Pressurizing method of diesel motor aluminium alloy cylinder metal mould low-pressure casting

A diesel engine and low-pressure casting technology, which is applied in the pressure field of low-pressure casting of diesel engine aluminum alloy cylinder metal molds, can solve the problems of low-density castings, holes, and failure to meet sealing requirements, etc., to meet the sealing requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

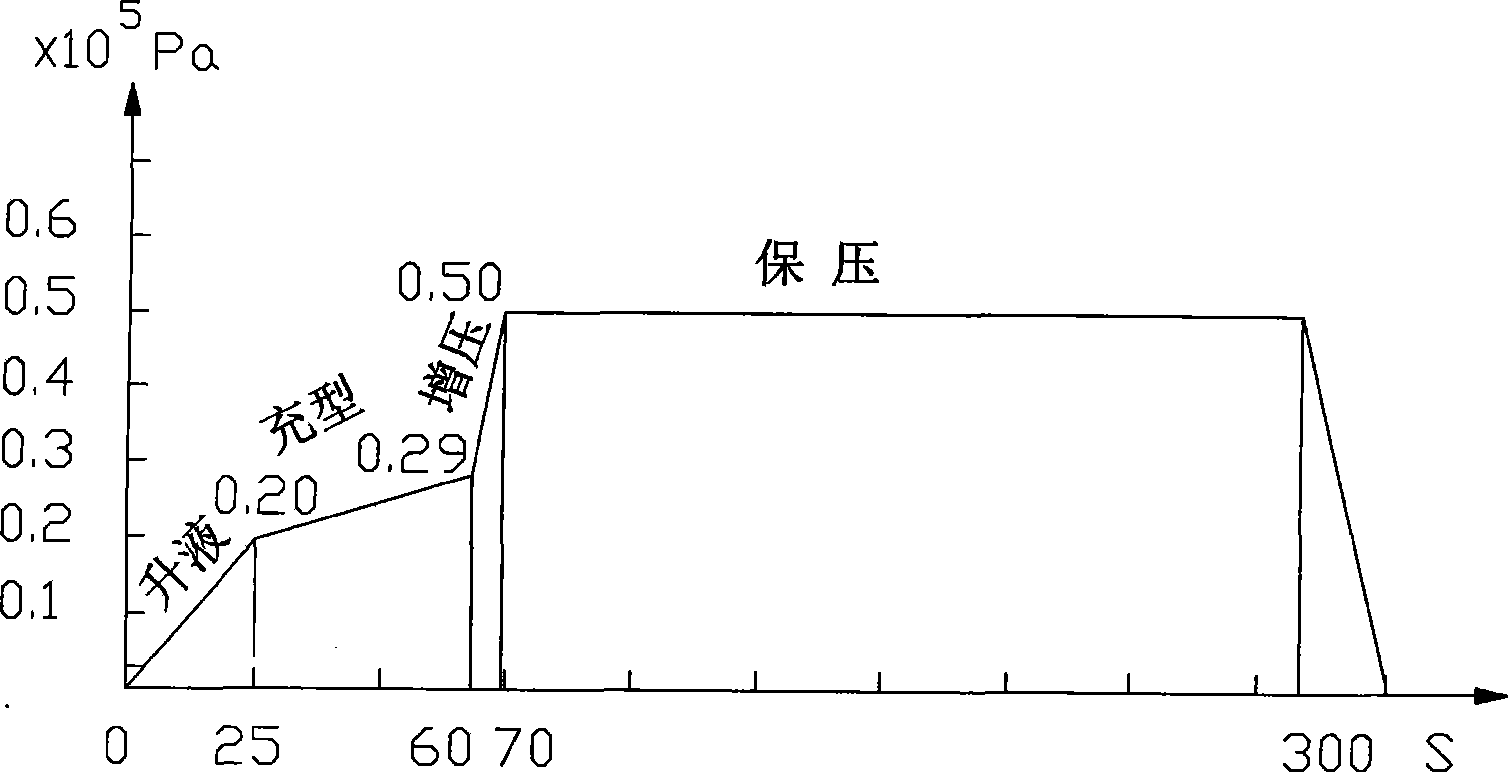

[0023] According to the technical scheme of the present invention, it can be obtained as figure 1 As shown in the casting pressurization curve, as shown in the figure, the entire casting process takes 300-305S. At the beginning, in the equipment, the aluminum liquid in the heat preservation furnace cavity can achieve a pressure from 0Pa to 0.20×10 within 25S. 5 The uniform speed of Pa increases, so that the aluminum liquid rises to the range of the ingate through the riser pipe and the liquid riser basin through the pressure, and prepares for the next filling process; during the period from 25S to 60S, the pressure on the aluminum liquid will be changed from 0.20× 10 5 Pa increases to 0.29×10 at a constant speed 5 Pa, so that the aluminum liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com