Heat holding furnace for drafting machine

A technology of heating and heat preservation and drawing machine, which is applied in the direction of textiles and papermaking, can solve the problems of large heat loss and high energy consumption, and achieve the effects of fast response, long service life and avoiding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

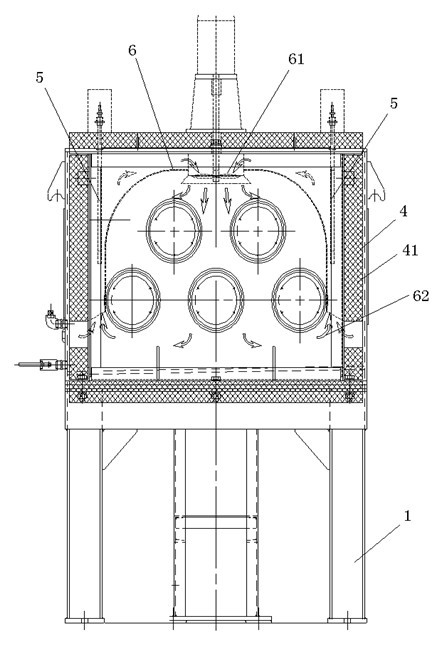

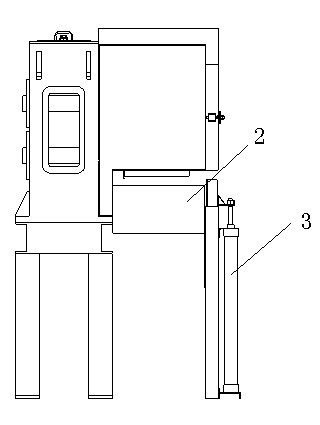

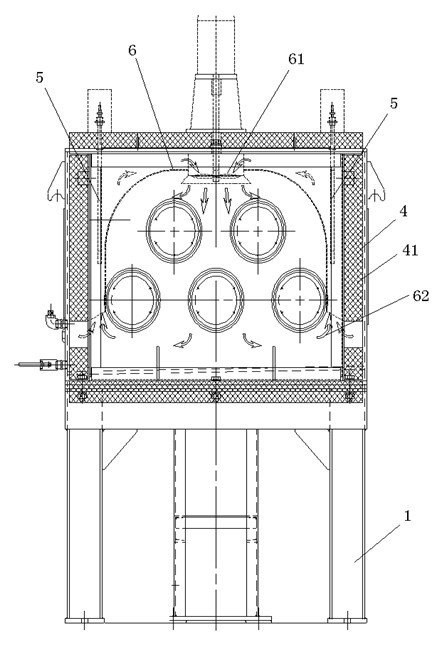

[0013] A closed five-roll drafting machine heating and holding furnace, see figure 1 with figure 2 The heating and holding furnace includes a shell 1, a furnace door 2, a furnace door lifting mechanism 3, a furnace lining 4, a heating element 5 and a hot air circulation system 6, and the furnace door 2 is arranged on the shell 1 and connected with the furnace door lifting mechanism 3. The furnace lining 4 is fixed on the casing 1, and a thermal insulation layer 41 is provided on the furnace lining 4; the heating element 5 is arranged in the casing 1 and located on both sides of the furnace. The hot air circulation system 6 includes a circulating fan 61 and an air duct 62 in the furnace. The circulating fan 61 blows the heat of the heating element 5 into the working area through the air duct 62 in the furnace.

[0014] Concrete reference of the present invention is as follows:

[0015] 1. Maximum temperature: 250°C

[0016] 2. Working temperature: 120-200℃

[0017] 3. Heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com