High-efficiency motor with full-circumference magnetic flux polarized circumferential winding and new-energy electric vehicle

A magnetic pole and winding technology, which is applied in the field of high-efficiency motors and new energy electric vehicles, can solve the problems of reduced utilization of the stator winding magnetic field, multiple eddy current losses, resistive copper losses, magnetic flux leakage and high heat generation, etc., so as to eliminate the problem of heat generation , good regularity and consistency, saving copper and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Such as Figure 5 As shown, it is a schematic diagram of the axial section of the stator of a full-circumference magnetic flux pole-splitting motor with single-phase circumferential winding, and its circumferential winding is the same as the above image 3 The same is shown for the circumferential windings, which are embedded in the slots between the circumferences 506 and 507 .

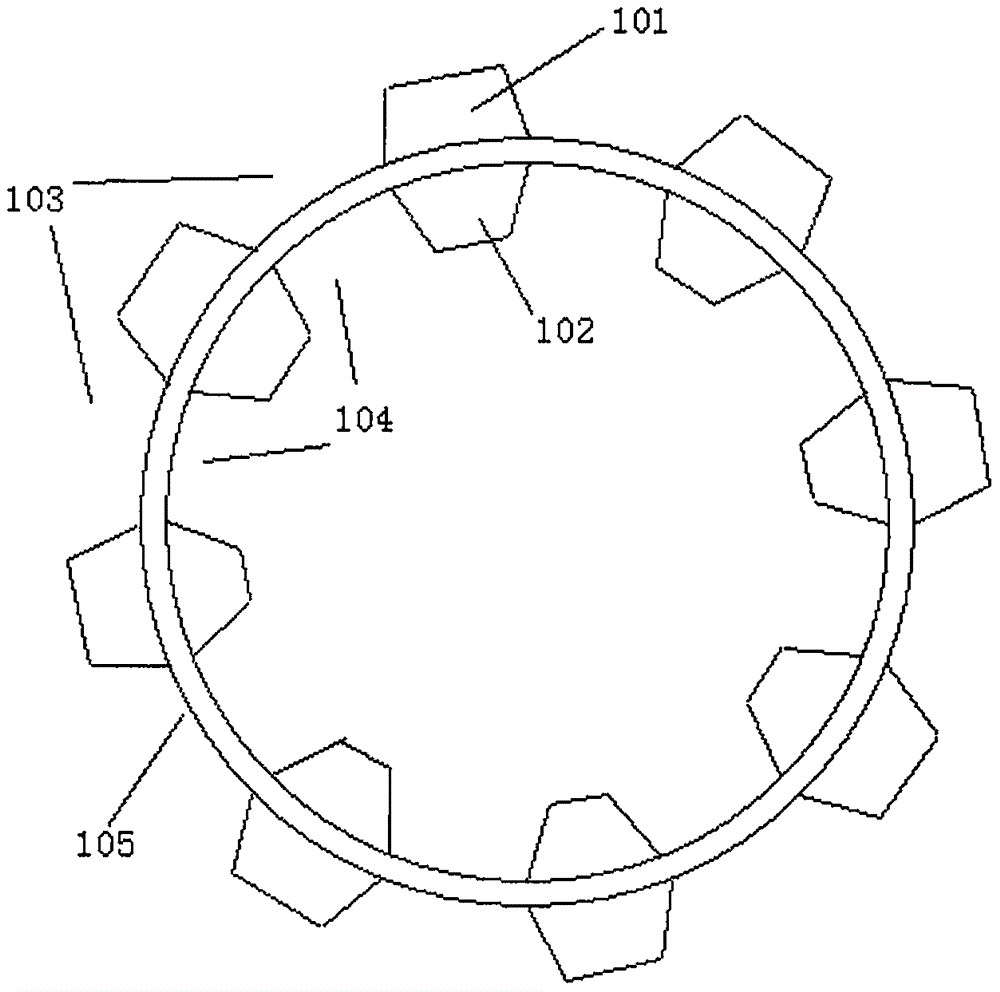

[0112] Such as Image 6 As shown, it is a schematic diagram of the axial section of the rotor of a full-circumference magnetic flux pole-splitting motor with single-phase circumferential winding. The stator core includes a yoke and a stator pole, and the yoke forms a continuous circumferential structure. The circumference of the yoke part has a slot cavity 505 capable of accommodating the stator windings. The stator poles are evenly distributed on both sides of the notch of the slot cavity, and the two sides of the slot are respectively connected to two opposite stator poles (such as the magn...

Embodiment 2

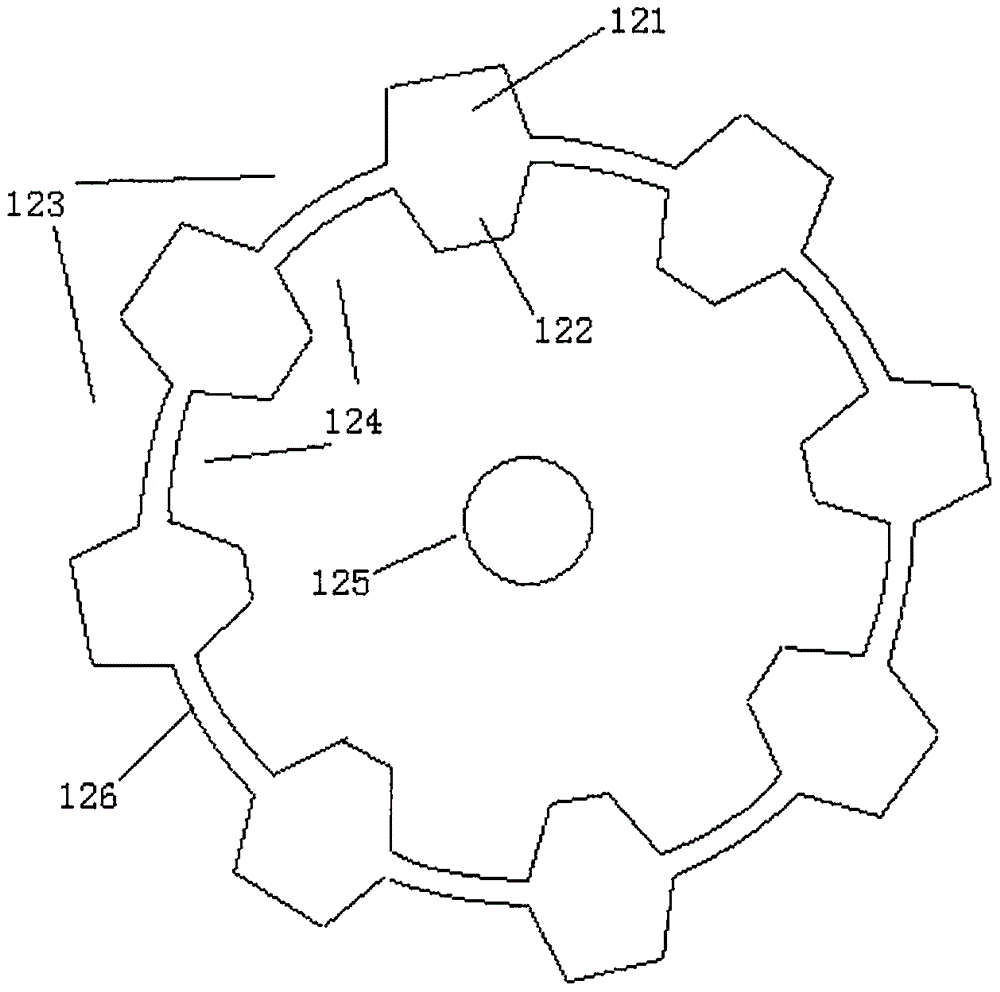

[0119] Such as Figure 8As shown, it is a sectional view of adjacent stator magnetic poles of a full-circumference magnetic flux split pole type circumferential winding motor. Two stator magnetic poles oriented 180° to each other are continuously distributed and alternately arranged on the entire circumference of the stator. The stator magnetic poles are now intercepted. A cross-sectional view of an adjacent stator pole of the core is used to illustrate the pole separation method of this embodiment.

[0120] In the figure, 142 is the cross-section of the circumferential winding, and 148 is a U-shaped magnetic core with the opening facing to the left: the U-shaped magnetic core includes a yoke 140, and two magnetic poles 143 and 144 are respectively connected on both sides of the notch to form a second magnetic pole. For a pair of magnetic poles facing one direction, when the circumferential winding is energized, the two magnetic poles 143 and 144 respectively exhibit different...

Embodiment 3

[0136] Such as Figure 10 As shown, it is a side sectional view of a single-phase circumferential winding with a full-circumference flux 90° polarized motor. Two U-shaped magnetic cores are alternately distributed on the stator circumference, and the bottom arcs of all U-shaped magnetic cores are A part of it is surrounded by a continuous groove structure capable of accommodating the circumferential winding. The circumferential winding 168 is placed in the groove, such as the stator core 173 (solid line in the figure). The core opening faces the left side as the first direction. Two magnetic poles connected in a circle form a pole pair 164; the stator core 174 (dotted line in the figure) facing the second direction has a magnetic core opening facing the upper side, and the two facing magnetic poles form an angle of 90° with each other, and the two sides of the notch are connected circumferentially. Two magnetic poles form a magnetic pole pair 166; similarly, the stator magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com