Permanent magnetic motor and bladeless fan with same

A permanent magnet motor and permanent magnet technology, applied in the field of permanent magnet motors, can solve the problems of unsatisfactory quiet effect, unacceptable motor cost, low noise, etc., and achieve the effect of low noise, high power density, and improved torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions and other beneficial effects of the present invention will be apparent through the detailed description of specific embodiments of the present invention below in conjunction with the accompanying drawings.

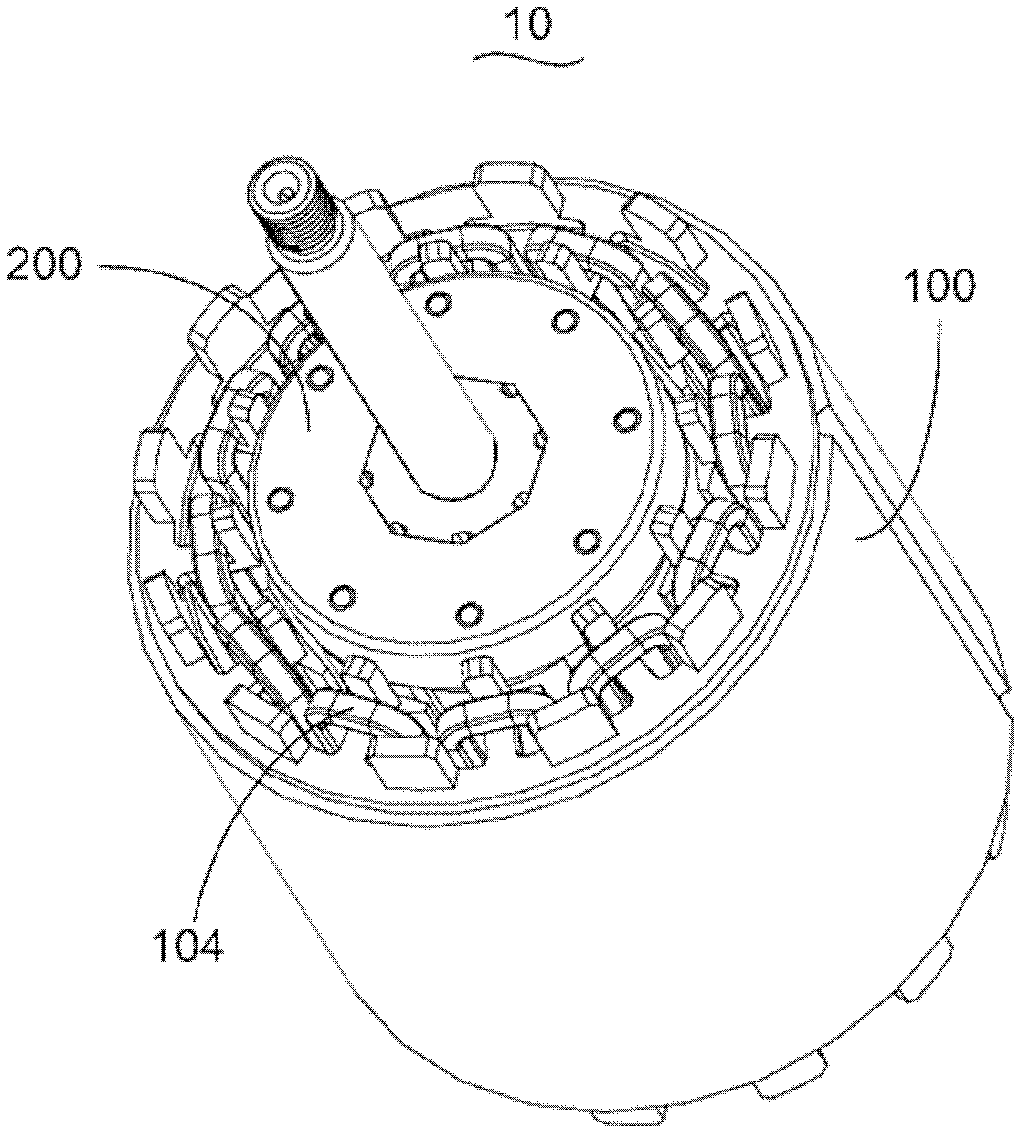

[0015] Please combine figure 1 , The permanent magnet motor 10 according to the preferred embodiment of the present invention includes a stator 100 and a rotor 200 accommodated in the stator 100 .

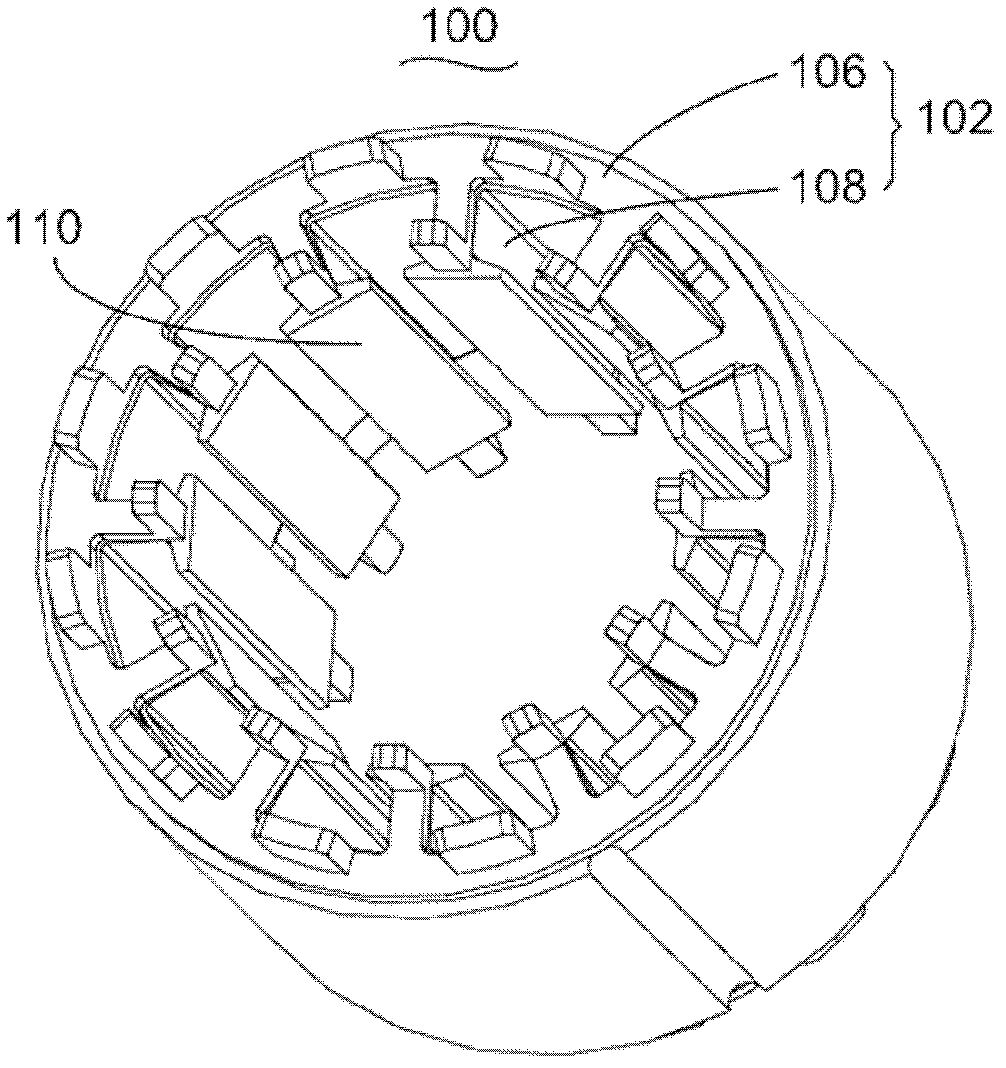

[0016] Please reunite figure 2 , the stator 100 includes a stator core 102 and a plurality of coils 104 . The stator core 102 includes an annular yoke 106 and twelve stator teeth 108 radially inwardly extending from the yoke 106 . The stator teeth 108 are arranged axially and have an arc surface 110 facing the axis. Each coil 104 is respectively wound on a corresponding stator tooth 108 .

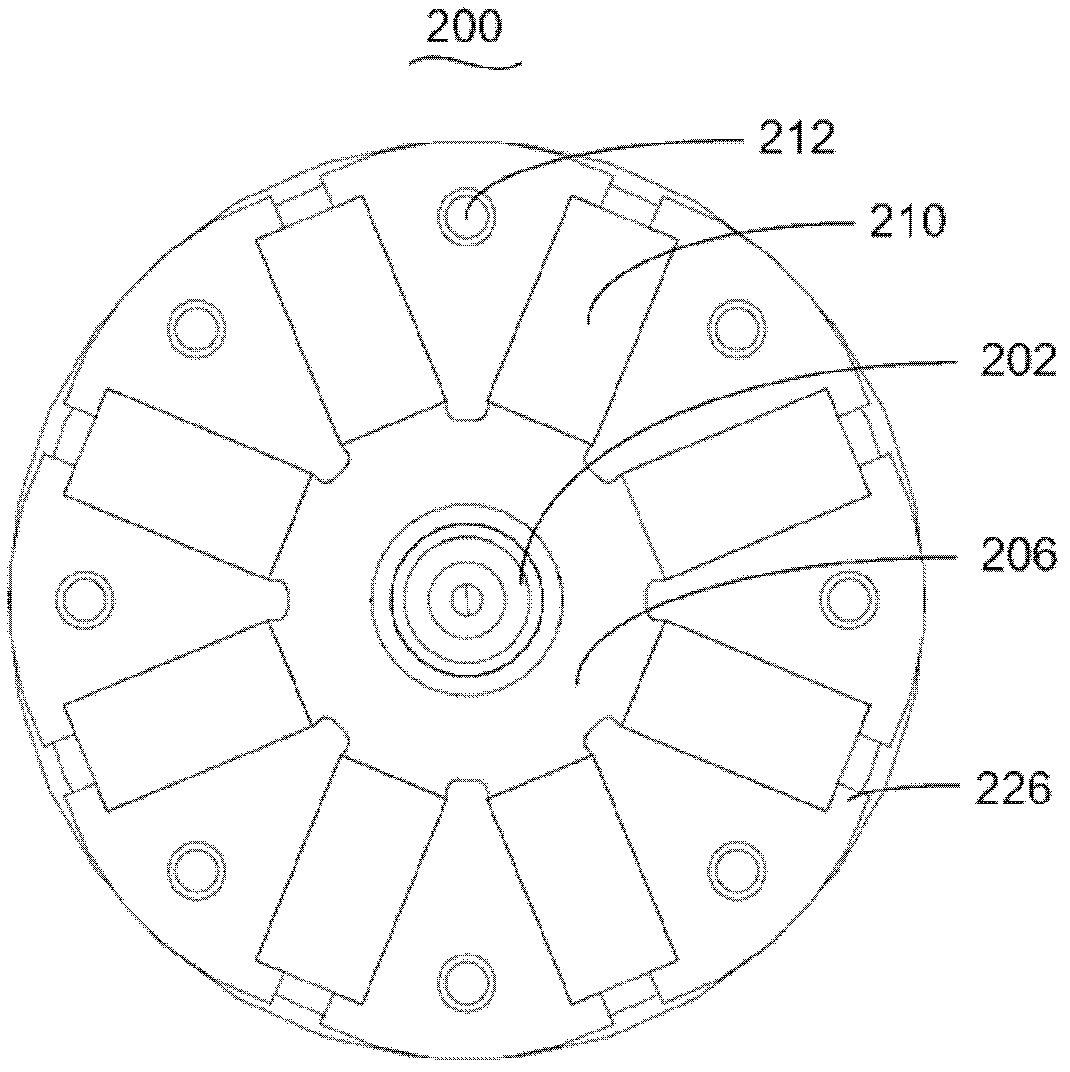

[0017] Please combine image 3 and Figure 4 , the rotor 200 includes a rotating shaft 202 and a magnetic core assembly 204 fixed to the rotating shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com