Roadbed construction method for soft foundation area

A base and subgrade technology, applied in infrastructure engineering, roads, roads, etc., can solve problems such as difficult construction of subgrades, and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

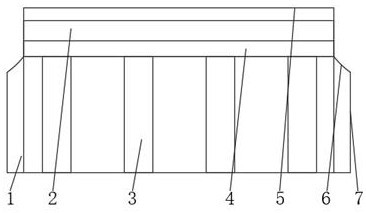

[0032] Such as figure 1 As shown, the embodiment of the present invention provides a method for subgrade construction in a soft ground area, including a main body 7, side layers 1 are arranged on both sides of the main body 7, and mixing piles 3 are provided through the inside of the main body 7 to form a pair of The stability of the roadbed increases the service strength of the roadbed and prevents the subsidence of the roadbed. The upper end of the main body 7 is provided with an adhesive layer 4, the upper end of the adhesive layer 4 is provided with a crushed stone layer 2, and the upper end of the crushed stone layer 2 is provided with an asphalt layer. 5. The upper end of the side layer 1 and the two sides of the gravel layer 2 are provided with arc-shaped sides 6 .

[0033] The asphalt in the asphalt layer 5 seeps into the middle gap of the gravel layer 2, so that the asphalt layer 5 and the gravel layer 2 are effectively bonded to increase the stability of the roadbed,...

Embodiment 2

[0035] A method for subgrade construction in a soft ground area, comprising the following steps:

[0036] S1. Clean up the surface of the roadbed, remove the weeds and large stones on the surface of the roadbed, fill in the potholes, and remove the surface water;

[0037] S2. Set pile driver, mixing pile and drilling rig, and position the mixing pile according to the designed drawings, and position the drilling rig relative to the mixing pile to ensure that the inclination angle of the pile driver is not greater than 0.8%;

[0038] S3. Check the mixing pile before use to avoid blockage of the pipeline and affect the use;

[0039] S4. Prepare a cement material, the cement mixing ratio is 0.4-0.5, the cement content is 13%, the ash content per meter is 46kg, and the superplasticizer is 0.6%;

[0040] S5. Start the drilling rig to drill to the designed position, the drilling speed of the drilling rig is about 350-450mm / min, and start the shotcrete pump to pour the cement at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com