Semiconductor device including semiconductor thin film, crystallizing method for the semiconductor thin film, and crystallizing apparatus

A technology of semiconductors and polycrystalline semiconductors, which is applied in semiconductor/solid-state device manufacturing, instruments, electrical components, etc., and can solve the problems of ablation film, grain alignment mark formation cannot be carried out at the same time, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

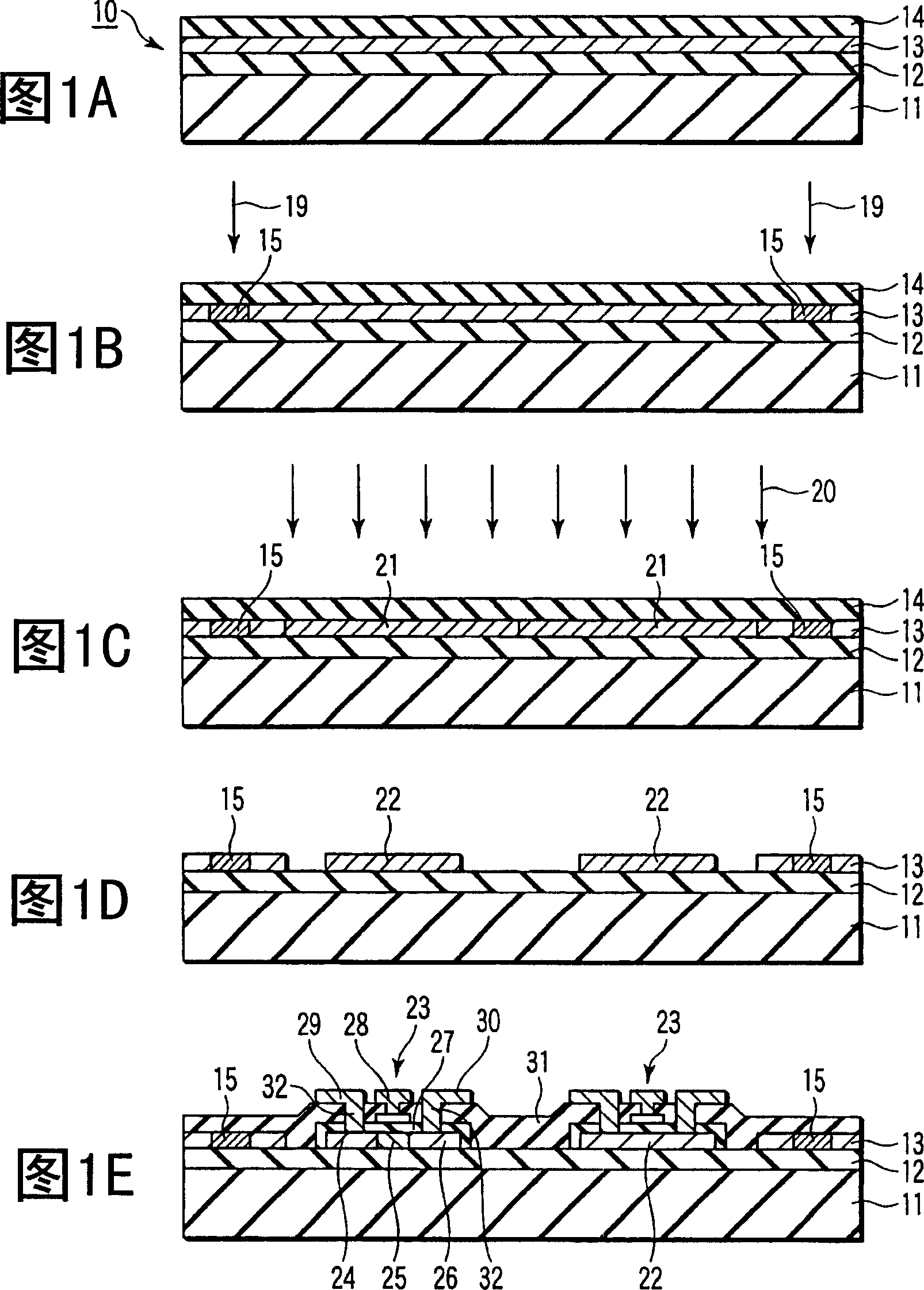

[0084] A first embodiment of the present invention will now be described with reference to FIGS. 1A to 1E. First, a support substrate 11 formed of an insulating material such as a glass substrate, a quartz substrate, or a plastic substrate is prepared. Using this supporting substrate 11 , a semiconductor film forming substrate 10 including this supporting substrate 11 and a semiconductor film 13 on this supporting substrate 11 will be manufactured. In the case where the present invention is applied to, for example, a liquid crystal display, it is recommended to use an alkali-free glass substrate such as Corning #1737 as the support substrate 11 . The material of the supporting substrate 11 in the present invention is not limited to insulating materials. A semiconductor substrate such as Si, Ge, SiGe, SiGeC, GaAs, GaP, InAs, GaN, ZnTe, CdSe, or CdTe may be used as necessary.

[0085] On this support substrate 11 is formed an insulating film 12 serving as an underlayer to a th...

no. 2 example

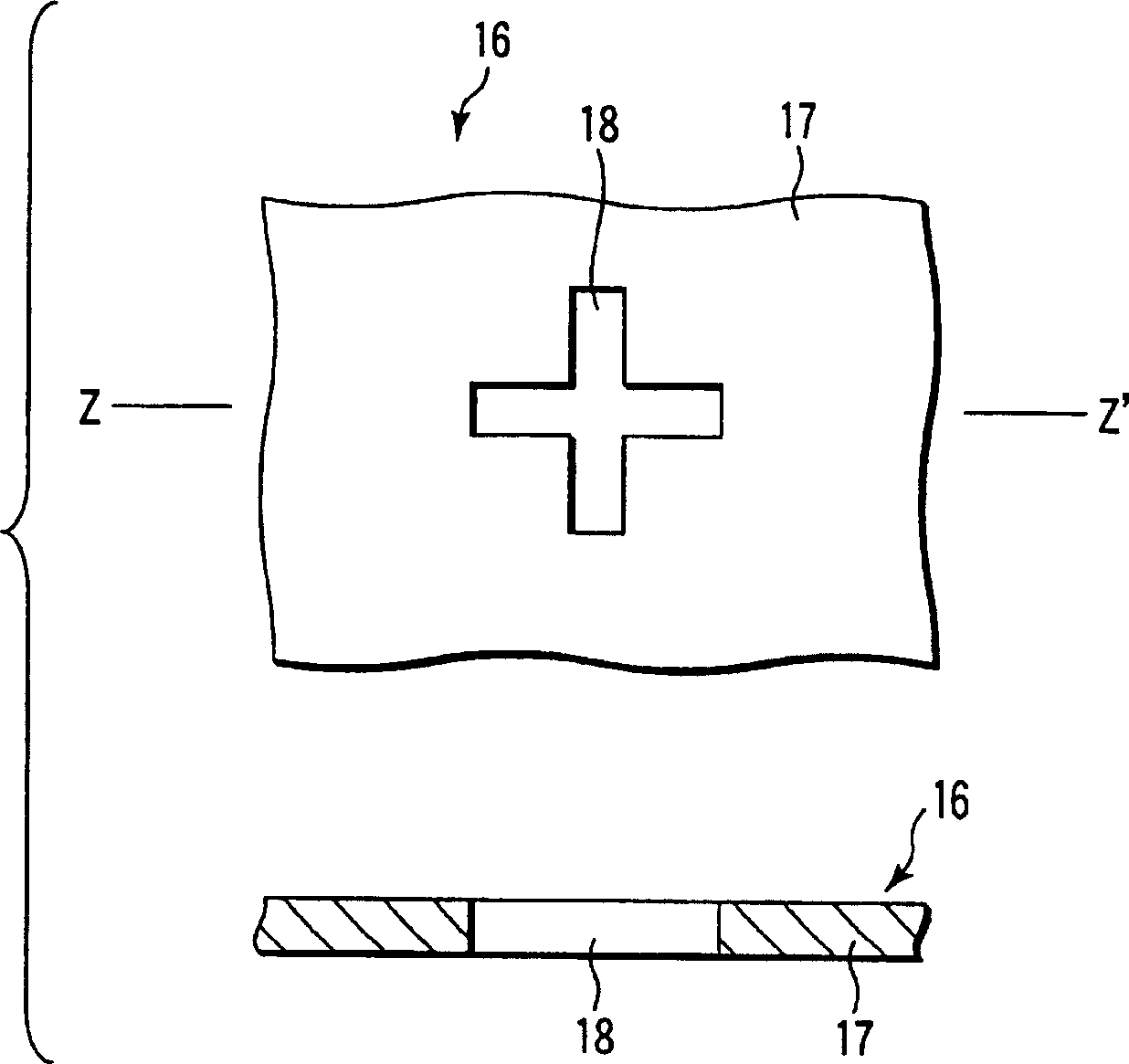

[0123] Next, the second embodiment will be described in detail. In the second embodiment, for example, as Figure 12A As shown, using the phase value modulation type mask pattern MK, an alignment mark for alignment is formed on a semiconductor film on a substrate. The techniques that will be described below are applicable to uses other than forming alignment marks.

[0124] FIG. 10 schematically shows an example of a crystallization apparatus suitable for forming an alignment mark in the second embodiment. The laser beam used in the crystallization apparatus shown in FIG. 10 has a wavelength of, for example, 248 nm for heating the non-single crystal semiconductor film formed on the substrate 206 . The crystallization device may include, for example, a KrF excimer laser 201 that can output a laser beam capable of melting the irradiated portion of the non-single crystal semiconductor film. As another example, a YAG laser may be used as the light source. Also, an XeCl laser c...

no. 3 example

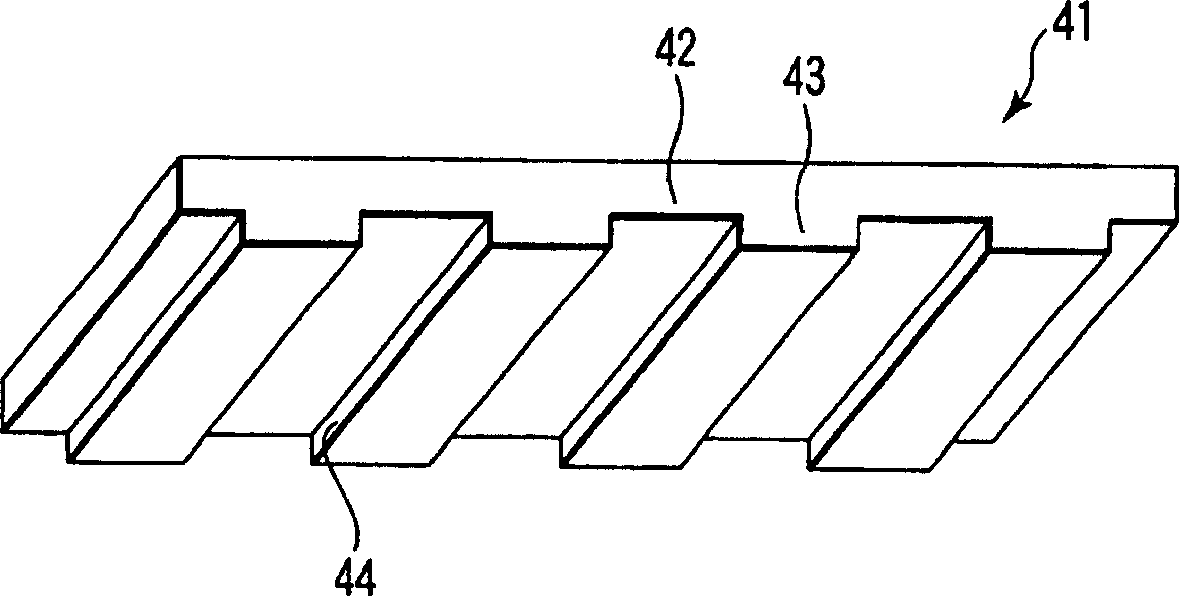

[0182] Next, an embodiment of the light transmission quantity modulation type will be described in which the mark pattern MK, such as a metal material capable of blocking light, is arranged on a glass substrate with a predetermined width (area) and pitch (interval).

[0183] Figure 18 A case where the mark pattern MK is applied to a method other than the above-described method of changing the phase value is shown. In this third implementation, alignment marks are formed on the semiconductor film on the substrate using the light-blocking type mask pattern MK. The techniques that will be described below are applicable to uses other than forming alignment marks.

[0184] In this case, a light-blocking metal film is selectively provided. Therefore, a shielding portion PS (or Pt) and a non-shielding portion (ie, light-transmitting portion) Ss (or St) having a predetermined area per 1 block (1 cell) are provided. For example, if Figures 19A to 19C As shown, in each 1 zone (1 u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com