Robot torque motor with excitation regulating rotor

A technology of excitation regulation and permanent magnet motors, applied in the field of torque motors, can solve problems such as waste of magnetic performance, damage to the motor, and heat generation on the stator side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides an excitation adjustable rotor system for a torque motor.

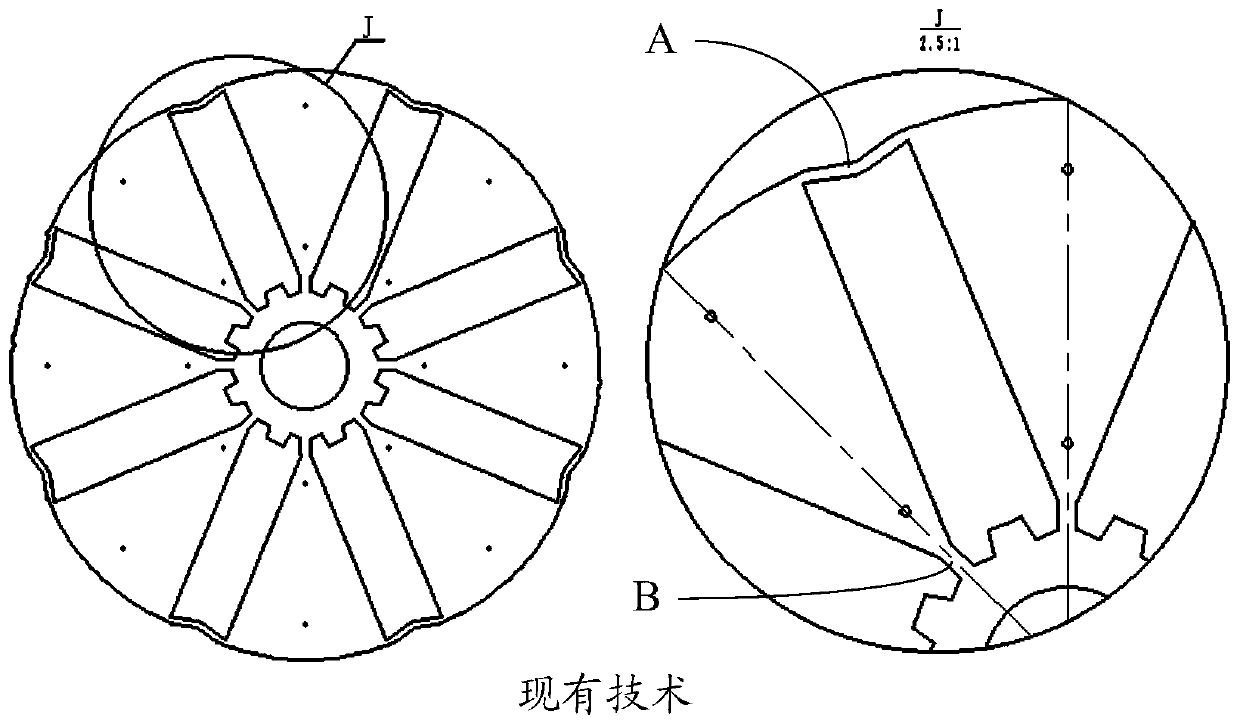

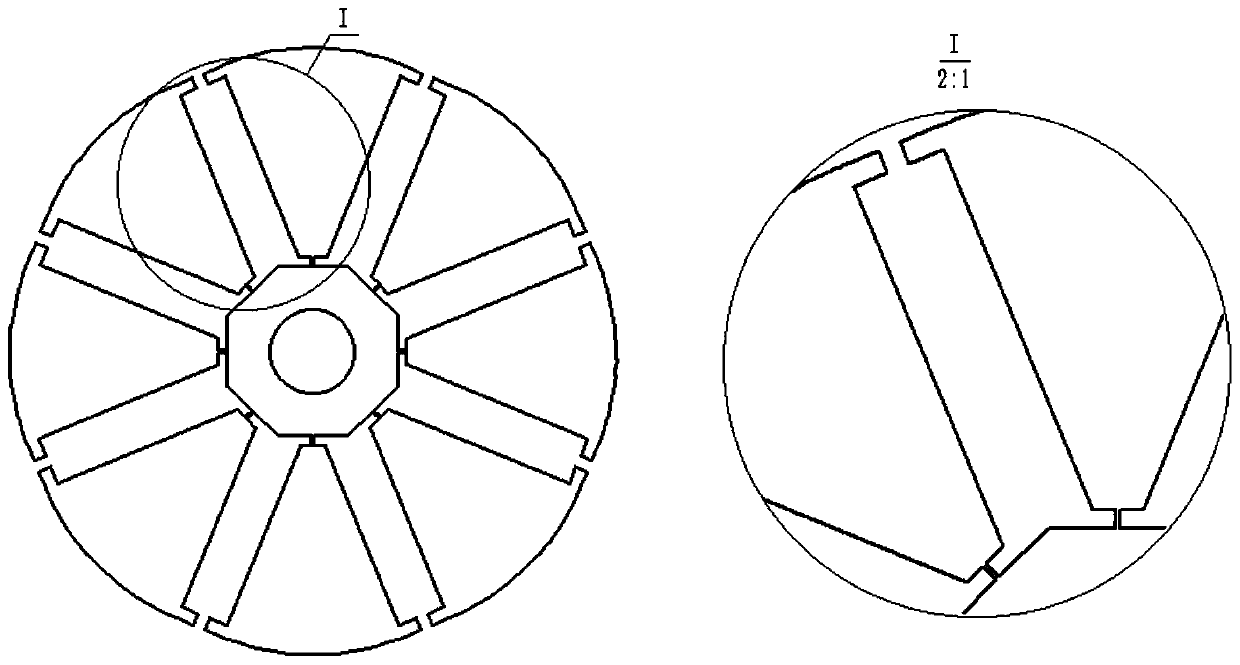

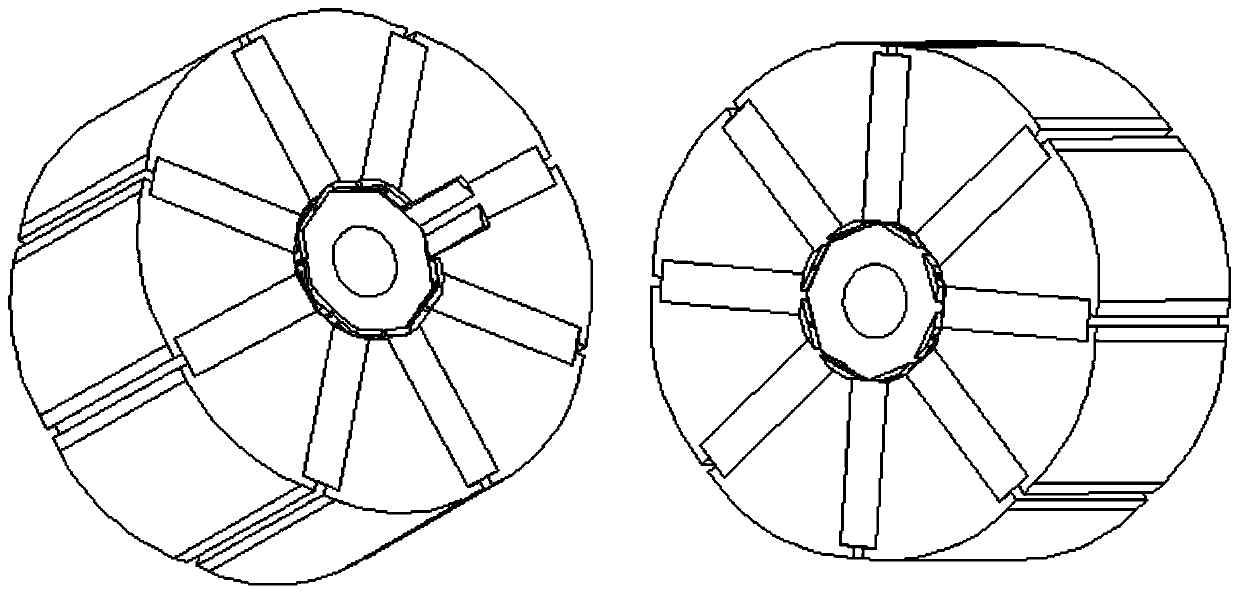

[0044] Such as Figure 2-4 As shown, the present invention passes through the figure 1 On the basis of the rotor iron core punching sheet of the technical scheme, the improved design of the leakage magnetic circuit is carried out to further reduce the magnetic flux leakage. figure 2 In the shown rotor core system according to the present invention, the outer magnetic isolation bridge is cut off, and the inner magnetic isolation bridge remains as a connecting bridge with a smaller size. As a result, the integrity of the rotor iron core stamping is guaranteed, and the leakage magnetic circuit is also greatly reduced.

[0045] exist figure 2 On the basis of the design of the rotor iron core stamping shown, an excitation adjustment device for adjusting the excitation is added to the connecting bridge in the rotor iron core.

[0046] Such as figure 2 As shown, the rotor system accord...

Embodiment 2

[0055] This embodiment provides a method for manufacturing a rotor system of a permanent magnet motor, comprising the following steps:

[0056] Provide rotor core punching;

[0057] Laminating the rotor iron core punching sheets to form a rotor iron core, the rotor iron core;

[0058] installing the dispersed winding in the magnetic isolation slot of the rotor core;

[0059] pouring thermal fluid insulating and shock-absorbing glue into the gap between the rotor core and the dispersed winding, so that the dispersed winding and rotor core form an integrated structure through the insulating and shock-absorbing glue;

[0060] Weld each dispersed winding for surface insulation treatment;

[0061] After connecting the distributed windings, they are connected end to end, and connected to an external circuit through a collector ring.

[0062] In a preferred embodiment, the dispersed windings are solid copper rods; the step of welding the dispersed windings is sequentially connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com