Forced circulation coal powder burning water heating boiler

A technology of hot water boiler and forced circulation, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as difficult ash removal, complicated water flow, and complicated tube bundles, so as to improve fuel combustion efficiency and prevent NOx from polluting the environment , the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

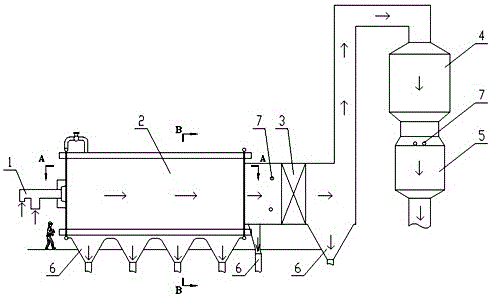

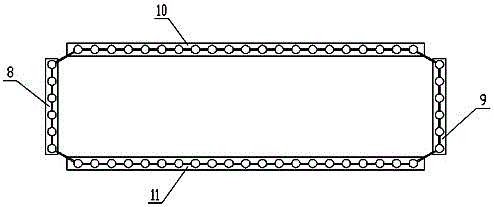

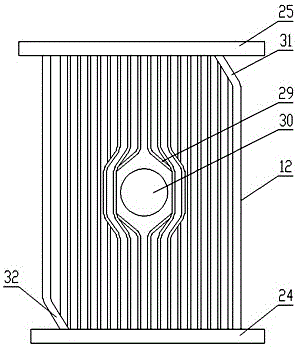

[0024] Such as figure 1 As shown, a forced circulation pulverized coal-fired hot water boiler includes a boiler body 2 and a mixing header 16, a burner 1 arranged at one end of the boiler body 2, and the boiler body 2 includes a furnace, an outlet header 17, connecting the furnace and The connecting pipe system of the water outlet header 17 and the furnace wall covering the outside of the boiler body 2 . The hearth is surrounded by the front wall of the hearth 8, the rear wall of the hearth 9, the left hearth wall, the right hearth wall, the hearth top wall and the hearth bottom wall. Wherein, the left furnace wall of the furnace and the top furnace wall of the furnace constitute the left wall 10 of the furnace, and the left wall 10 of the furnace is arranged side by side by several bent L-shaped light pipes, and the adjacent L-shaped light pipes are welded by flat steel. The heating surface of the integral membrane water wall formed together. The right wall of the hearth an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com