Novel microcrystalline arc plate mould

A microcrystalline and arc-shaped technology, applied in the field of building materials, can solve the problems of high production cost, long production cycle and low application efficiency, and achieve the effect of high application efficiency, accurate size and small heat storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following is a further description of the present invention in conjunction with the accompanying drawings and embodiments.

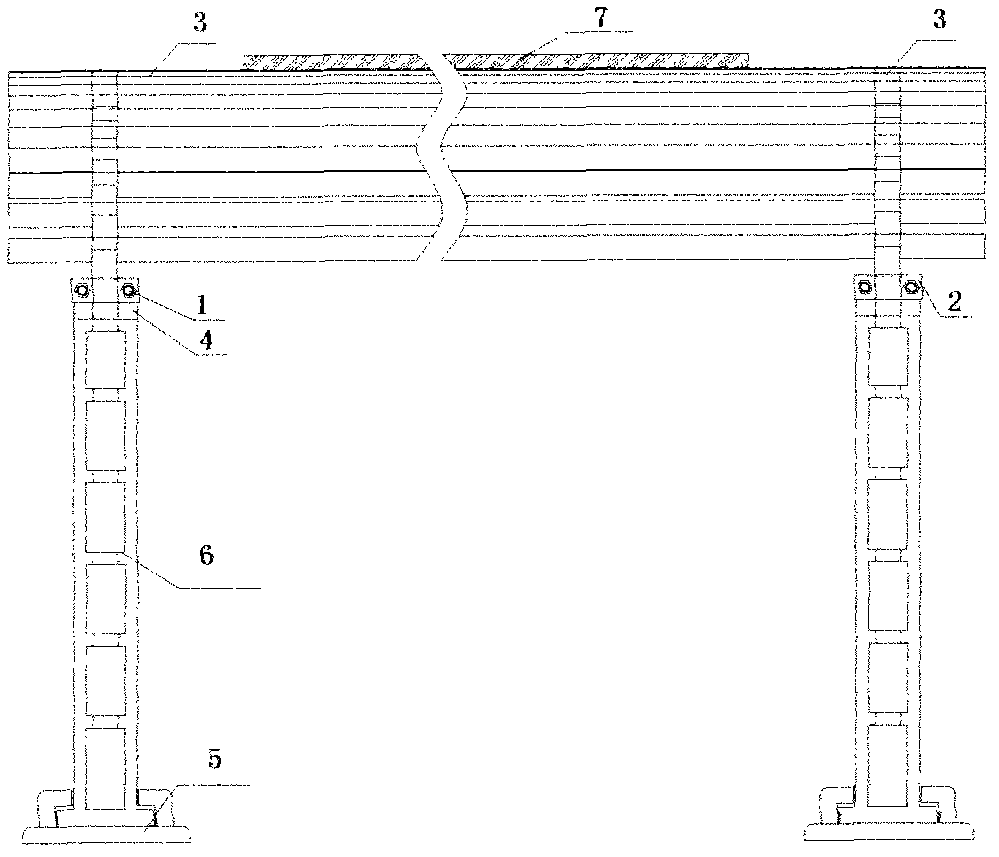

[0012] A novel microcrystalline arc-shaped plate mold of the present invention is composed of ceramic bolts (1), ceramic fasteners (2), ceramic rods (3), cordierite-mullite casing plate (4), cordierite-mullite It consists of a stone fixing frame (5), a cordierite-mullite pillar (6) and the like. The cordierite-mullite fixing frame (5) is used as a mold base, and the hollow cordierite-mullite pillar (6) is clamped, and the ceramic rod (3) is inserted in the cordierite-mullite pillar (6), And use the cordierite-mullite sleeve plate (4) to enclose the ceramic rods (3) and connect them in rows, and then use ceramic fasteners (2) and ceramic bolts (1) to fix the ceramic rods (3). Then it can be heated in the kiln using the principle of hot bending, and finally a microcrystalline arc plate is formed. After cooling, take it out of the mold directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com