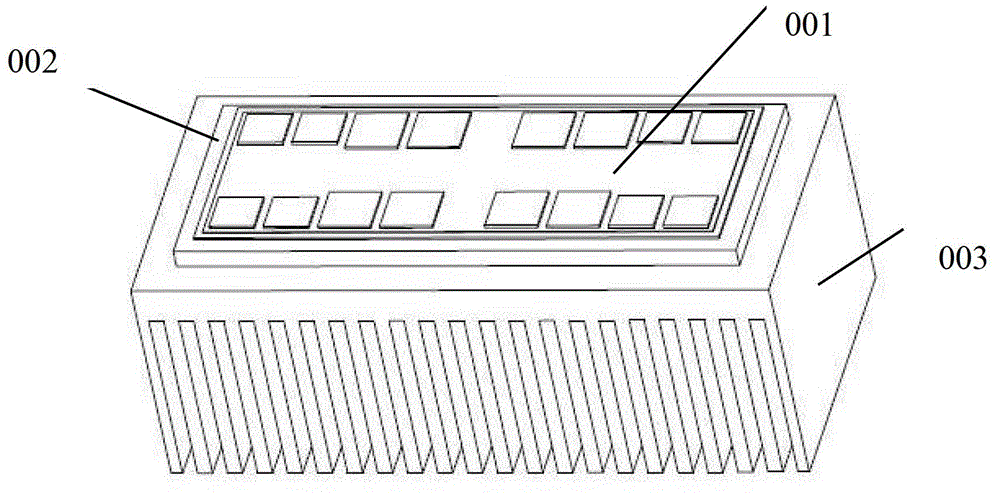

IGBT (Insulated Gate Bipolar Translator) module radiating structure

A technology of heat dissipation structure and heat sink, applied in cooling/ventilation/heating transformation, electrical components, electrical solid devices, etc. Affect the heat dissipation effect of IGBT products and other issues, to achieve the effect of reducing material cost, improving heat dissipation effect, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

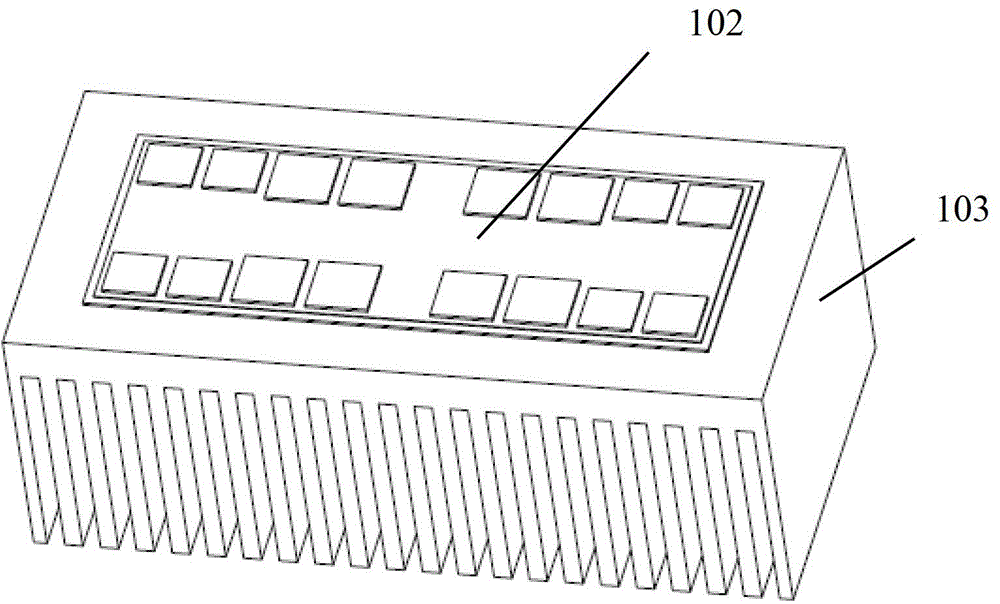

[0016] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 2 As shown, the present invention discloses a heat dissipation structure of an IGBT module, including a housing (not shown), a DBC board 102 and a radiator 103, and the housing exerts longitudinal pressure on the DBC board 102, thereby pressing the DBC board 102 tightly against the heat dissipation device 103.

[0018] In the DBC board in the prior art, solder is firstly placed on the AlSiC base plate, then the DBC board is welded on the AlSiC base plate, and then the AlSiC base plate is fixed on the radiator by screws. In this existing IGBT module, the following problems generally exist when the heat generated by the chip is conducted to the heat sink:

[0019] 1. The heat generated by the chip is first conducted to the AlSiC base plate through the solder between the DBC board and the AlSiC base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com