Three-dimensional three-phase amorphous alloy transformer iron core

A three-phase transformer and three-phase iron core technology, applied in the direction of transformer/inductor core, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problem of increasing transformer load loss, transformer temperature rise, transformer coil average turn length pull It can eliminate the magnetic leakage, overcome the three-phase current imbalance, and reduce the iron loss and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

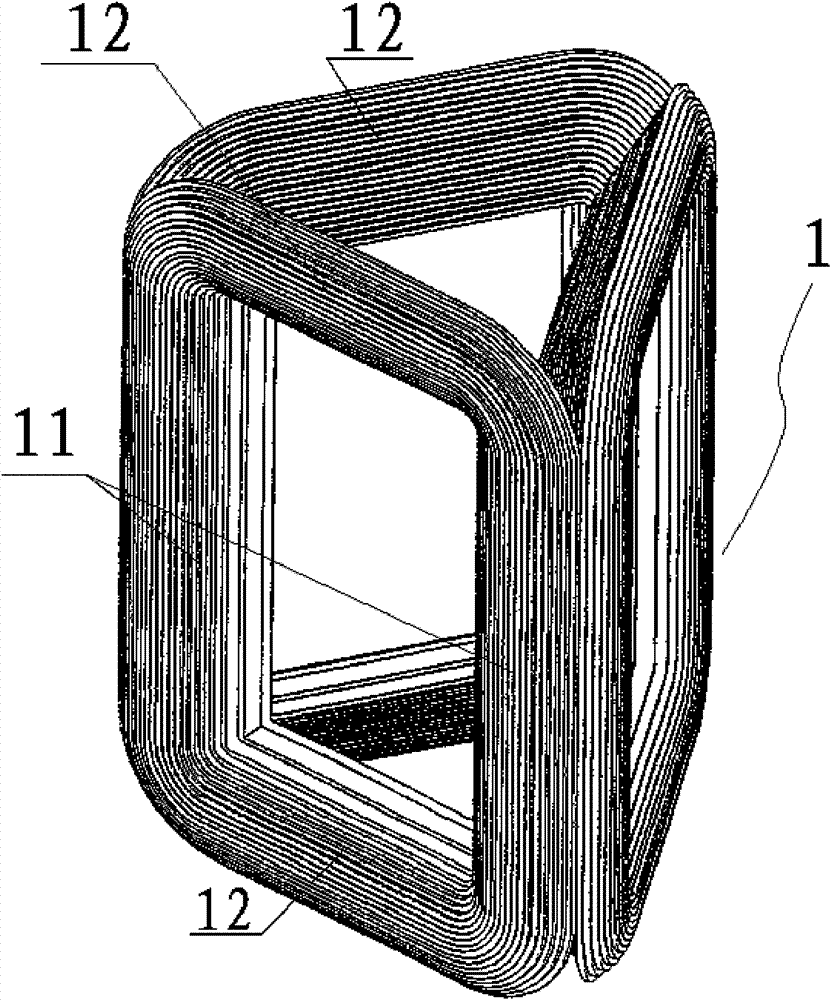

[0023] see figure 1 , the amorphous alloy three-dimensional three-phase transformer iron core of the present invention comprises a three-phase iron core 1, three single-phase iron core covers 2 and six iron yoke inner covers 3, wherein:

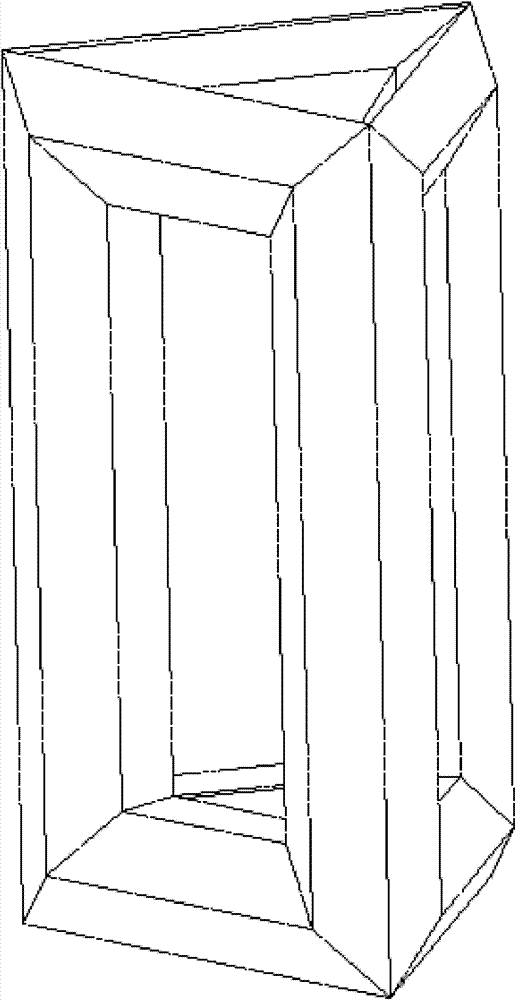

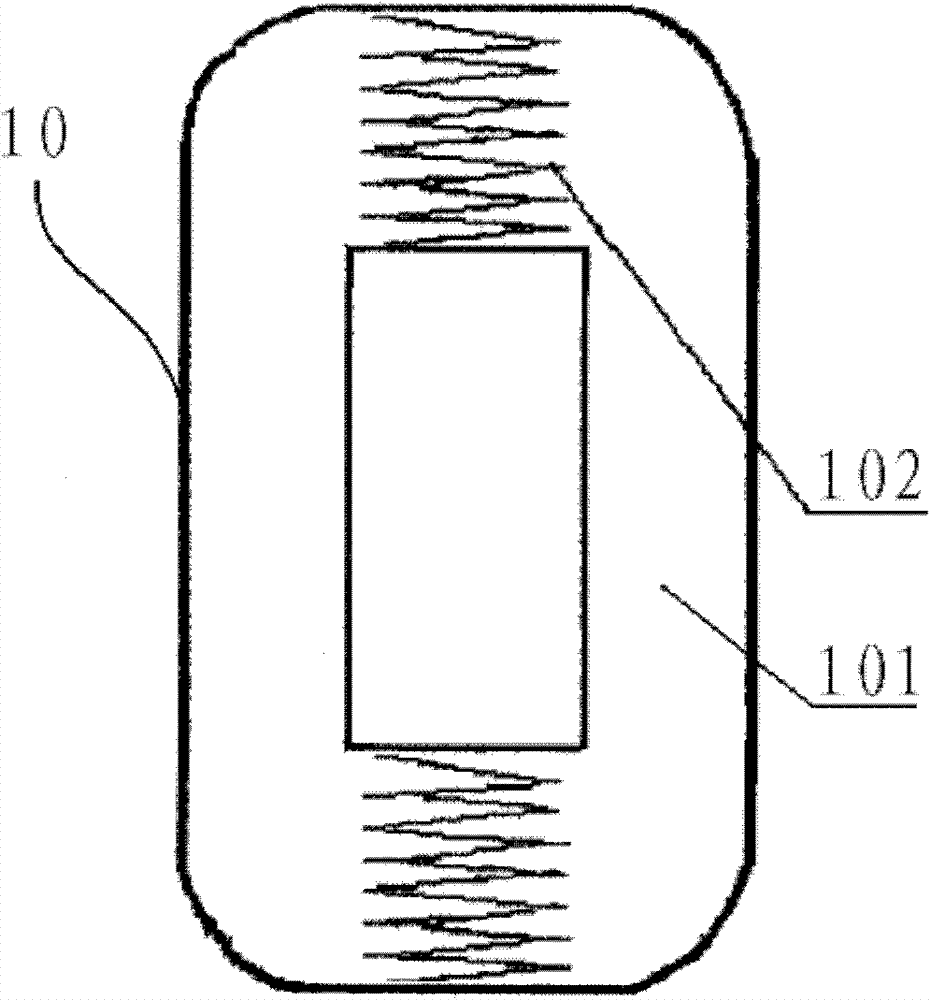

[0024] see again Figure 2 to Figure 4 , the three-phase iron core 1 is spliced by three single-phase iron cores 10 with the same shape and size, and each single-phase iron core is composed of left and right iron core columns 101 and upper and lower iron yokes 102 respectively and forms a closed rectangular frame , the three single-phase iron cores 10 are assembled into a three-dimensional triangular structure according to the structure of an equilateral triangle; the three single-phase iron cores 10 are respectively formed by winding amorpho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com