Multi-section servo submersible motor

A submersible motor and motor shaft technology, applied in the field of servo motors, can solve the problems of low motor efficiency and power factor, low oil production cost, low system efficiency, and low system efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

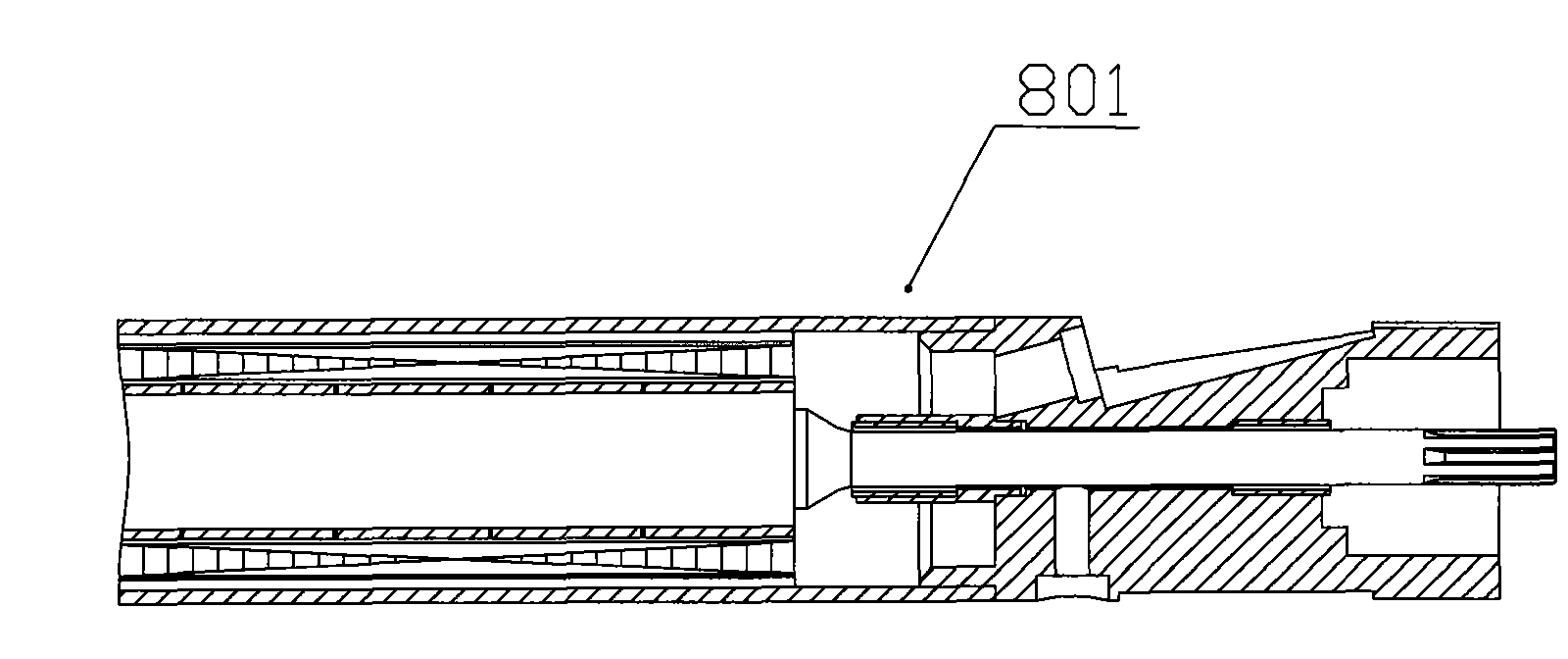

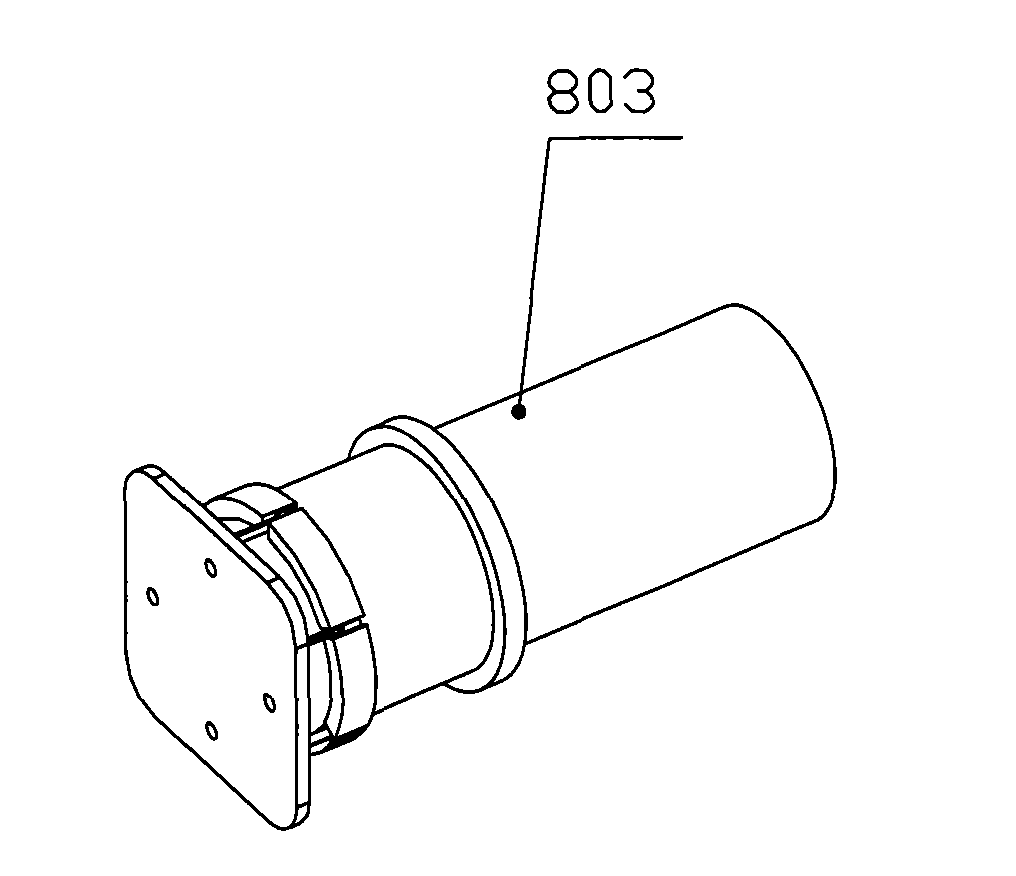

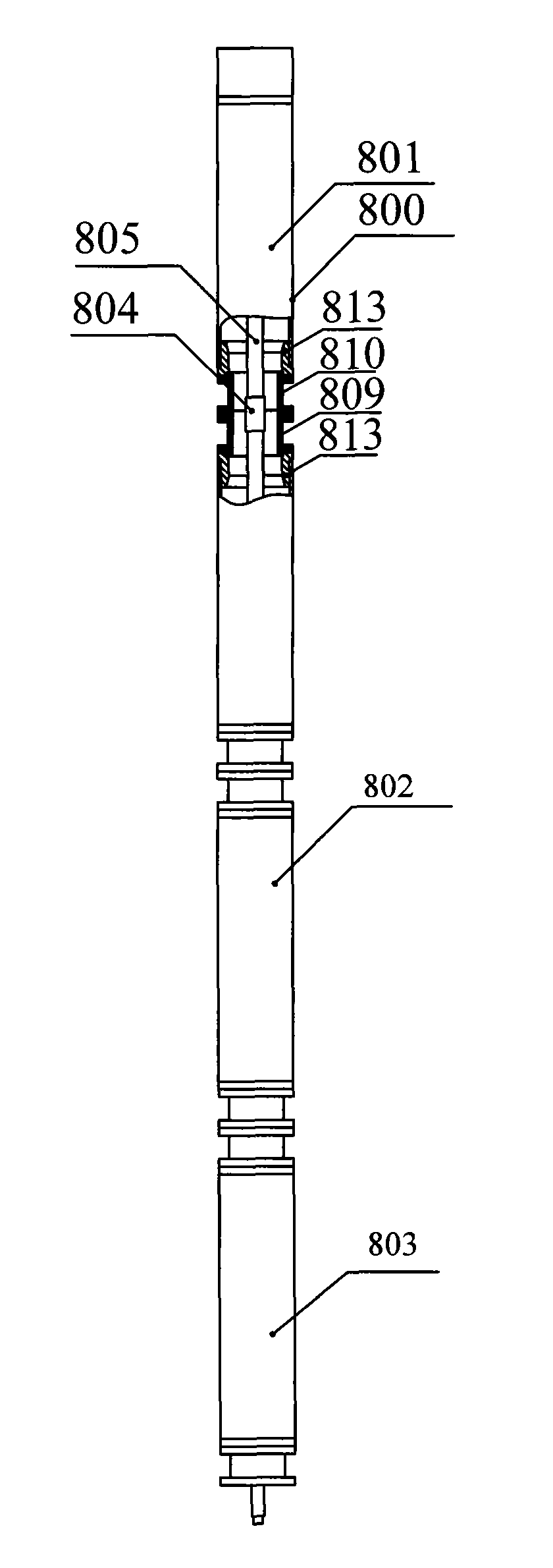

[0125] figure 1 , figure 2 They are respectively the internal structure schematic diagrams of the first section and the last section of the present invention. combine image 3 As shown, in order to solve the above problems, the present invention provides a permanent magnet synchronous servo motor in a multi-section form, in order to provide greater power. image 3 It is a schematic diagram of permanent magnet synchronous servo submersible motor with four motors connected by threads and flanges. Figure 4 It is the three-dimensional structure diagram of the permanent magnet synchronous servo submersible motor. The first section motor 801 is at the top of the whole servo motor, and has a motor head (not shown) that is used to connect with the protector; the last section motor 803 is the last section of the servo motor, and the tail is equipped with a motor tail shaft, which is used to install the magnet. The steel ring, the lower flange 810 is connected with the sealing dev...

Embodiment 2

[0127] refer to Figure 5 , Figure 6 It is a schematic diagram of the assembly structure of the permanent magnet synchronous servo submersible motor according to the second embodiment of the present invention. In this embodiment, most of the structures are the same as those in Embodiment 1, and the same structures will not be described again. The difference is that in this embodiment, the middle of every two motors is connected by bolts, and the upper flange and the lower flange are connected to the motor housing by bolts. This form is suitable for the situation when the motor casing is thick enough to screw on the bolts.

Embodiment 3

[0129] refer to Figure 7 , Figure 8 It is a schematic diagram of the assembly structure of the permanent magnet synchronous servo submersible motor according to the third embodiment of the present invention. In this embodiment, most of the structures are the same as those in Embodiment 1, and the same structures will not be described again. The difference is that in this embodiment, every two sections are connected in the middle by bolts. The upper threaded flange 811, the lower threaded flange 812 and the motor housing 800 are connected by threads; the upper threaded flange 811, the lower threaded flange 812 are connected by bolts, and a wide nut 814 is installed on the upper threaded flange 1. Narrow nut 815 two movable nuts, after adjusting the positions of each section of the motor during assembly, complete the assembly of the motor by tightening the two nuts 814, 815, which can prevent the rotation between each section of the motor.

[0130] The two submersible motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com