Kiln furniture structure with height-adjustable shelf board

A shed board and height technology, applied in the field of stable connection structure between kiln furniture, can solve the problems that affect the aesthetics of ceramic products, product quality, excessive temperature difference between the upper and lower pre-tropical zones, and increase the labor intensity of workers, etc., to reduce the temperature difference between the upper and lower Effects of temperature instability, enhanced stability, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

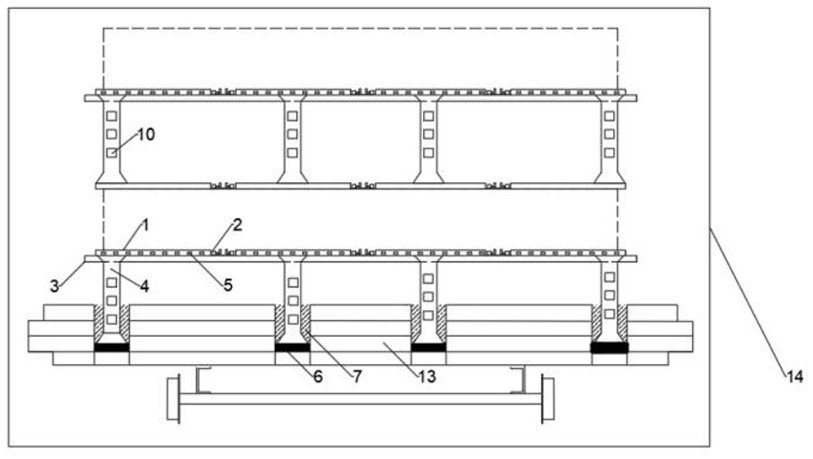

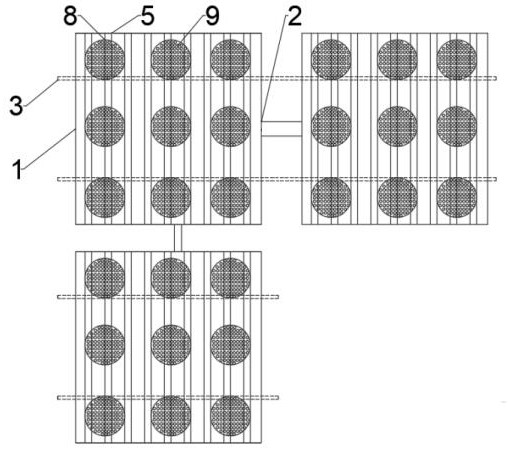

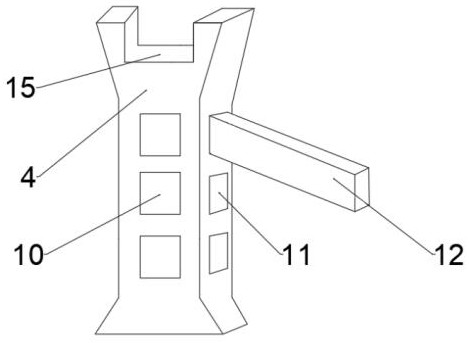

[0021] The present invention will be further described below in conjunction with the accompanying drawings:

[0022] like Figure 1-4 As shown, a stable connection structure of kiln furniture with adjustable shelf plate height of a tunnel kiln includes several shelf plates 1, several shelf plate connectors 2, several beams 3, several vertical columns 4, flow channels 5, energy-saving sand 6, high Pure blanket 7, circular channel 8, circular small hole 9, beam hole 10, side beam hole 11, several side beams 12, several refractory bricks 13, kiln car 14 and U-shaped groove 15.

[0023] From the table top of the kiln car to the bottom shed 1, it is supported by uprights 4, which are inserted into the lower refractory bricks 13 and filled with energy-saving sand 6 and high-purity blankets 7. The uprights 4 are distributed on the front and rear sides of the shelf plate 1 and are set up symmetrically, and the beams 3 are placed at the U-shaped grooves 15 of the uprights 4 .

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com