Optical fiber laser and liquid cooling plate thereof

A fiber laser and liquid cooling plate technology, applied in the field of lasers, can solve the problems of high cost and low production efficiency, and achieve the effects of saving costs, improving production efficiency and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

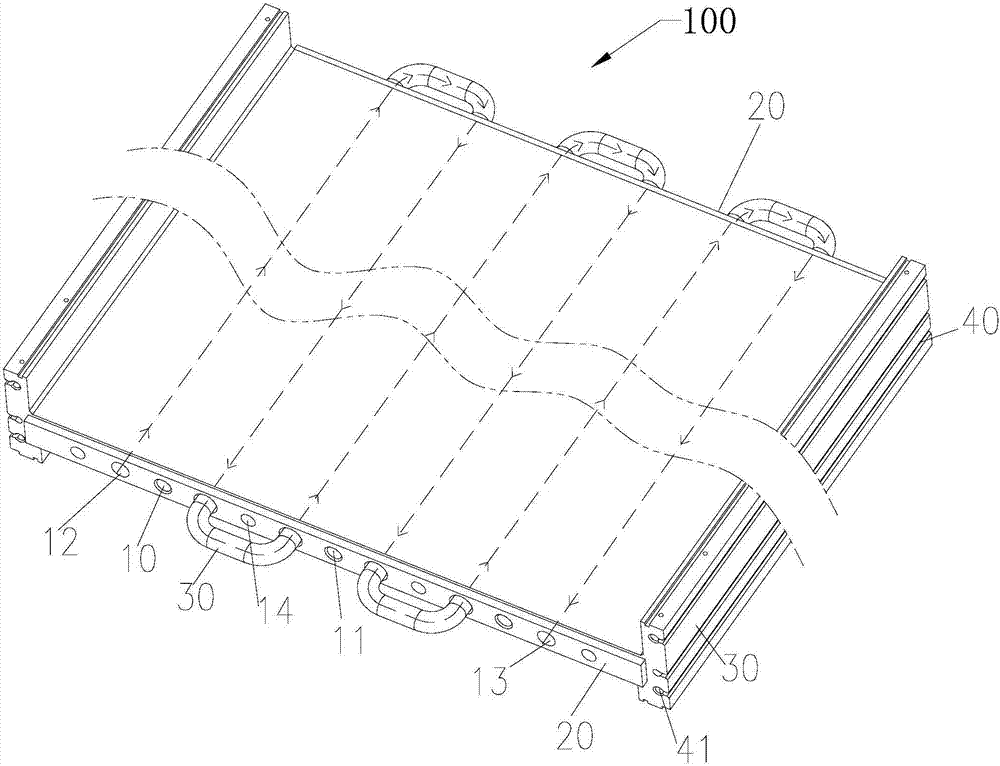

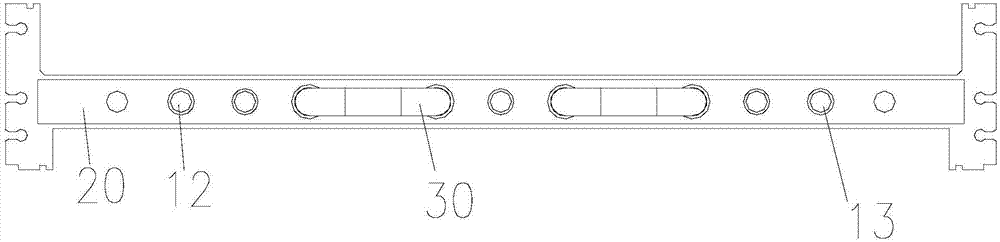

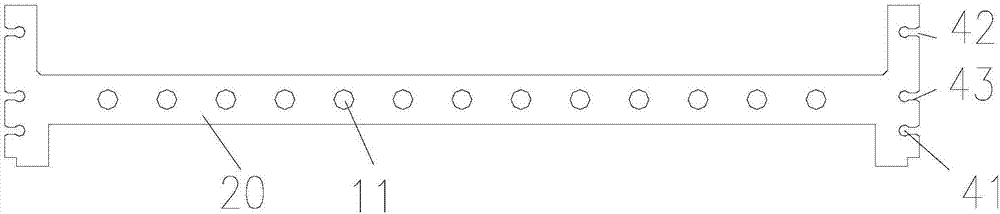

[0030] figure 1 It is a schematic structural diagram of the liquid cold plate of the embodiment of the present invention. like figure 1 As shown, the liquid cooling plate 100 for fiber laser, the liquid cooling plate 100 is used for heat dissipation of the optical path module and circuit module of the fiber laser, and the liquid cooling plate 100 is an expandable integrated liquid cooling plate, the liquid cooling plate One side of the cold plate 100 is used for installing the optical path module, and the other side is used for installing the circuit module.

[0031] The beneficial effects of the embodiments of the present invention are: different from the situation in the prior art, when liquid cooling plates of different sizes are required, for example, when it is necessary to manufacture fiber lasers with different output powers, multiple scalable liquid cooling plates can be integrally formed When spliced together, the overall length of the liquid cooling plate 100 can...

Embodiment 2

[0043] Figure 4-6 For the structural schematic diagram, side view and top view of the fiber laser 200 according to the embodiment of the present invention, please refer to Figure 4-6 , the fiber laser 200 includes: an optical path module (not shown in the figure) and a circuit module (not shown in the figure), and the fiber laser 200 also includes a liquid cooling plate 100 and a cover plate 230 .

[0044] The liquid cold plate 100 is an expandable integrated liquid cold plate 100 that dissipates heat for the optical path module and the circuit module. The optical path module is installed on one side of the liquid cold plate 100, and the circuit module is installed on the other side; the cover plate 230 The cover is arranged on the liquid cooling plate 100 and forms an accommodating cavity (not shown) with the liquid cooling plate 100 to accommodate the optical path module and the circuit module, and the cover plate 230 is sealed with the liquid cooling plate 100 .

[0045]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com