Airflow transportation method for vertical roller mill airflow device of cement raw material slag

A vertical roller mill and cement raw material technology, applied in cement production, grain processing, etc., can solve the problems of increased wear of nozzle rings, increased number of shutdowns for maintenance, and increased operating power of system fans, so as to reduce the probability of circulation and cycle The effect of reducing the number of times, reducing airflow turbulence, and low conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

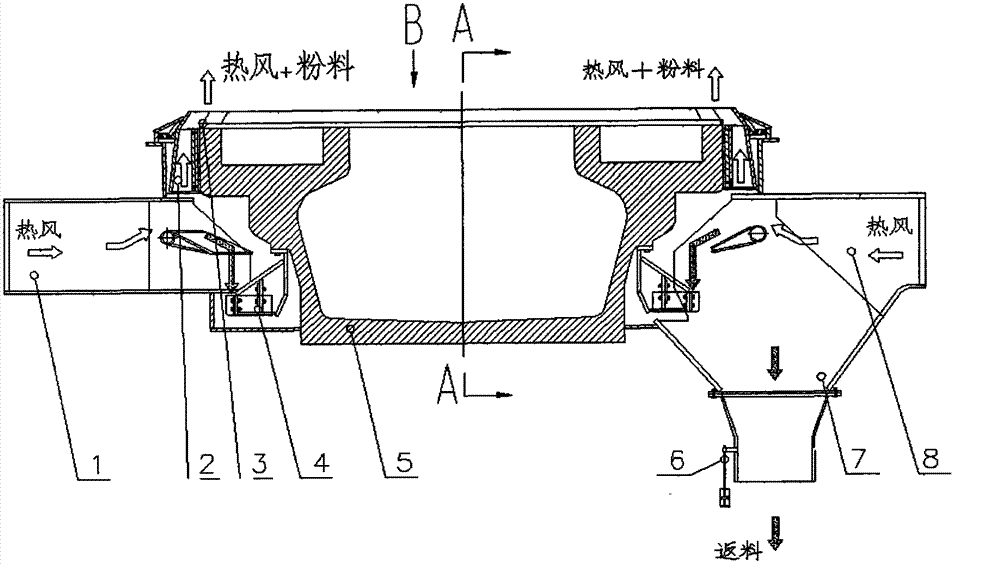

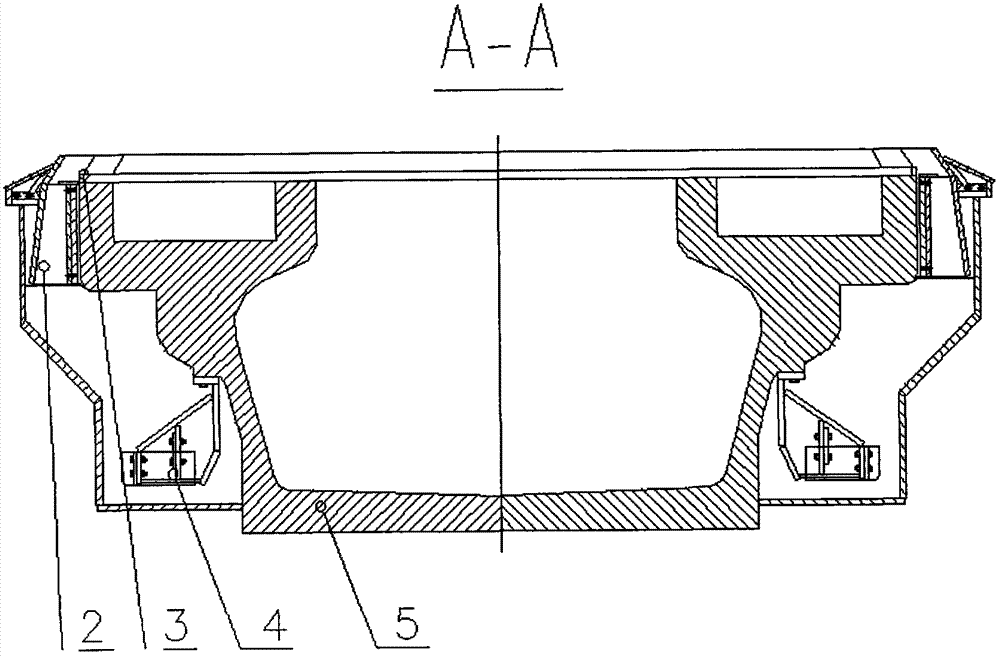

[0035] Such as figure 1 As shown: the lower barrel body is set on the middle and lower part of the periphery of the millstone 5, the nozzle ring 2 is set on the upper part of the periphery of the millstone 5, and the material retaining ring 3 is set on the upper edge of the millstone 5; the two sides of the lower barrel body of the millstone 5 are symmetrically reserved for air inlets, and one side The outlet end of the free-end air inlet 1 box is set in the air inlet; the outlet end of the air inlet 8 at the return end is set in the air inlet on the other side, and the return collection cone 7 is set at the lower port of the air inlet 8 at the return end. The lower opening of the return material collection cone 7 is provided with an air-lock flap ash unloading valve 6; a boss is arranged in the middle of the periphery of the grinding disc 5, and at least eight wear-resistant scrapers 4 are evenly distributed and fixed under the boss, and the wear-resistant scraper 4 is arrange...

Embodiment 2

[0037] Such as Figure 1-9 Shown: Free end upper cover plate 9 is set above the free end air inlet 1 box body, free end lower cover plate 10 is set below, free end upper cover plate 9 and free end lower cover plate 10 are respectively set free end left The baffle plate 11, the right side is provided with the free end right baffle plate 13; the air inlet 1 box body of the free end is set as two box sections, the inlet end is provided with an air inlet section, and the outlet end is provided with a wind guide section; the air inlet section box body is free The middle part between the end upper cover plate 9 and the free end lower cover plate 10 is provided with a free end middle partition 12; Annular material guide reinforcement tube 14, guide material upper wear-resistant plate 15 is arranged above the guide material reinforcement tube 14, guide material lower wear-resistant plate 16 is arranged below, guide material lower wear-resistant plate 16 and guide material upper wear-r...

Embodiment 3

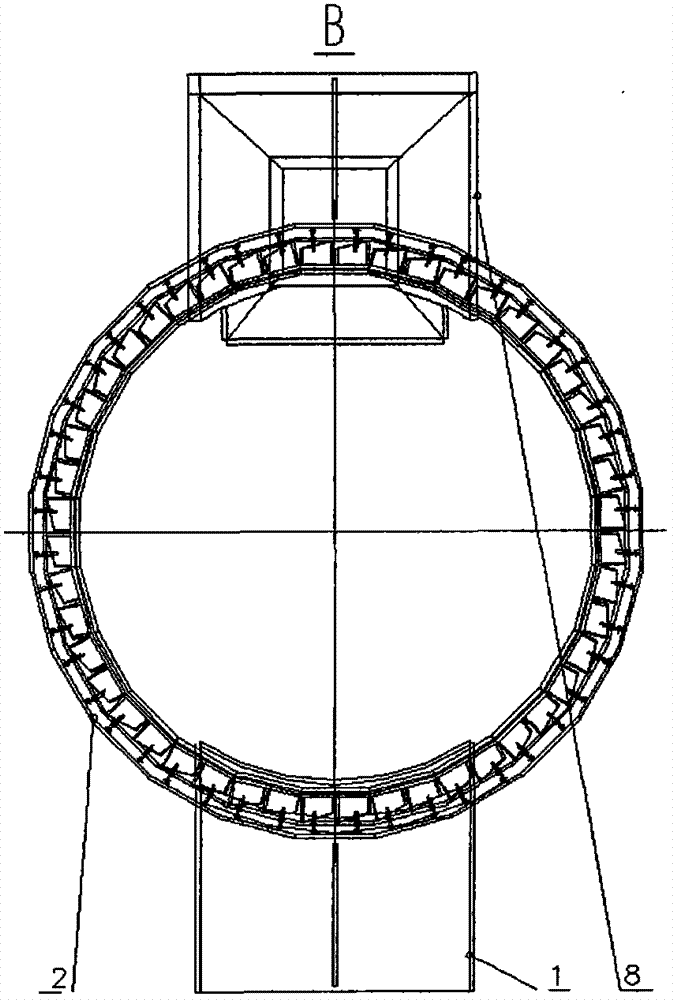

[0039] Such as figure 1 .10.11.12.13 shows: the nozzle ring 2 is an annular cavity, and at least eight units are arranged in the annular cavity, and the hot air flow passes between each unit. The nozzle ring support plate 25 is arranged on the outer side, and at least six pairs of corresponding grooves are arranged on the surface of the nozzle ring inner baffle 27 and the nozzle ring support plate 25. Nozzle ring wear-resistant guide vanes 26 are arranged in the groove; a nozzle ring adjustment plate 24 is arranged on the upper end of the inner baffle plate 27 of the nozzle ring, and a wind guide material baffle is arranged on the upper end of the nozzle ring support plate 25 of the nozzle ring 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com