Multi-stage shielding electric pump comprising inner circulating hole

A technology of shielding electric pump and internal circulation, which is applied to the components, pumps, pump devices and other directions of pumping devices for elastic fluids, can solve the problems of increasing the connection structure, reducing the safety, increasing the pipeline, etc., and achieves structural safety. Reliable, reduce flow loss, increase the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

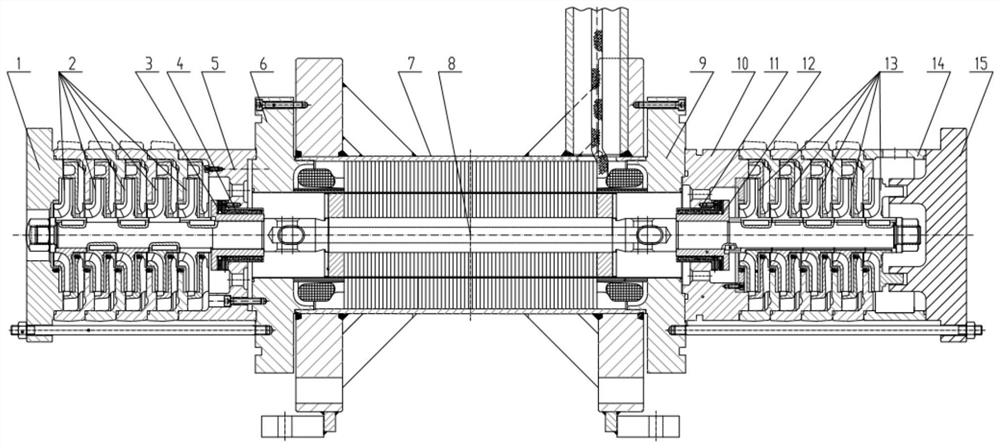

[0023] This embodiment discloses a multi-stage shielded electric pump with internal circulation holes, the structure of which is as follows Figure 1-2 As shown, it includes a shielded motor stator housing 7, a front impeller group and a rear impeller group. The inner side of the shielded motor stator housing 7 is covered with non-magnetic Hastelloy to avoid the invasion and damage of the conveying medium. The shielded motor stator casing 7 is provided with a shielded electric pump shaft rotor assembly 8, and an air gap is provided between the shielded motor stator casing 7 and the shielded electric pump shaft rotor assembly 8 (the air gap is generally about 2 mm to 3 mm ), the chamber of the front impeller group 2 communicates with the air gap.

[0024] The rotor shaft of the shielded electric pump shaft rotor assembly 8 is a hollow shaft, and the central hole diameter of the hollow shaft is determined according to the design of the motor and the design of the circulation cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com