Bottom flue gas passage structure of electrode calcination furnace with cap

A flue gas channel and roasting furnace technology, which is applied in the field of flue gas channel structure at the bottom of the covered electrode roasting furnace, can solve the problem of large resistance loss of the flue gas channel at the bottom of the covered electrode roasting furnace, large heat storage capacity and structural strength. To improve the quality of electrode roasting, reduce the amount of flue gas, and improve the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

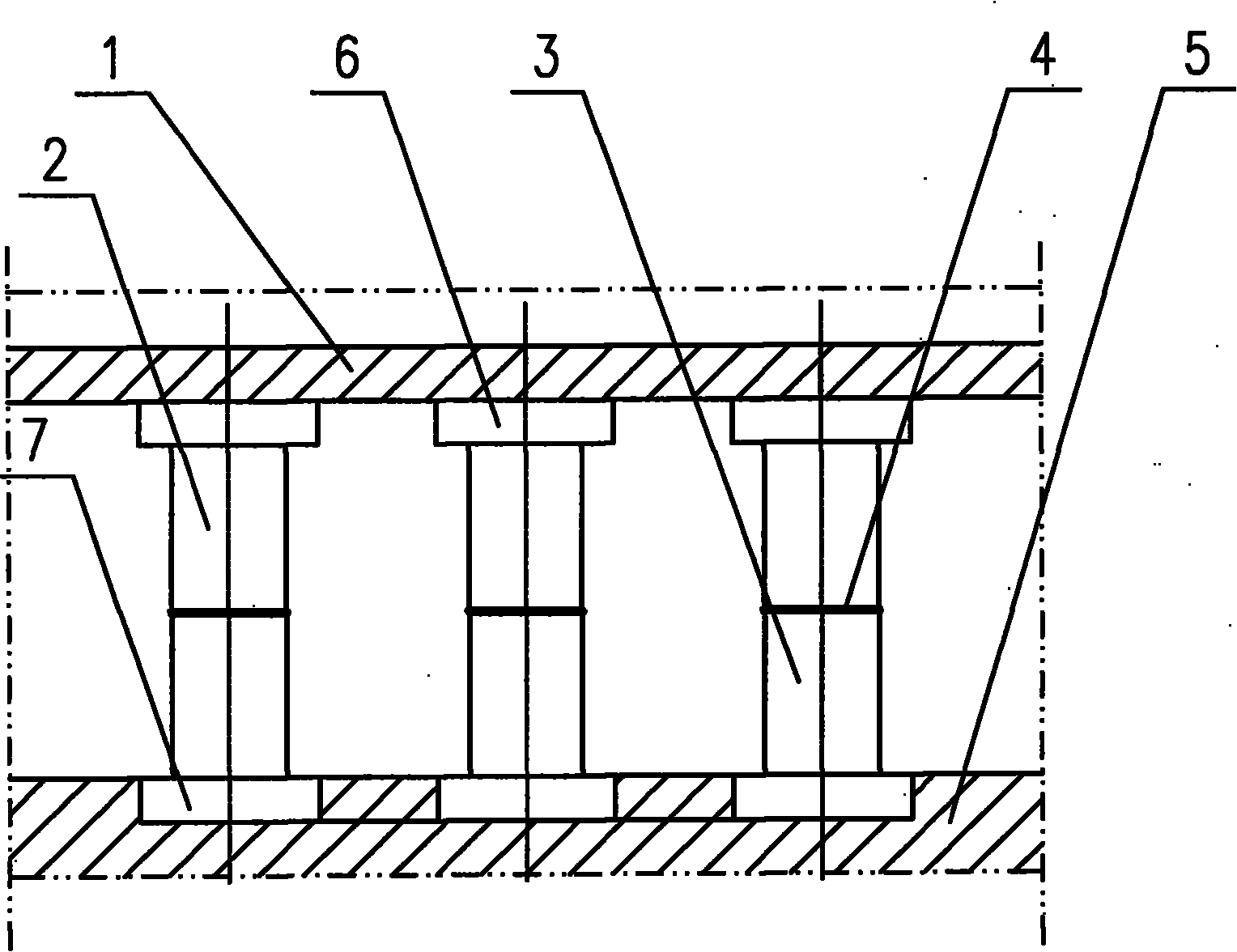

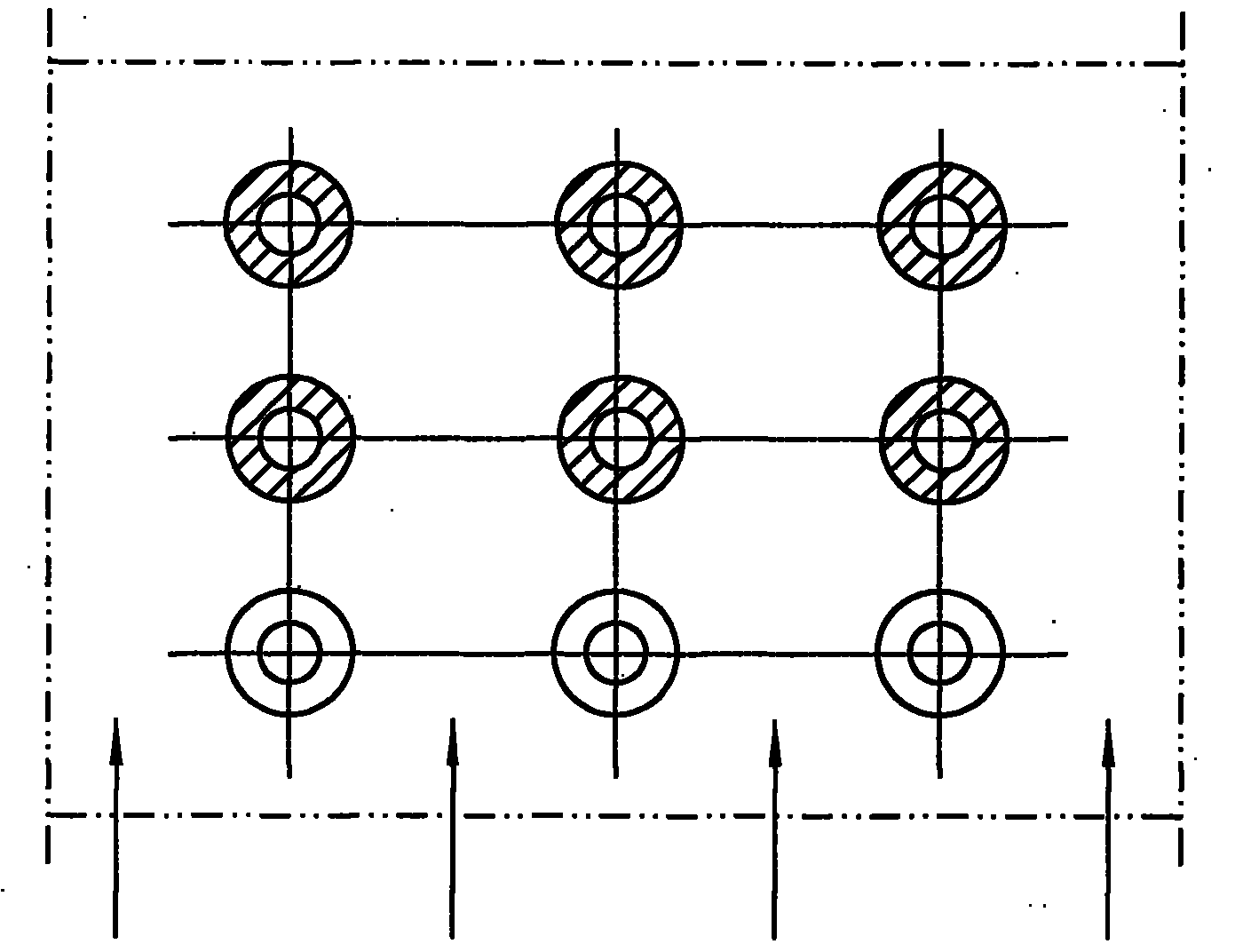

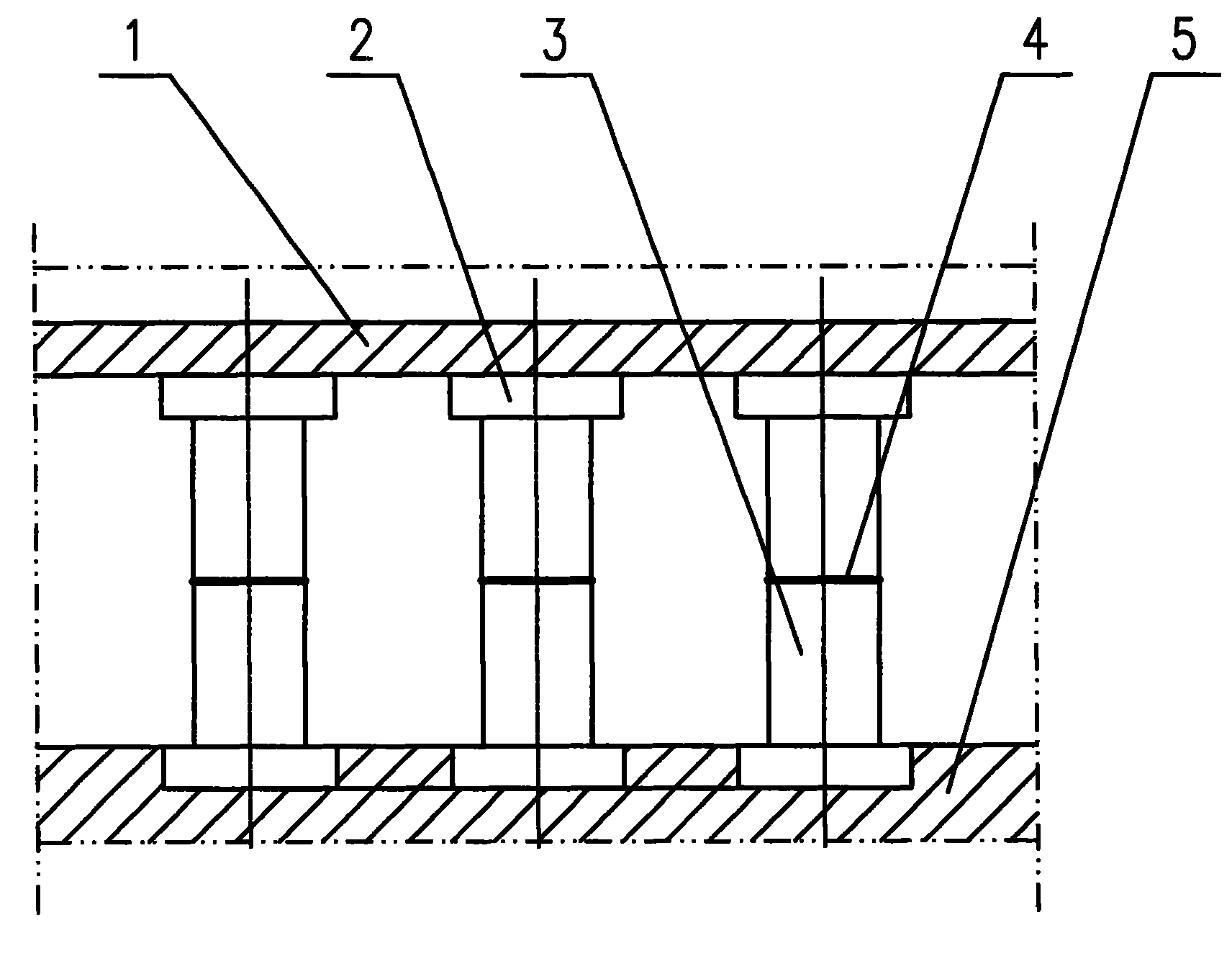

[0025] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments. Arrows point to the direction of flue gas flow.

[0026] As shown in the figure, the flue gas passage structure at the bottom of the electrode roasting furnace with a cover of the present invention is provided with a kang pier between the furnace bottom masonry 5 and the kang face brick 1, and the kang pier is composed of an upper section of the kang pier brick 2 and a lower section of the kang pier brick 3 forms, is provided with support cap 6 on the top of cut kang pier brick 2, and support cap 6 upper surface is solid plane; On the support cap upper surface of section cut kang pier brick 2, be coated with refractory mud; The shape of support cap 6 is Rectangular, its thickness is 80~300mm, and side length size is 150~400mm, and the inside of the upper cut kang pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com