Refining furnace decarburization end point detection method and detection system

A technology of endpoint detection and refining furnace, which is applied in the field of steelmaking, and can solve problems such as extended refining time, poor control accuracy of decarburization endpoint, steel production efficiency, product quality, and energy and material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

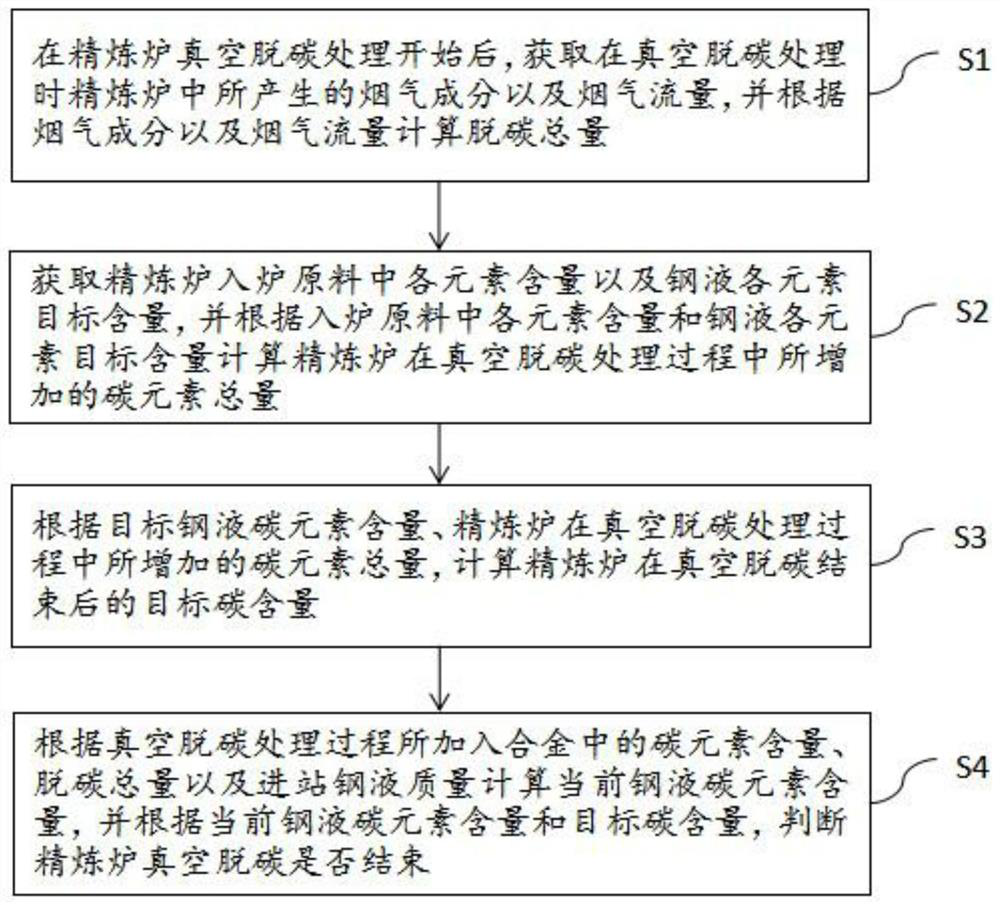

[0034] The invention provides a method for detecting the decarburization endpoint of a refining furnace, such as figure 1 As shown, the detection method includes:

[0035] S1. After the vacuum decarburization process in the refining furnace starts, obtain the flue gas composition and flue gas flow rate generated in the refining furnace during the vacuum decarburization process, and calculate the total amount of decarburization based on the flue gas composition and flue gas flow rate. Contains carbon monoxide and / or carbon dioxide.

[0036] Calculate the total amount of decarbonization according to the flue gas composition and flue gas flow, including:

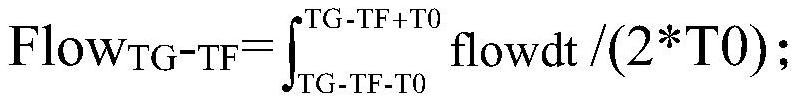

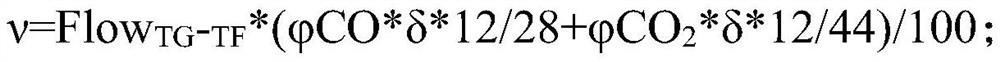

[0037] Obtain the delay time of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com