Permanent magnet motor and electric tool and mower utilizing the same

A technology of permanent magnet motors and permanent magnets, applied in synchronous motors with stationary armatures and rotating magnets, agricultural machinery and implements, applications, etc., can solve problems such as unacceptable cost of motors, achieve high power density, eliminate magnetism Effects of bridge flux leakage and air-gap flux density improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions and other beneficial effects of the present invention will be apparent through the detailed description of specific embodiments of the present invention below in conjunction with the accompanying drawings.

[0026] Understandably, the electric tool of the present invention may be an electric drill, electric hammer, electric saw, electric planer, electric wrench and the like. To simplify the description, an electric drill is taken as an example below.

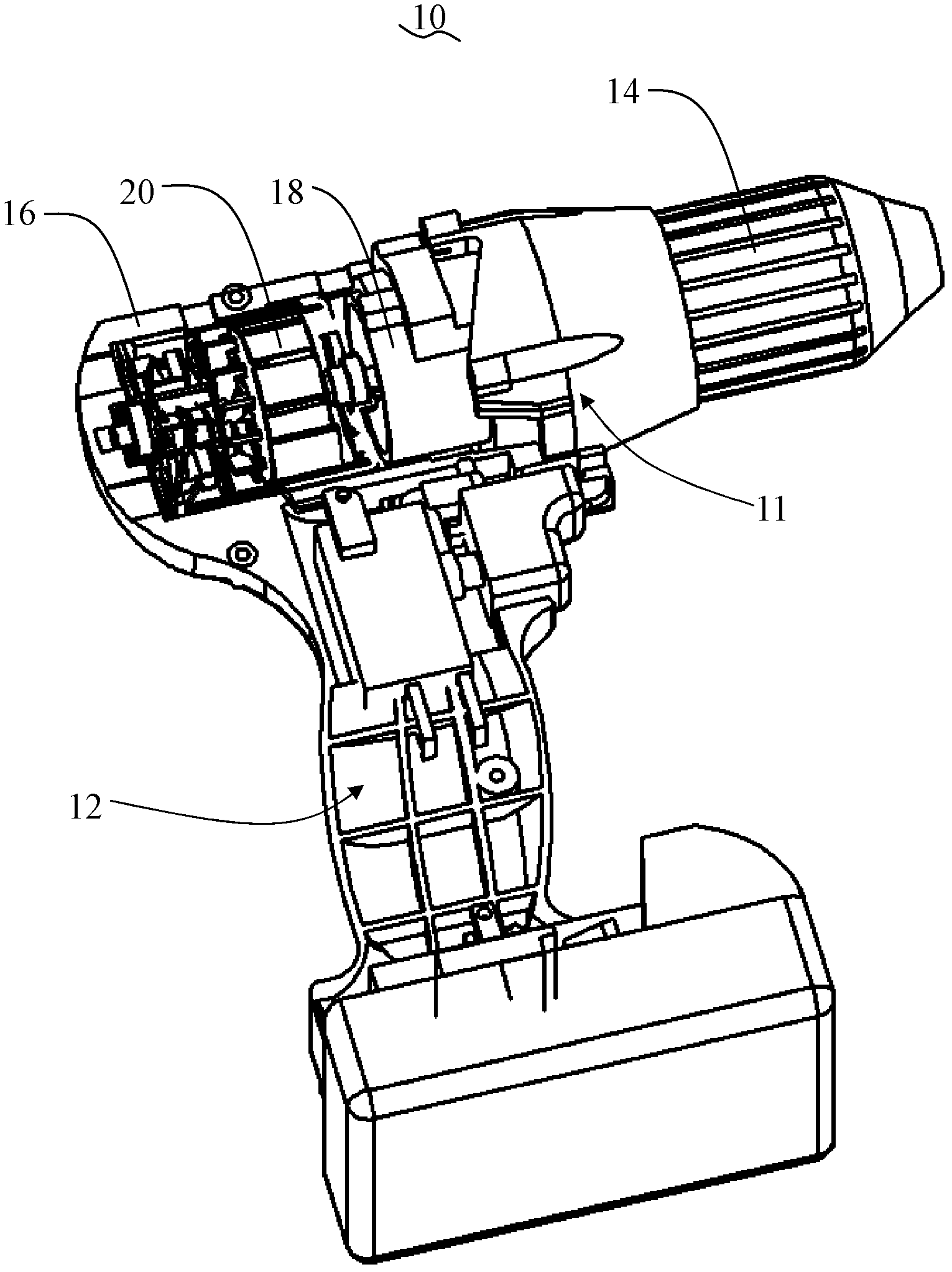

[0027] see figure 1 According to an embodiment of the present invention, an electric drill 10 includes a body 11 , a handle 12 disposed below the body 11 , and a tool head (drill bit) 14 mounted on the front end of the body 11 . The machine body 11 includes a housing 16 , a motor 20 housed in the housing 16 and a reduction mechanism 18 , and the rotation output of the motor 20 is transmitted to the tool head 14 through the reduction mechanism 18 .

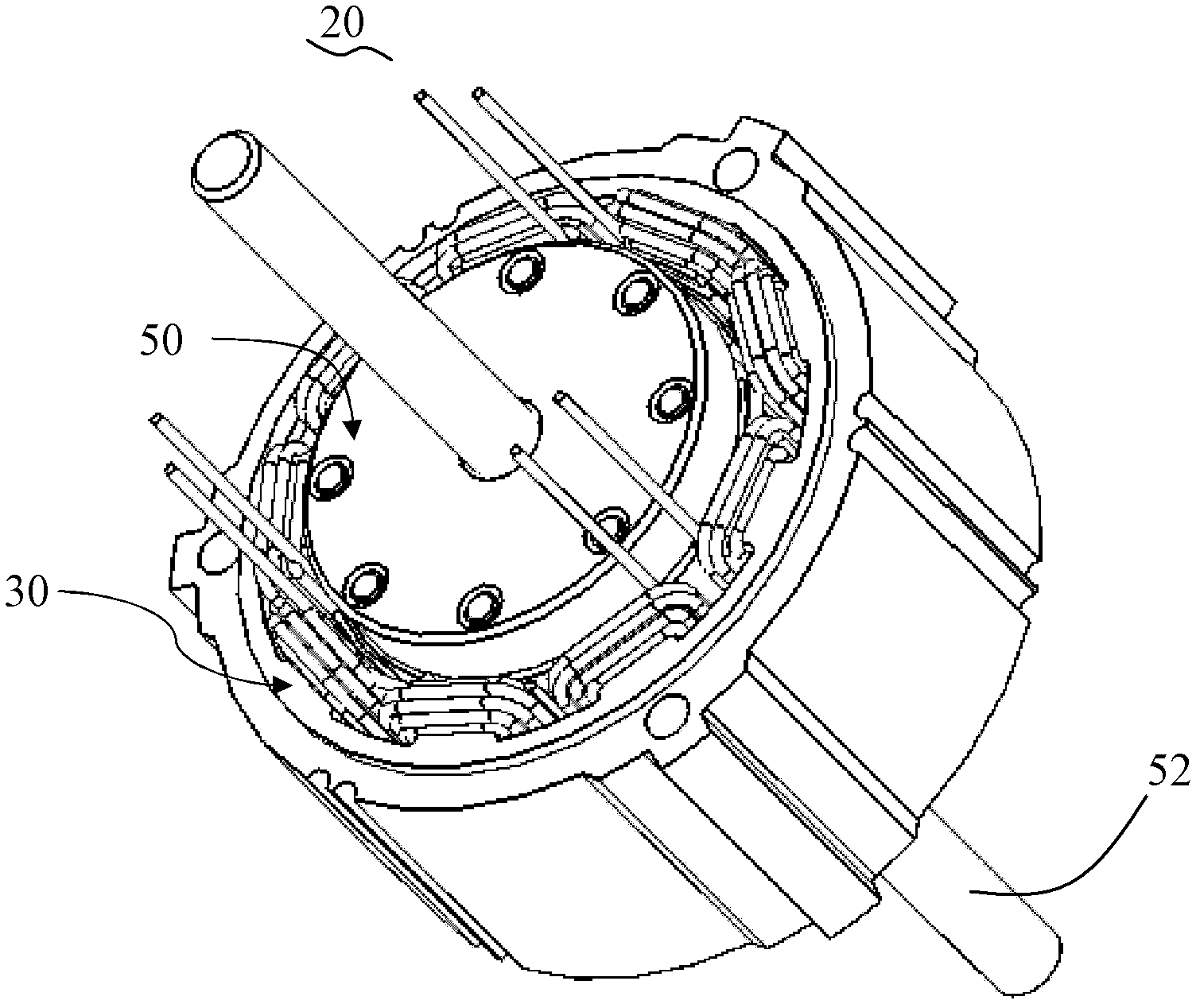

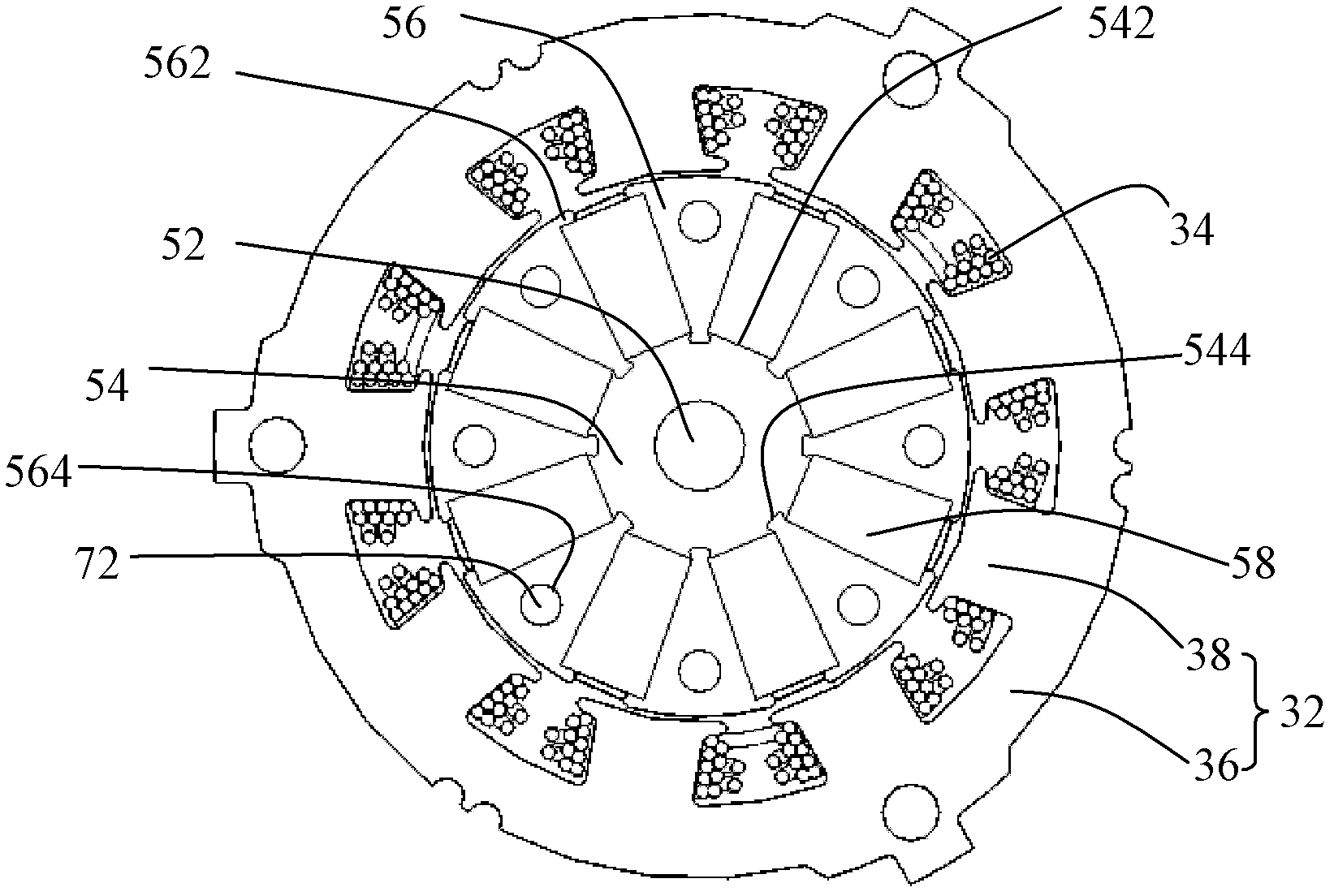

[0028] see Figure 2 to Figure 5 , the motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com