LED luminous module with heat radiation structure

A technology of light-emitting modules and heat-dissipating structures, which is applied to semiconductor devices, light sources, point light sources, etc. of light-emitting elements, can solve the problems of difficult processing, high cost, poor heat dissipation, etc., and achieve the effects of low cost, reduced medium, and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following describes the utility model in further detail with reference to the drawings and specific embodiments:

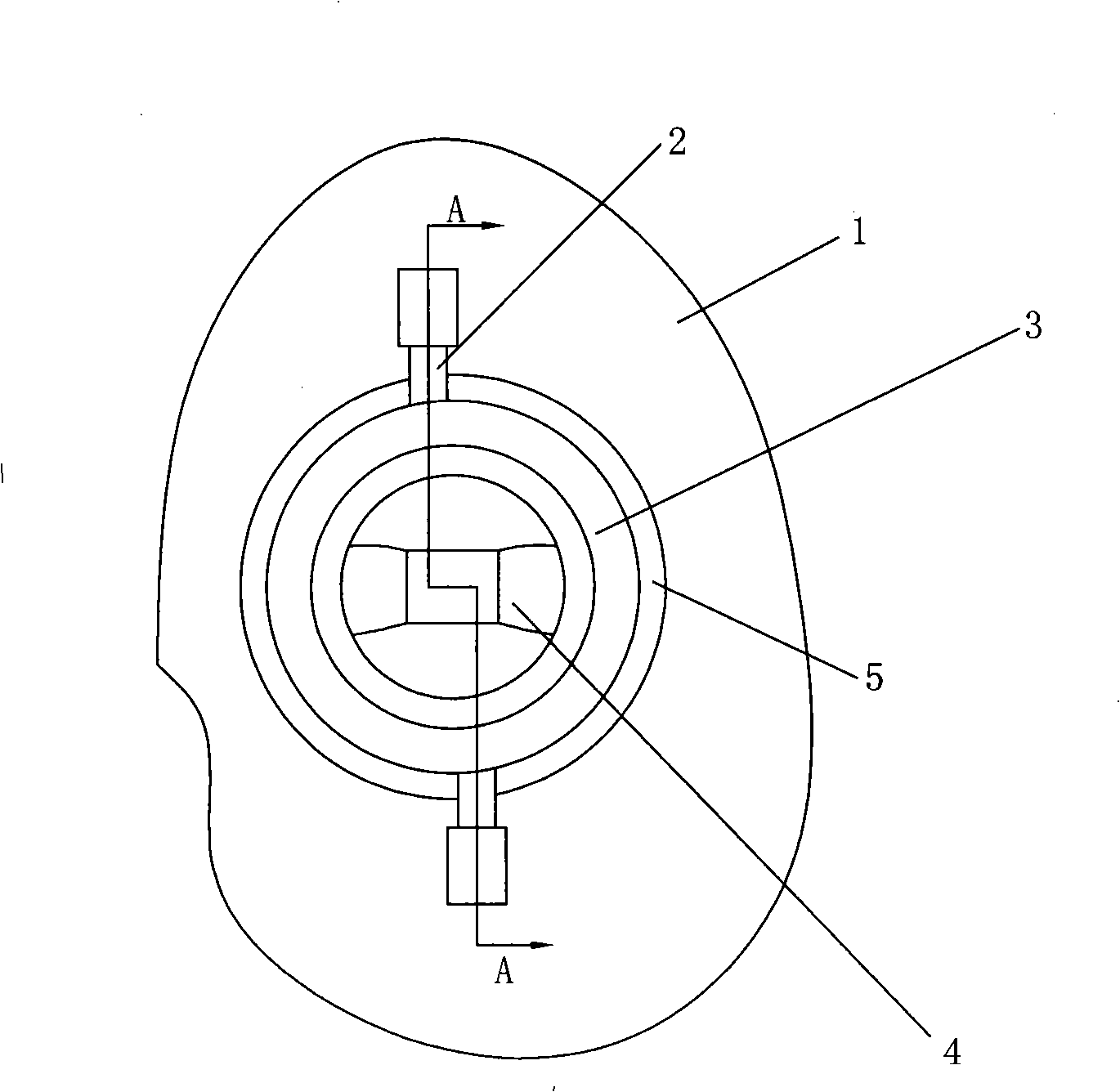

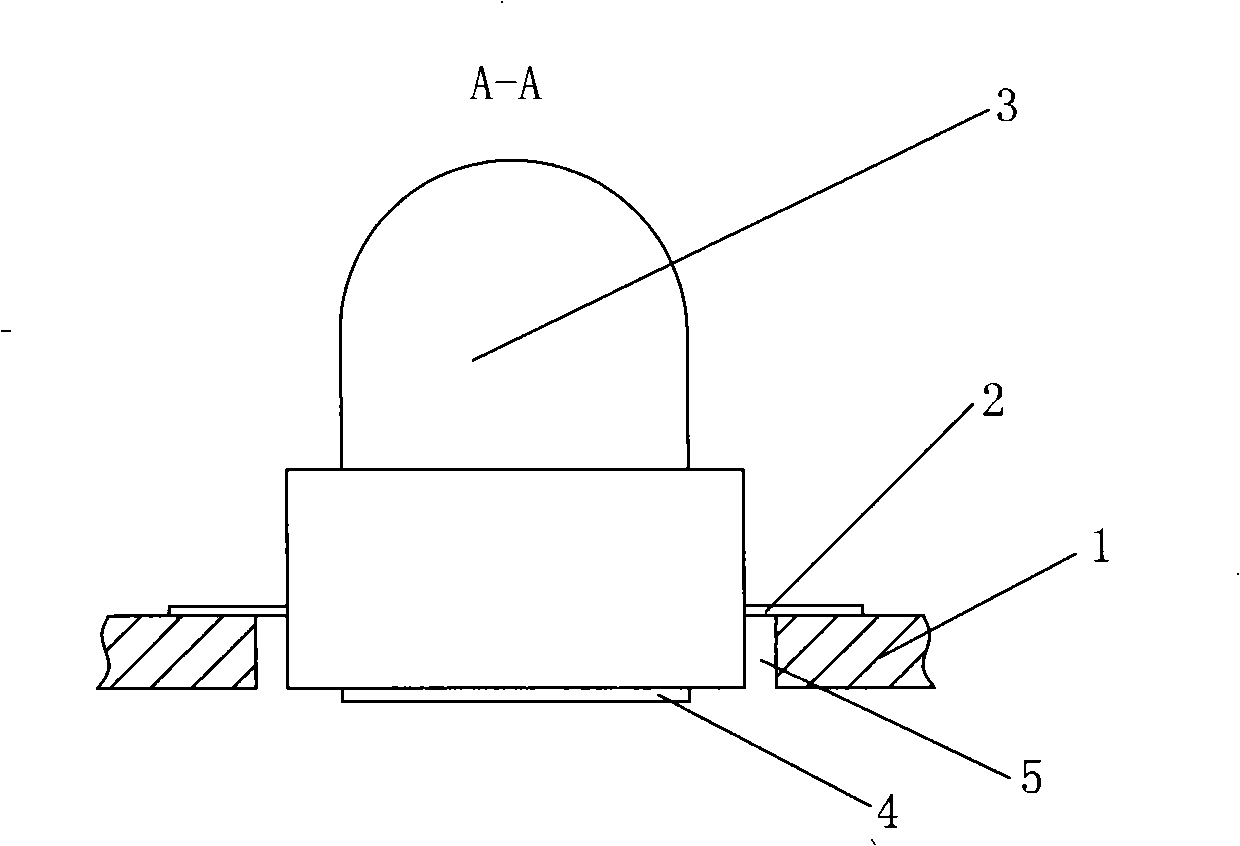

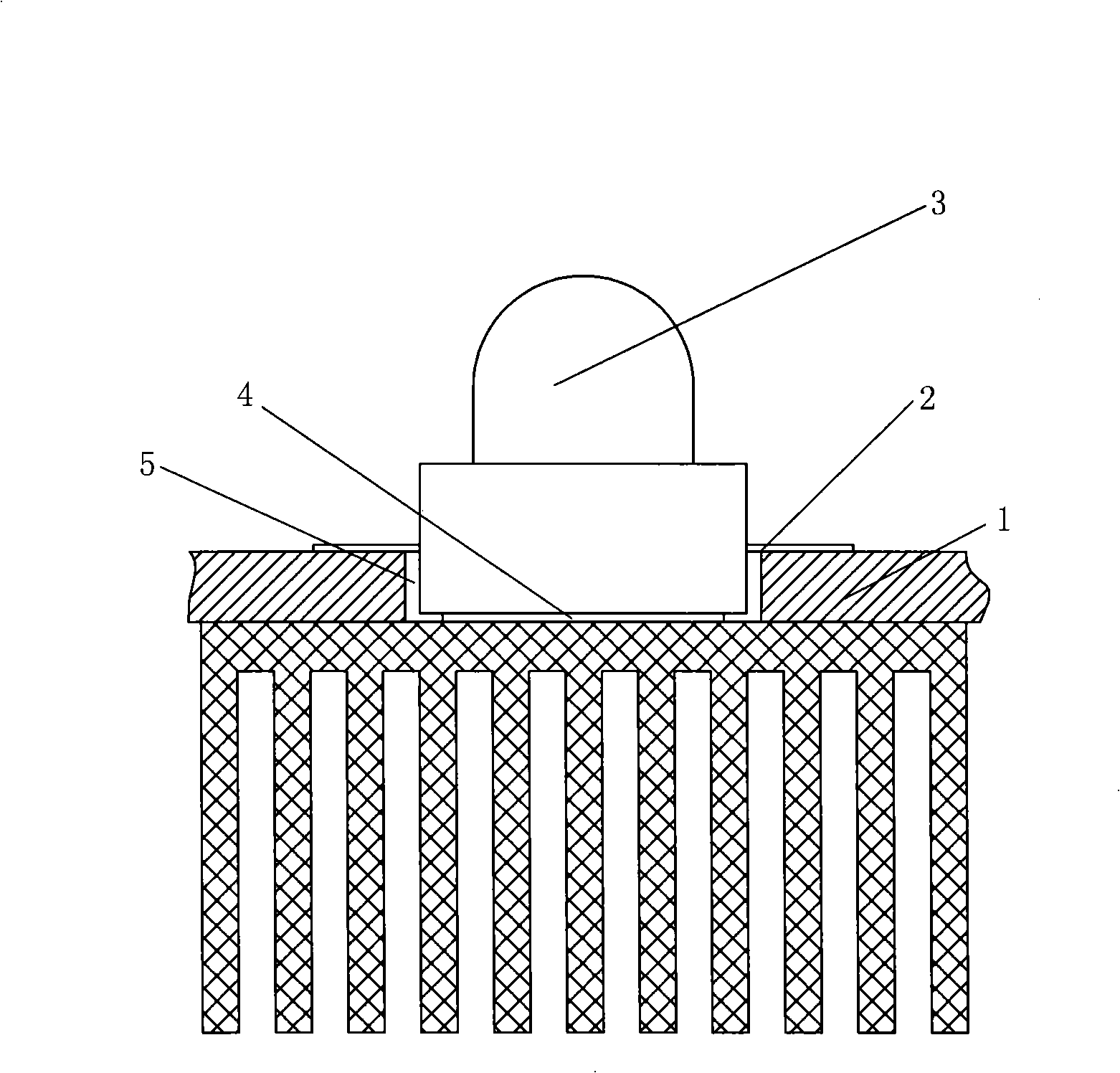

[0020] see figure 1 , figure 2 , image 3 Since the present utility model relates to the innovation of the heat dissipation structure, when drawing, the bottom plate 1, that is, the circuit connection on the PCB board is not drawn.

[0021] The bottom plate 1 uses a common PCB board, which has a low cost. The bottom plate 1 has holes 5, and the number of holes 5 is set according to the brightness. Generally speaking, the brightness is controlled by the number of LED lights 3. That is to say, the number of holes 5 is correspondingly set according to the number of LED lights 3. The holes 5 can also be arranged according to different uses to diversify the shape of the light-emitting module, which can be a series of shapes such as circle, bar, rectangle or font. Preferably, the hole 5 is a round hole, and the hole diameter is larger than the outer diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com