Power motor with circumferential windings and new energy electromobile

A winding and power technology, which is applied in the field of power motors and new energy electric vehicles, can solve the problems of reducing motor reliability, magnetic field utilization rate, and insulation reliability, etc., to save copper and cost, improve power and efficiency, The effect of improving the utilization rate of the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141] The description in this embodiment is for illustration: the stator structure, the circumferential winding and the rotor structure of the circumferential winding motor.

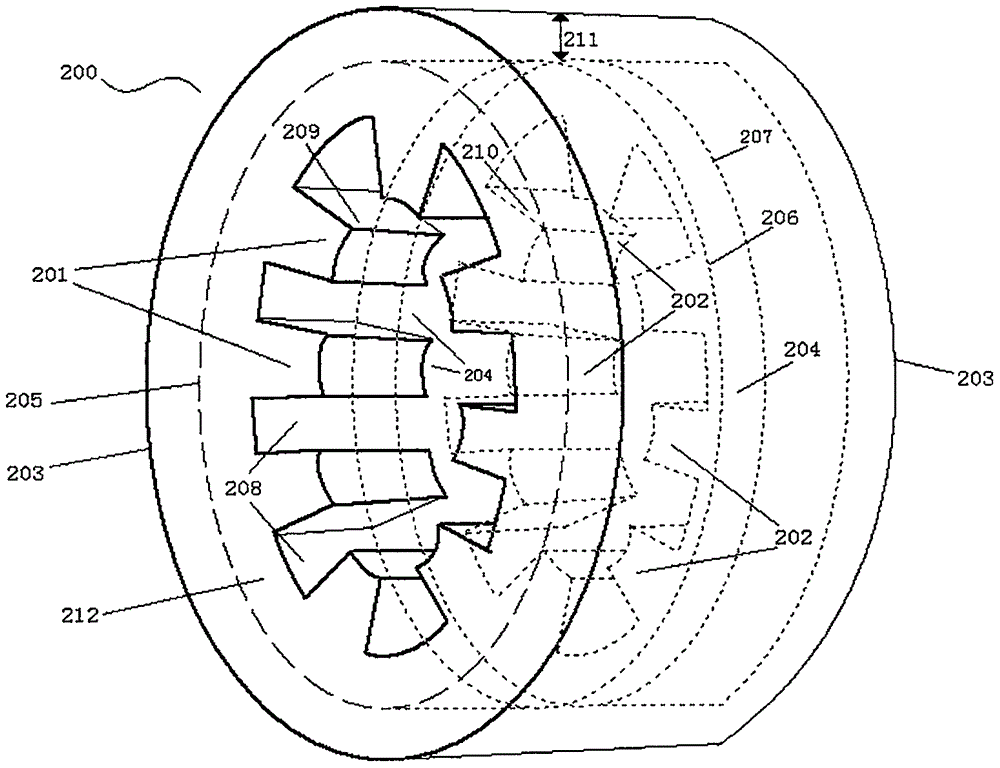

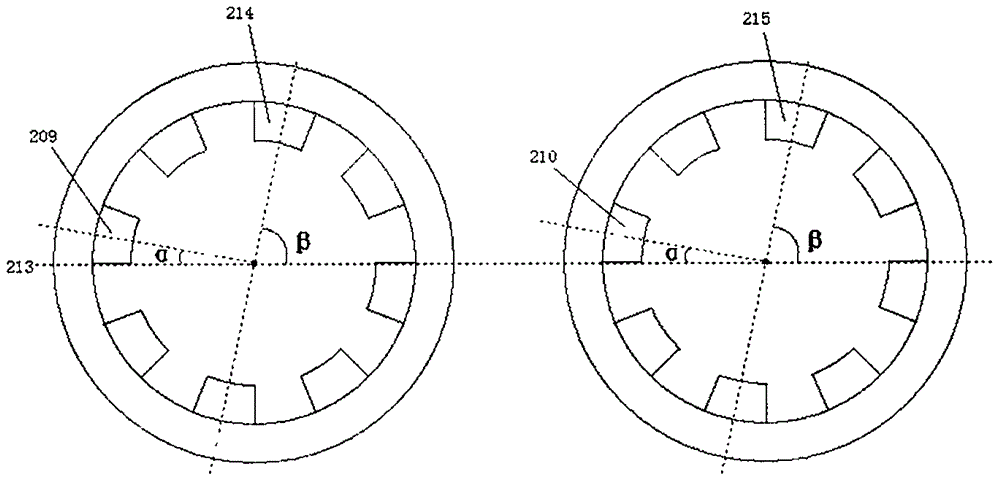

[0142] Such as figure 1 As shown, it is a three-dimensional structural diagram of a single-phase stator of a circumferential winding motor. There are 8 pairs of magnetic poles in the circumference of the stator core 200. The magnetic poles can be salient poles. Each pair of convex poles facing in the axial direction The pole is 1 "magnetic pole pair", such as the magnetic pole 209 and the magnetic pole 210 are 1 magnetic pole pair, and the magnetic pole pair is the "teeth" of the motor stator (the left magnetic pole 201, the right magnetic pole 202, etc. in the figure), There are axial slots between two adjacent magnetic poles along the circumferential direction of the stator. The "axial slots" are the "tooth pitch", that is, the magnetic pole spacing, which is called "magnetic pole pitch" (hereinafter ...

Embodiment 2

[0158] The description of this embodiment is for illustration: an axial field motor with a single-phase circumferential winding.

[0159] Such as Figure 8 As shown, it is a side sectional structural schematic diagram of an axial field motor with single-phase circumferential winding, wherein the stator core 230 has a circumferential inner ring groove 235, and the notches are evenly distributed on the circumferential portion 234 on both sides of the 236 There are stator magnetic poles (such as 231, 232), two magnetic poles facing axially form a magnetic pole pair such as 231 / 232 magnetic pole pairs, and the inner ring groove 235 is equipped with a circumferential stator winding 223; the main part of the stator core 230 includes The stator core yoke circumference 233 and the stator pole pairs 231 and 232 can establish an axial magnetic field; the rotor pole 401 on the rotor 400 extends into the space between the stator poles 231 and 232 in the slot, and the rotor pole 401 is con...

Embodiment 3

[0161] The description of this embodiment is for illustration: a side stator type axial field motor with single-phase circumferential winding.

[0162] Such as Figure 9 As shown, it is a side sectional structure schematic diagram of a side stator type axial field motor with single-phase circumferential winding. The circumferential groove is a side ring groove, and a circumferential winding 245 is embedded in the groove. An insulating bracket 243 is provided between the circumferential winding 245 and the side ring groove of the stator. The end leads of the circumferential winding 245 can be placed in the stator Magnetic core drilling etc. lead out; the notch 244 of the side ring groove faces the direction of the stator magnetic pole (shown as the direction to the right), and the inner circumference of the notch 246 is evenly distributed with salient pole type stator magnetic poles (such as the stator magnetic pole 242 ), the circumference of the outer circumference 247 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com