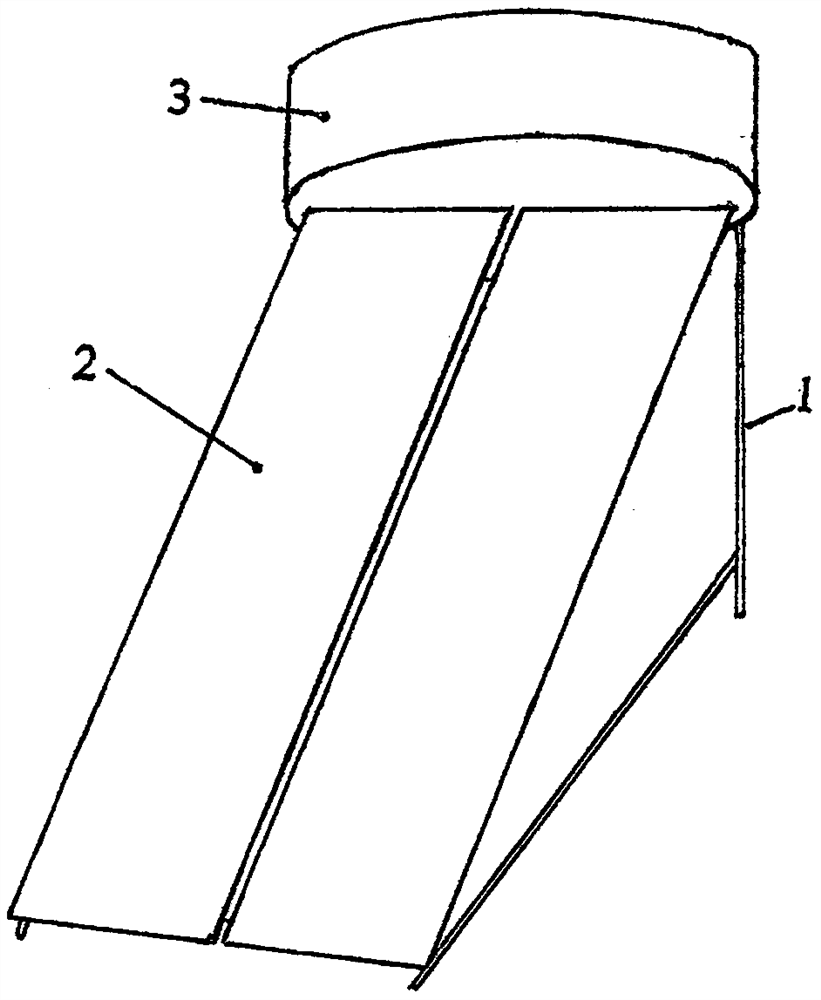

Flat-plate vacuum tube water heater

A vacuum tube water heater and vacuum tube technology, which is applied in the field of solar energy applications, can solve the problems of large thermal storage, poor thermal insulation effect, and low thermal energy, and achieve the effects of high heat collection efficiency, material saving, and small thermal storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] The specific embodiment of the present invention is illustrated below in conjunction with accompanying drawing: a kind of flat vacuum tube water heater is made up of support 1, heat collector 2 and water tank 3, and heat collector 2 and water tank 3 are fixed on the support 1; Said heat collector 2 It is a flat vacuum tube heat collector, and the water tank 3 is a vacuum flat water tank; the heat collector includes: an outer flat glass flat tube, an inner flat glass flat tube, a support column, a getter, and a heat-absorbing coating; wherein: the inner The two outer planes of the flat glass flat tube have dot-like protrusions with the same horizontal spacing, and these dot-like protrusions are vacuum support columns; one outer surface of the inner flat glass flat tube is made with a heat-absorbing coating; the The lower end of the outer flat glass flat tube is welded or brazed to form an outer glass flat tube, the lower end of the inner flat glass flat tube is welded or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com