Phase-change energy storage heat-insulation solid wood and manufacturing method thereof

A phase change energy storage and manufacturing method technology, which is applied in the directions of heat preservation, manufacturing tools, wood treatment, etc., can solve the problems of not being able to create a comfortable space environment for the human body, and the effect of heat insulation and heat preservation is not ideal, so as to improve the efficiency of impregnation treatment and improve the Latent heat of phase change and the effect of efficient adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

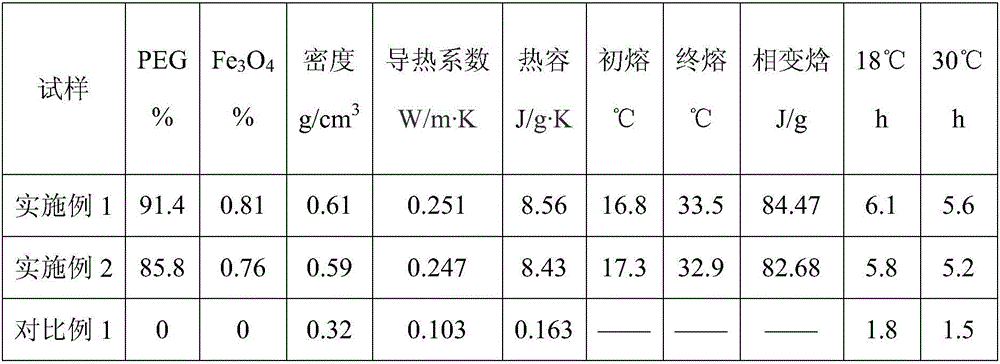

Examples

Embodiment 1

[0048] A thermal insulation solid wood with phase change energy storage of the present invention, the thermal insulation solid wood includes solid wood components, and magnetic Fe is attached and grown in situ in the wood conduits and cell cavities of the solid wood components themselves. 3 o 4 Nano particles, impregnated and filled with PEG-600 and PEG-800 composite phase change energy storage materials, and coated with polyurethane protective coating on the surface of thermal insulation solid wood.

[0049] The manufacturing method of the phase change energy storage thermal insulation solid wood comprises the following steps:

[0050] (1) Select poplar boards with no defects such as rot, moth, stuttering, and cracking, and uniform material as the base material, and saw and plan the selected poplar boards into 600mm×300mm×30mm poplar board squares (solid wood components).

[0051] (2) put the poplar plank square prepared in step (1) into the pretreatment tank, add degreasing...

Embodiment 2

[0057] A thermal insulation solid wood with phase change energy storage of the present invention, the thermal insulation solid wood includes solid wood components, and magnetic Fe is attached and grown in situ in the wood conduits and cell cavities of the solid wood components themselves. 3 o 4 Nano particles, impregnated and filled with PEG-600 and PEG-800 composite phase change energy storage materials, and coated with polyurethane protective coating on the surface of thermal insulation solid wood.

[0058] The manufacturing method of the phase change energy storage thermal insulation solid wood comprises the following steps:

[0059] (1) Select poplar boards with no defects such as rot, moth, stuttering and cracking, and uniform material as solid wood components, and saw and plan the selected poplar boards into poplar board squares of 600mm×300mm×30mm.

[0060] (2) put the poplar plank square prepared in step (1) into the pretreatment tank, add degreasing liquid (this degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com