Salient-pole halbach composite array and permanent magnet motor

A composite array and permanent magnet motor technology, applied in the direction of salient poles, electrical components, electromechanical devices, etc., can solve the problems of small thrust/weight ratio, high cost, large volume, etc., to increase motor power and output, reduce volume and The effect of manufacturing usage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

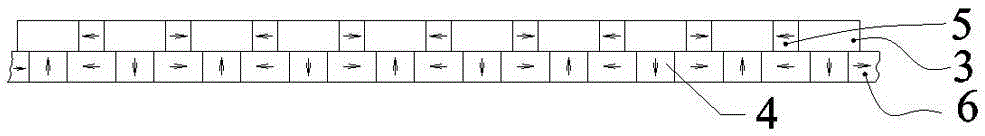

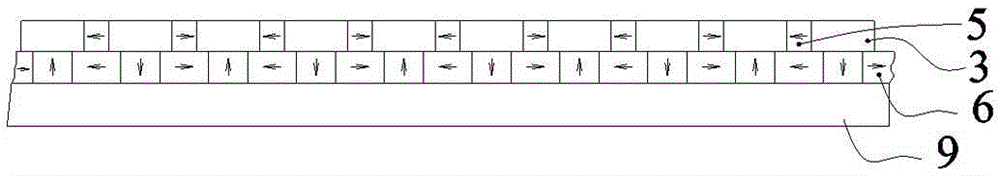

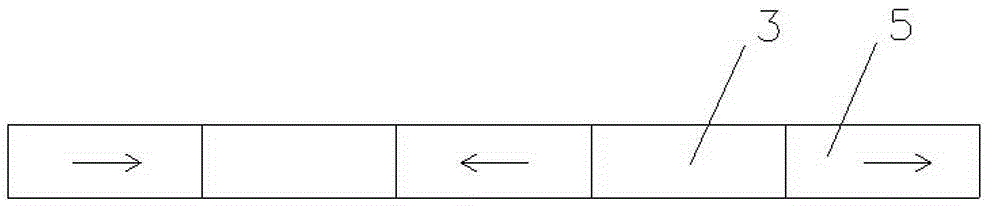

[0044] Such as Figure 1-Figure 24 as shown, figure 1 Shown is a kind of salient pole halbach composite array structure schematic diagram of the present invention Figure 1 , a salient pole halbach composite array, including a halbach magnet array with or without a yoke, the salient pole halbach composite array includes a single-layer salient pole halbach composite array and or a double-layer salient pole halbach composite array, with a yoke or The halbach magnet array without yoke is placed close to the surface of the salient pole magnet array without yoke or with yoke to form a single-layer salient pole halbach composite array. Double-layer salient pole halbach composite array, the salient pole magnet array is formed by alternately mounting magnetically conductive convex irons 3 and horizontal magnets 5, and the horizontal magnets 5 on both sides of the convex iron 3 form magnetically concentrating convex iron poles on the convex iron 3. The halbach magnet array is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com