An electric heat preservation and decoration integrated wall and floor tile and its preparation method

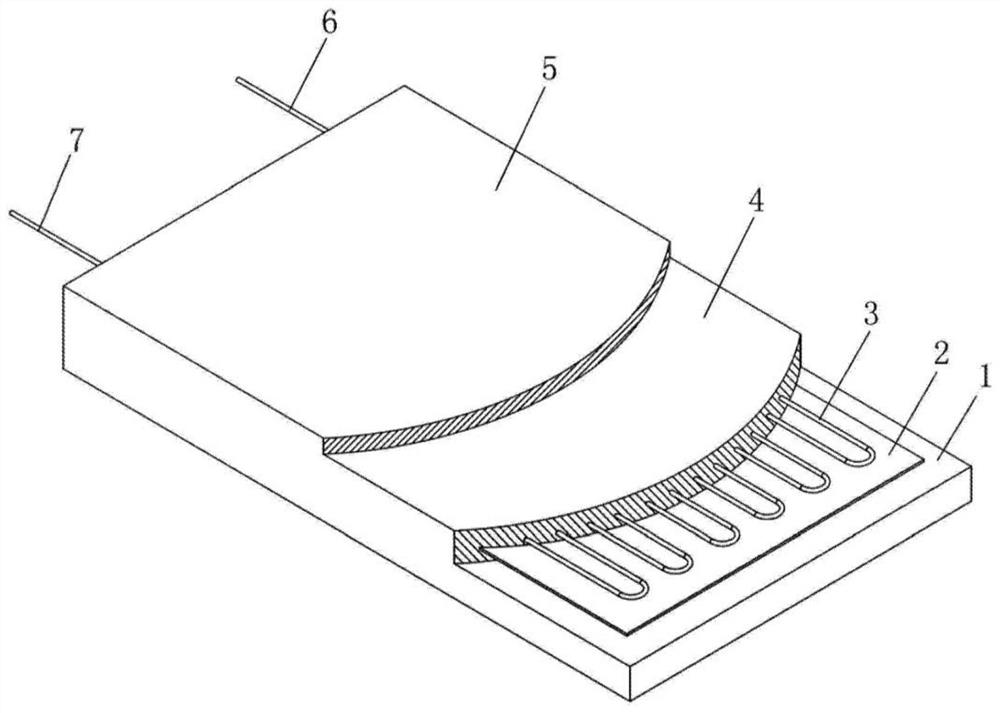

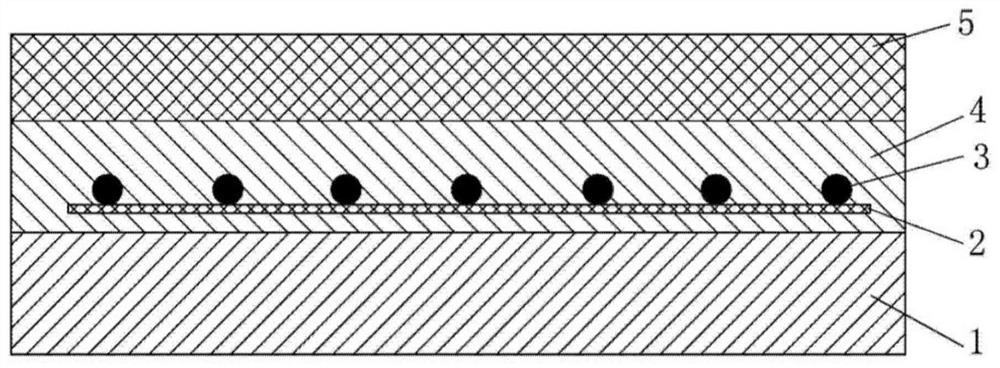

A technology for wall and floor tiles and electric heating, which is applied in chemical instruments and methods, clay preparation devices, ceramic products, etc., can solve the problems of inconvenient maintenance, difficult construction, low thermal efficiency, etc., and achieves reduced heat loss and good cold-heat cycle performance. , the effect of reducing heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

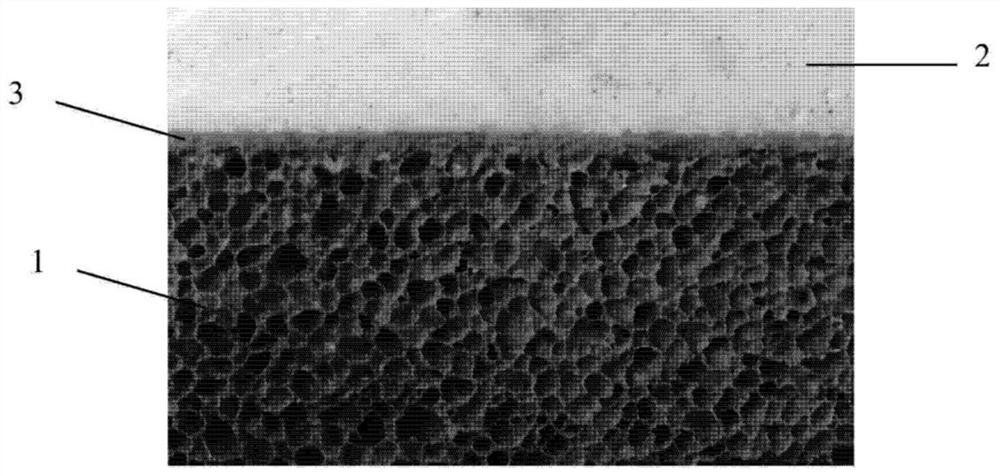

[0032] In terms of weight percentage, the composition of the brick matrix layer mixture is as follows: 60% of pyrophyllite, 20% of Zibo quartz, 20% of albite, and 0.5% of cobalt blue;

[0033] In terms of weight percentage, the composition of the non-metallic conductive layer mixture is as follows: flake graphite 15%, bentonite 60%, iron ore waste slag 15%, albite feldspar 10%;

[0034] In terms of weight percentage, the composition of the foamed ceramic insulation layer mixture is as follows: 60% of polished brick waste, 30% of shale, 8% of potassium feldspar, 2% of black mud, and 0.5% of silicon carbide.

[0035] in:

[0036] The main components and content of pyrophyllite are: SiO 2 45~55%, Al 2 o 3 22~35%, Fe 2 o 3 0.1~3.0%, TiO 2 0.1~3.0%, CaO0.1~2.0%, MgO0.1~2.0%, K 2 O0.1~1.0%, Na 2 O0.1~1.0%, loss on ignition ≤10%.

[0037] The main composition and content of Zibo quartz are: SiO 2 95~99%, Al 2 o 3 0.1~3%, Fe 2 o 3 0~3.0%, TiO 2 0~3.0%, CaO0~2.0%, MgO0~2...

Embodiment 2

[0056] In terms of weight percentage, the composition of the brick matrix layer mixture is as follows: pyrophyllite 40%, ball clay 20%, quartzite 10%, potassium feldspar 30%, and praseodymium yellow 0.5%;

[0057] In terms of weight percentage, the composition of the non-metallic conductive layer mixture is as follows: 10% carbon black, 70% xingzi kaolin, 10% red mud, 5% albite, and 5% potassium feldspar;

[0058] In terms of weight percentage, the composition of the foamed ceramic insulation layer mixture is as follows: 85% of shale, 8% of potassium feldspar, 5% of albite, 2% of ball clay, and 5% of calcium carbonate.

[0059] in:

[0060] The main components and content of pyrophyllite are: SiO 2 45~55%, Al 2 o 3 22~35%, Fe 2 o 3 0.1~3.0%, TiO 2 0.1~3.0%, CaO0.1~2.0%, MgO0.1~2.0%, K2 O0.1~1.0%, Na 2 O0.1~1.0%, loss on ignition ≤10%.

[0061] The main composition and content of quartzite are: SiO 2 95~99%, Al 2 o 3 0.1~3%, Fe 2 o 3 0~3.0%, TiO 2 0~3.0%, CaO0~2.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com