Hollow pedicle screw with oval side hole

A pedicle screw and oval technology, applied in the field of vertebral surgery, can solve problems such as uneven outflow of bone cement, and achieve the effects of reducing local resistance loss and high injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

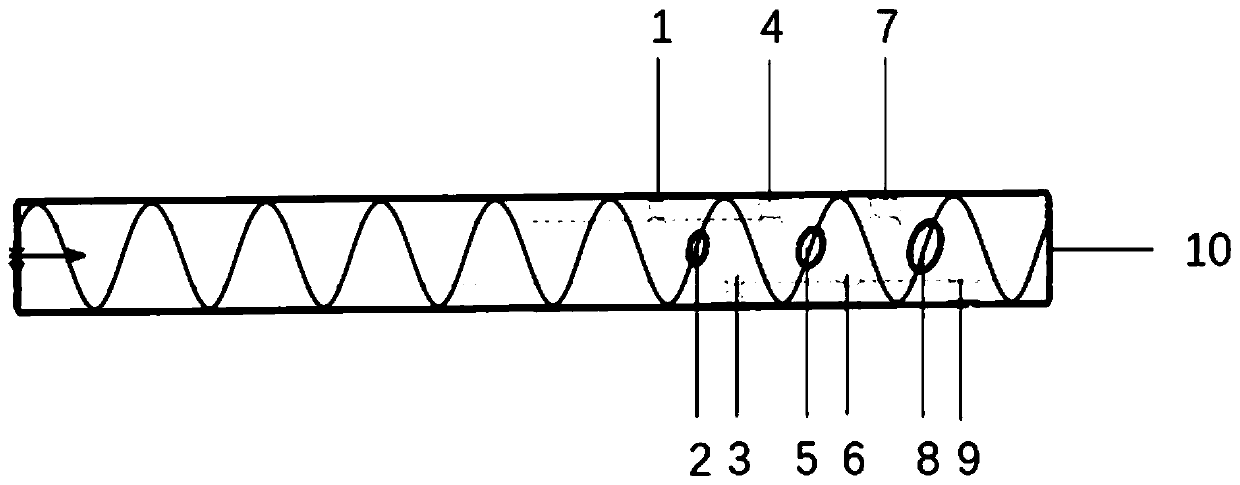

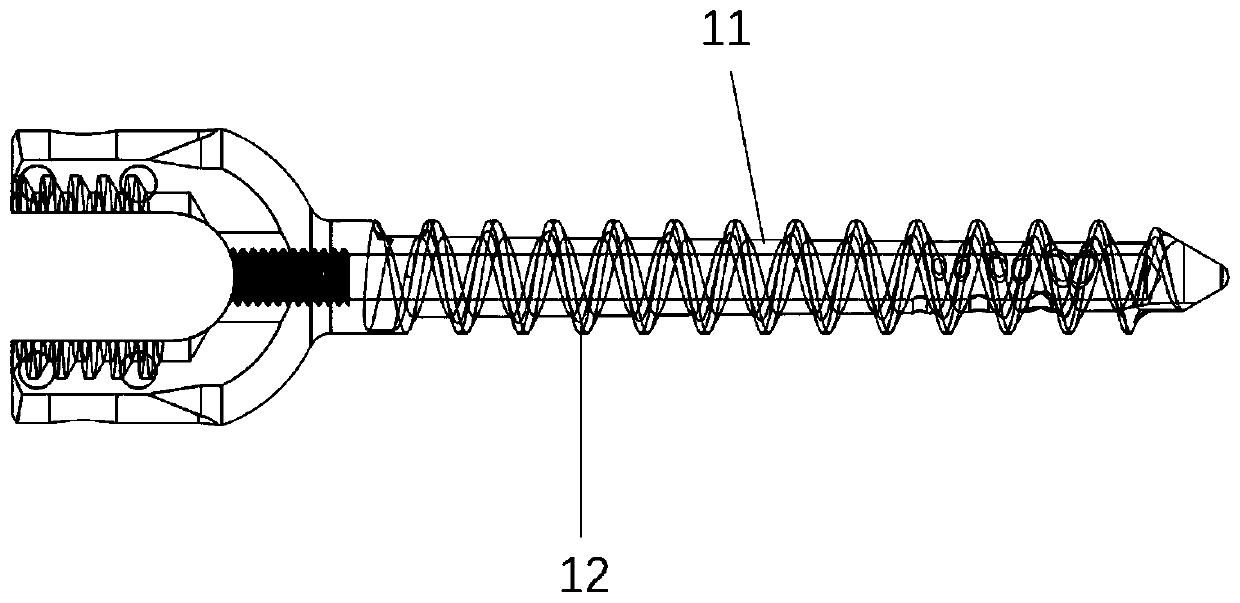

[0027] combine Figure 1-2 As shown, a hollow pedicle screw with an elliptical side hole includes a screw body 11, the screw body 11 is hollow and the end is penetrated; the screw body 11 is provided with an external thread section 12; the external thread section There are side holes distributed on the third of the distal end of 12, specifically nine bone cement outflow holes 1 to 9 penetrating through the unilateral side wall of the screw body, and three bone cement outflow holes are arranged along each thread, arranged at equal intervals , the size of bone cement injection hole 1 to hole 9 increases along the nail depth direction; that is, the size of the major and minor semi-axes of the elliptical hole increases in a parabolic manner.

[0028] The side holes are distributed along the thread line of the external thread segment 12, and there are 3 side holes in each circle with a mutual interval of 120°; the side holes are elliptical. The central axis of the side hole is per...

Embodiment 2

[0037] Two types of pedicle screws were designed according to the method of Example 1, and the hollow channels of the nails were 1.6 mm and 2.1 mm, respectively. The side holes of these two pedicle screws were optimized separately, so that the perfused bone cement could flow out evenly from each side hole.

[0038] The optimization schemes of the two hollow pedicle screws are shown in Table 1.

[0039] Table 1 screw optimization scheme

[0040]

[0041] Note: Table 1 is the screw optimization scheme, and 5 schemes are designed for the screws with the through hole diameters of 2.1mm and 1.6mm respectively. Among them, NO.01 and NO.06 are control groups with the same side hole size.

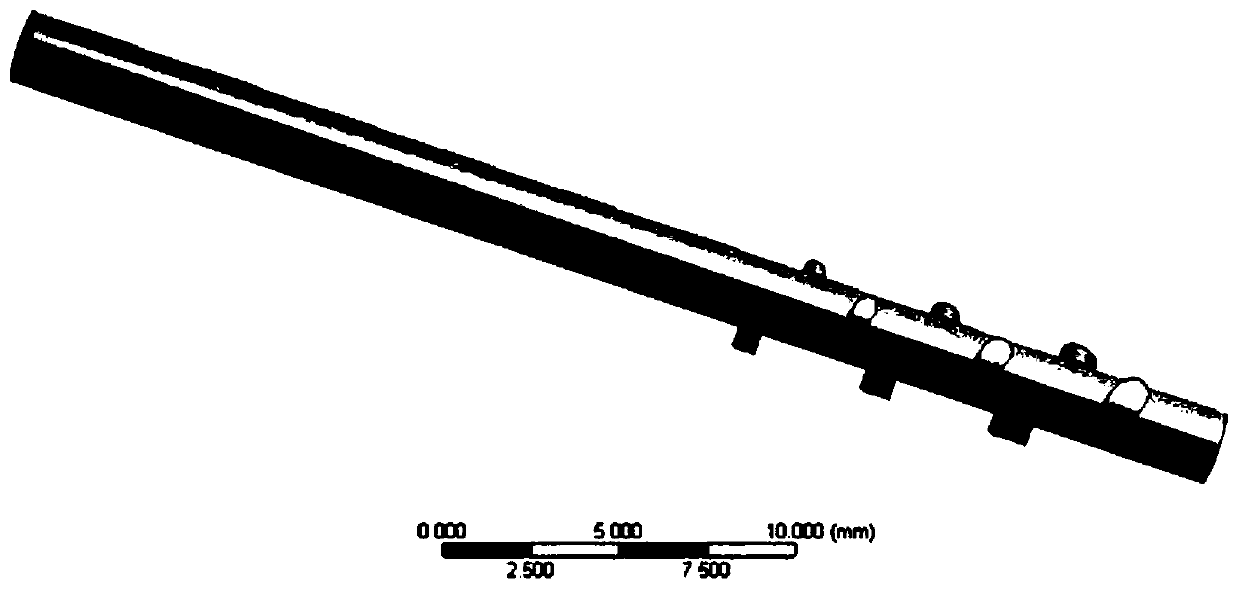

[0042] Such as image 3 As shown in , the inner channel area of the hollow pedicle screw was extracted to establish a flow field model.

[0043] Divide the tetrahedral grid for the flow field area in the nail channel, such as Figure 4 As shown, a total of 283,362 nodes and 1,579,725 unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com