Non-leakage reversed flow type plunger pump

A plunger pump, no leakage technology, applied in the field of reciprocating pumps, can solve the problems of ordinary plunger reciprocating pumps such as limited application range, wear medium, leakage, etc., and achieve huge economic benefits, positive social benefits, stable working pressure, and energy saving medium effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

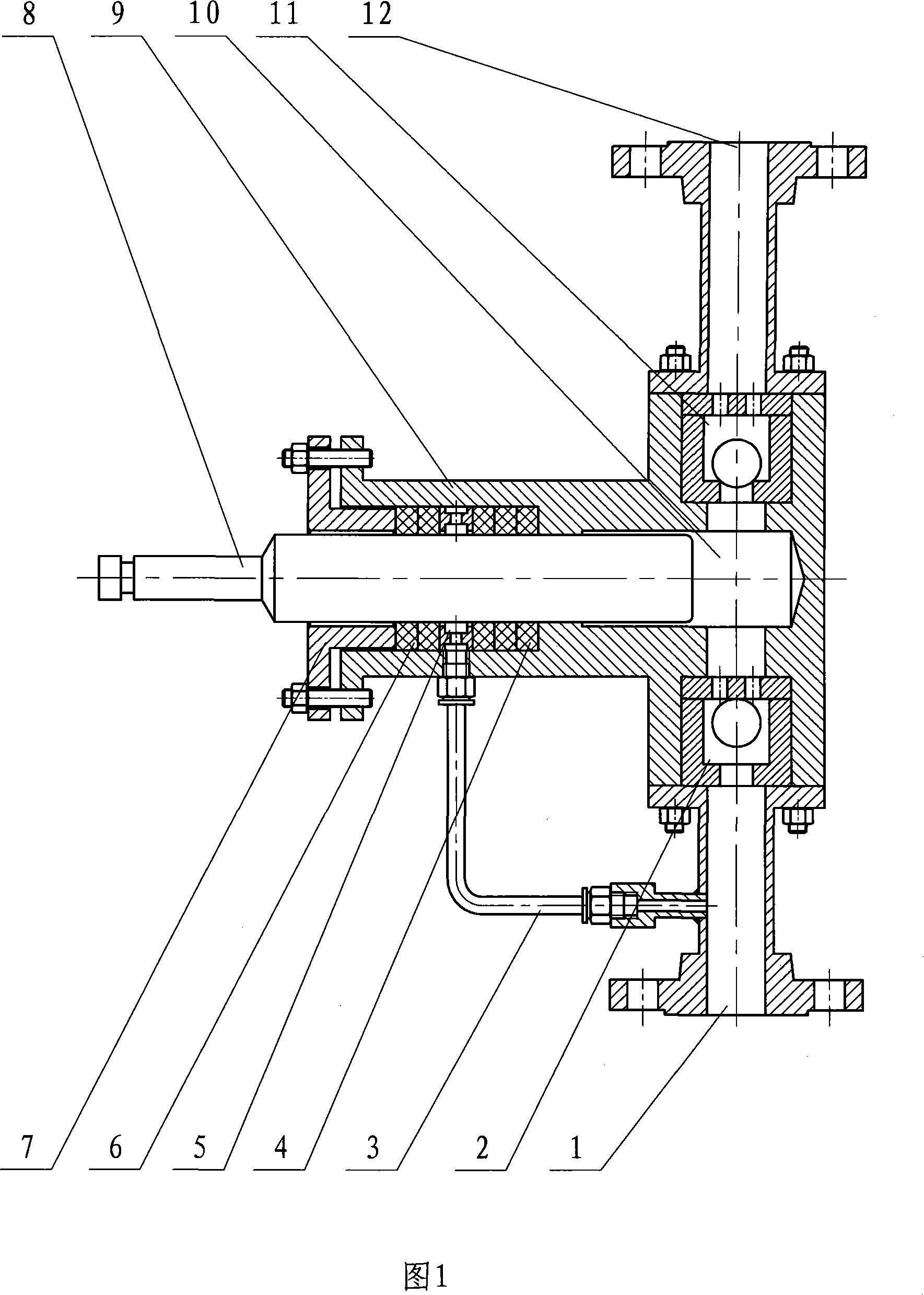

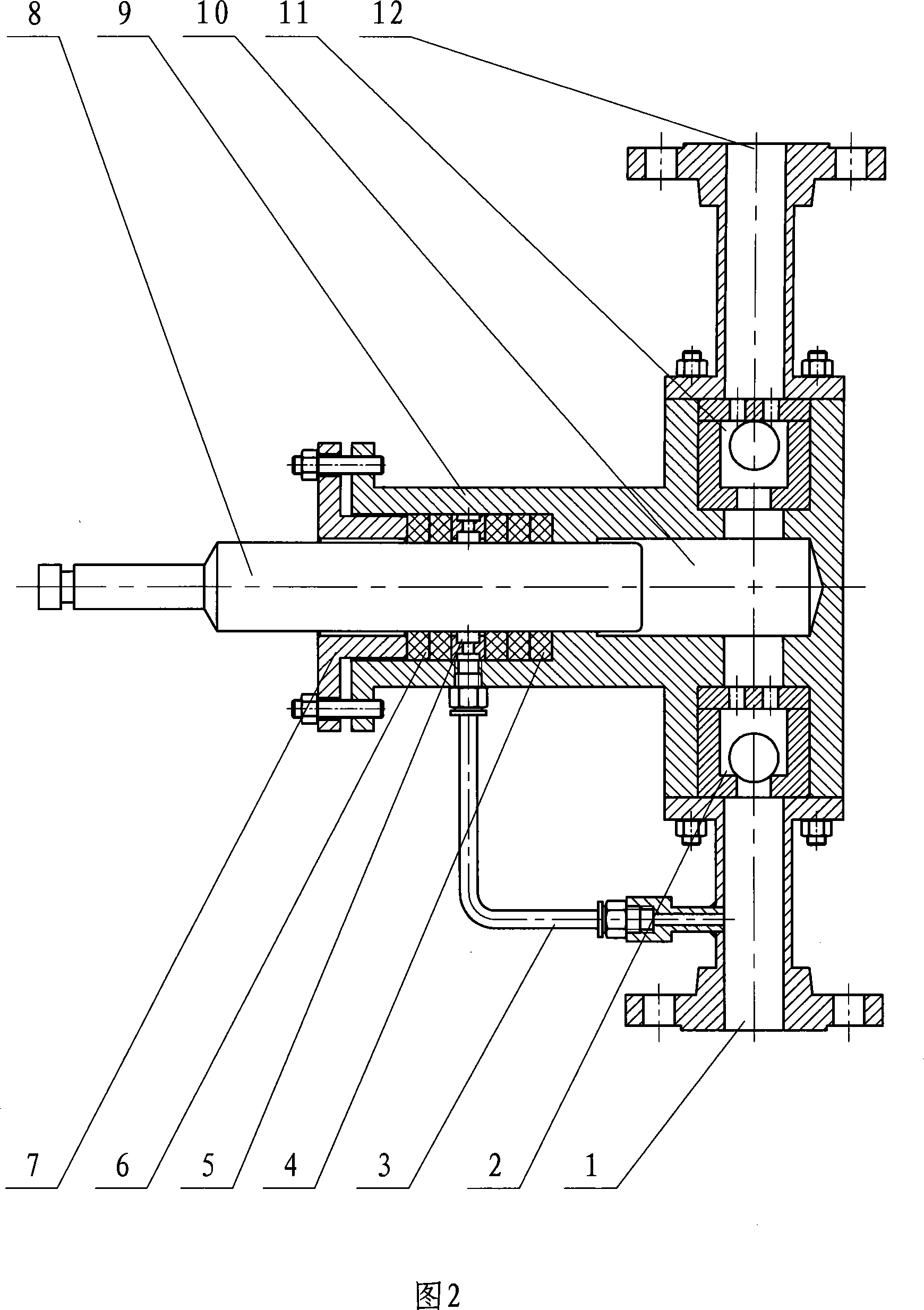

[0016] The present invention will be further described below in conjunction with Figures 1, 2, and 3.

[0017] The plunger pump is composed of pump inlet 1, inlet check valve 2, inner packing 4, outer packing 6, packing gland 7, plunger 8, pump body 9, working chamber 10, outlet check valve 11 and pump outlet 12.

[0018] The leakage-free return mechanism of the plunger pump is composed of a return pipe 3 and a spacer ring 5.

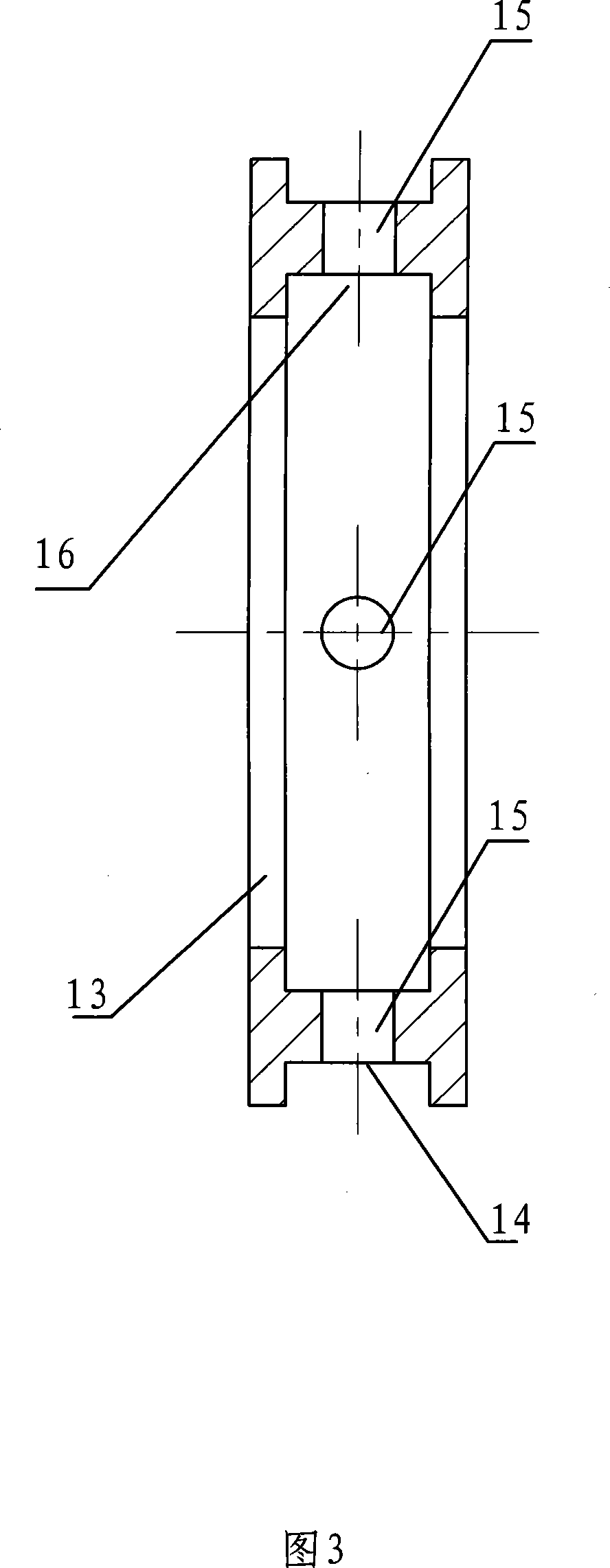

[0019] Both the outer surface and the inner surface of the spacer ring 5 have grooves, namely the spacer ring outer surface groove 14 and the spacer ring inner surface groove 16, and 8 through holes are evenly distributed at the bottom of the groove, namely the spacer ring groove overflow hole 15 . The spacer ring 5 is installed between the inner packing 4 and the outer packing 6 of the plunger pump body 9; both ends of the return pipe 3 have pipe joints respectively connected to the pump body 9 and the pump inlet 1 corresponding to the installation positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com