Lead-free low-melting sealing glass and preparation method thereof

A glass and fusion sealing technology, which is applied in the field of lead-free sealing glass, can solve the problems of easy oxidation and high cost, and achieve the effects of high qualified rate of finished products, scientific and reasonable components and ratio, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

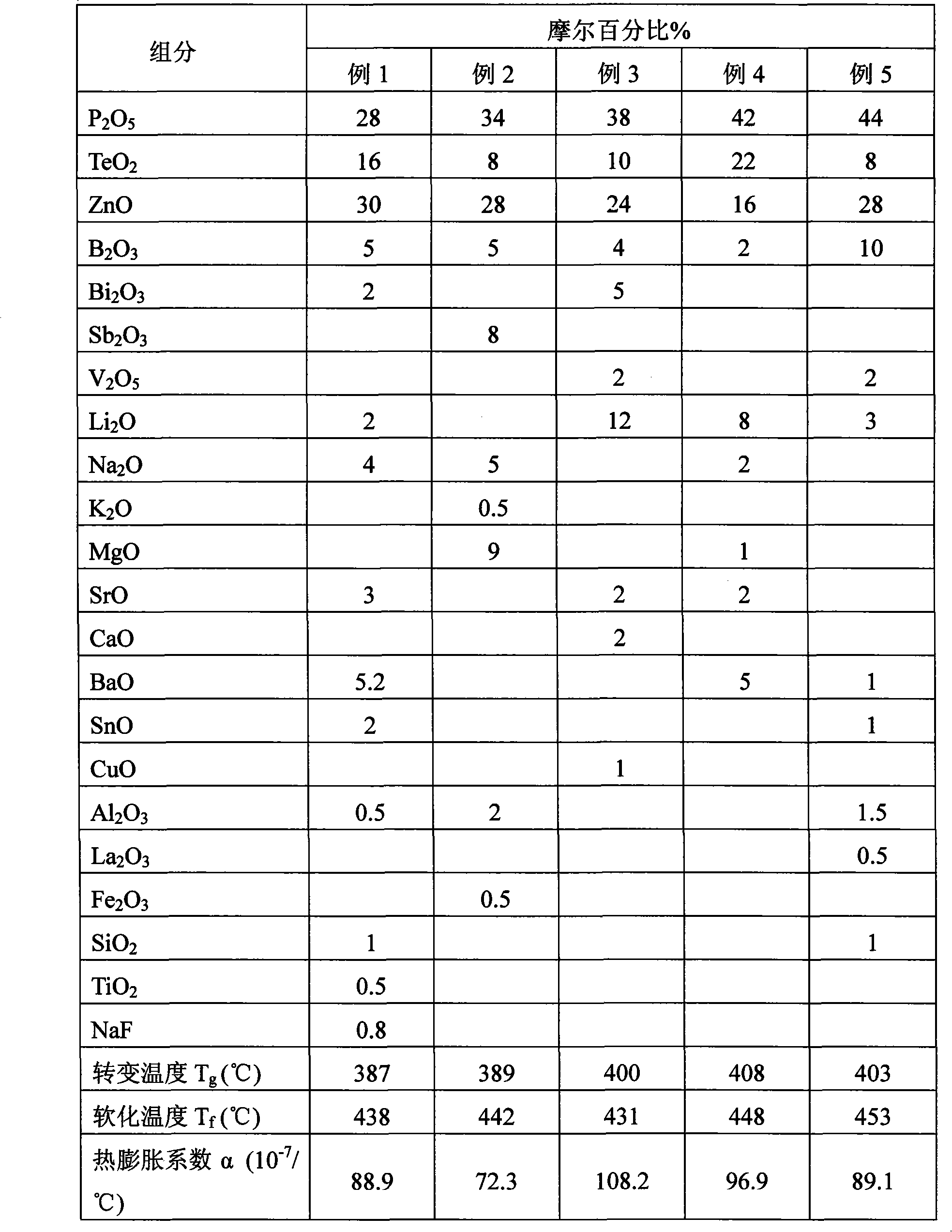

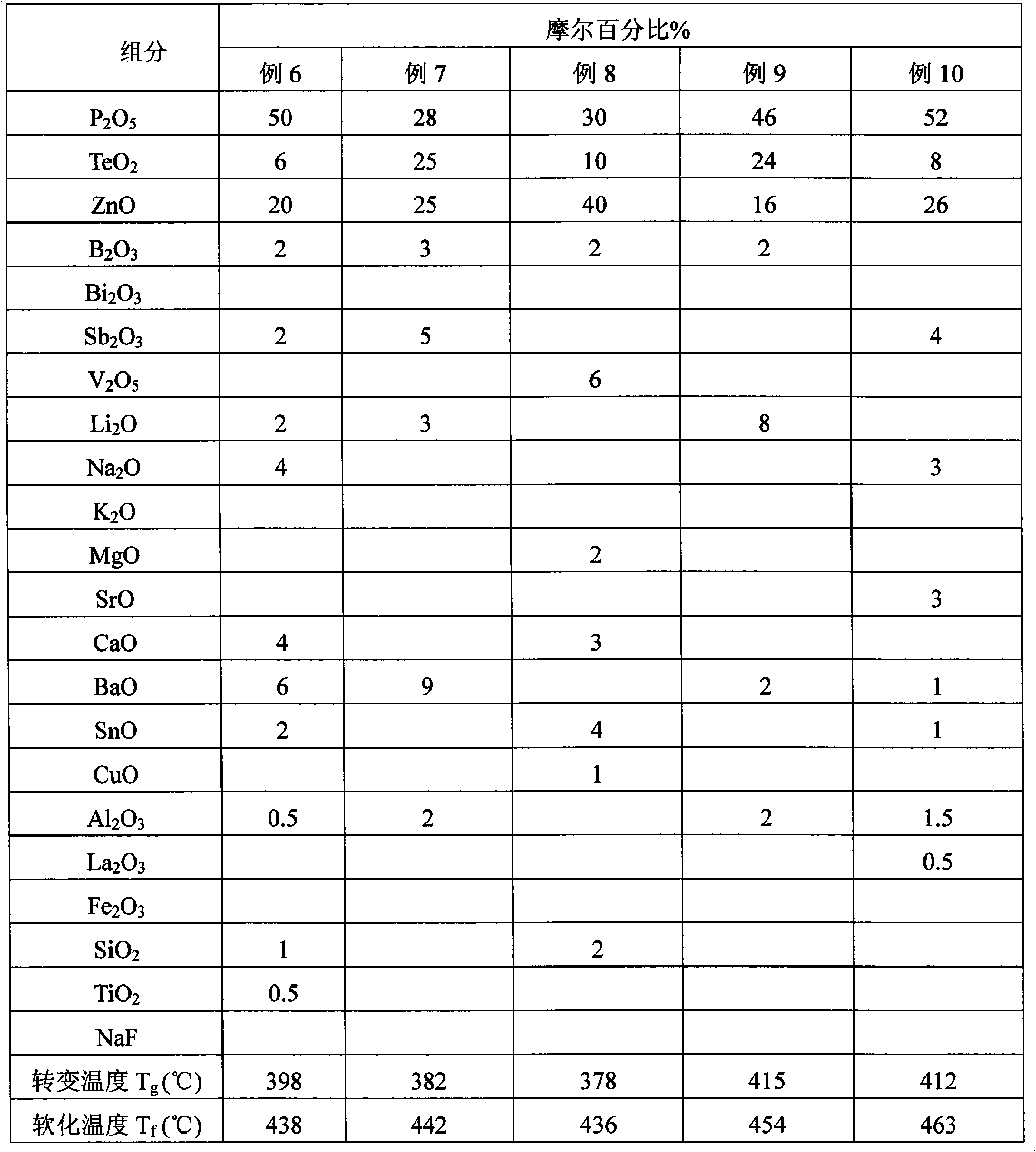

[0023] Calculate and select each raw material according to the example 1 design scheme in table 1, wherein P 2 o 5 Introduced as ammonium phosphate, other raw materials are the corresponding carbonates, oxides and fluorides. The raw materials are weighed and mixed evenly, and dried and heat-treated at 260°C, then ground and crushed, then placed in a quartz crucible, and then placed in a silicon carbide rod electric furnace, heated and melted at 1200°C Take out the molten glass after one hour, pour it on a cold iron plate immediately, then crush the cooled glass pieces, grind them, and pass through a 200-mesh sieve to obtain a glass powder.

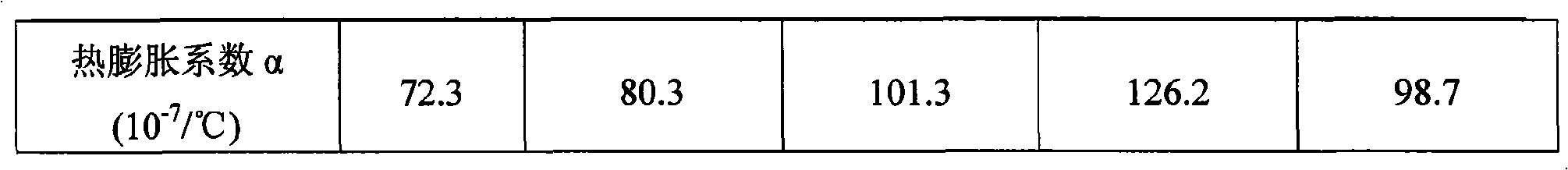

[0024] The prepared glass powder was measured according to the Chinese electronics industry standard SJ / T 10893-6 for relevant property parameters, including softening temperature and thermal expansion coefficient of the finished product, and the corresponding measurement results are shown in Table 1.

[0025] Table 1: Glasses with diffe...

Embodiment 2

[0028] Calculate and select each raw material according to the example 2 design scheme in table 1, wherein P 2 o 5 Introduced as ammonium phosphate, other raw materials are the corresponding carbonates or oxides. The raw materials are weighed and mixed evenly, and dried and heat-treated at 250°C, then ground and crushed, then placed in a quartz crucible, and then placed in a silicon carbide rod electric furnace, heated and melted at 1050°C for 3 Take out the molten glass after one hour, pour it on a cold iron plate immediately, then crush the cooled glass pieces, grind them, and pass through a 200-mesh sieve to obtain a glass powder.

[0029] The prepared glass powder was measured according to the Chinese electronics industry standard SJ / T 10893-6 for relevant property parameters, including softening temperature and thermal expansion coefficient of the finished product, and the corresponding measurement results are shown in Table 1.

Embodiment 3

[0031] Carry out calculation and select each raw material by the design scheme of example 3 in table 1, wherein P 2 o 5 Introduced as ammonium phosphate, other raw materials are the corresponding carbonates or oxides. The raw materials are weighed and mixed evenly, and dried and heat-treated at 250°C, then ground and crushed, then placed in a quartz crucible, and then placed in a silicon carbide rod electric furnace, heated and melted at 1100°C for 3 Take out the molten glass after one hour, pour it on a cold iron plate immediately, then crush the cooled glass pieces, grind them, and pass through a 200-mesh sieve to obtain a glass powder.

[0032] The prepared glass powder was measured according to the Chinese electronics industry standard SJ / T 10893-6 for relevant property parameters, including softening temperature and thermal expansion coefficient of the finished product, and the corresponding measurement results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com