Method for producing ferrochrome nitride with microwave as heat source

A technology of ferrochromium nitride and micro-carbon ferrochromium, which is applied in the field of ferrochromium nitride production, can solve the problems of difficult control of the smelting process, poor appearance quality, long nitriding time, etc., achieve broad industrial application prospects, and short synthesis time , the effect of low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

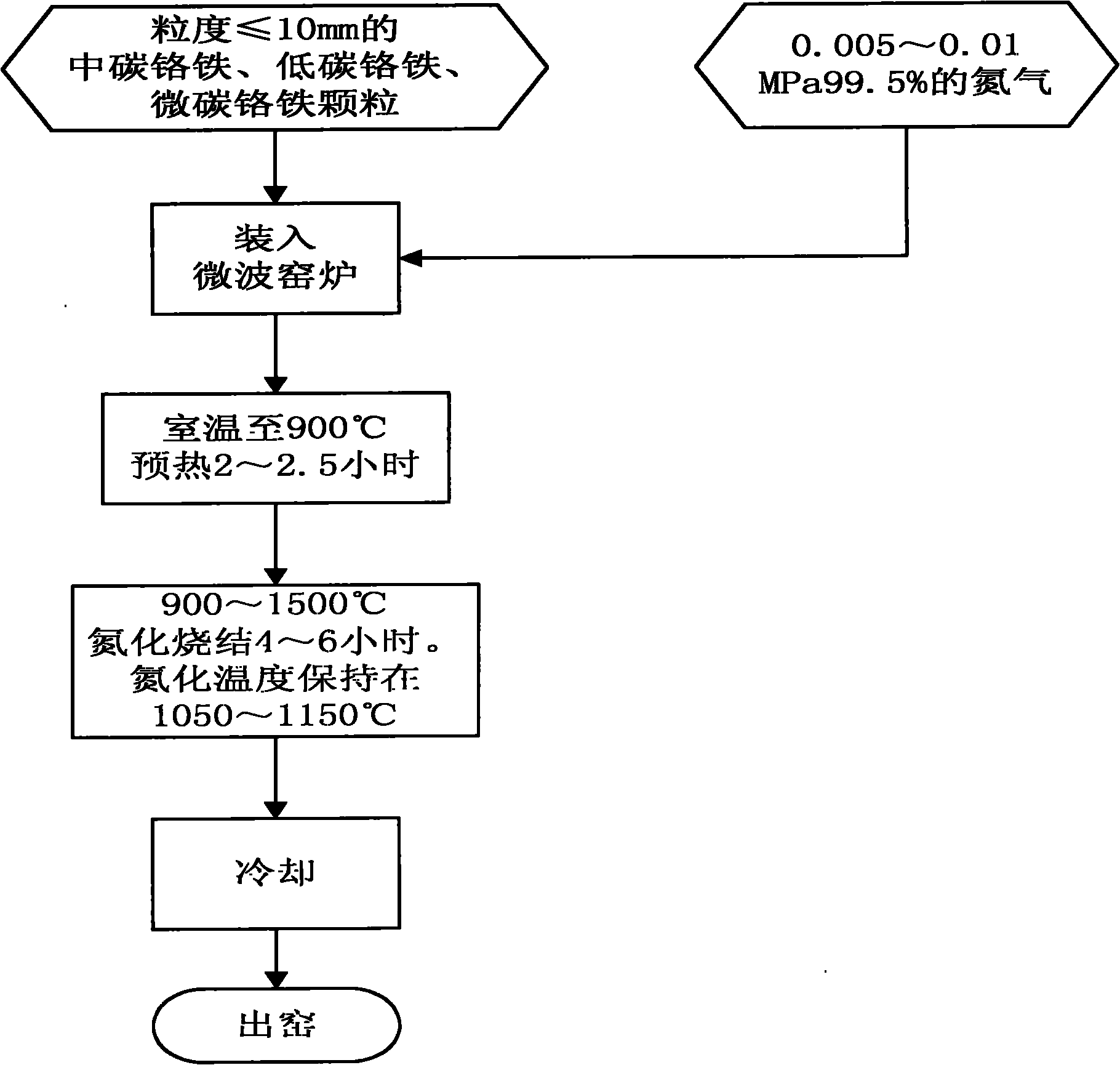

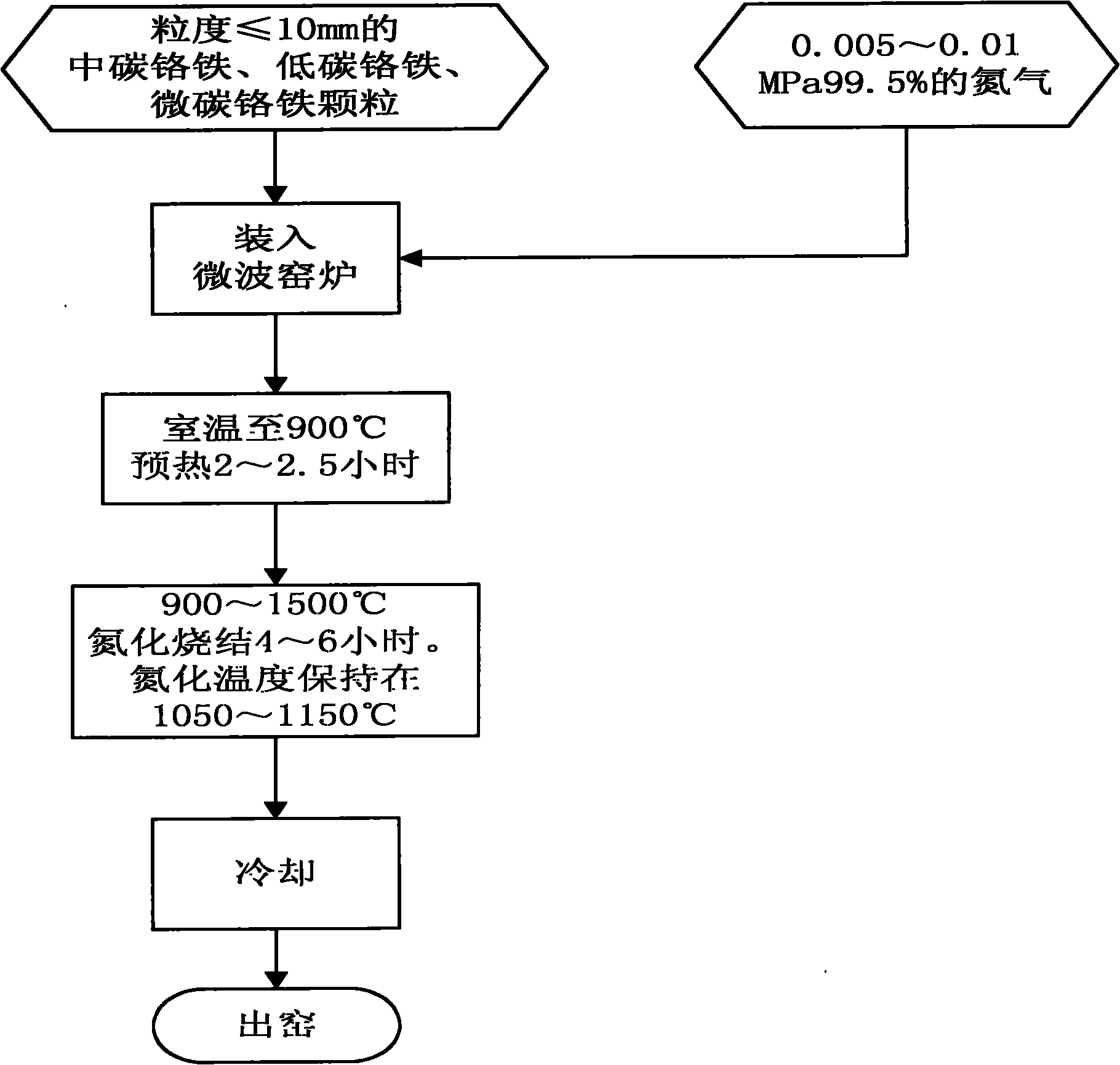

[0017] Now, the present invention will be further described as follows in conjunction with the accompanying drawings and specific embodiments. Lay medium-carbon ferrochrome, low-carbon ferrochrome, and micro-carbon ferrochrome particles with a particle size of ≤10mm in the push boat used in the microwave tunnel kiln, and use the push plate to continuously and automatically push the material into the microwave high-temperature microwave with a microwave frequency of 2.45GHz In the nitriding tunnel kiln, pure nitrogen with a purity of more than 99.5% is introduced. Under a nitrogen atmosphere with a pressure of 0.005-0.01MPa, preheat from the greenhouse to 900°C for 2-2.5 hours, and the microwave synthesis temperature is controlled at 900-1500°C. After 4 to 6 hours of synthesis time, the optimal nitriding heat preservation interval is 1050 to 1150 ° C. After cooling out of the kiln, the composite obtained is a finished ferrochromium nitride alloy. The nitrogen content of ferrochr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com