Leakproof interface flange for connecting water pump

An interface flange and water pump technology, which is applied to the components of the pumping device for elastic fluids, pump components, variable displacement pump components, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The leak-proof interface flange used for connecting the water pump of the present invention will be further described below.

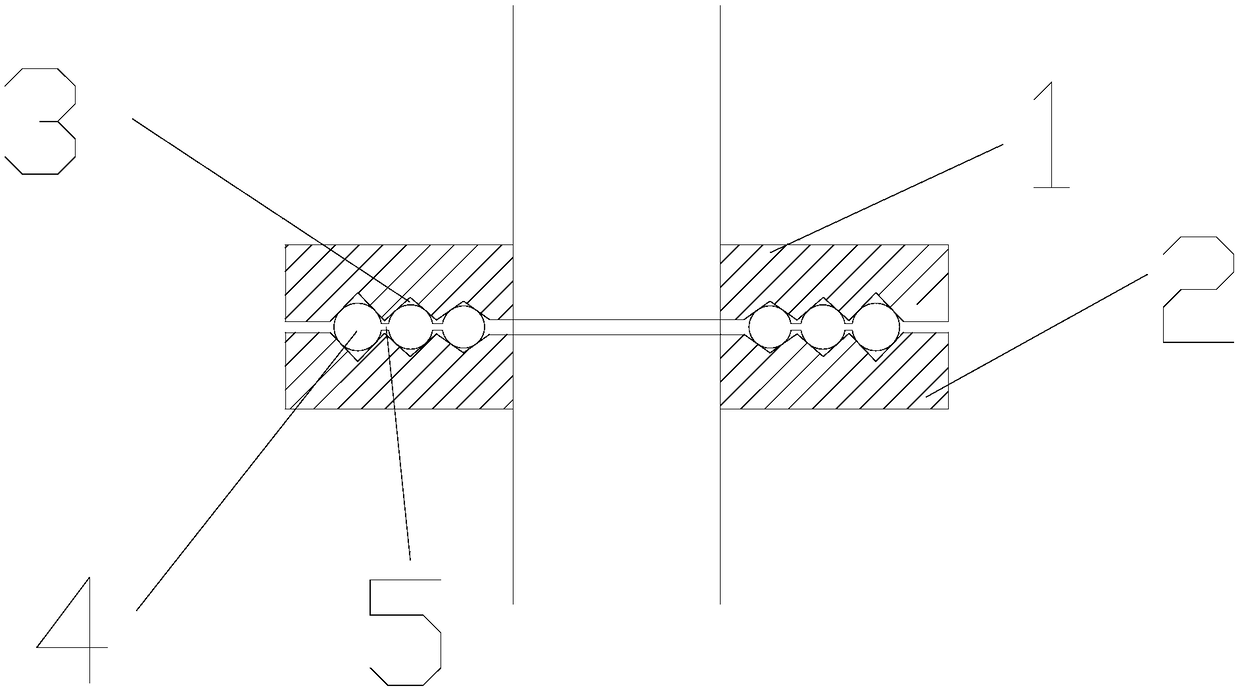

[0011] Leakproof connection flange for connection to the pump, see figure 1 , including the first flange 1 and the second flange 2; the first flange 1 and the middle of the second flange 2 are provided with a group of annular grooves 3 opposite; each annular groove is provided with an annular gasket 4; the annular groove The number of grooves 3 is more than two; the adjacent annular gaskets 4 are connected by annular flat gaskets 5; the longitudinal section of the annular gaskets 4 is a prototype, and the longitudinal section of the annular flat gaskets 5 is square; the diameter of the annular gaskets 4 is slightly larger than that of the annular gaskets. Groove 3. The height of the annular groove 3 is the same as the thickness of the compressed limit of the annular gasket 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com