Power station silent energy-saving type heat dissipation system

A cooling system, energy-saving technology, applied in the control of coolant flow, engine components, machines/engines, etc., can solve the problems of high noise, heavy weight, large power station ventilation, etc., to meet the needs of heat dissipation, and to replace pollution-free , the effect of increased ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A specific embodiment of the present invention will now be described in detail in conjunction with the accompanying drawings.

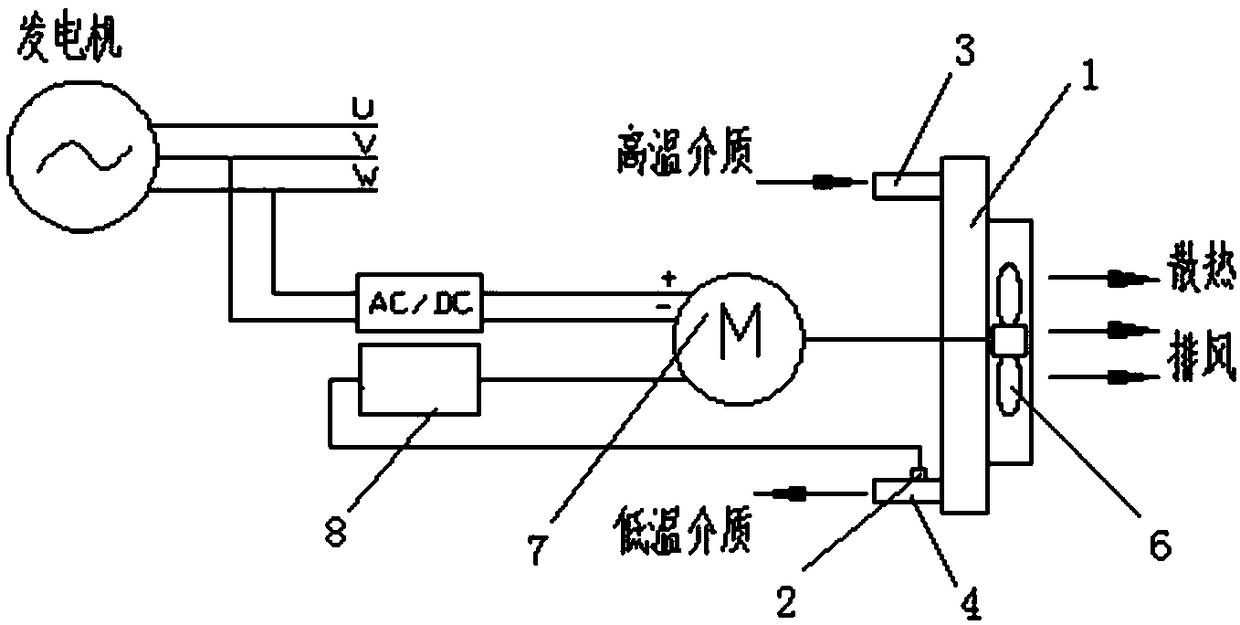

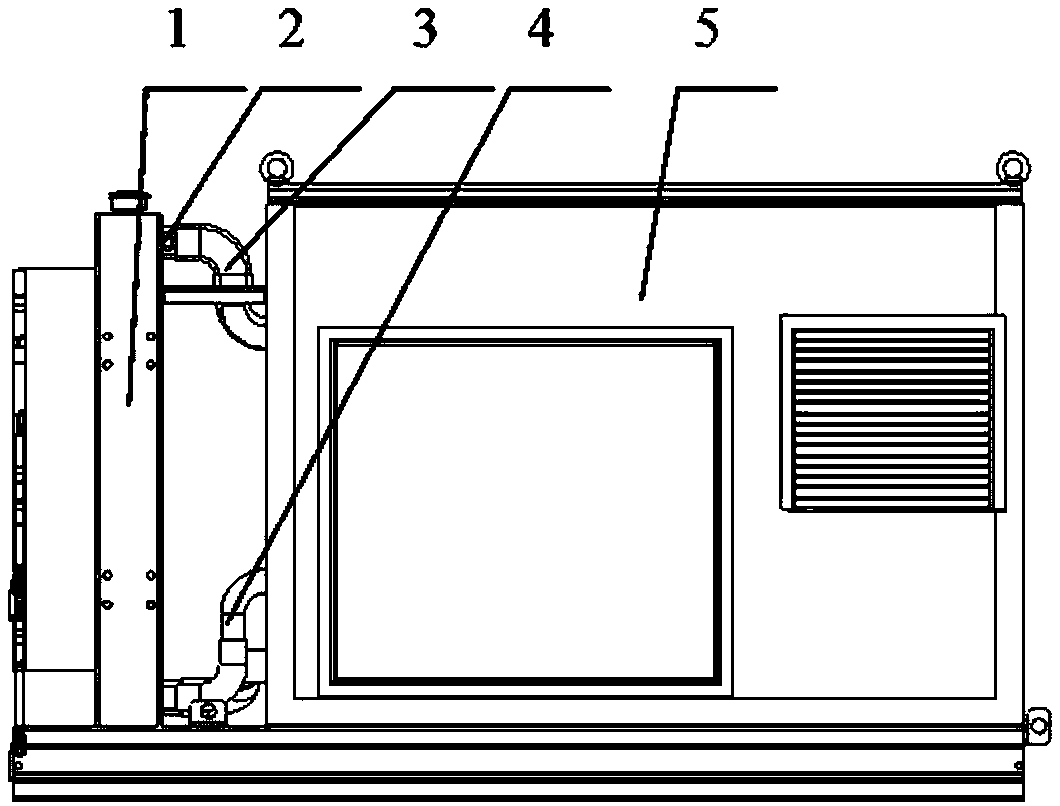

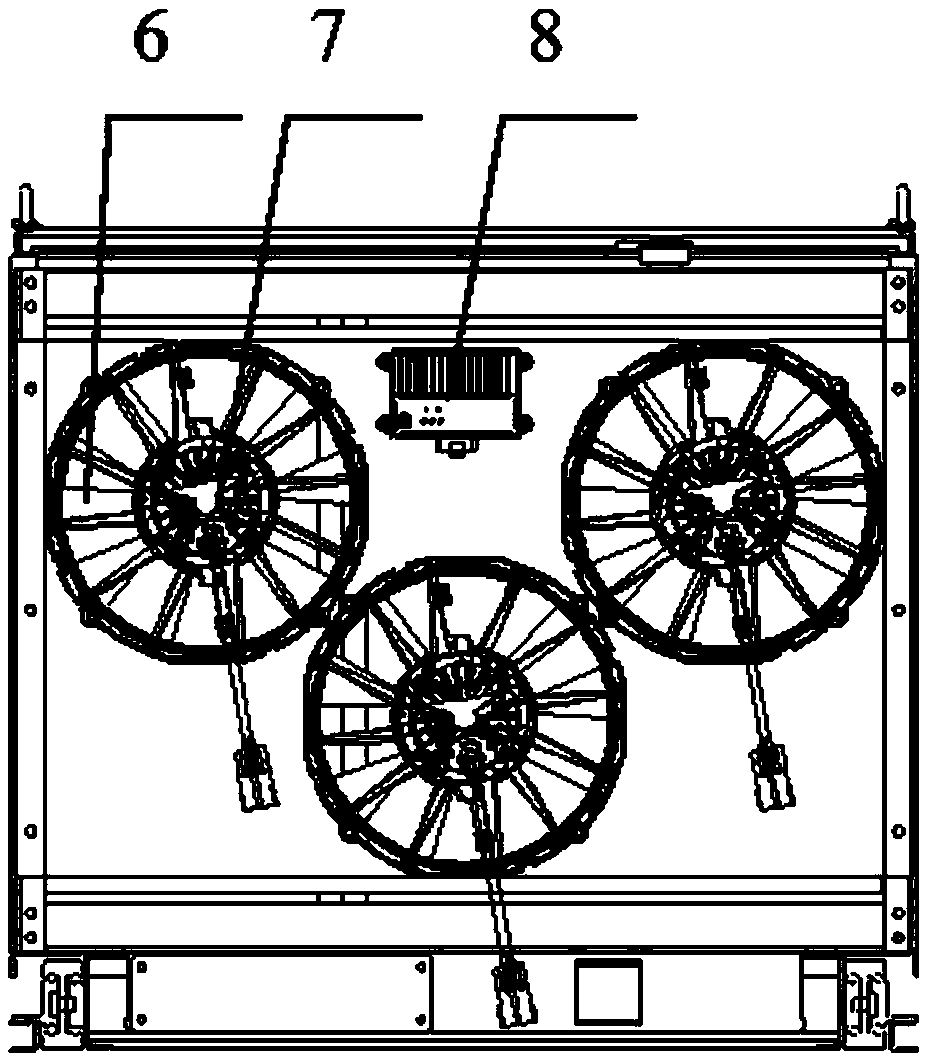

[0019] A silent and energy-saving cooling system for a power station, comprising a radiator 1, a temperature sensor 2, a radiator inlet pipe 3, a radiator return pipe 4, a box-type unit 5, a cooling fan 6, a cooling fan 7 and a fan controller 8.

[0020] The radiator 1 is arranged outside the box-type unit 5, the upper part of the radiator 1 is connected to the box-type unit 5 through the radiator water inlet pipe 3, and the lower part of the radiator 1 is connected to the box-type unit 5 through the radiator return pipe 4 to form a medium cooling cycle. The circulating cooling medium absorbs heat in the box-type unit 5 and releases heat in the external radiator 1, thereby reducing the temperature of the diesel engine in the box-type unit 5. In this embodiment, the circulating cooling medium adopts cooling liquid.

[0021] The connection betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com