Waste gas and dust treating device

A dust treatment and gas collection device technology, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, can solve environmental pollution and other problems, and achieve the effect of ensuring cleanliness, meeting sealing requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0034] In the prior art, the waste gas and dust generated in the production process of the workshop environment with high cleanliness and tightness requirements such as the clean room of the pharmaceutical factory are usually directly discharged into the outside atmosphere by means of a draft exhaust device. It will pollute the atmosphere, and because the workshop environment communicates with the outside world through the exhaust device, it will affect the cleanliness and sealing of the workshop environment.

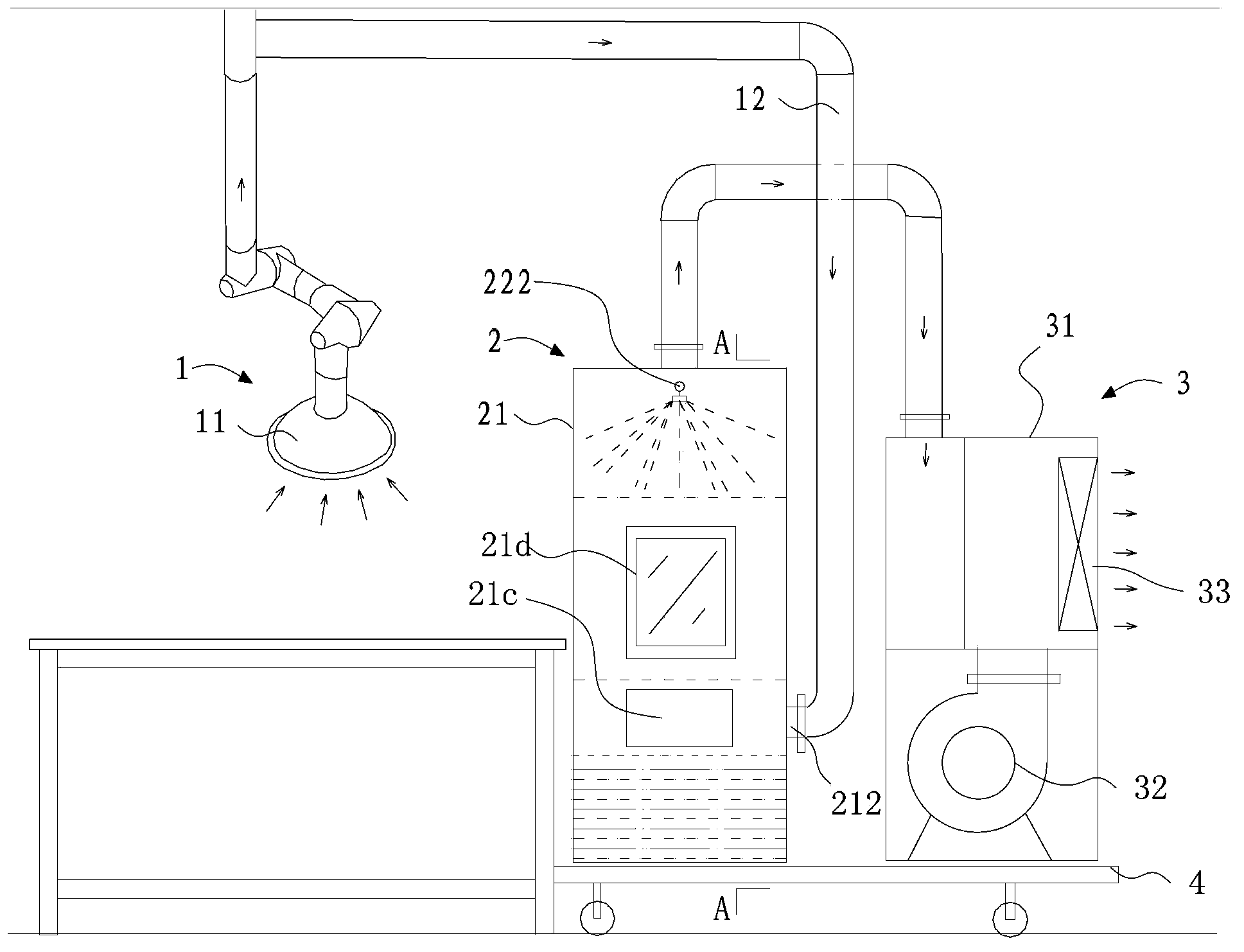

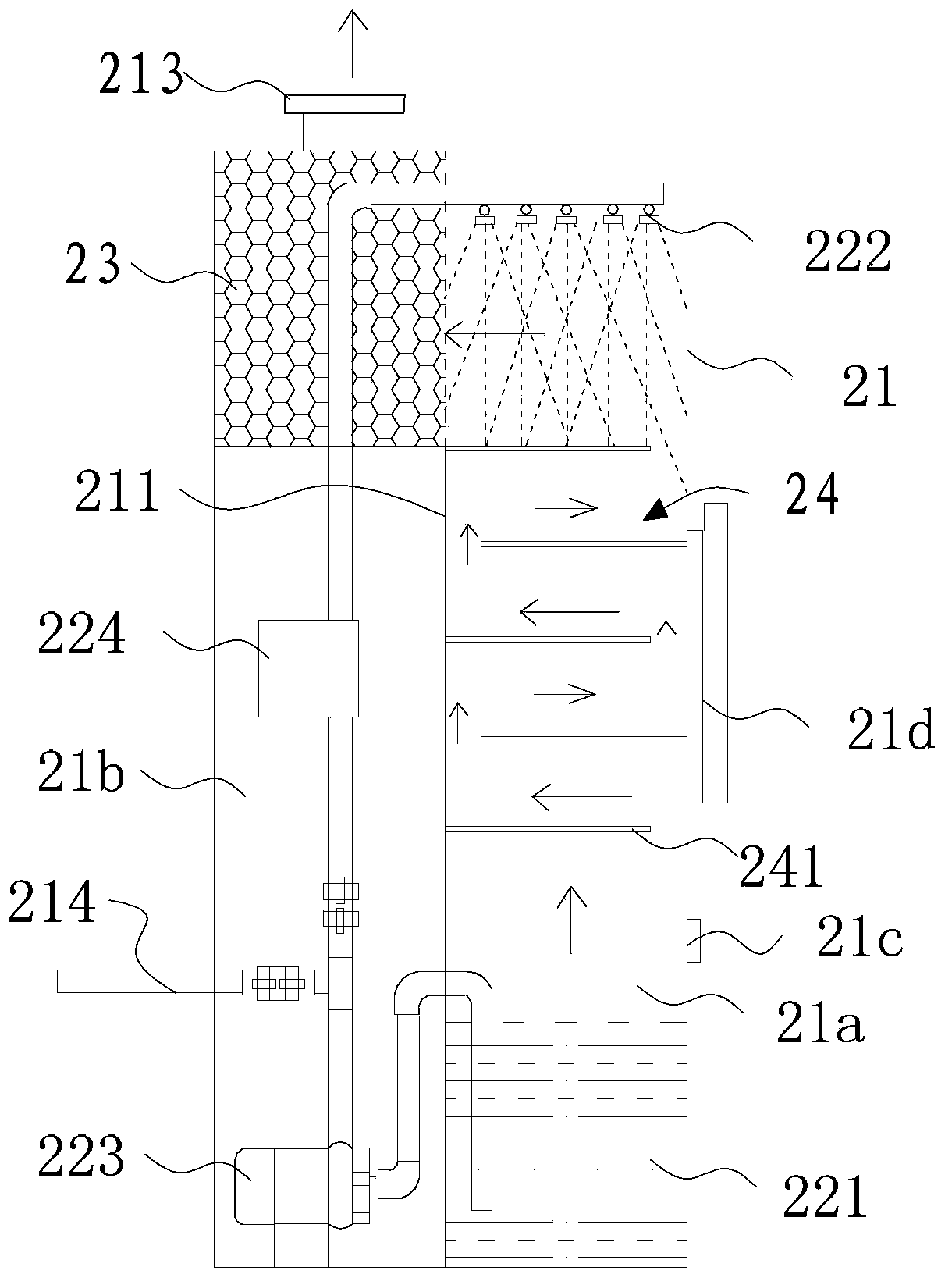

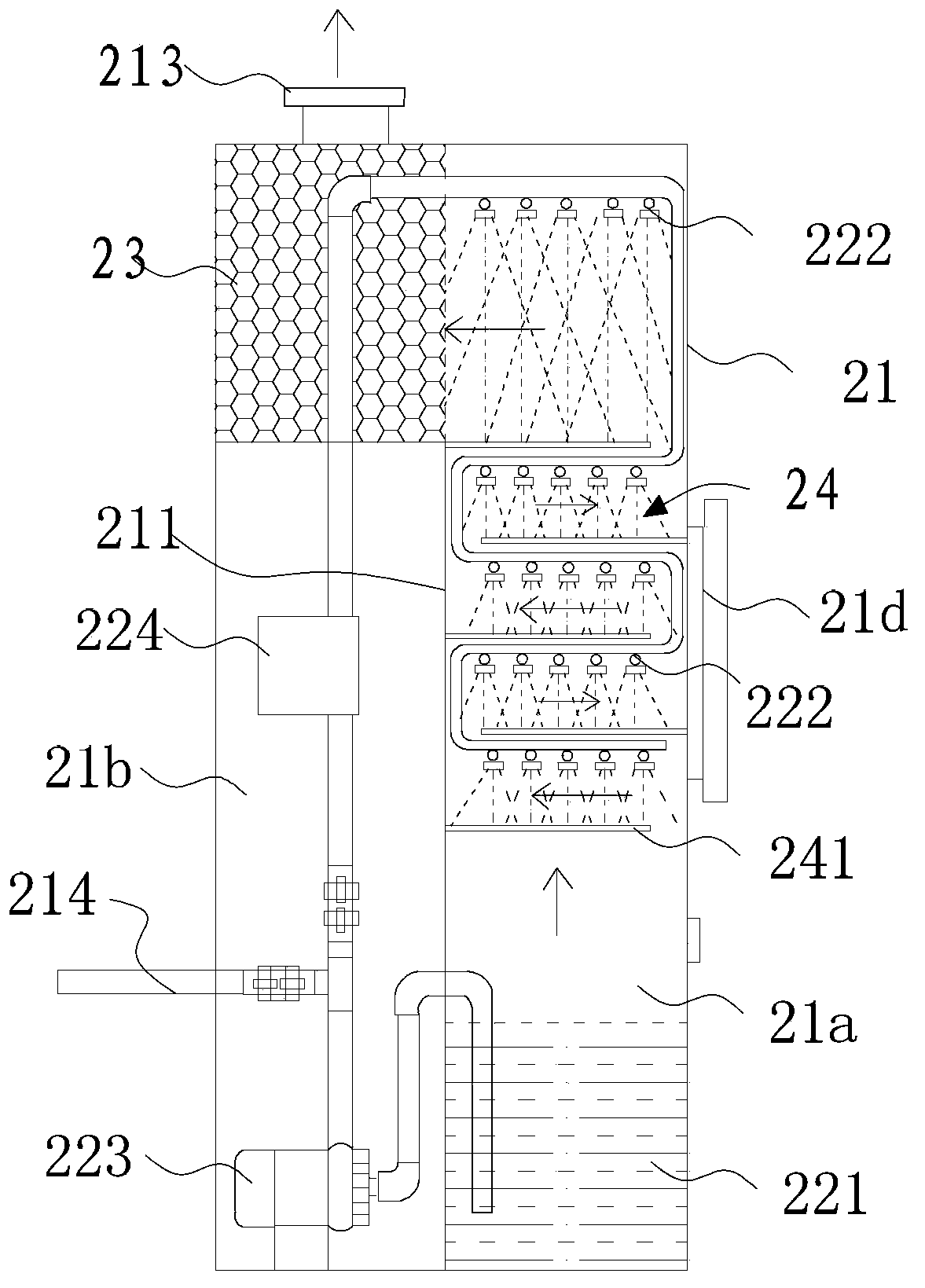

[0035] In order to solve the above problems, such as Figures 1 to 3 As shown, the present invention provides a waste gas dust treatment device, which includes:

[0036] Gas collection device 1 for collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com