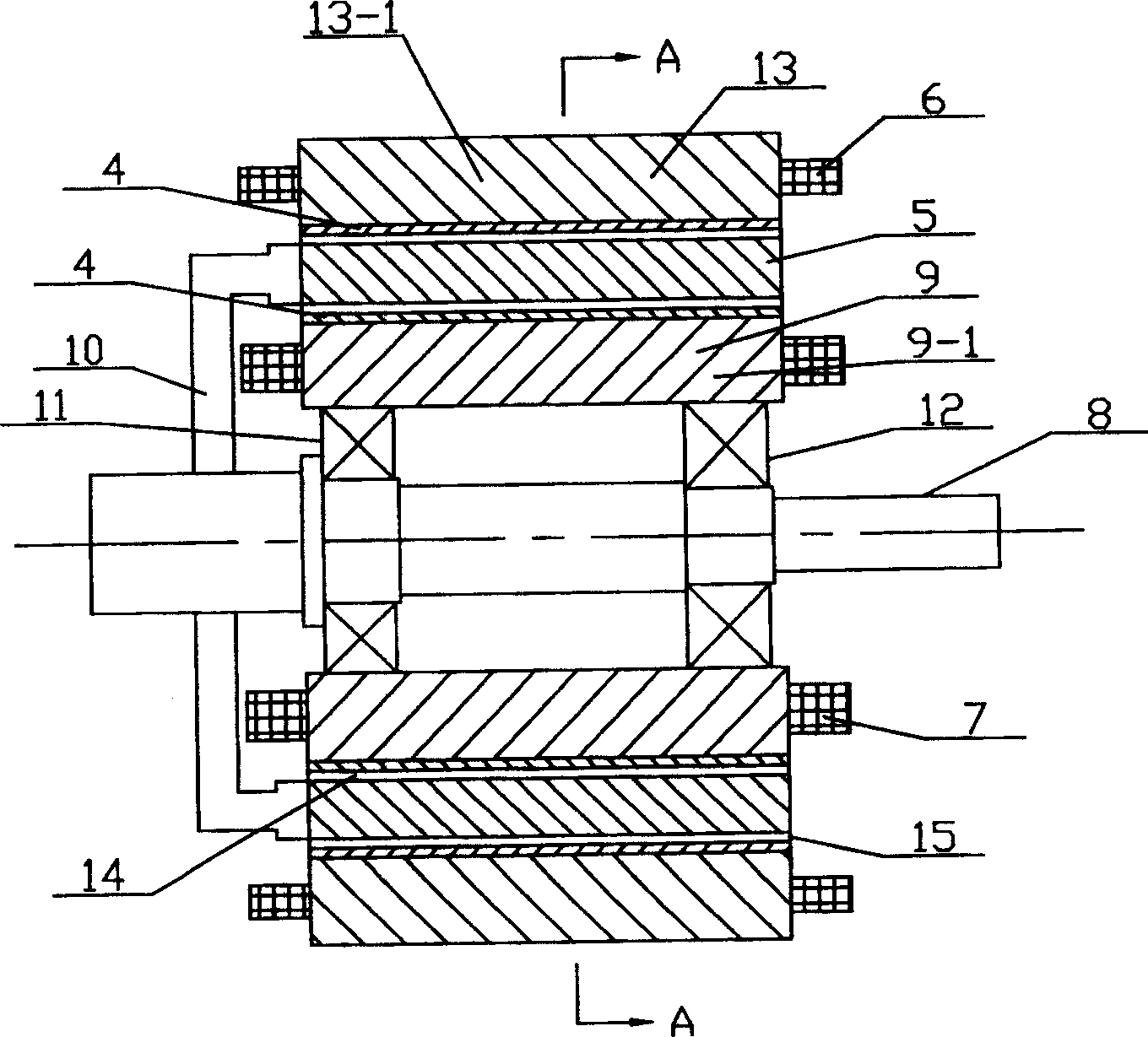

Electromagnetic clutch device

InactiveUS6997294B2Improve energy efficiencyIncrease currentMagnetically actuated clutchesFriction clutchesElectrical and Electronics engineeringElectromagnet

An electromagnetic clutch 1 is disclosed having a magnetic flux loop 31 formed, in magnetic flux loop forming members 5, 7, 9, 11, 13 involving an electromagnet 5 and an armature 13, by the electromagnet 5 to allow the armature 13 to be operatively shifted to couple and uncouple a clutch 11, and a proximate member, close proximate to the members 5, 7, 9, 11, 13, includes magnetic flux leakage minimizing sections 15, 17, 19, 21, 23, 25 that minimize magnetic fluxes leaked from the armature 13 to the proximate member.

Owner:TOCHIGI FUJI IND CO LTD

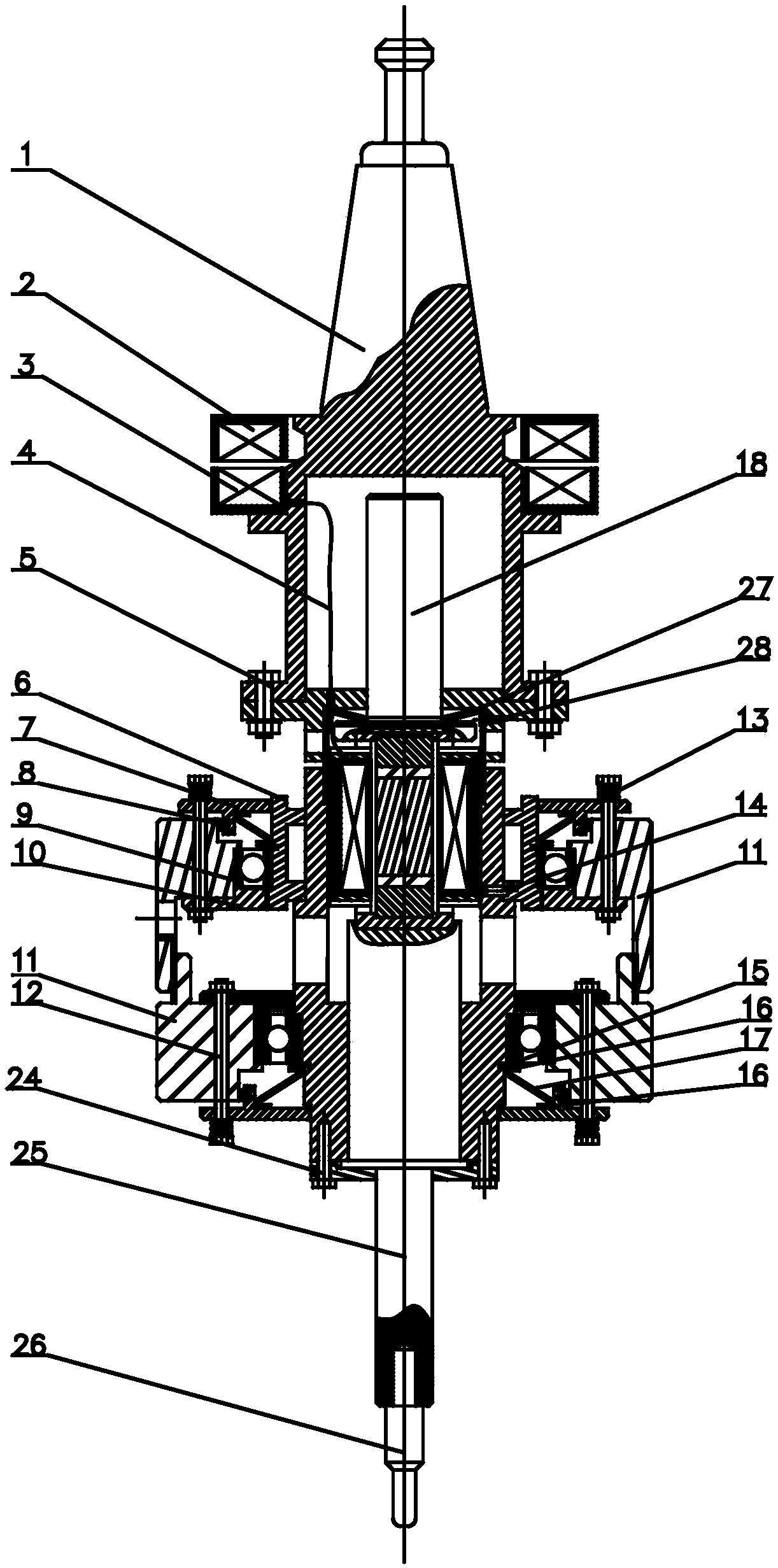

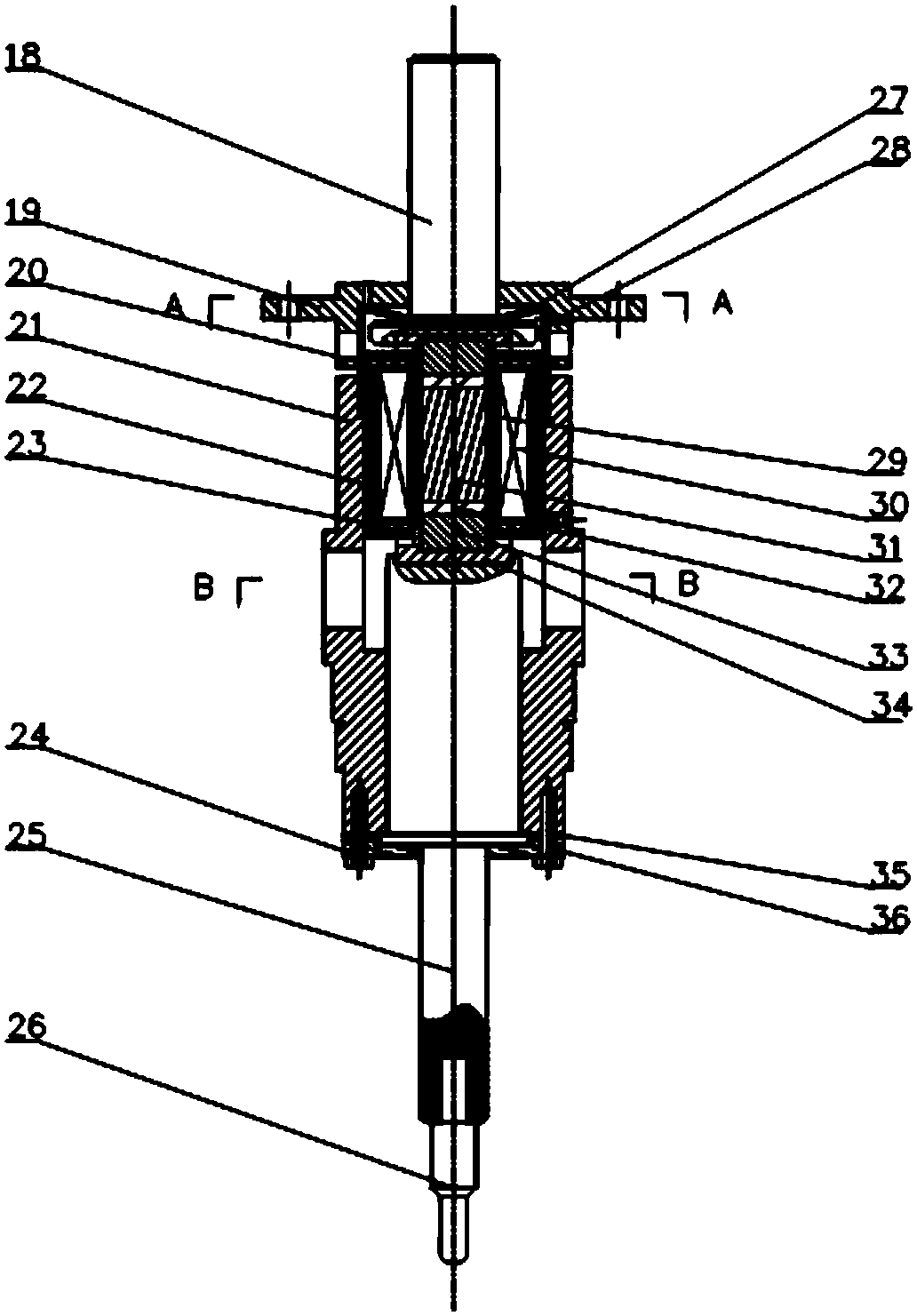

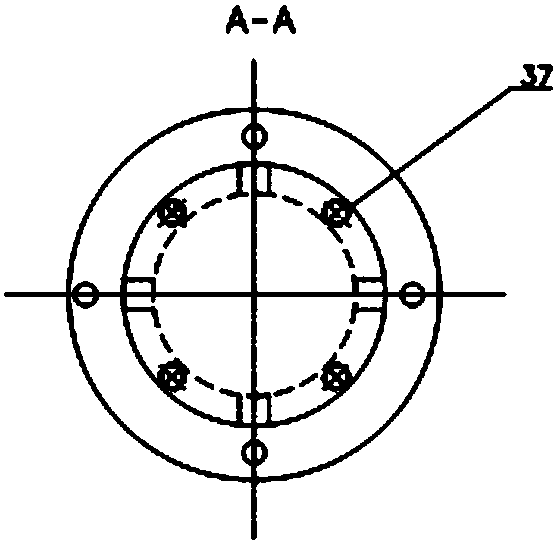

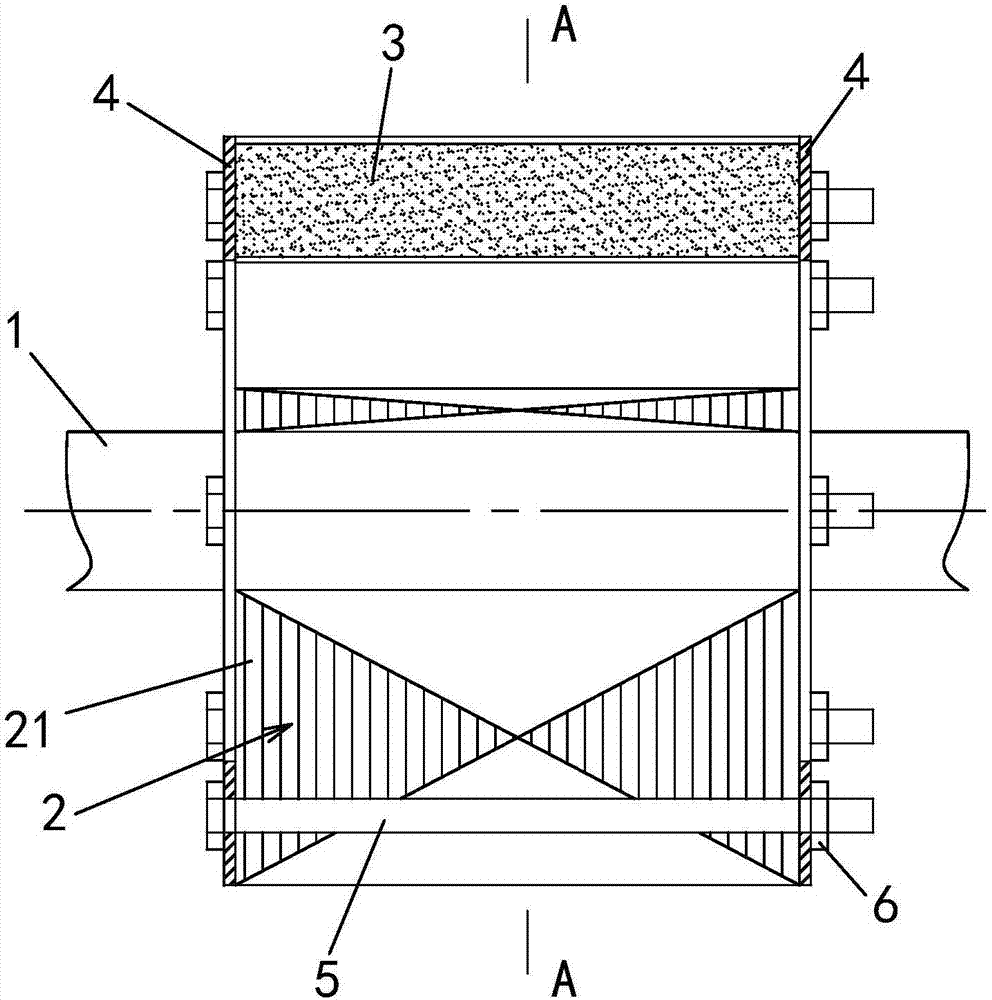

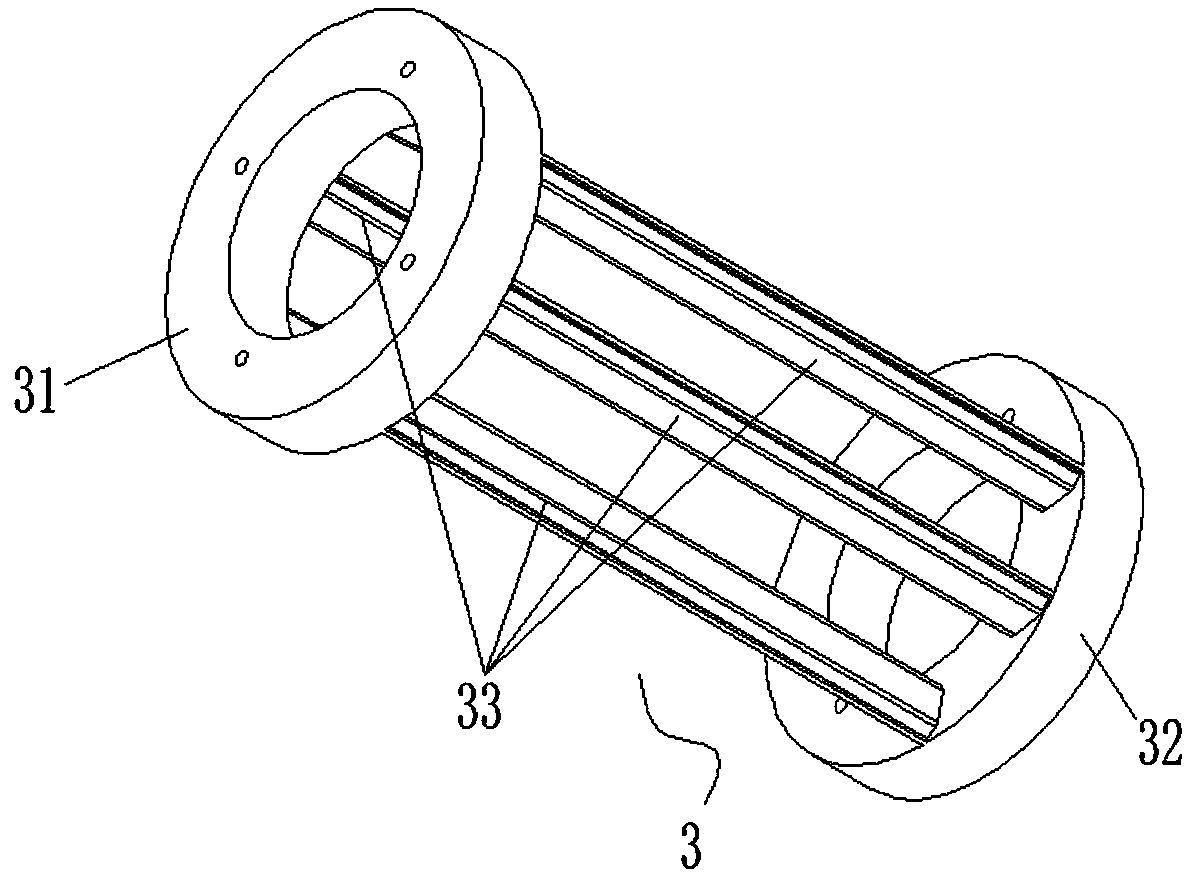

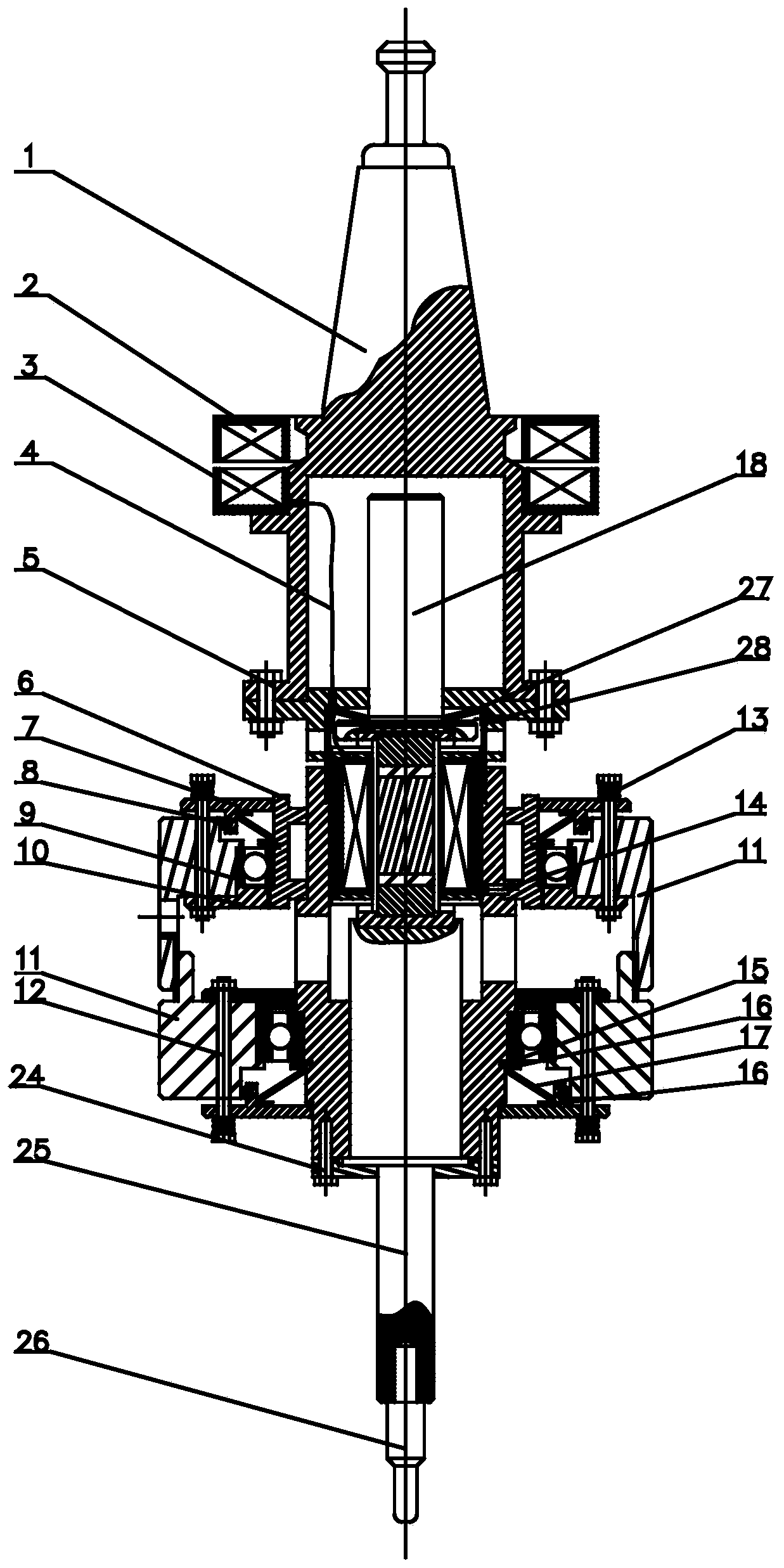

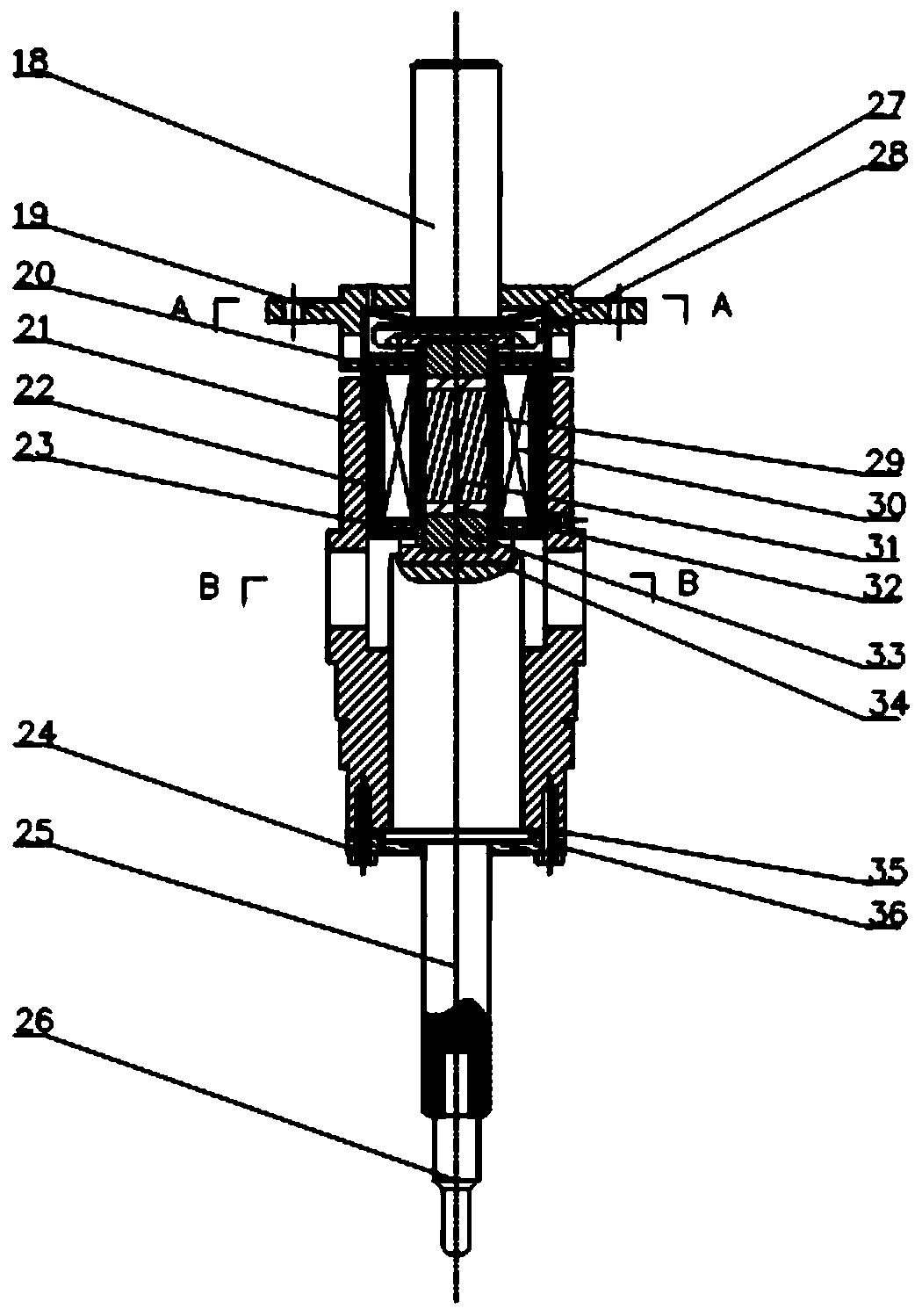

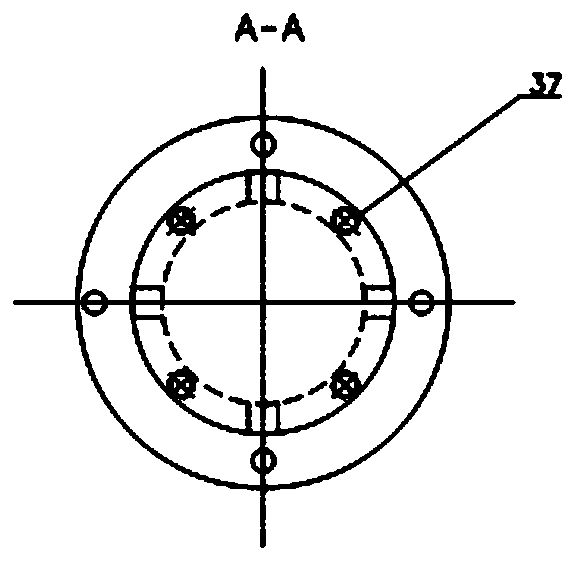

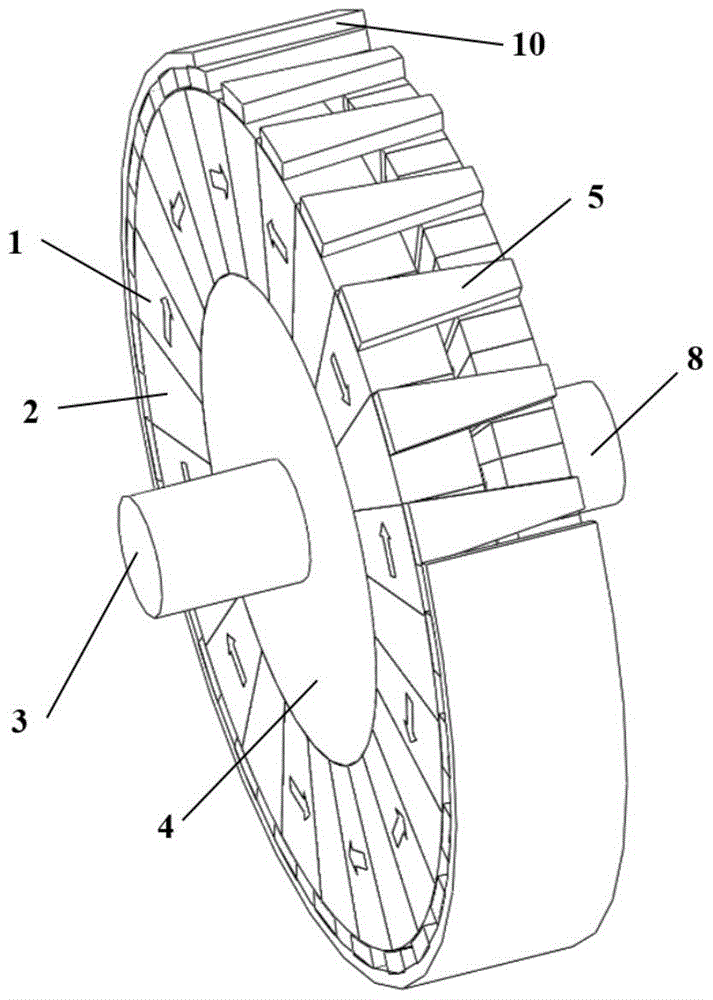

Giant magnetostriction rotary ultrasonic vibration device

ActiveCN107931079ASolve fever problemLower operating temperatureMechanical vibrations separationCopper wireEngineering

The invention discloses a giant magnetostriction rotary ultrasonic vibration device comprising a knife handle, a primary winding, and two sets of bearing systems. A secondary winding is arranged on the knife handle, and the primary winding and the secondary winding are connected through inductive coupling; a giant magnetostriction transducer is installed at the lower part of the knife handle; thegiant magnetostriction transducer is sleeved with the two sets of bearing systems; and the bottoms of two sets of bearing systems are opposite and the two sets of bearing systems are connected by screw threads. An air cooling system is adopted to cool the giant magnetostriction transducer, and the problem of heat generation of the giant magnetostriction transducer in actual processing can be effectively solved; copper stranded wires are adopted by driving coils, compared with commonly used copper wires, the copper stranded wires are more conducive to heat dissipation, and the operating temperature of the coils is reduced; a thin-walled sleeve inside a transducer shell and a flange are arranged to ensure the coaxiality of the flange and the transducer shell, and the giant magnetostriction rod is subjected to uniform pre-tightening force; and the sleeve is arranged to facilitate the outward diffusion of heat generated by the giant magnetostriction rod and the coils.

Owner:XIAN UNIV OF TECH

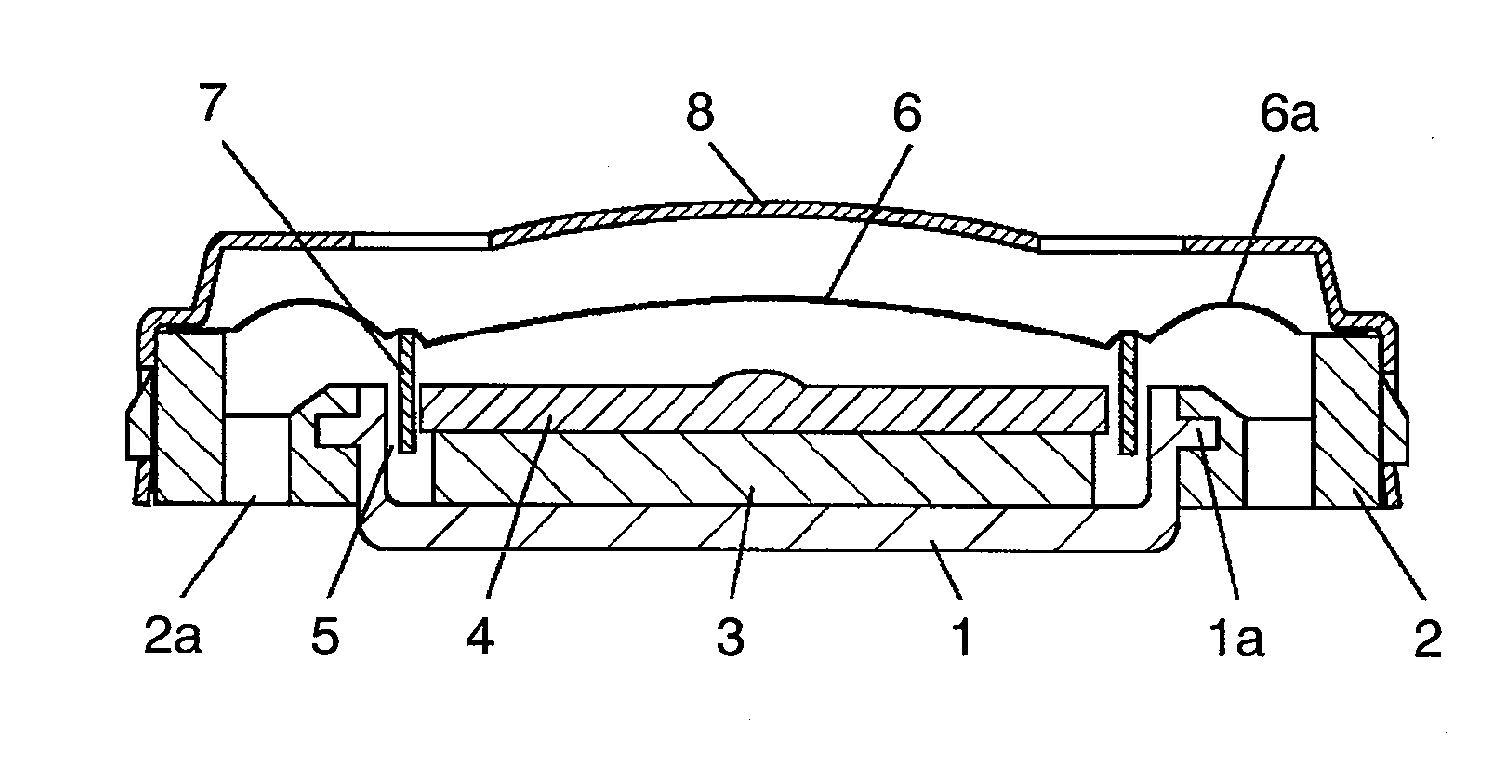

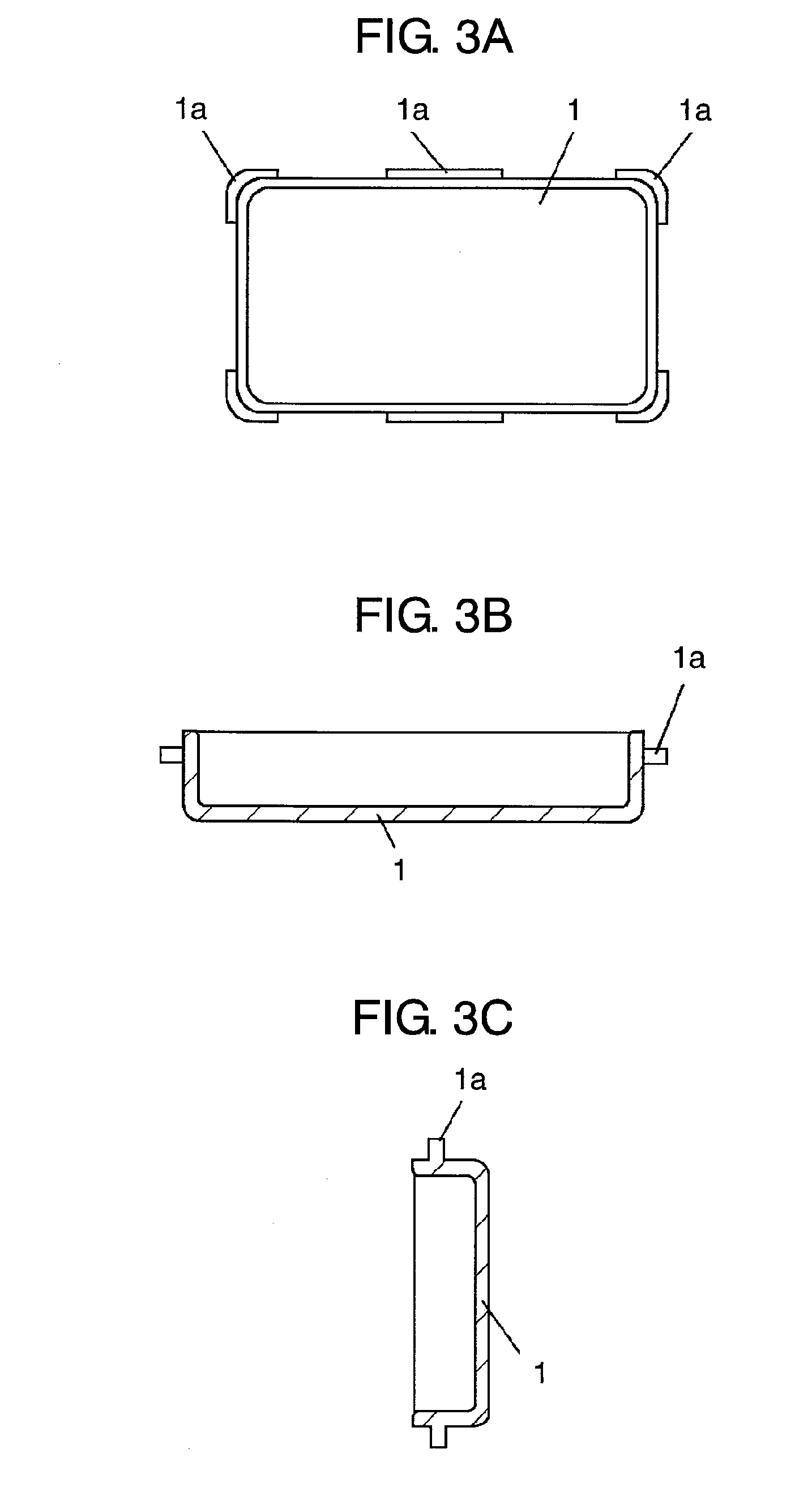

Speaker and method of producing the same

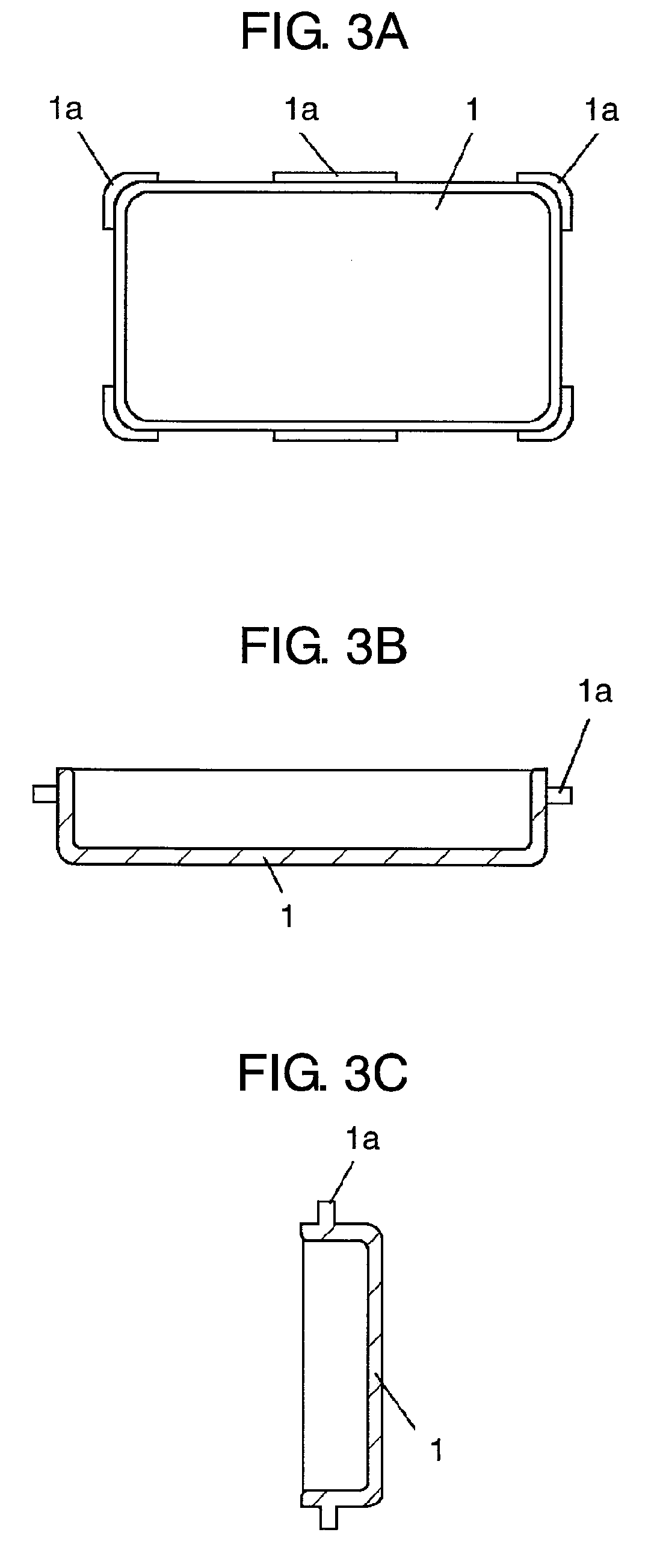

A plate material is drawn into the shape of a rectangular dish and the peripheral border of each corner is press worked. A yoke is fabricated which has an outwardly projecting tongue-like flange provided at a position a predetermined distance below the top end surface. A frame made of resin is insert molded in a manner covering the flange. A magnet is secured inside the yoke and a magnetic circuit having magnetic gap is formed. A diaphragm joined with a voice coil is joined with the frame. By making a loudspeaker in this way, the bonding strength between the yoke and the frame is enhanced and a low-profile loudspeaker is achieved. Also, clearance at each corner of the yoke is eliminated, and a loudspeaker that is free from magnetic flux leakage and excellent both in quality and performance is obtained.

Owner:PANASONIC CORP

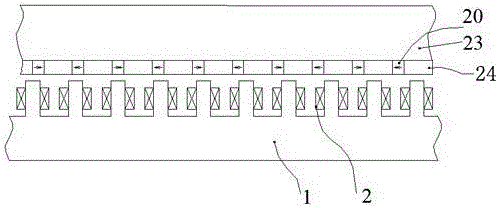

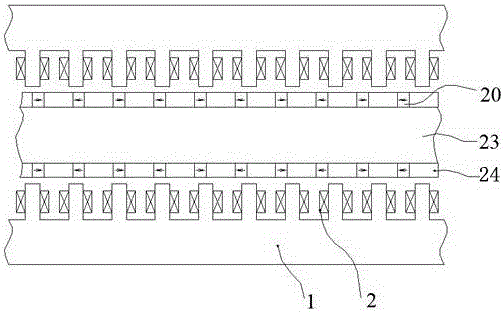

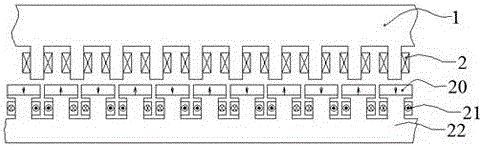

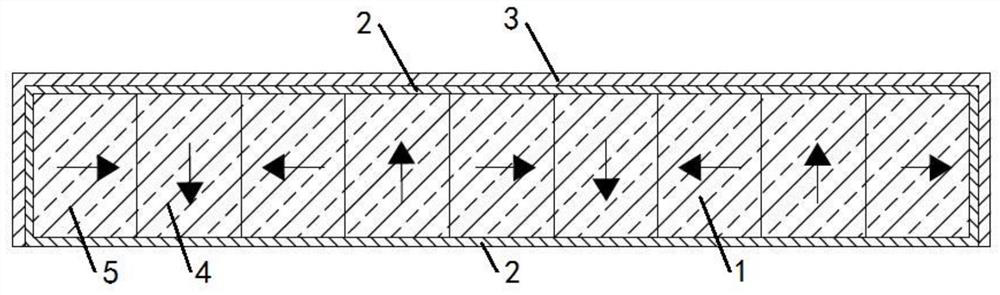

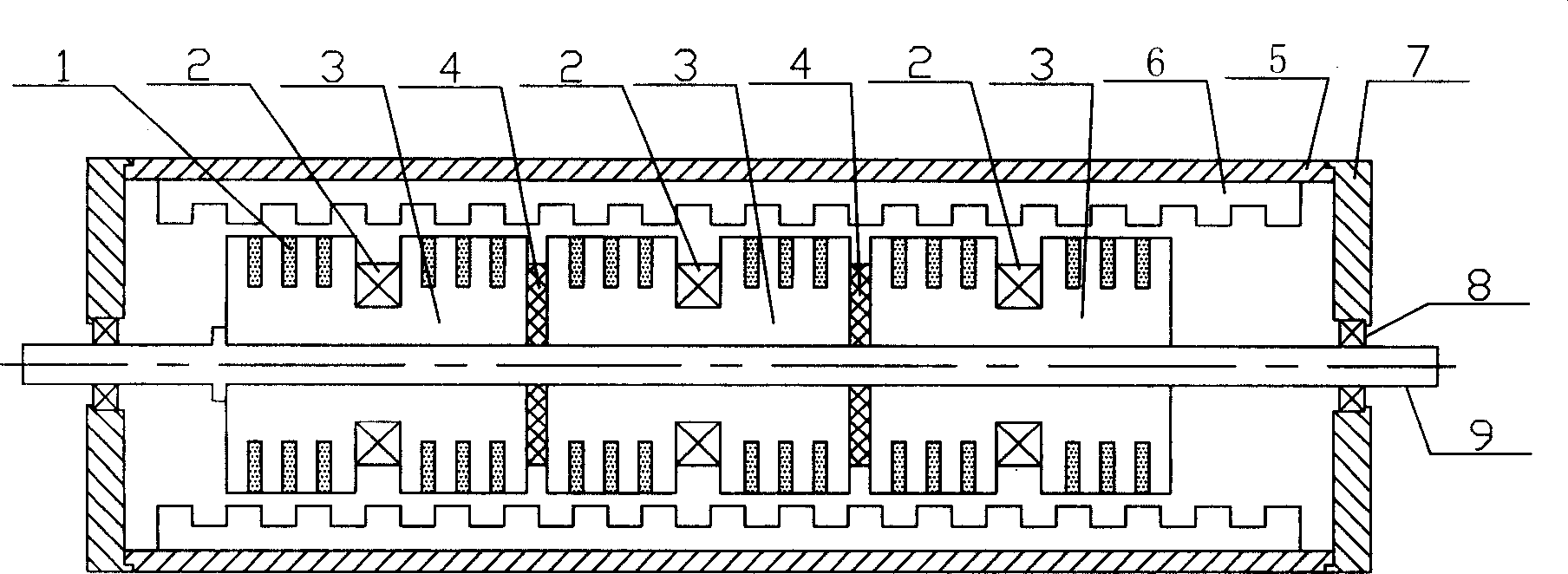

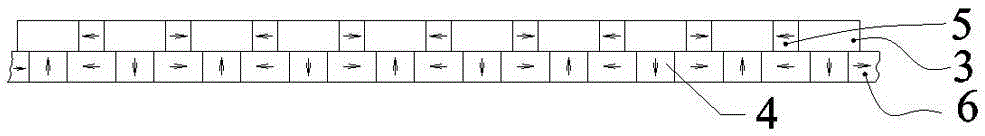

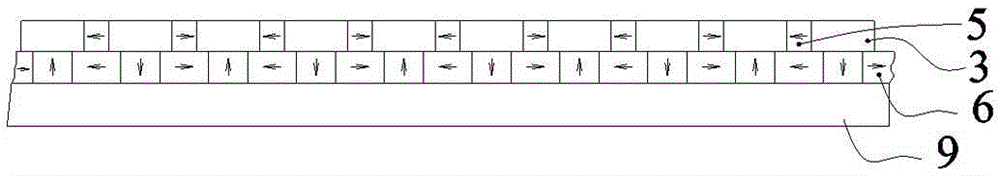

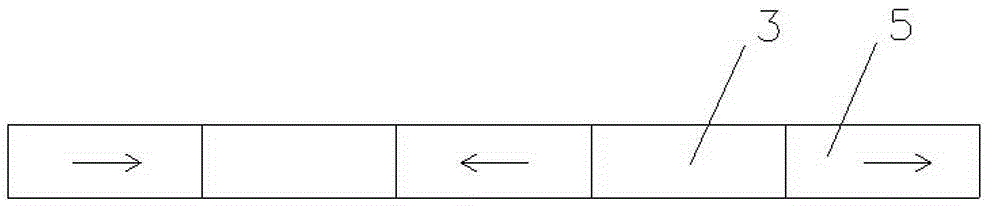

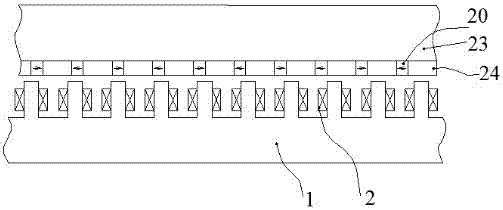

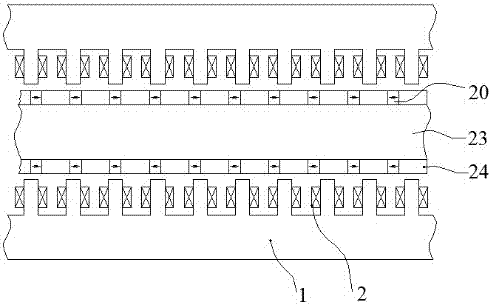

High-efficiency high-thrust double-sided linear motor with excitation regulation function

ActiveCN106253529AReduce volumeLow costPropulsion systemsWindings conductor shape/form/constructionSurface mountingElectric machine

The invention belongs to the linear motor and linear motor driving field and relates to a high-efficiency high-thrust double-sided linear motor with an excitation regulation function. Double-sided primary sides and a double-sided secondary side located between the double-sided primary sides are matched with each other so as to form the double-sided linear motor; the double-sided secondary side is composed of at least one group of magnetic flux concentrators and magnets which are installed in a surface-mount manner alternately, the magnetizing directions of adjacent magnets face each other or depart from each other; each magnetic flux concentrator is provided with an excitation coil; the magnetic flux concentrators provide a passage for the series and parallel magnetic path of double-sided secondary permanent magnets, direct current excitation and double-sided primary sides; magnetic resistance is small, leakage flux is decreased greatly and is even completed eliminated; an excitation regulation ability is increased significantly; a bottleneck problem that restricts the engineering application of a linear motor for a long term is solved; and under the same size and manufacture cost, the power and output of the motor can be greatly increased, or under the same power, the size, manufacture and use cost of the motor can be greatly decreased. The linear motor of the invention is particularly applicable to to high-thrust, high-power and long-stroke linear motor engineering application conditions which require magnetic levitation guide control.

Owner:华鹰云智(深圳)技术有限公司

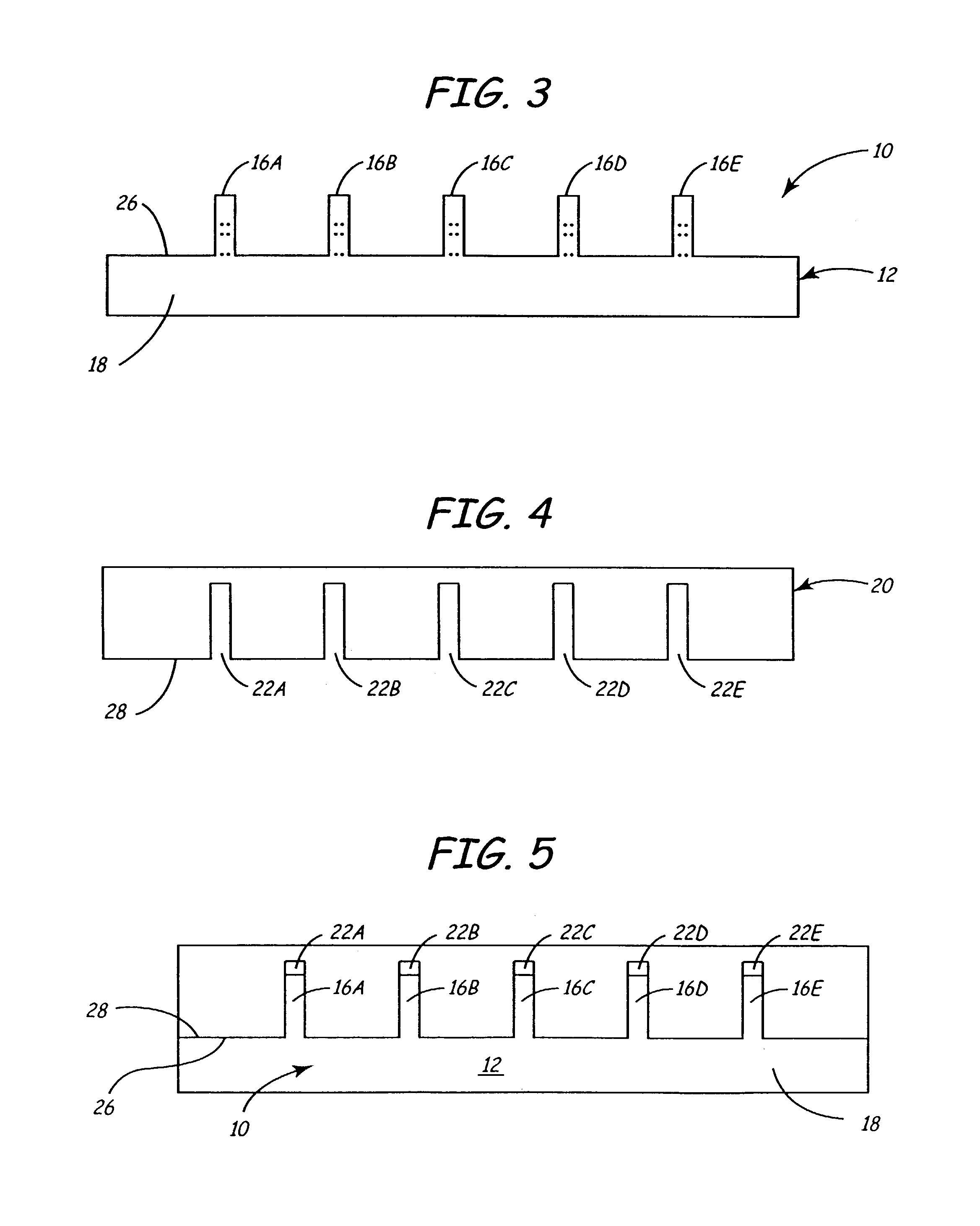

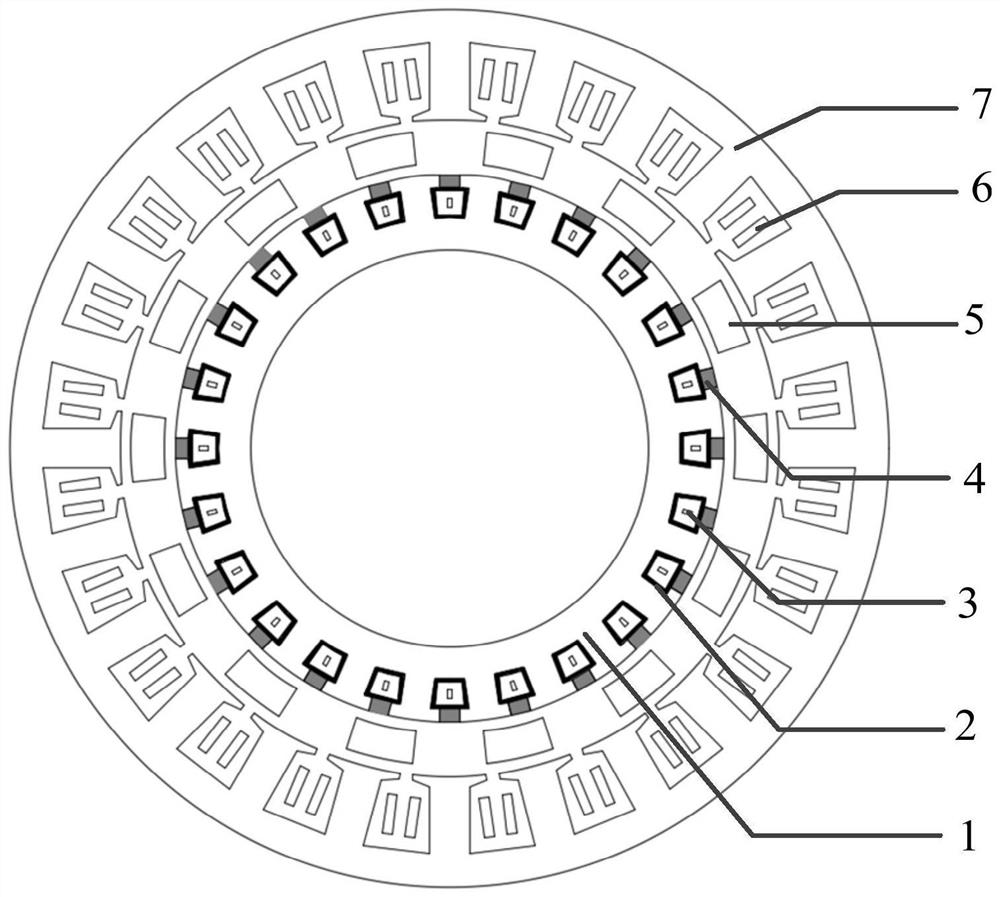

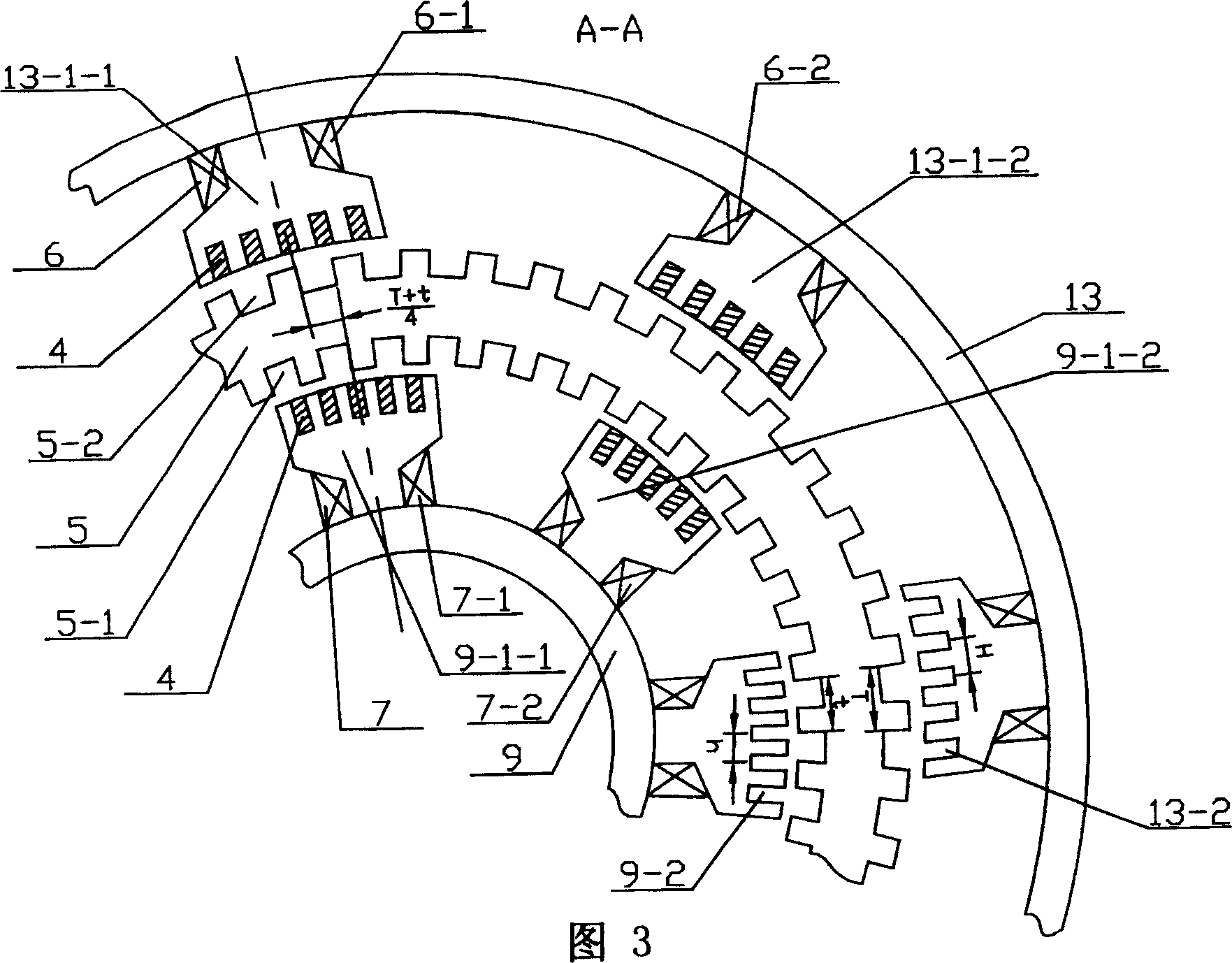

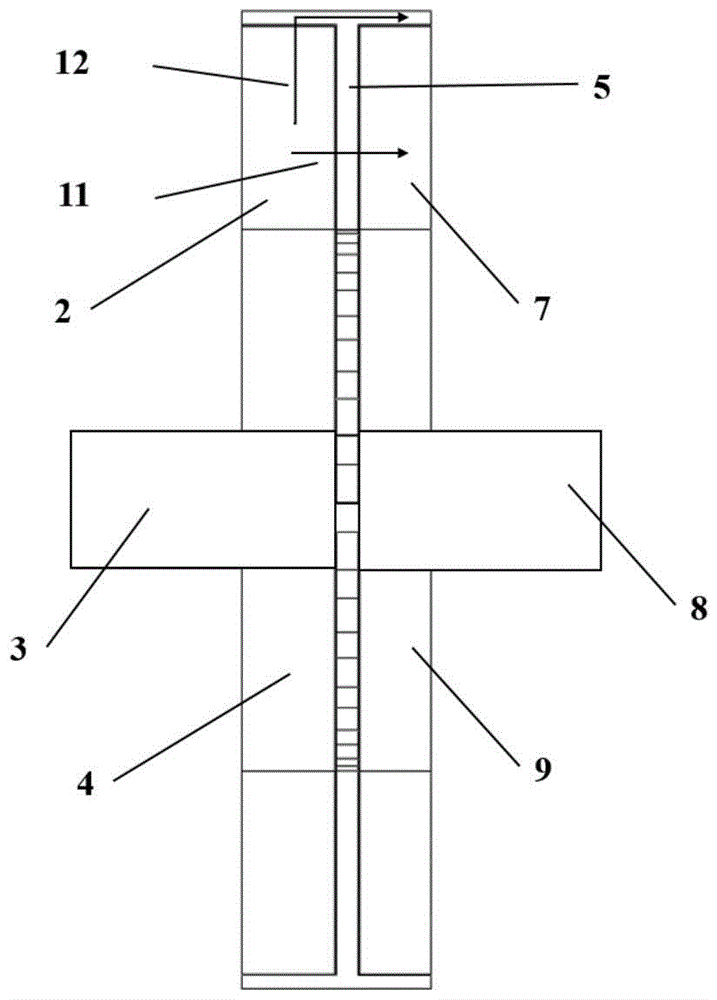

Power motor with circumferential windings and new energy electromobile

PendingCN106655556AEliminate magnetic flux leakageIncrease powerMagnetic circuit rotating partsElectric machinesBrushless motorsNew energy

A power motor with circumferential windings is a switch reluctance type brushless motor composed of a stator, a rotor and an electronic control system; the rotor comprises three rotor magnetic poles as 436, 437 and 438 which are 120 degree from one another; the stator comprises a stator magnetic core and the circular circumferential windings; the stator magnetic core includes three circumferential grooves vertical to the axial and radial directions, and the circumferential windings 311, 312 and 313 are placed in the grooves respectively, three stator magnetic-pole pairs as 284, 285 and 286 are distributed uniformly at the two sides of notches in an aligned manner respectively, and magnetic pole distances between adjacent magnetic poles are as 287, 288 and 289. Stator sequential phase-splitting and rotor spatial phase-splitting are used, the motor serves as the switch reluctance type motor or power generator under control of the electronic power system, end-portion magnetic flux leakage and loss of traditional windings are overcome, the pole number of the motor is not limited by the windings, the phase number is easy to adjust, consumables are saved, temperature rise is reduced, the power and efficiency are improved, loss of a power supply cell is low, and the reliability is high.

Owner:杨明

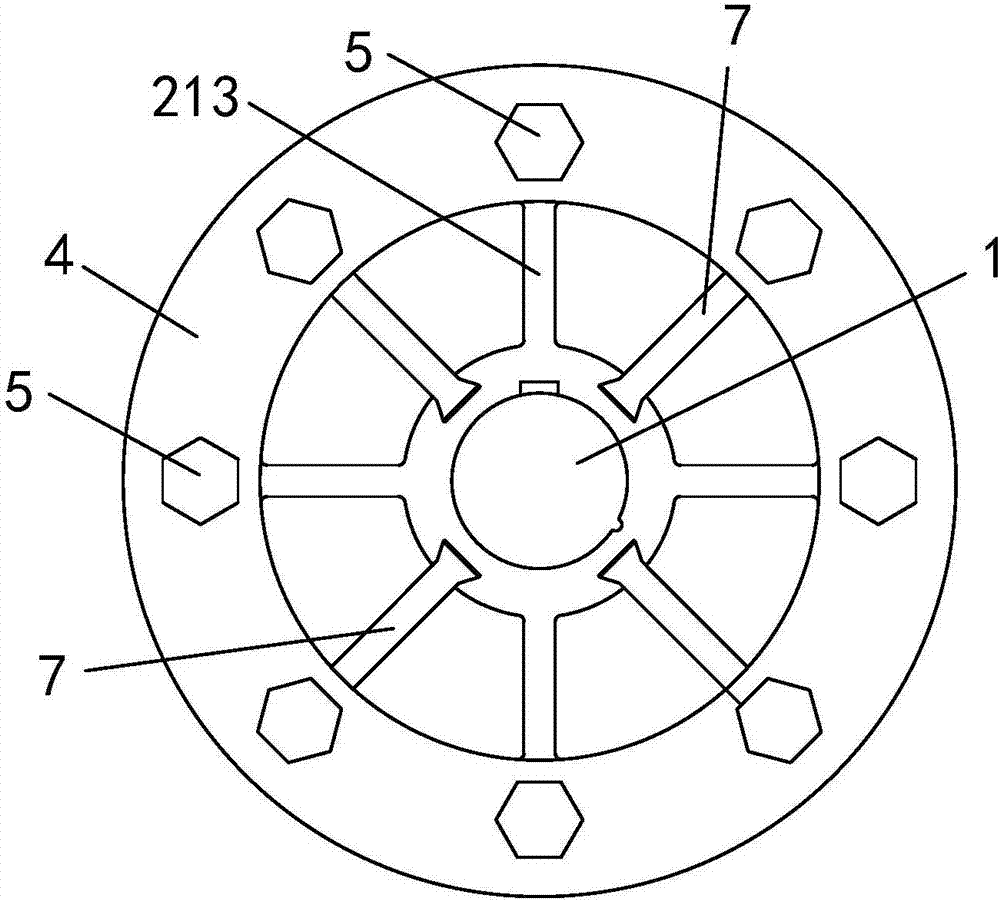

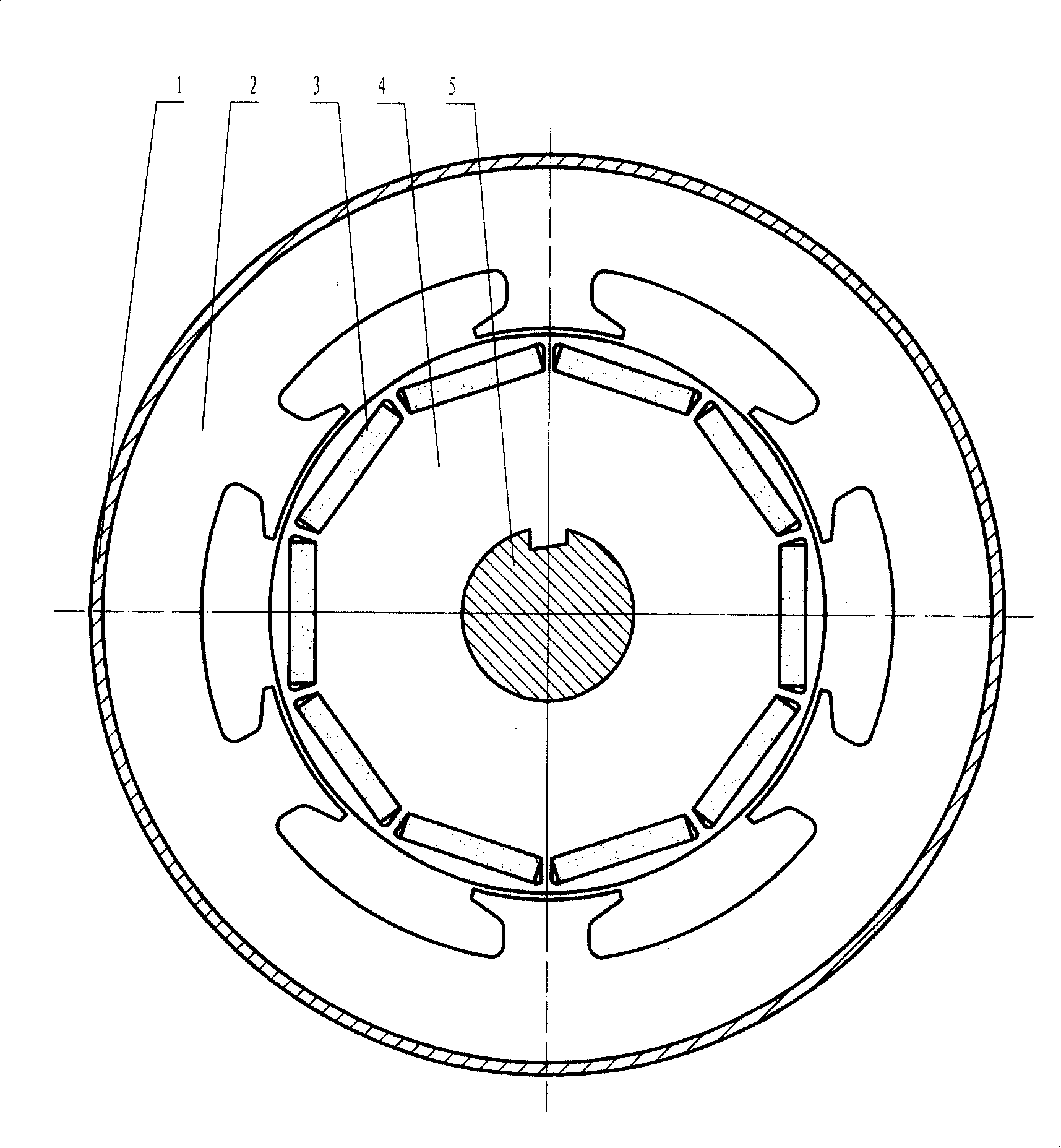

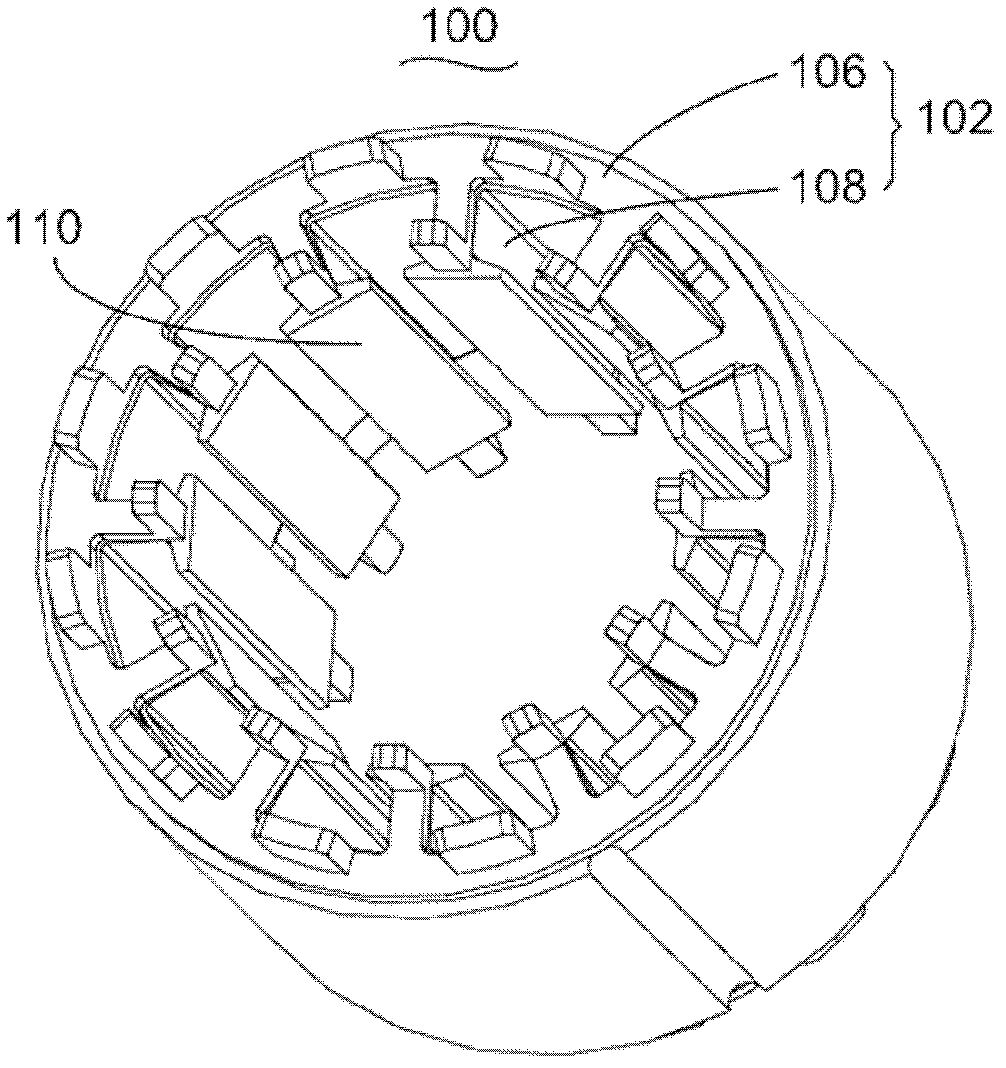

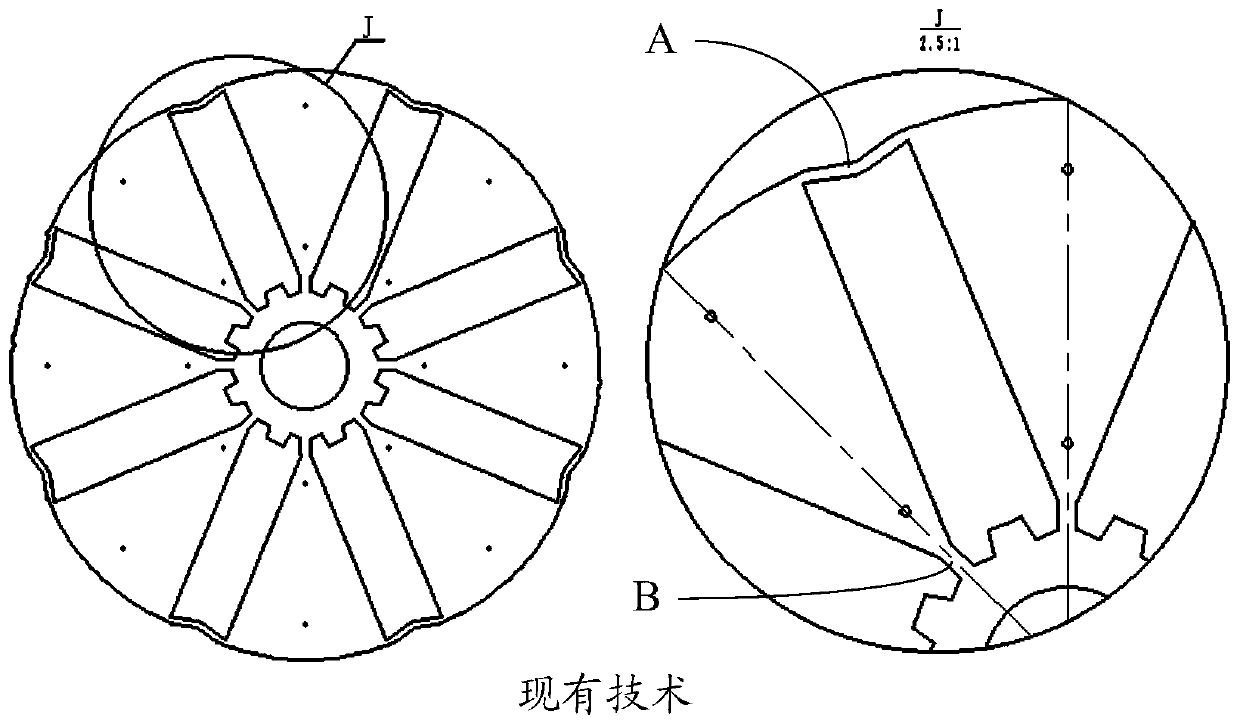

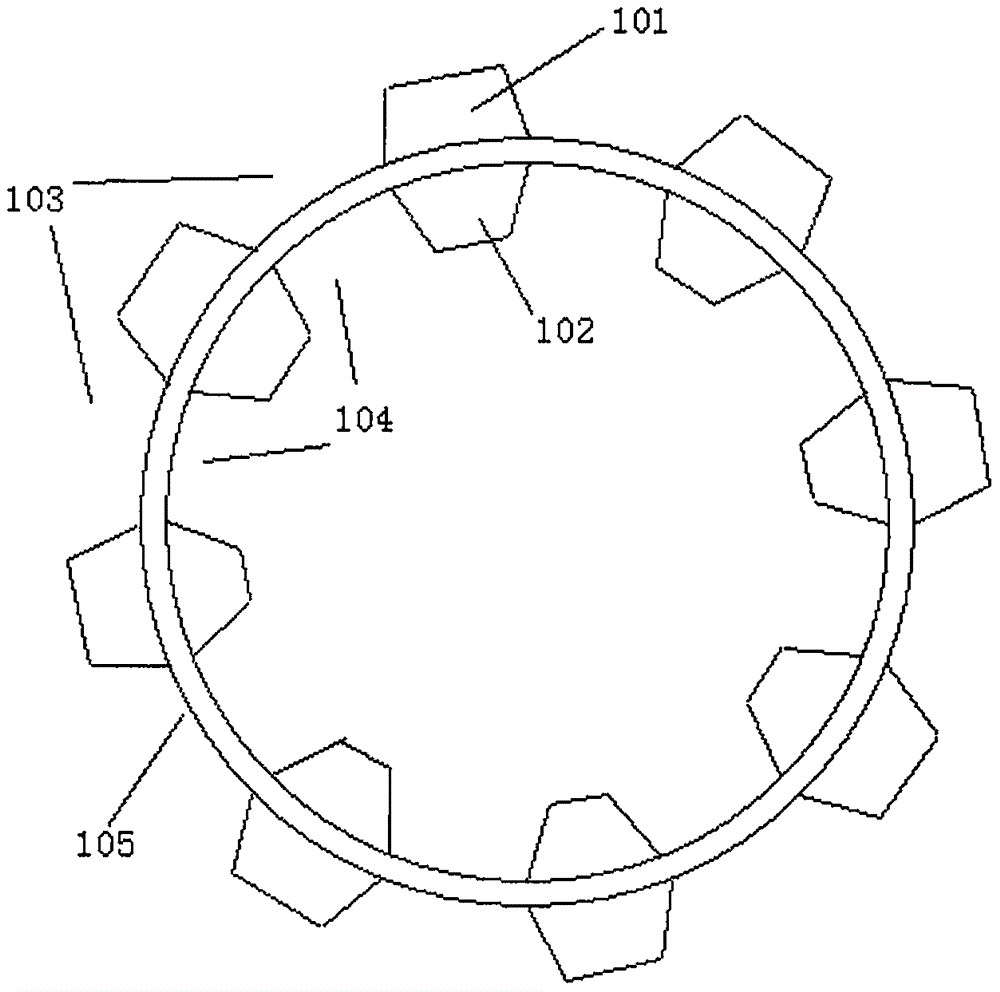

Permanent magnetism motor rotor and motor

ActiveCN106961174AIncrease profitReduce Flux LeakageMagnetic circuit rotating partsPunchingEngineering

A permanent magnetism motor rotor and a motor are provided; a rotor iron core is forming by stacking punching sheets; each punching sheet is provided with a central hole and a magnetic steel slot, and an air magnetic isolation slot; the features are that one side, facing the air slit, of the magnetic steel slot is broken and provided with a fracture; one side, facing the air magnetic isolation slot, of the magnetic steel slot is broken and provided with a fracture connecting with the air magnetic isolation slot; each the air magnetic isolation slot is connected with two adjacent magnetic steel slots; two axial ends of the rotor iron core are respectively stacked with a magnetic isolation fastening plate made of non-magnetic conductive material; the positions between adjacent magnetic steel slots of the rotor iron core are respectively penetrated by a fastening bolt along the rotor axial direction; the fastening bolt penetrates the magnetic isolation fastening plate on one end, passes the rotor iron core and reaches the magnetic isolation fastening plate on the other end, and is fastened and connected with a nut. The permanent magnetism motor rotor can greatly reduce magnetic flux leakage, can basically realize no magnetic flux leakage, thus greatly improving the permanent magnet utilization rate, ensuring the rotor intensity not to drop, and the motor is suitable for large power high rotating speed work occasions.

Owner:李致真

Single protrusion permanent magnetic motor scheme

InactiveCN101237167AIncrease the number of effective teethReduced torque ripple at low speedsMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorWinding machine

The invention relates to a single salient pole permanent magnet motor scheme, which is characterized in that: a stator keeps a salient pole structure which is often used in a general magnetic resistance motor; permanent magnets are orderly and fully embedded in a rotor core along the circumferential direction of an air gap; a novel motor is formed by similarly changing the stator of the general permanent magnet motor into the salient pole type magnetic resistance stator; by adopting the magnetic biasing theory of a major loop and a tooth socket magnetic biasing type magnetic resistance motor and referring to the permanent magnet rotor structure of the general permanent magnet motor, the single salient pole permanent magnet motor scheme has the characteristics of advanced technique and good manufacturability; moreover, because the invention can make a stator trunking and a notch bigger, thereby facilitating to the winding of a winding machine on the one hand and being capable of adopting the multi-span winding of the magnetic biasing motor on the other hand; as a result, the number of turns of each trunking are reduced times, and the consumption of copper wires is greatly reduced.

Owner:苏州扬名机电有限公司 +1

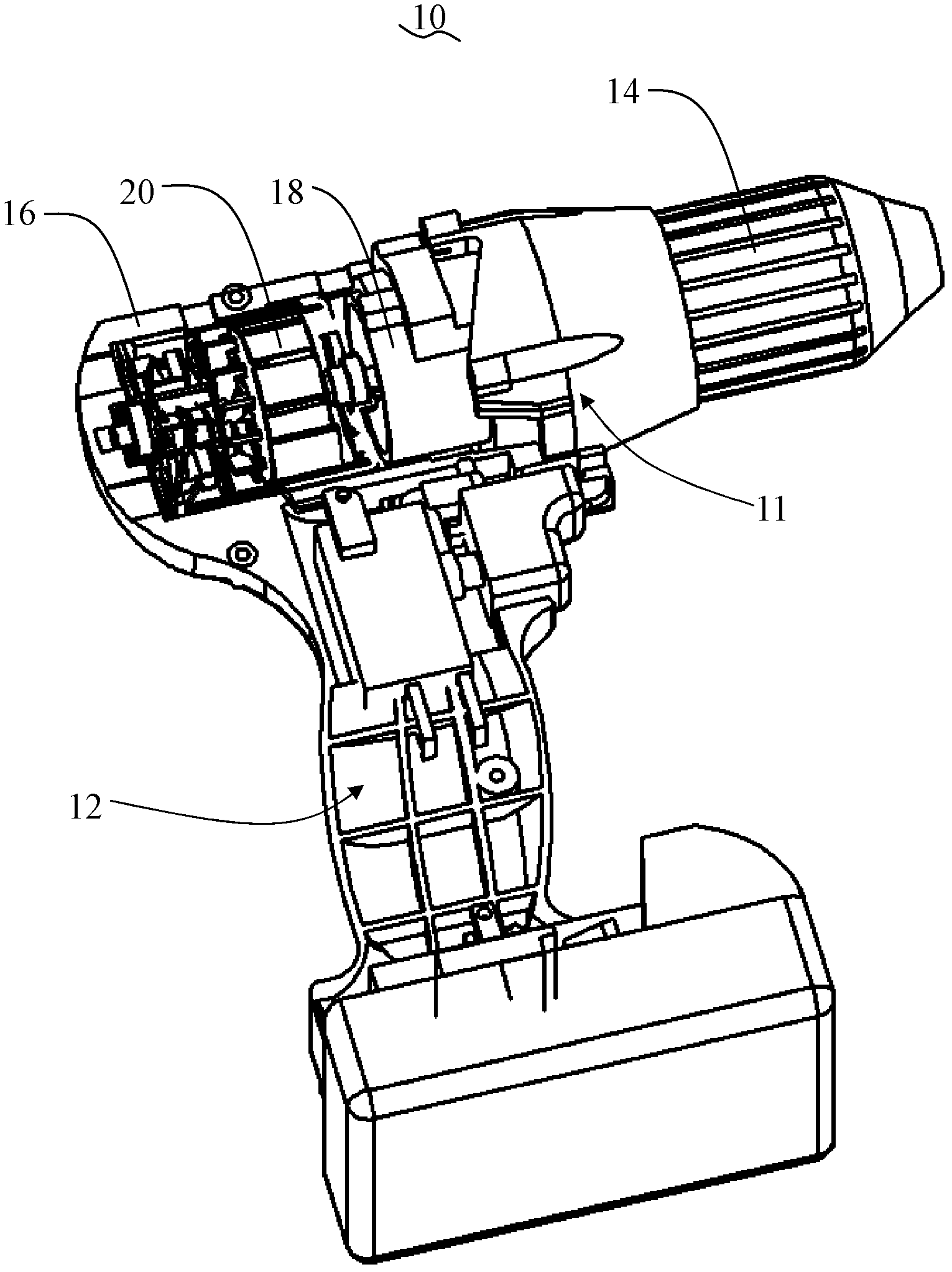

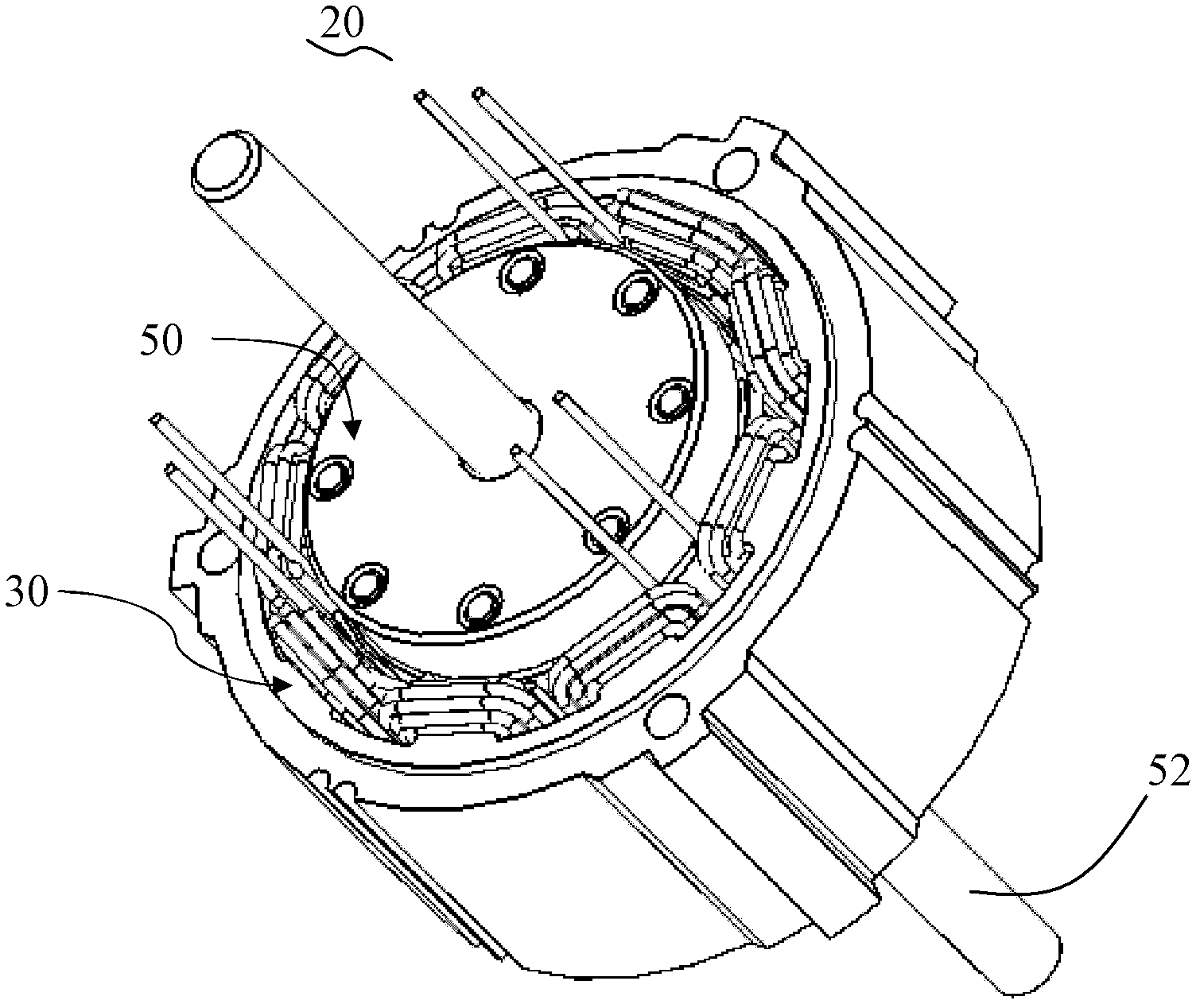

Permanent magnet motor and electric tool and mower utilizing the same

InactiveCN103107665AIncrease air gap flux densityImprove power densityMowersPortable power-driven toolsSurface mountingRare earth

Owner:JOHNSON ELECTRIC SHENZHEN

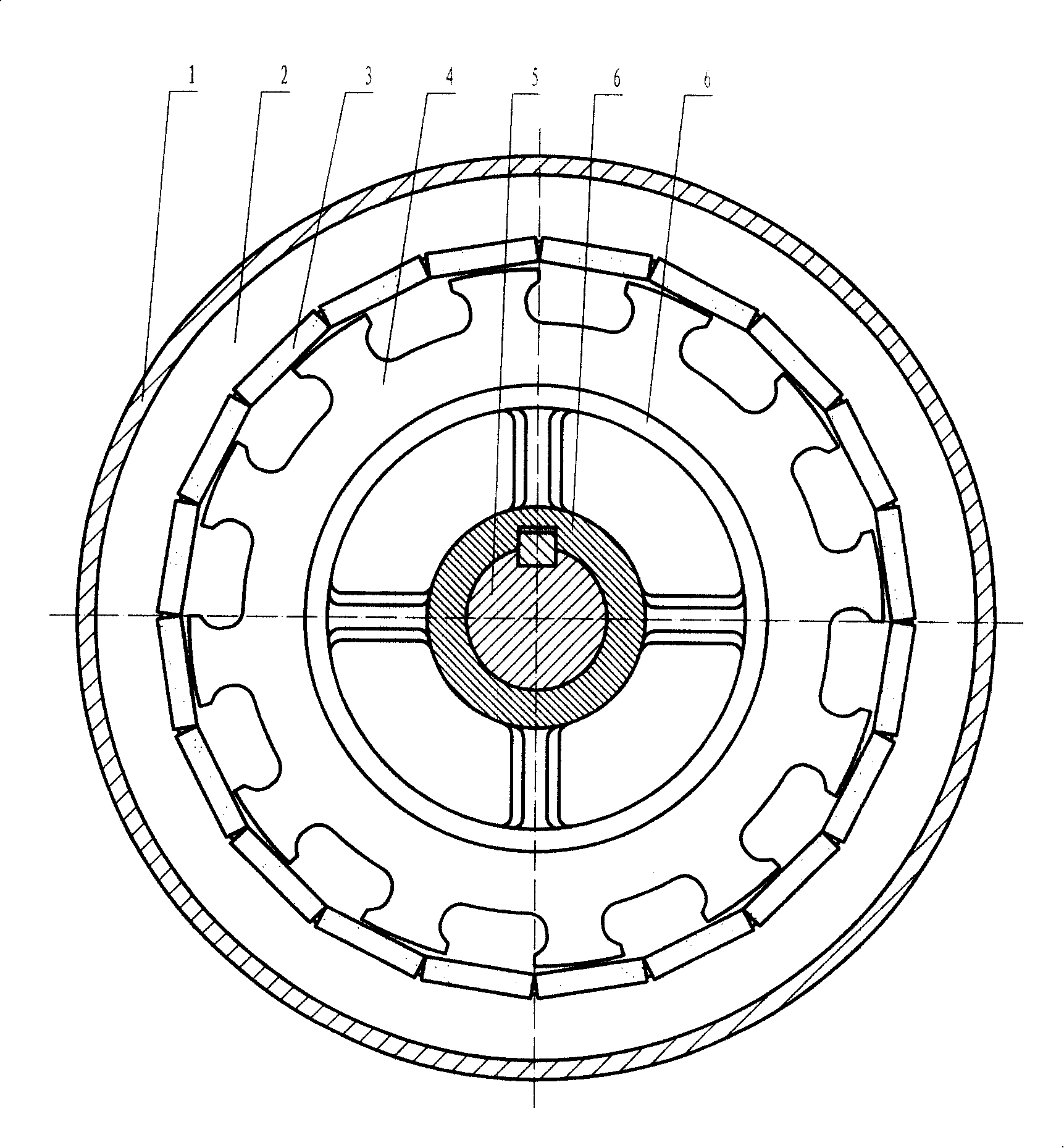

Permanent magnetic motor and bladeless fan with same

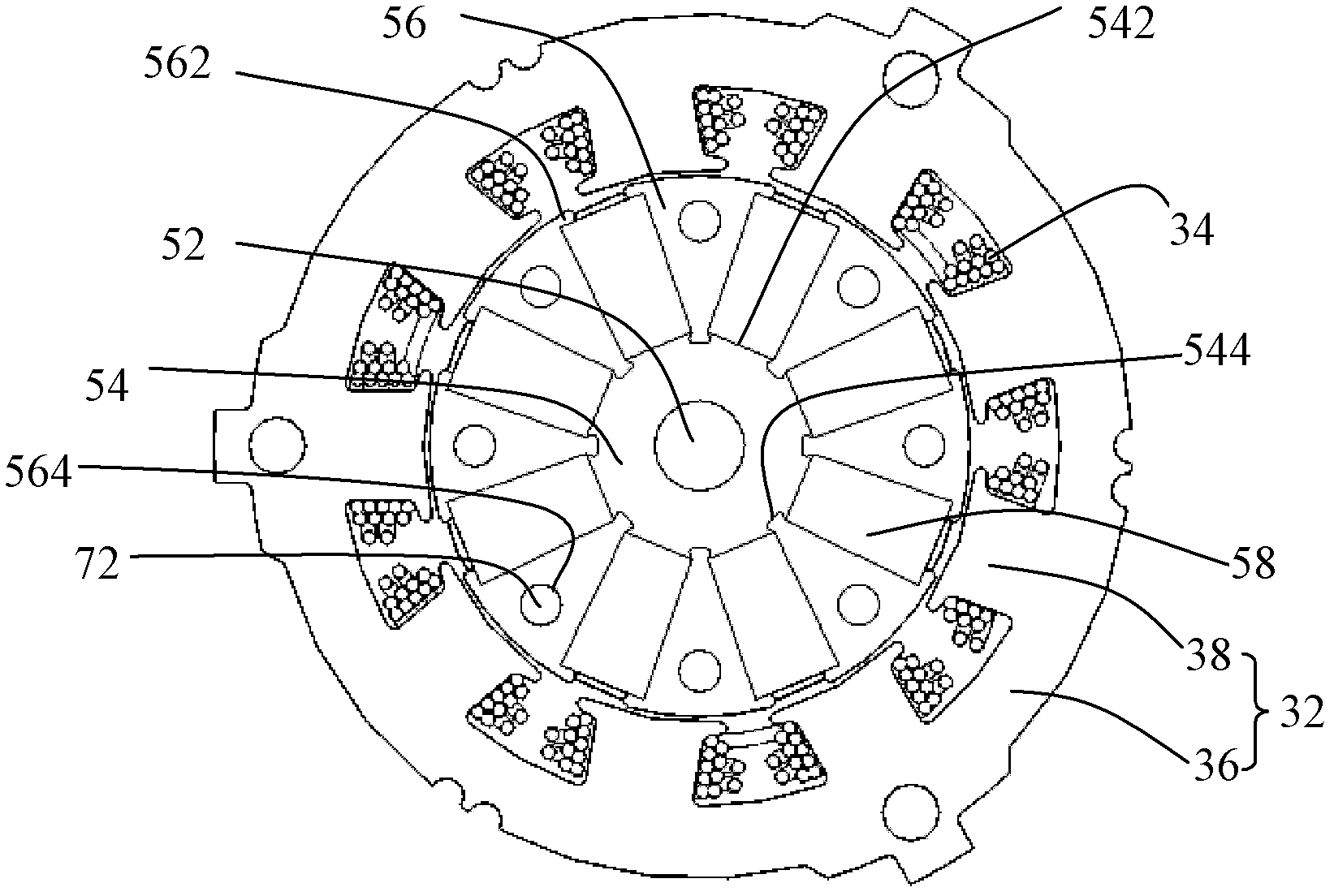

InactiveCN103296789AIncrease air gap flux densityImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsRare earthTorque density

The invention relates to a permanent magnetic motor. The permanent magnetic motor comprises a stator and a rotor arranged inside the stator. The stator comprises a stator core provided with 12 stator teeth and a coil wound on the stator teeth, and the rotor comprises a rotating shaft and at least one magnetic core set which is fixed on the rotating shaft. The magnetic core set comprises 8 rotor cores and 8 permanent magnets, wherein the 8 rotor cores are arranged at intervals in the circumferential direction of the rotor, each permanent magnet is made of ferrite materials, each permanent magnet is clamped between two adjacent rotor cores, each permanent magnet is polarized in the circumferential direction of the rotor, and the polarities of every two adjacent permanent magnets are opposite. According to the permanent magnetic motor, a multi-polarity embedded magnetic focusing structure is applied, so that the gap flux density of the motor is improved, the objective that a high power density and a high torque density are obtained through the ferrite materials is realized, and the objective that the torque density of the ferrite motor is equal to or approximates that of a surface-attached rare-earth permanent magnet motor is realized. In addition, the permanent magnetic motor is low in noise and meets design requirements. The invention further provides a bladeless fan with the permanent magnetic motor.

Owner:JOHNSON ELECTRIC SHENZHEN

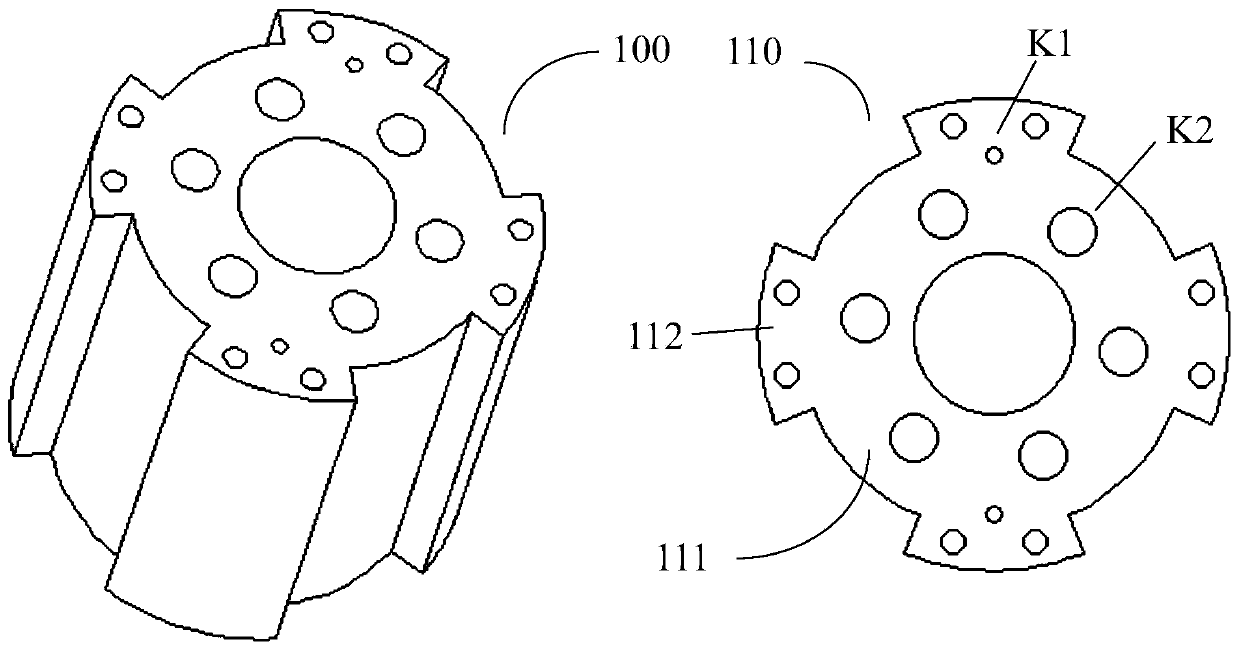

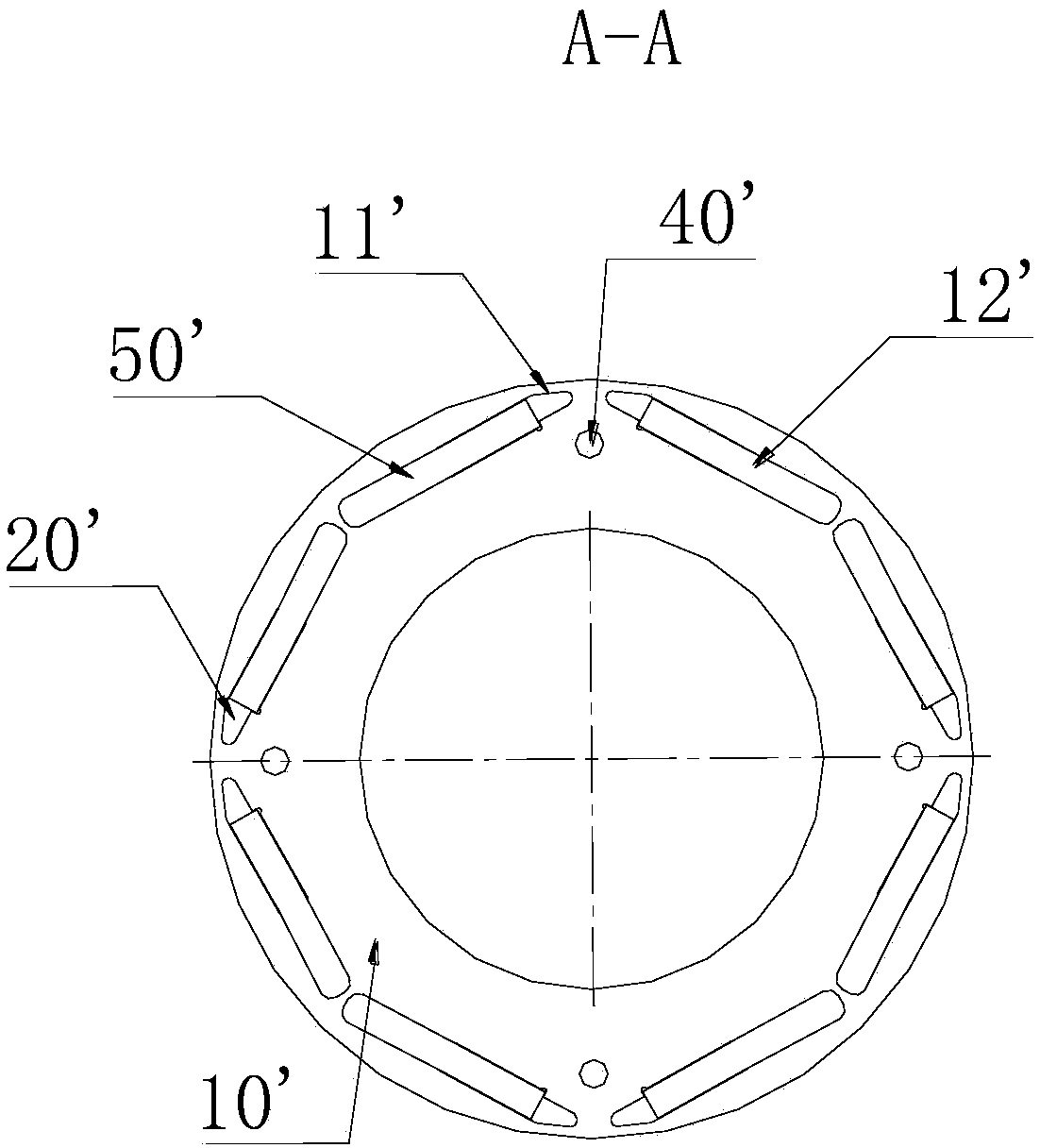

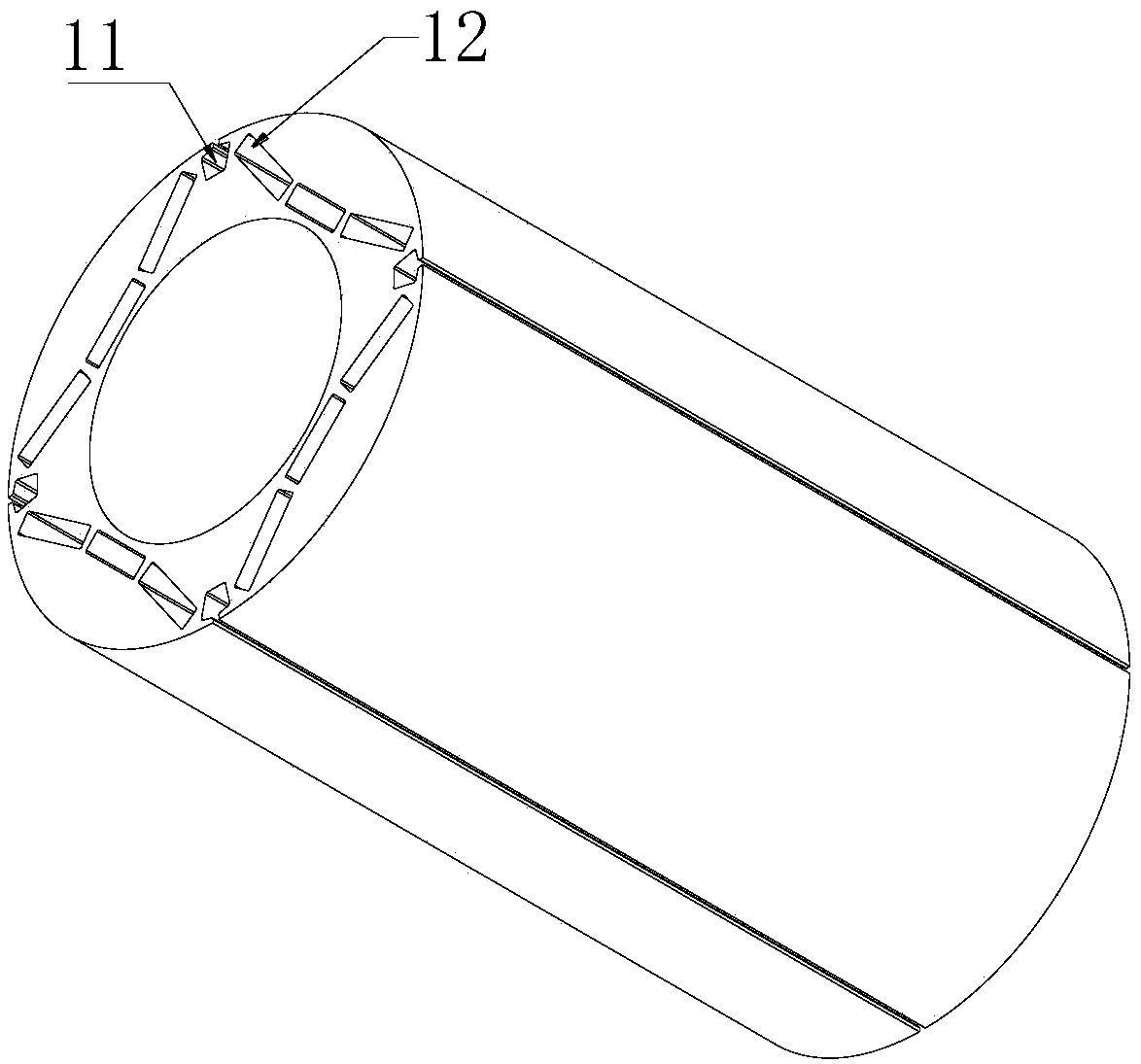

Motor rotor, assembly method thereof and motor

ActiveCN108880037AImprove connection reliabilitySimple structureMagnetic circuit rotating partsPermanent magnet synchronous motorMagnetic poles

The invention provides a motor rotor, an assembly method and a motor. The motor rotor is used in a permanent-magnet synchronous motor and comprises a rotor core, wherein a first end ring and a secondend ring are respectively arranged at two ends of the rotor core, a plurality of magnetic isolation guide strips are connected between the first end ring and the second end ring, the plurality of magnetic isolation guide strips penetrate through grooves in the rotor core, a plurality of magnetic steel grooves are formed in the rotor core, and the grooves are arranged in a region between two magnetic steel grooves with opposite-polarity magnetic poles. In the motor rotor, the assembly method thereof and the motor, provided by the invention, the magnetic isolation guide strips are connected withthe end rings, the connection reliability and the structure integration of the motor rotor are improved, and meanwhile, magnetic isolation can be performed on adjacent opposite-polarity magnetic poles of the motor rotor.

Owner:GREE ELECTRIC APPLIANCES INC +1

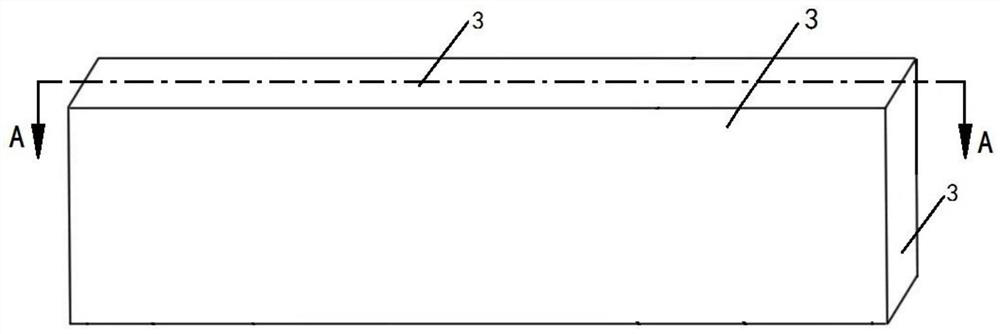

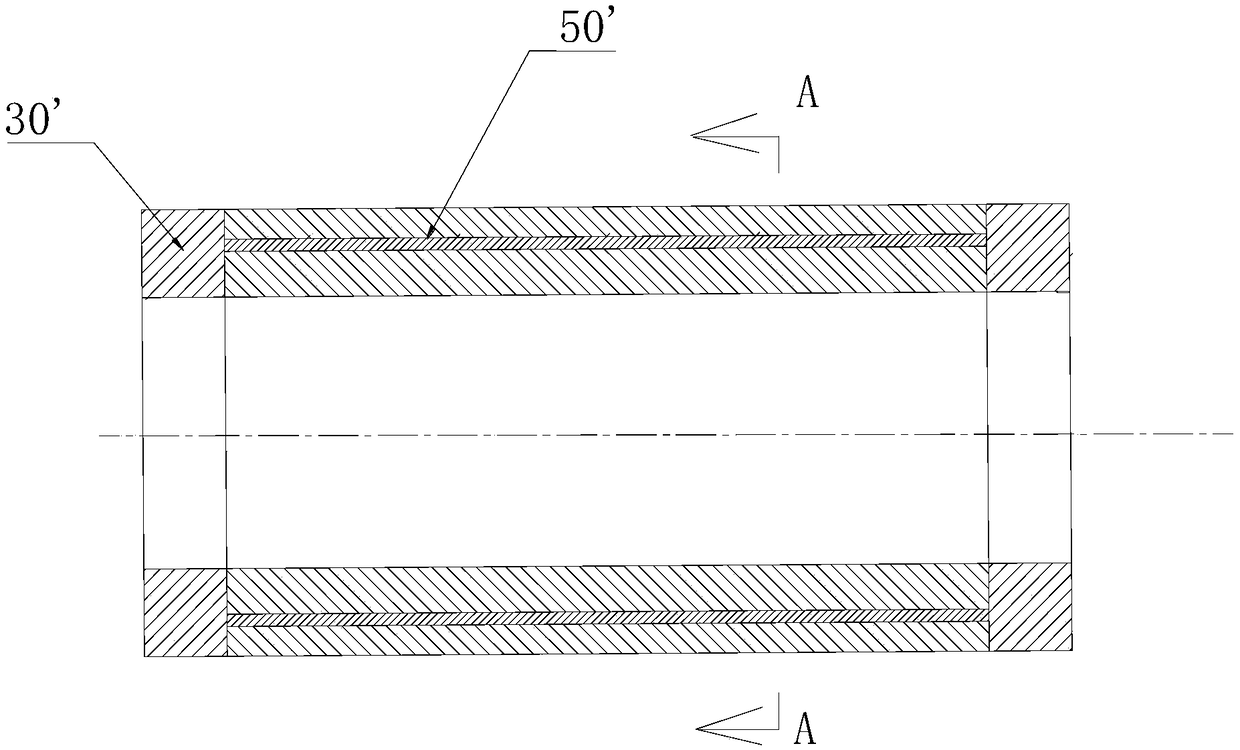

Halbach permanent magnet array structure capable of reducing magnetic flux leakage and application of structure

The invention provides a Halbach permanent magnet array structure capable of reducing magnetic flux leakage. The Halbach permanent magnet array structure comprises a Halbach permanent magnet array body, a carbon fiber protective sleeve and a Fe-based soft magnetic composite material, wherein the Halbach permanent magnet array body is formed by alternately arranging and combining a plurality of radial magnetizing permanent magnets and a plurality of tangential magnetizing permanent magnets; the outer surface of the Halbach permanent magnet array body is composed of a magnetism gathering surfaceand a plurality of magnetism shielding surfaces; the magnetism gathering surface is coated with a carbon fiber protective sleeve; and the magnetic shielding surfaces are coated with a carbon fiber protective sleeve, and the Fe-based soft magnetic composite material is fixed on the carbon fiber protective sleeve. The carbon fiber protective sleeve and the Fe-based soft magnetic composite materialare adopted for coating, so that magnetic flux leakage is greatly reduced, and even magnetic flux leakage can be completely eliminated. Due to the arrangement of the Fe-based soft magnetic composite material, the magnetic induction intensity at the air gap area can be enhanced. The Halbach permanent magnet array structure can be applied to a radial permanent magnet bearing and a disc type corelessbilateral permanent magnet motor.

Owner:XIAN UNIV OF SCI & TECH

Desaturation magnetic field modulation motor

InactiveCN111917261AReduce maintenance costsIncreased torque densityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineTorque density

The invention discloses a desaturation magnetic field modulation motor, and the motor comprises an inner stator core, an inner air gap, a rotor modulation ring, an outer air gap and an outer stator core which are sequentially distributed from inside to outside in the radial direction. The motor also comprises an excitation winding which is placed in an inner stator core groove, a magnetic steel which placed at an opening of the inner stator core groove, an armature winding which is placed in an outer stator core groove, and a cryostat which is used for wrapping the excitation winding, whereinthe inner stator core, the rotor modulation ring and the outer stator iron core are all made of ferromagnetic materials. The excitation winding and the armature winding are placed on the two stators respectively, rotary excitation, an electric brush and a slip ring are not needed, the maintenance cost of the motor is reduced, and the reliability of the structure is improved; meanwhile, the doublestators and the rotor modulation ring are made of ferromagnetic materials, so the torque density of the motor can be effectively improved, and the superconducting consumption is reduced; and the modular cryostat is adopted, so the equivalent air gap flux density can be effectively reduced, and the torque density of the motor is further improved.

Owner:HUAZHONG UNIV OF SCI & TECH

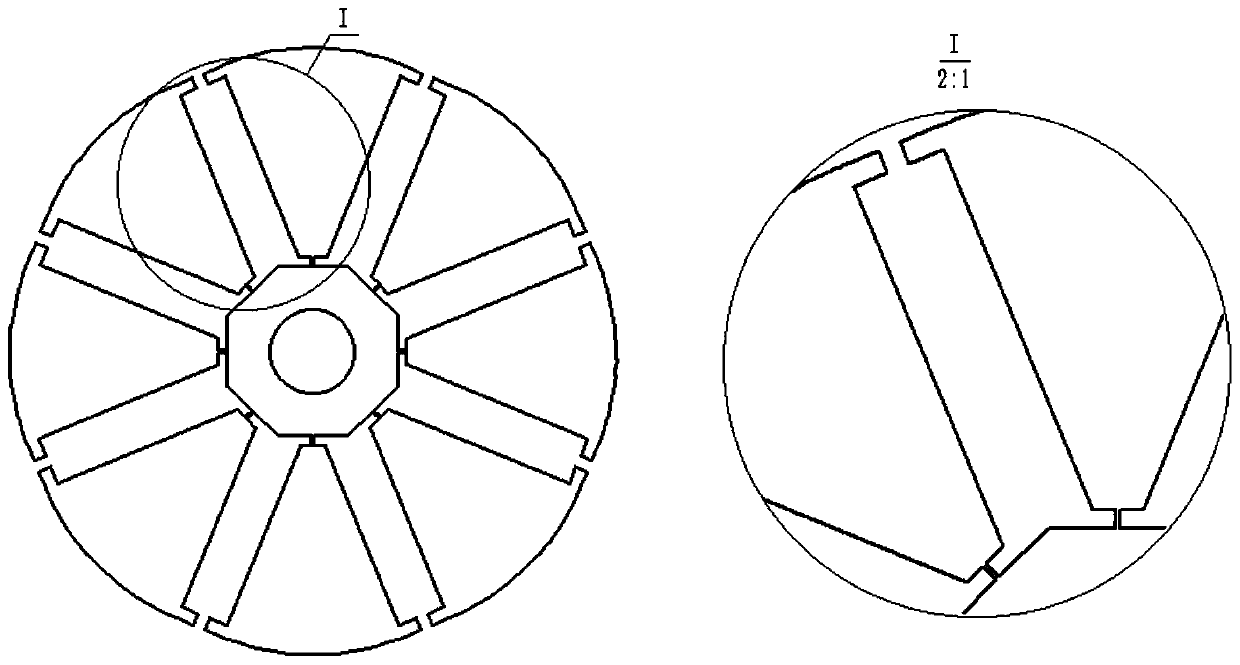

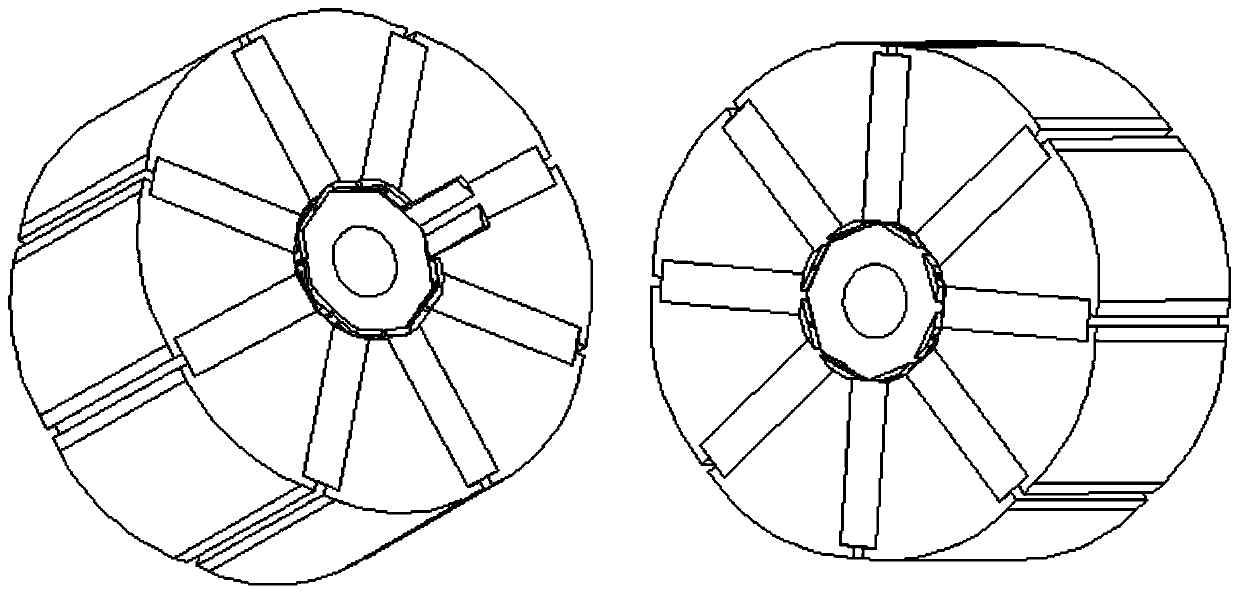

High-efficiency permanent magnet motor with low leakage flux flexible rotor

ActiveCN110311491AImprove energy efficiencyIncrease loading capacityMagnetic circuit rotating partsPunchingInterface design

The invention provides a high-efficiency permanent magnet motor with a low leakage flux flexible rotor. A chained rotor iron core structure is adopted. The rotor iron core of the magnetic circuit partis composed of two kinds of punching sheets, which can completely eliminate leakage flux circuits. The magnetic field utilization rate is improved, and thus the energy efficiency and the load capacity of the motor are significantly improved. According to the invention, inner and outer iron core structures are used; a shock absorbing material is increased in the overall transmission path; the damping of the transmission path is improved; the radial force and the torque fluctuation are weakened; in addition, a cage-shaped shock absorbing structure is designed, supplemented by the concave and convex interface design of inner and outer iron cores, so as to eliminate the radial electromagnetic force; the quality is better; and the structural strength is more reliable than the structural strength of permanent magnet motors in the prior art.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Columnar linear motor in permanent magnet reluctance type

InactiveCN1293695CEvenly distributedIncrease in sizePropulsion systemsLinear motorMagnetic insulation

The linear motor is composed of the case, the spindle, the armature core, the magnetic insulation loop, the annular armature winding and the non-armature core. The motor is mobile type structure of columnar non-armature core put onto the spindle. The armature core is columnar. The exicrcle surface of the armature core is closely matched with the inner surface of the case. The annular tooth sockets are distributed along axial on the surfaces facing the gap between the armature core and the non-armature core. The annular permanent magnet is setup in each tooth socket of the armature core. The adjacent permanent magnet is magnetized in axial, but with opposite direction. The tooth pitch on an armature core with permanent magnet is a half tooth pitch on an armature core without permanent magnet. Comparing with prior art, the invention makes the excitation magnetic field distribute evenly and raises the ratio between performance and volume.

Owner:HARBIN INST OF TECH

Salient-pole halbach composite array and permanent magnet motor

InactiveCN105305767AIncrease powerHigh outputSalient polesPropulsion systemsElectric machineEngineering

The invention belongs to the field of motors and electrical appliances, and specifically relates to a salient-pole halbach composite array and a permanent magnet motor. A salient-pole halbach composite array comprises a halbach magnet array, the salient-pole halbach composite array comprises a single-layer salient-pole halbach composite array and / or a double-layer halbach composite layer, the surface of a salient-pole magnet array is tightly attached to a halbach magnet array to form the single-layer salient-pole halbach composite array, and surfaces at two sides of the salient-pole magnet array are respectively provided with halbach magnet arrays to form the double-layer salient-pole halbach composite layer, and the salient-pole halbach composite array and a corresponding secondary to form the permanent magnet motor. According to the salient-pole halbach composite array and the permanent magnet motor, the characteristic of small magnetism leakage in a weak-magnetism area of the halbach magnet array is employed, the salient-pole magnet array is tightly attached to the halbach magnet array, the salient-pole halbach permanent magnet motor is formed by the cooperation of the salient-pole magnet array and the electrified winding, magnetism leakage of the salient-pole magnet array is greatly reduced or even completely eliminated, the size and the manufacturing usage cost of the motor can be greatly reduced, and the salient-pole halbach composite array and the permanent magnet motor are especially applicable to occasions of long-stroke, high-power, and high-thrust linear motor engineering application, and the bottleneck problem of engineering application of the linear motor is well solved.

Owner:JIAOZUO HUAYING ELECTROMECHANICAL TECH

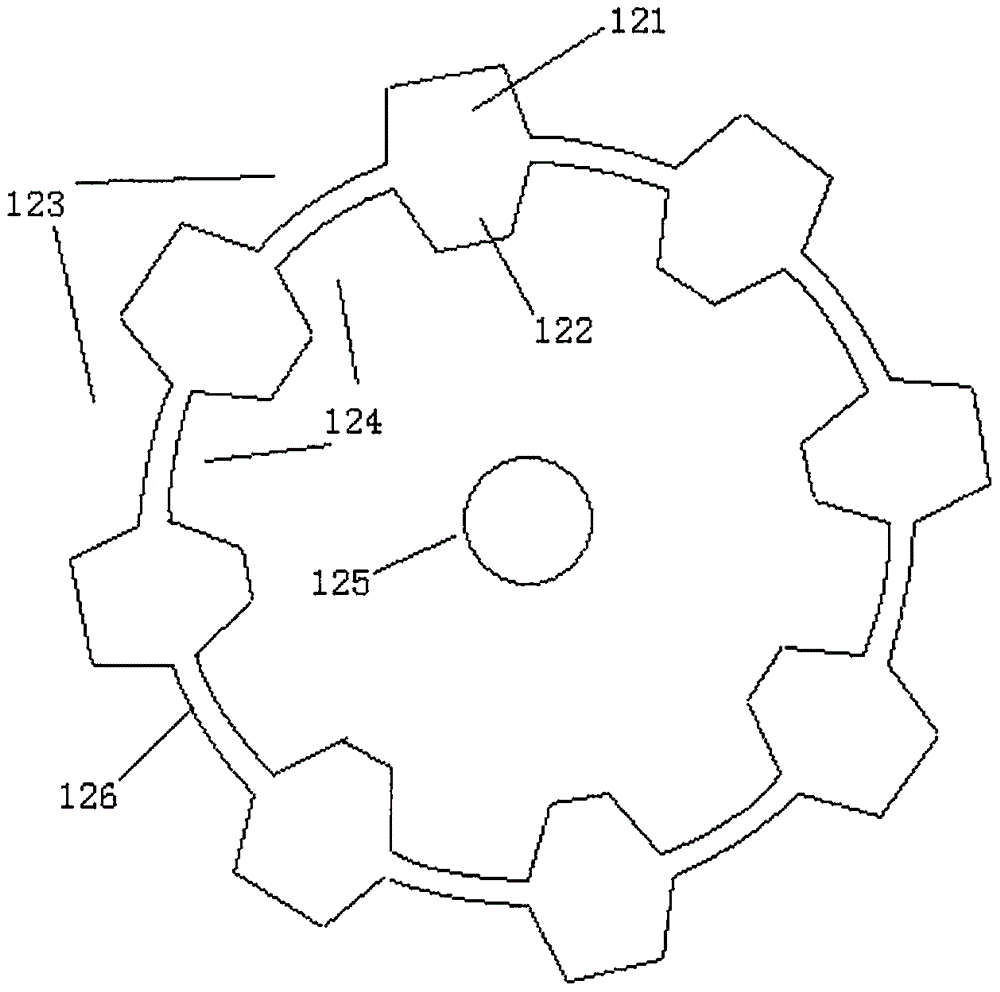

Punching sheet, rotor, motor and air conditioning system

InactiveCN109510349APlay the role of magnetic isolationReduce eddy currentMagnetic circuit rotating partsSynchronous machine detailsPunchingEddy current

The invention provides a punching sheet, a rotor, a motor and an air conditioning system. The punching sheet comprises a body, wherein the body has a plurality of magnetic isolation grooves and a plurality of magnetic steel grooves, two kinds of magnetic steel of different magnetic properties are correspondingly arranged in the plurality of magnetic steel grooves, at least one magnetic isolation groove is arranged between the magnetic steel grooves corresponding to the two kinds of magnetic steel of different magnetic properties, and at least part of each magnetic isolation groove is communicated to the edge of the punching sheet so as to form an open groove. The punching sheet, the rotor, the motor and the air conditioning system solve the problem of high eddy current on the surface of the rotor in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC +1

Speaker and method of producing the same

ActiveUS8126188B2Improve performanceQuality improvementTransducer detailsEngineeringUltimate tensile strength

A plate material is drawn into the shape of a rectangular dish and the peripheral border of each corner is press worked. A yoke is fabricated which has an outwardly projecting tongue-like flange provided at a position a predetermined distance below the top end surface. A frame made of resin is insert molded in a manner covering the flange. A magnet is secured inside the yoke and a magnetic circuit having magnetic gap is formed. A diaphragm joined with a voice coil is joined with the frame. By making a loudspeaker in this way, the bonding strength between the yoke and the frame is enhanced and a low-profile loudspeaker is achieved. Also, clearance at each corner of the yoke is eliminated, and a loudspeaker that is free from magnetic flux leakage and excellent both in quality and performance is obtained.

Owner:PANASONIC CORP

A giant magnetostrictive rotating ultrasonic vibration device

ActiveCN107931079BSolve fever problemLower operating temperatureMechanical vibrations separationCopper wireConductor Coil

The invention discloses a giant magnetostriction rotary ultrasonic vibration device comprising a knife handle, a primary winding, and two sets of bearing systems. A secondary winding is arranged on the knife handle, and the primary winding and the secondary winding are connected through inductive coupling; a giant magnetostriction transducer is installed at the lower part of the knife handle; thegiant magnetostriction transducer is sleeved with the two sets of bearing systems; and the bottoms of two sets of bearing systems are opposite and the two sets of bearing systems are connected by screw threads. An air cooling system is adopted to cool the giant magnetostriction transducer, and the problem of heat generation of the giant magnetostriction transducer in actual processing can be effectively solved; copper stranded wires are adopted by driving coils, compared with commonly used copper wires, the copper stranded wires are more conducive to heat dissipation, and the operating temperature of the coils is reduced; a thin-walled sleeve inside a transducer shell and a flange are arranged to ensure the coaxiality of the flange and the transducer shell, and the giant magnetostriction rod is subjected to uniform pre-tightening force; and the sleeve is arranged to facilitate the outward diffusion of heat generated by the giant magnetostriction rod and the coils.

Owner:XIAN UNIV OF TECH

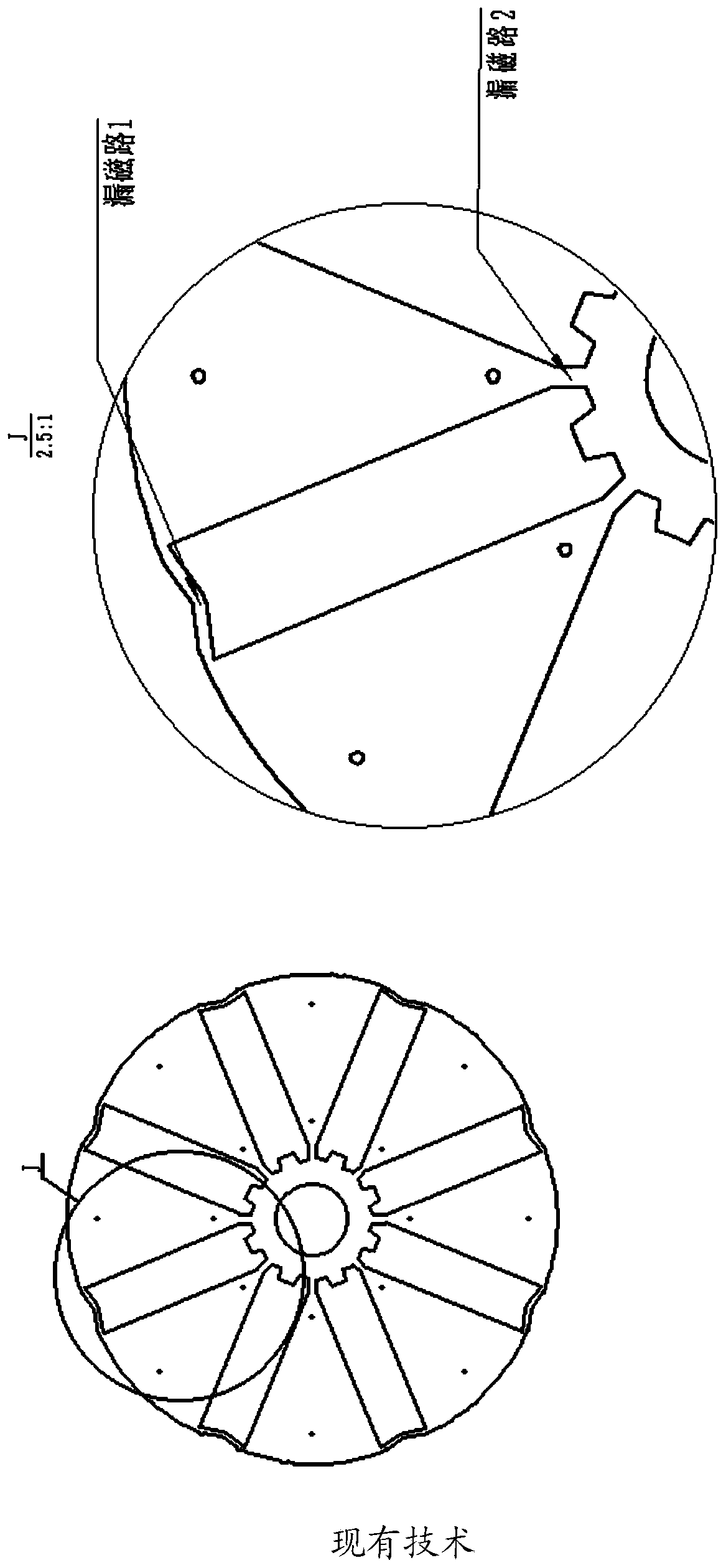

Direct driving permanent magnet type magnetic resistance motor

InactiveCN1297059CEliminate magnetic flux leakageHigh flux densityMagnetic circuit stationary partsMagnetic reluctanceConductor Coil

This invention discloses a direct drive permanent magnetic reluctance machine including rotor core, external stator excitation winding, inner stator excitation winding, sliaft, inner stator core, rotor keep frame, a bearing, bearing, and outer stator core among which, spline and spline are opened on internal and external cycles of the rotor core laminated by silicon steel sheets, permanent magnet is included, several uniform-distributed splines are opened on the surface of pole, splines on the surface of pole, strip magnet is iserted insplines and permanent magnet has a magnetic field along the tangent of, eliminating leackage in slot and increasing flux density of tooth.

Owner:HARBIN INST OF TECH

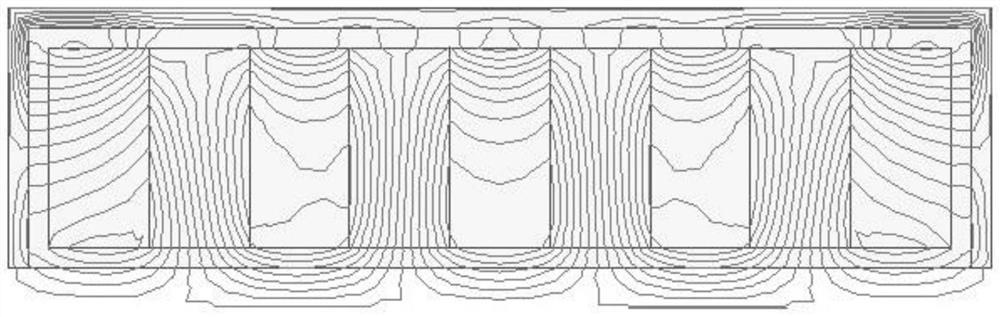

Wear pads for timing-based surface film servo heads

InactiveUS7701665B2Improve linearityEliminate magnetic flux leakageManufacture head surfaceManufacturing heads with multiple gapsBearing surfaceElectrical and Electronics engineering

A thin film magnetic recording head is provided with a tape bearing surface that has magnetically isolated channels while still providing a maximum continuous surface area with which to engage the media. This can be accomplished by providing spaces in the magnetically permeable thin film that are large enough to prevent cross-talk between the channels, but small enough to prevent significant interference with the moving media. Alternatively, magnetically impermeable thin film spacers can be provided to magnetically isolate each of the channels. The spacers are generally even with the magnetically permeable thin film so as to provide a continuous media-bearing surface.

Owner:ADVANCED RES

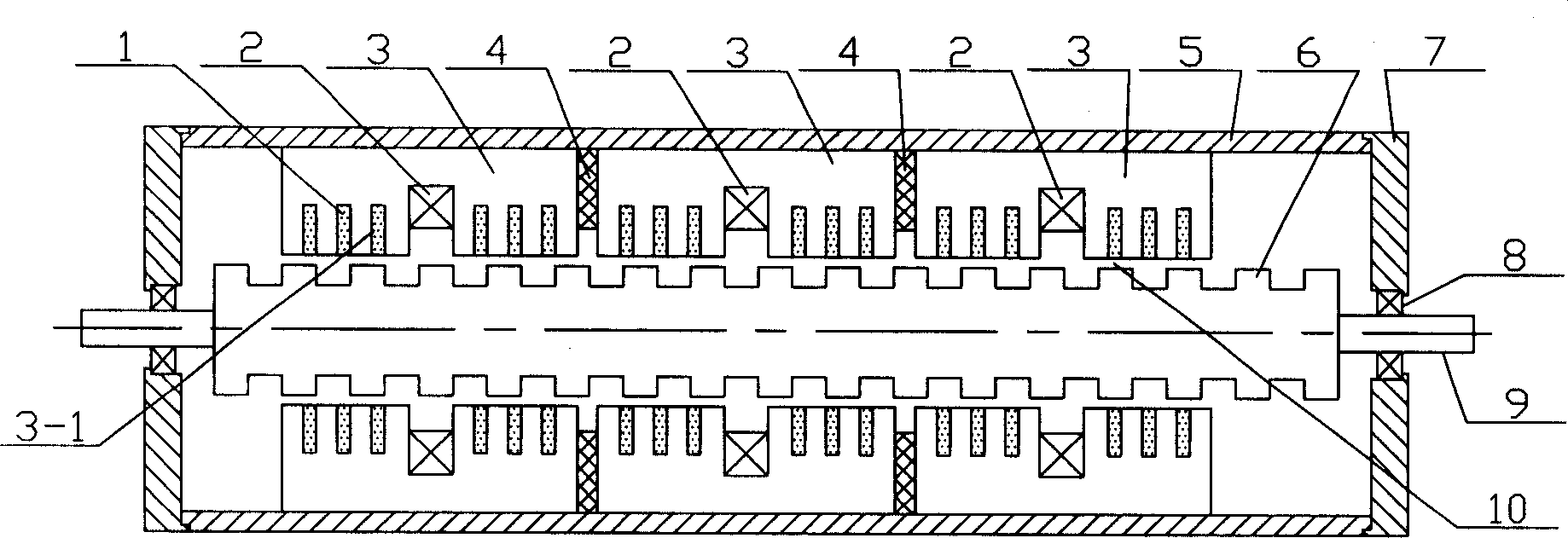

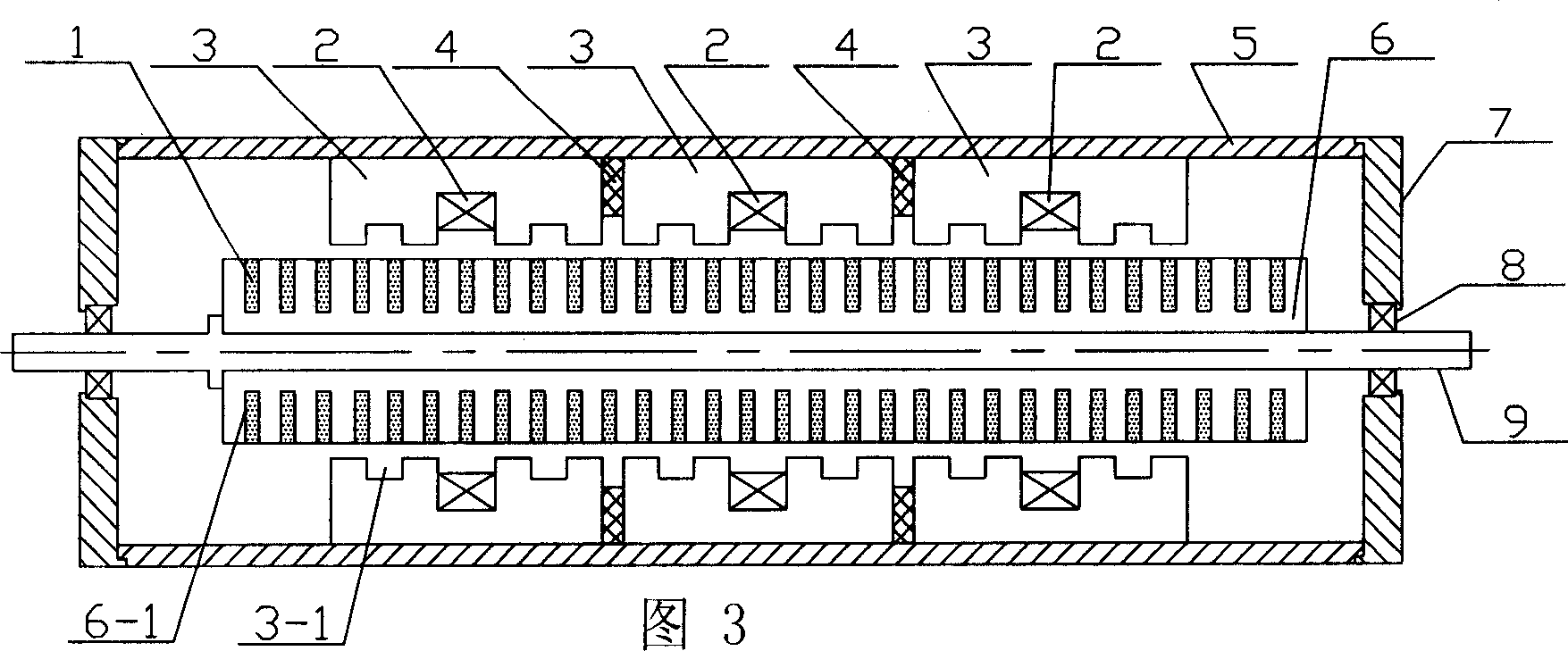

High-efficiency and high-thrust bilateral linear motor

The invention belongs to the field of linear motors and drive of the linear motors, in particular to a high-efficiency high-thrust double-sided linear motor. The high-efficiency high-thrust double-sided linear motor comprises a double-sided primary consisting of two one-sided primaries arranged face to face, each one-sided primary is composed of a primary winding with or without an iron core, the double-sided primary is matched with a double-sided secondary arranged between the double-sided primary to form a double-sided linear motor, the double-sided secondary comprises at least one group of guide magnets and magnetic bodies which are mounted alternately, and the magnetizing directions of adjacent magnetic bodies are opposite to each other or depart from each other. With adoption of the structure, leakage flux inside the secondary can be reduced largely or eliminated completely and the bottleneck problem restricting the engineering application of linear motors for a long term can be solved. Under the condition of the same size and manufacturing cost, the power and output of the motor can be improved greatly; or under the condition of the same power, the size and manufacturing and use costs of the motor can be reduced largely; therefore, the invention is particularly applicable to the engineering application situation of long-stroke, high-thrust and high-power linear motors and the like.

Owner:HENAN POLYTECHNIC UNIV +1

Halbach Permanent Magnet Array Structure and Its Application to Reduce Flux Leakage

The present invention provides a kind of Halbach permanent magnet array structure that reduces flux leakage, comprising Halbach permanent magnet array body, carbon fiber protective sleeve and Fe-based soft magnetic composite material; Halbach permanent magnet array body is composed of multiple radially magnetized permanent magnets and multiple Tangentially charged permanent magnets are alternately arranged and combined; the outer surface of the Halbach permanent magnet array body is composed of a magnetic collecting surface and multiple magnetic shielding surfaces; the magnetic collecting surface is covered with a carbon fiber protective sleeve; the magnetic shielding surface is covered with There is a carbon fiber protective cover, and the Fe-based soft magnetic composite material is fixed on the carbon fiber protective cover. The invention adopts the carbon fiber protective sheath and the Fe-based soft magnetic composite material to cover, which greatly reduces the magnetic flux leakage, and can even completely eliminate the magnetic flux leakage. The arrangement of the Fe-based soft magnetic composite material can enhance the magnetic induction intensity at the air gap region. The Halbach permanent magnet array structure of the present invention can be applied in radial permanent magnet bearings and disc type iron-coreless bilateral permanent magnet motors.

Owner:XIAN UNIV OF SCI & TECH

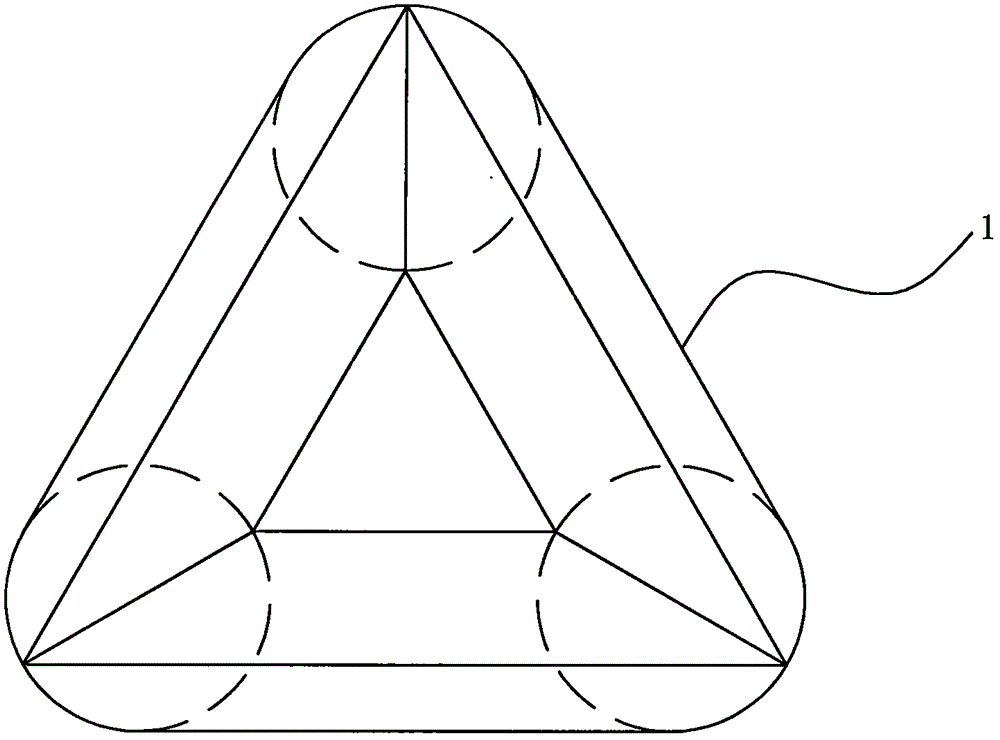

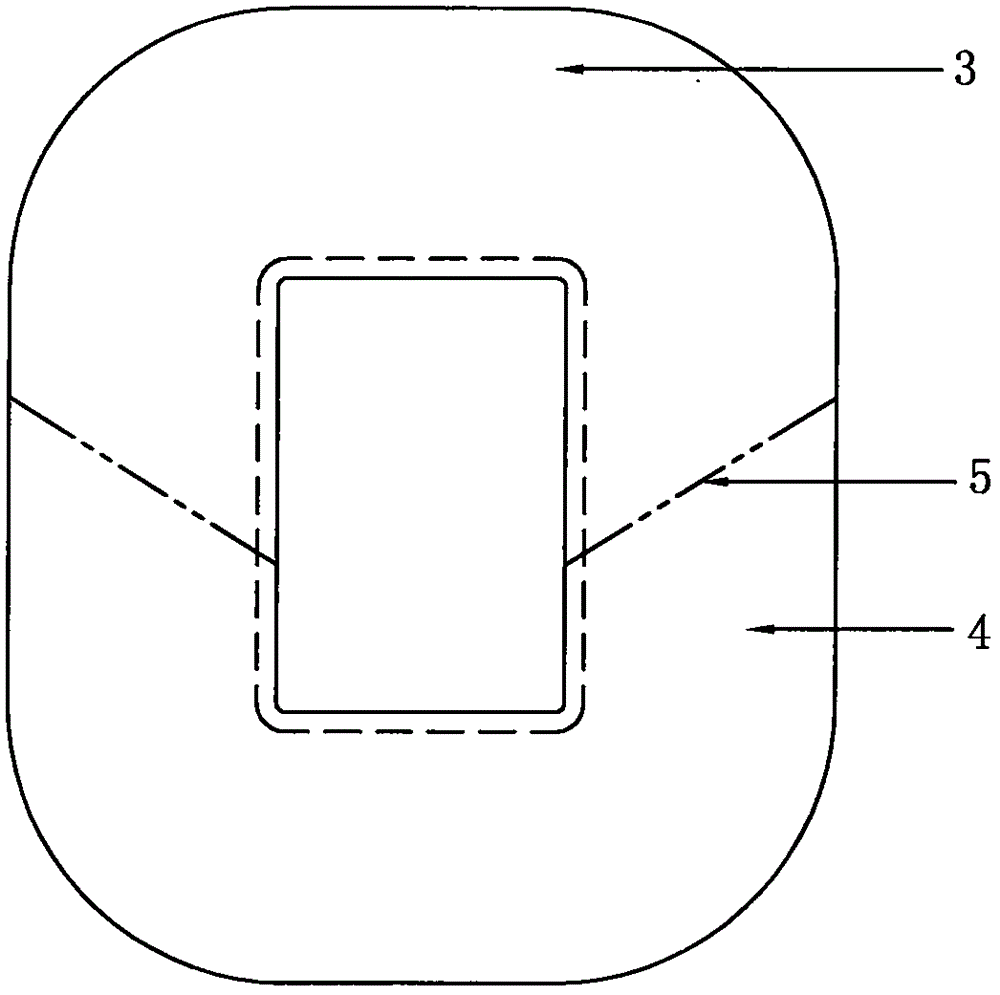

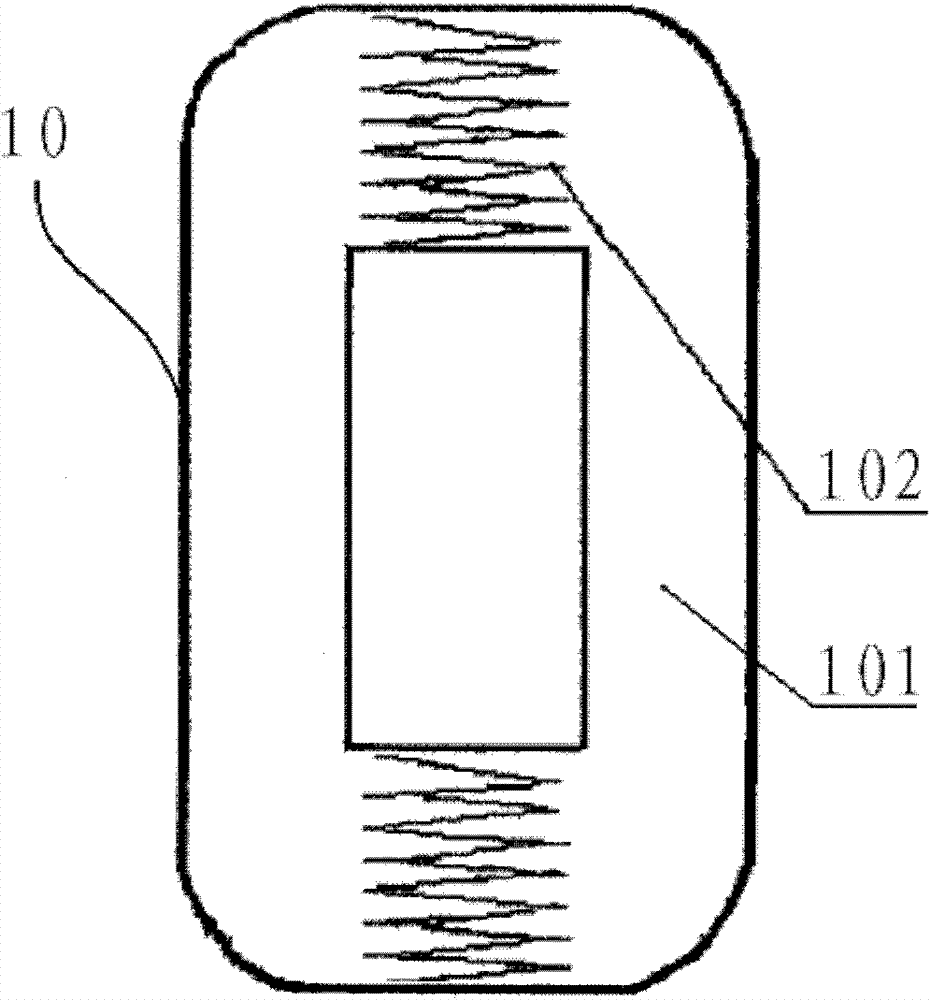

High-permeability three-phase open-type equivalent-magnetic circuit amorphous alloy core

PendingCN106601445AReduce load lossReduce temperature riseTransformers/inductances magnetic coresTransformerThree-phase

The invention provides a high-permeability three-phase open-type equivalent-magnetic circuit amorphous alloy core and relates to the technical field of transformer cores. The high-permeability three-phase open-type equivalent-magnetic circuit amorphous alloy core comprises three single-box open-type amorphous alloy cores with consistent shape and size, wherein each single-box open-type amorphous alloy core is a rectangular box formed by a left core limb, a right core limb, an upper yoke and a lower yoke; the cross section shape of each core limb of each single-box open-type amorphous alloy core is a semicircle; the core limbs of the three single-box open-type amorphous alloy cores are assembled into the three-phase open-type amorphous alloy core with a three-dimensional triangular structure in a manner that the diameters of the cross sections are laminated with one another; and the cross sections of three core limbs of the three-phase open-type amorphous alloy core are round. An opening is formed in each single-box open-type amorphous alloy core. The core limbs are round in cross sections, are closely spliced, and are small in loss and low in noise.

Owner:网为机电(邳州)有限公司

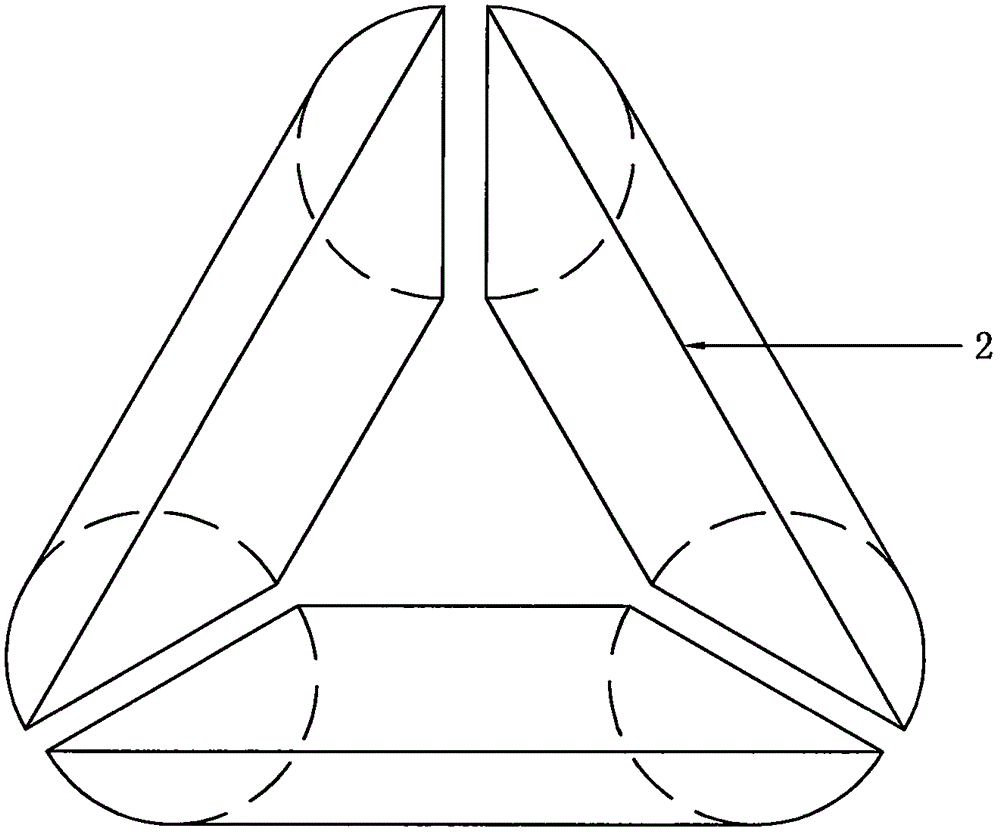

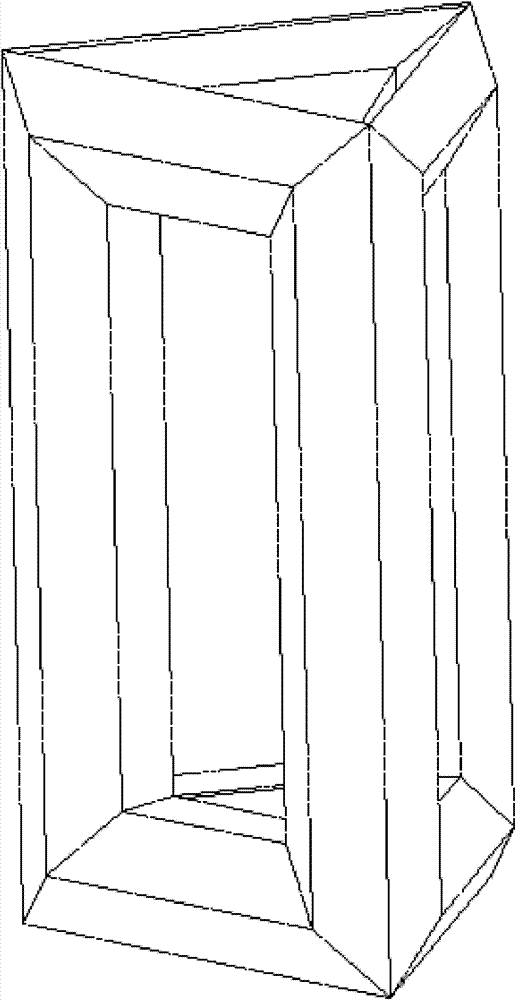

Three-dimensional three-phase amorphous alloy transformer iron core

InactiveCN102290201BLarge capacityReduce volumeTransformers/inductances magnetic coresInductances/transformers/magnets manufactureIsosceles trapezoidIsoetes triquetra

The invention discloses a three-dimensional three-phase amorphous alloy transformer iron core, which comprises a three-phase core, three single-phase iron core covers and six inner iron yoke covers. The three-phase iron core is formed by assembling three closed rectangular frame type single-phase cores according to an equilateral triangle shape, the three single-phase cores are respectively formed through winding amorphous alloy tapes with different widths, and the cross-sections of a left iron core column, a right iron core column, an upper iron yoke and a lower iron yoke are isosceles trapezoid-shaped with the length of the upper bottoms identical to length of the waist parts and the length of the lower bottoms being twice as along as the upper bottoms; the three iron core columns of the three-phase iron core are formed through gluing the iron core columns of two single-phase cores with the lower bottoms of the cross-sections being adhered, so that the cross-sections of the three iron core columns of the three-phase iron core forming an equilateral hexagon; the three single-phase iron core covers are correspondingly sleeved outside the three single-phase cores, so that the threeiron core columns of the three-phase iron core are packaged in iron core column shells; and the six inner iron yoke covers are correspondingly connected with yoke covers so that three upper yokes andthree lower yokes of the three-phase iron core are packaged in yoke shells.

Owner:SHANGHAI GOODRUN ELECTRIC POWER TECH

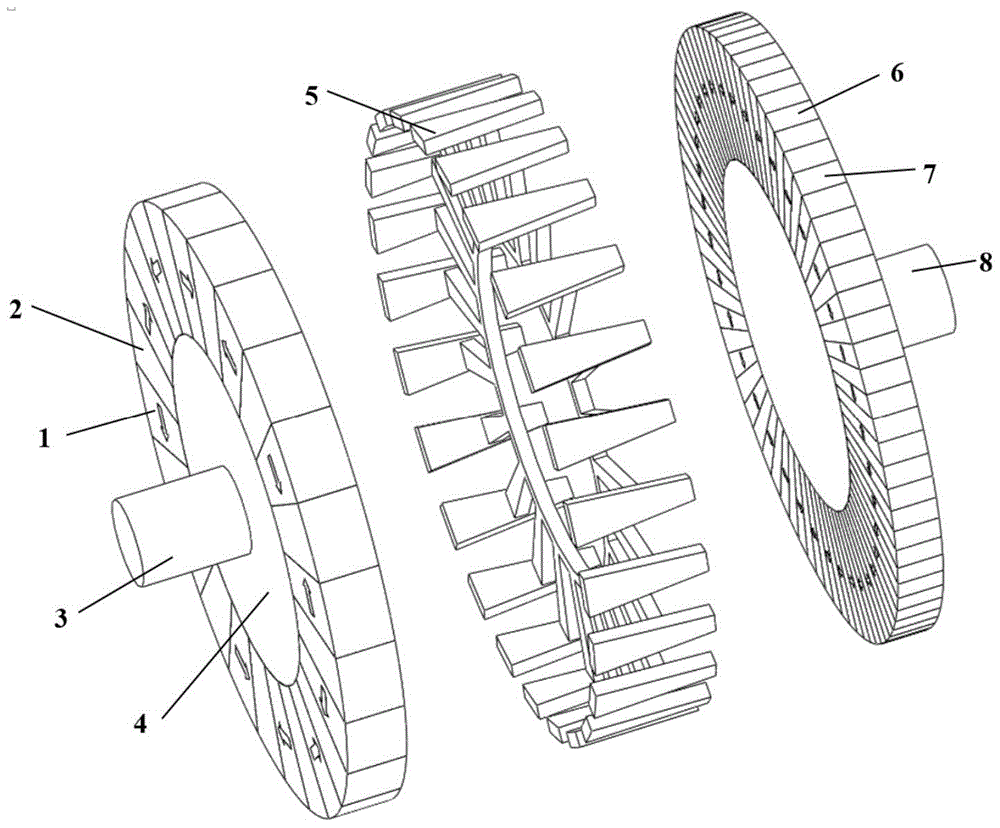

A magnetic gear with variable-width adjustable magnetic teeth

InactiveCN104578690BEliminate friction lossImprove transmission efficiencyDynamo-electric gearsDrive wheelNew energy

The invention discloses a magnetic gear with variable width magnetic flux adjusting teeth. The magnetic gear comprises a driving wheel, a driven wheel and a magnetic flux adjusting grid which are coaxially installed in a stator housing, wherein the driving wheel and the driven wheel are installed at two ends of the magnetic flux adjusting grid respectively, and intervals exist; driving wheel permanent magnets are evenly distributed on the peripheral surface of the inner circle of the driving wheel at intervals; driven wheel permanent magnets are evenly distributed on the peripheral surface of the inner circle of the driven wheel at intervals; driven wheel magnetism gathering blocks are installed between the adjacent driving wheel and the driven wheel; the magnetic flux adjusting teeth are evenly distributed on the outer periphery of the inner circle of the magnetic flux adjusting grid at intervals, and the arc lengths of two ends of the axial part of the T-shaped magnetic flux adjusting teeth are different; an air-gap field magnetic field penetrates axial and radial air gaps to form a closed magnetic circuit; non-contact transmission is achieved through mutual action of the permanent magnets and the magnetic field. The magnetic gear is high in transmission efficiency, large in torque density of unit volume, high in reliability, free of abrasion caused by mechanical contact, free of being lubricated, and capable of achieving isolation of an input shaft and an output shaft, has the overload protection function and can be widely applied to the field of new energy resources such as wind power generation, electric vehicles and electric ships.

Owner:ZHEJIANG UNIV

Robot torque motor with excitation regulating rotor

InactiveCN110311523AFree to change intensityAchieve magnetizationSynchronous machine detailsManufacturing stator/rotor bodiesElectric machineTorque motor

The invention provides a robot torque motor with an excitation regulating rotor. The rotor comprises a rotor core, an excitation regulating device and an insulating shock absorbing material. Accordingto the invention, the design of the leakage magnetic circuit is more perfect, and the magnetic separation effect is better; magnetic flux leakage can be completely eliminated; a rotor winding is usedto freely change the strength of a magnetic field, and the functions of flux enhancing and flux weakening are realized; problems in high speed and low speed operation of schemes in the prior art aresolved; perfused insulating damping rubber has an elastic damping effect, which can weaken radial electromagnetic force and torque fluctuation transmitted to a load through the rotor core and improvethe noise effect; the rotor winding and the iron core are integrated through glue filling; and the overall structural strength of the rotor can be ensured.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

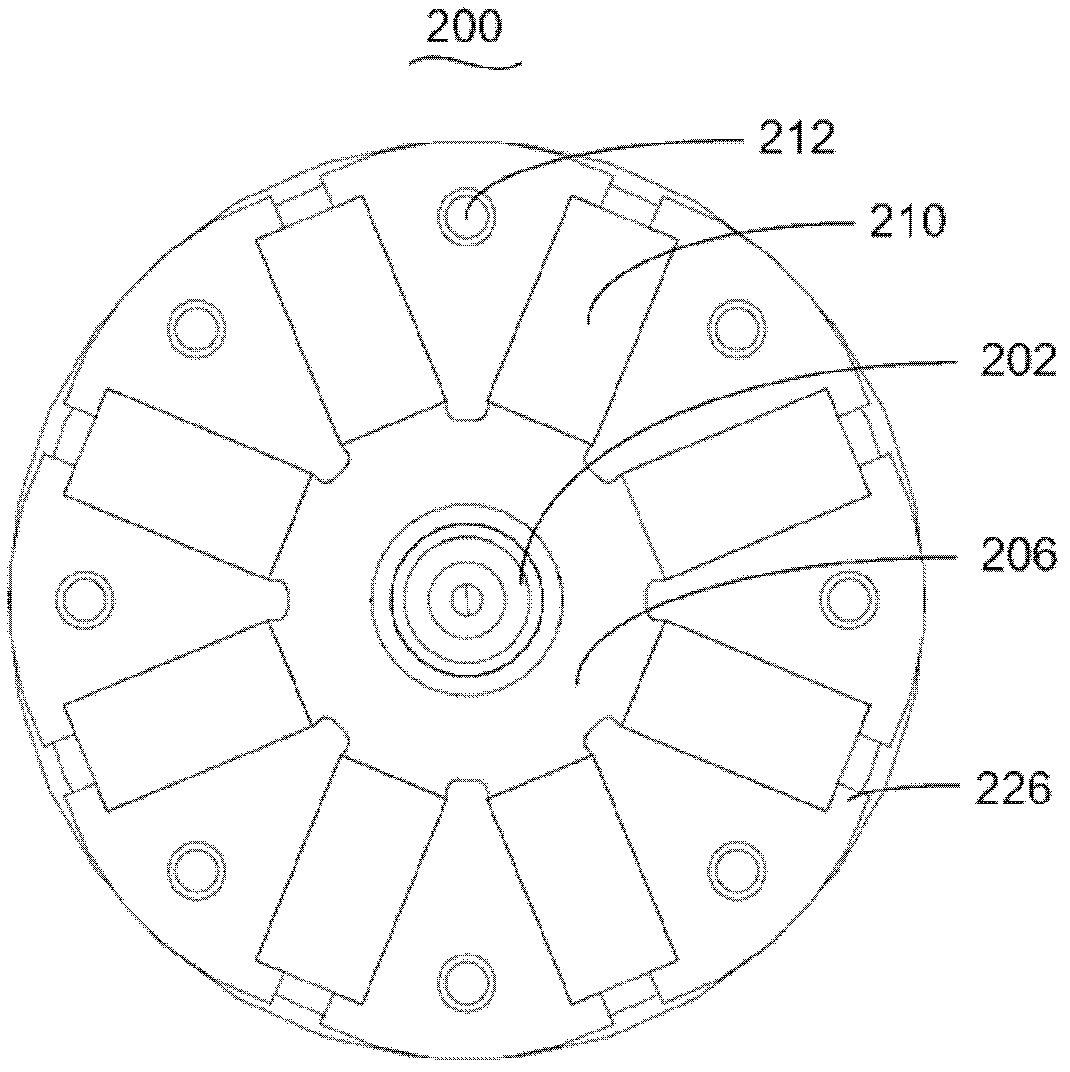

High-efficiency motor with full-circumference magnetic flux polarized circumferential winding and new-energy electric vehicle

PendingCN106385125AEliminate magnetic flux leakageIncrease powerMagnetic circuit rotating partsMagnetic circuit stationary partsNew energyMagnetic poles

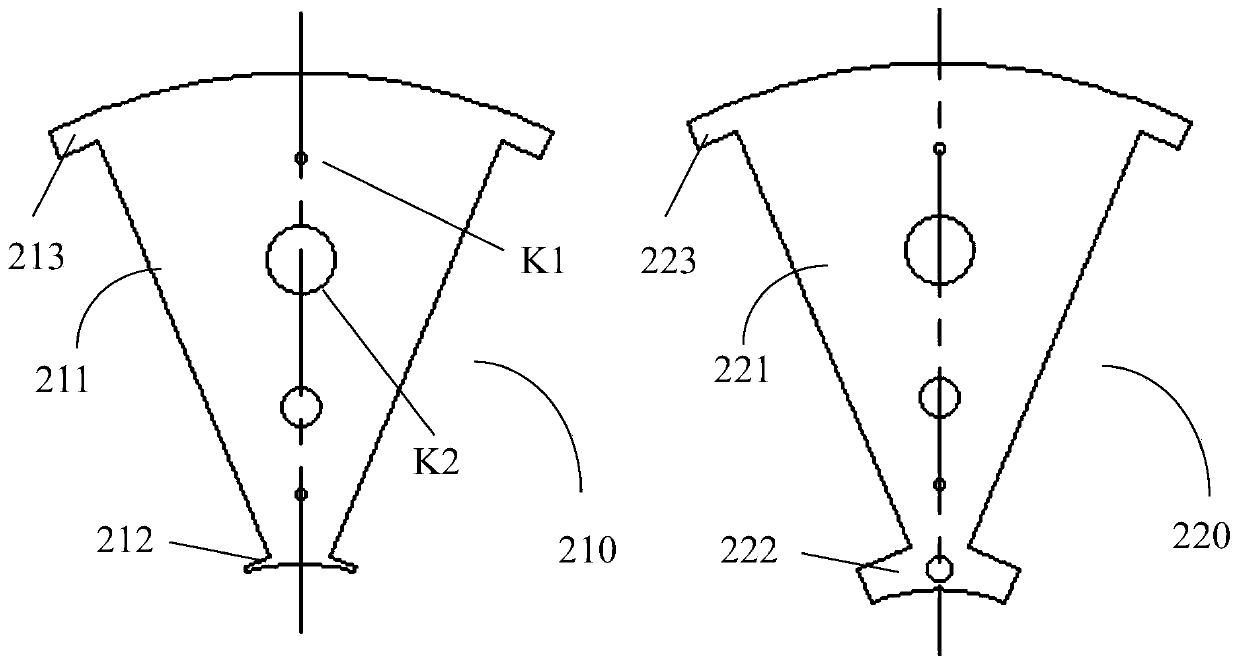

A motor with a full-circumference magnetic flux polarized three phase circumferential windings comprises three phase circumferential windings and six U-shaped stator magnetic poles which perform full-circumference magnetic flux polarization on the circumferential winding and have different orientations. A rotor shaft (200) is connected with rotor magnetic poles (202,203), (206,207), (212,213), (216,217), (222,223), (226,227) with a first orientation to a sixth orientation through rotor discs (201,211,221,231). The number of stator magnetic poles in a random orientation is same with that of the rotor magnetic poles in the orientation. Each phase circumferential winding controls two stator magnetic fields which performs polarization on the full circumference and in two orientations. The three phase circumferential windings (204,214,224) respectively control three phase stator and rotor magnetic fields which are at 120 DEG electric angle to one another. An electronic control system controls current of the three phase circumferential windings through testing the position of a rotor and is used as a motor or a power generator. The motor has advantages of small amount of magnetic flux leakage and high efficiency.

Owner:杨明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com