Hole sealing structure and hole sealing method as well as expansive cement for sealing hole

A technology of expansive cement and hole sealing, applied in the field of expansive cement, which can solve the problems of high cost, long solidification time, and complicated hole sealing process, and achieve the effect of meeting the sealing requirements and low sealing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

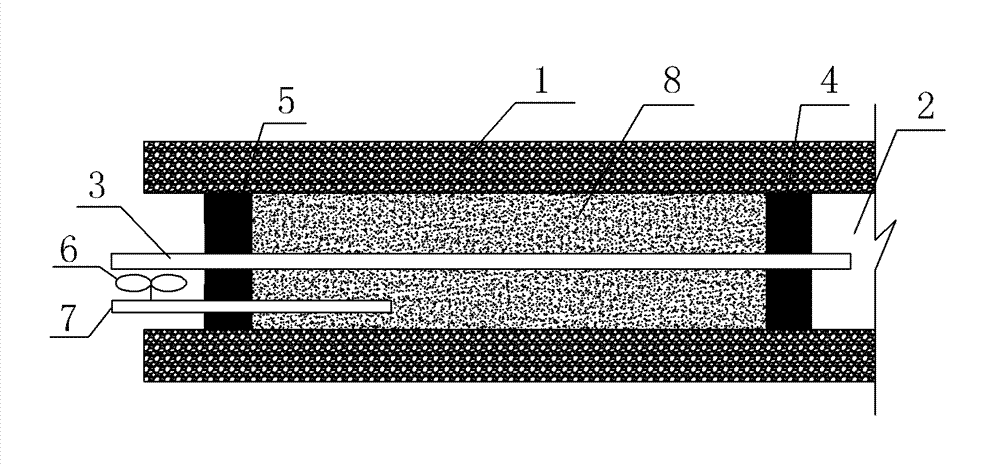

[0018] An embodiment of a sealing structure, such as figure 1 As shown, including the gas collection pipe 3 and the grouting pipe 7 arranged in the borehole 1, the outer peripheral surfaces of the two ends of the gas collection pipe are respectively provided with a front plug 5 and a rear plug 4, and the front and rear plugs It includes flexible fabrics wrapped around the outer peripheral surfaces of the two ends of the gas collection pipe 3 and expansion cement that is coated on the flexible fabrics when it is wet and dispersed, expands and solidifies, and then seals and cooperates with the outer wall of the gas collection pipe and the inner wall of the borehole. A fiber mucus solid-sealing section 8 is arranged between the plugs, the gas collection inlet of the gas collection pipe is located in the gas extraction chamber 2, the grouting pipe 7 is installed on the front plug 5, and the outlet of the grouting pipe is located at the front and rear plugs. Between the heads, a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com