Shell for hybrid power drive device

A driving device and hybrid technology, applied in transmission parts, electromechanical devices, cooling/ventilation devices, etc., can solve the problems of difficult-to-drive motor devices integrating transmissions, difficult integration of driving motor devices, etc., and achieve the effect of meeting assembly process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

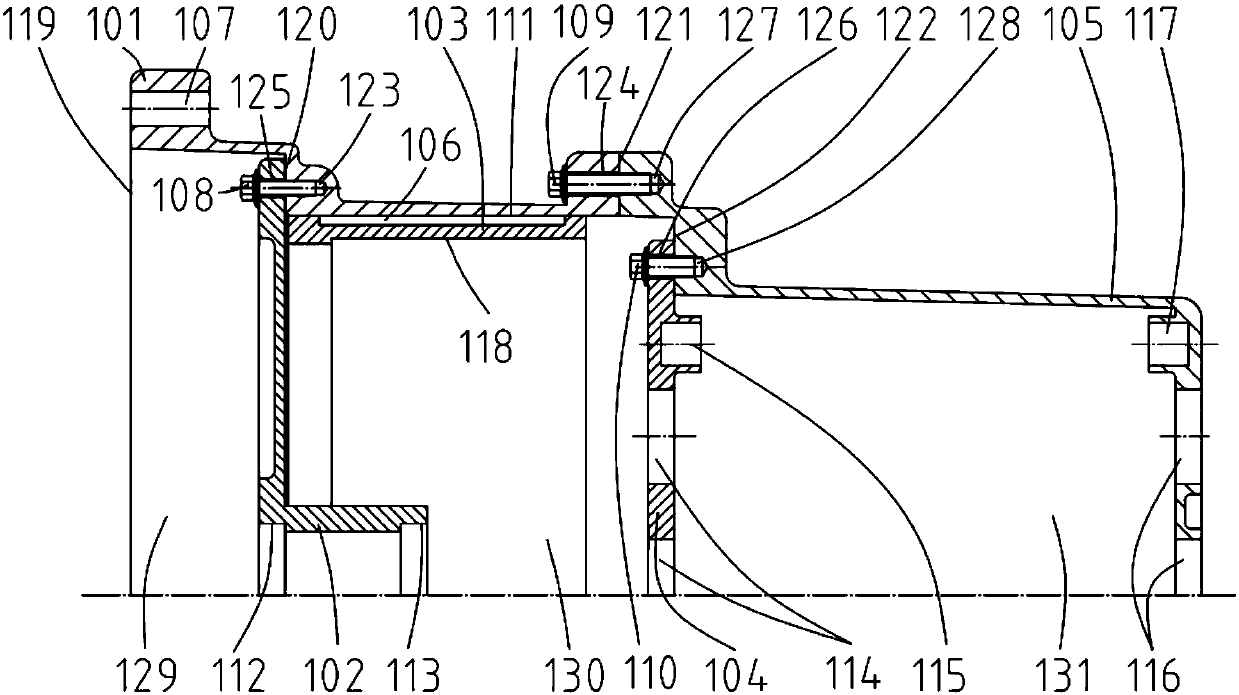

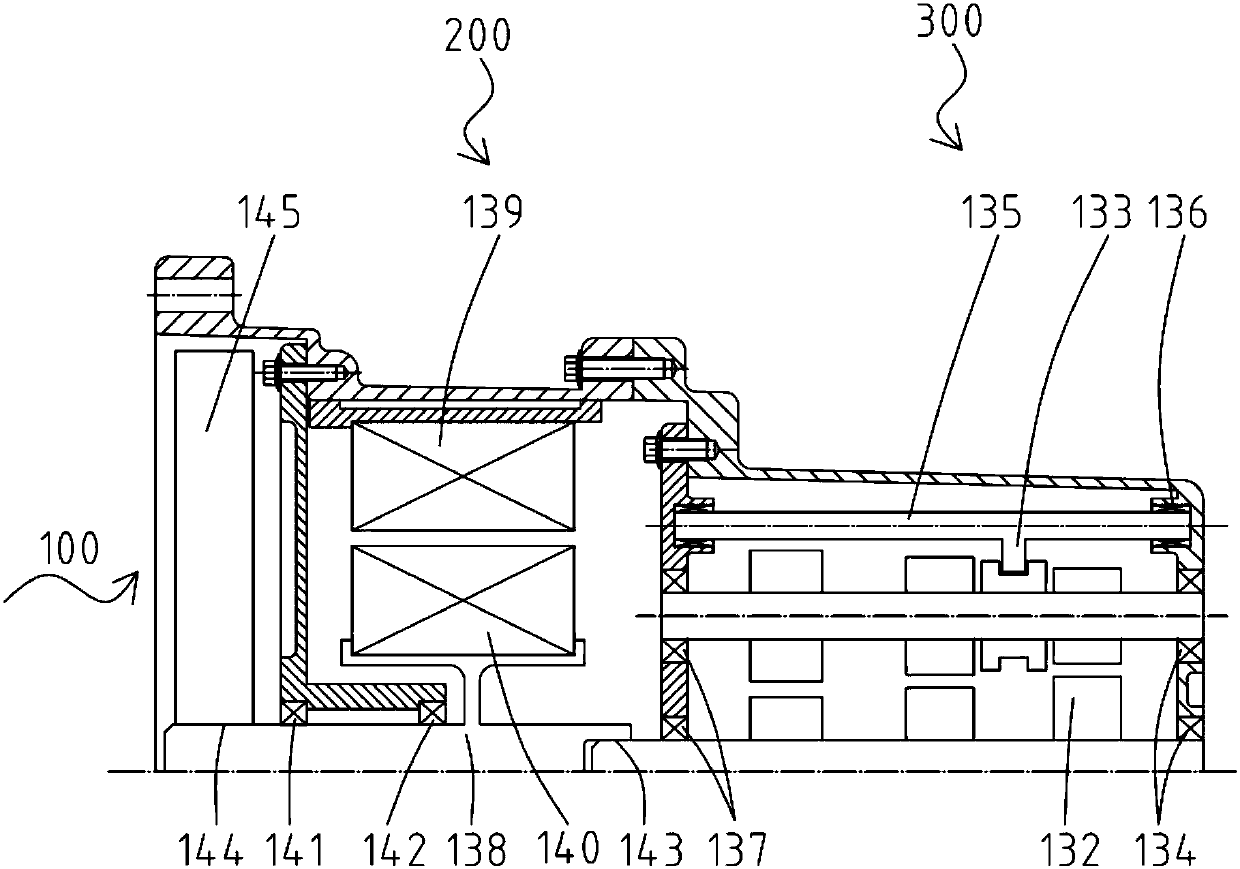

[0125] Such as figure 1 As shown, this embodiment provides a housing for a hybrid drive device, the housing includes: a front end housing 101, a motor end cover 102, a motor water jacket 103, a supporting hydraulic partition 104 and a rear end housing 105 , the motor end cover 102 is connected with the front end casing 101 through a connecting piece, the motor water jacket 103 is arranged in the water jacket installation hole 111 of the front end casing, and the supporting hydraulic diaphragm 104 is connected with the The rear shell 105 is connected by a connecting piece, and the front shell 101 is connected with the rear shell 105 by a connecting piece. The internal space formed by the front end housing 101, the motor water jacket 103 and the rear end housing 105 is divided into the first housing in turn by the motor end cover 102 and the supporting hydraulic partition 104 from front to back. The cavity 129 , the second accommodating cavity 130 and the third accommodating ca...

no. 2 Embodiment

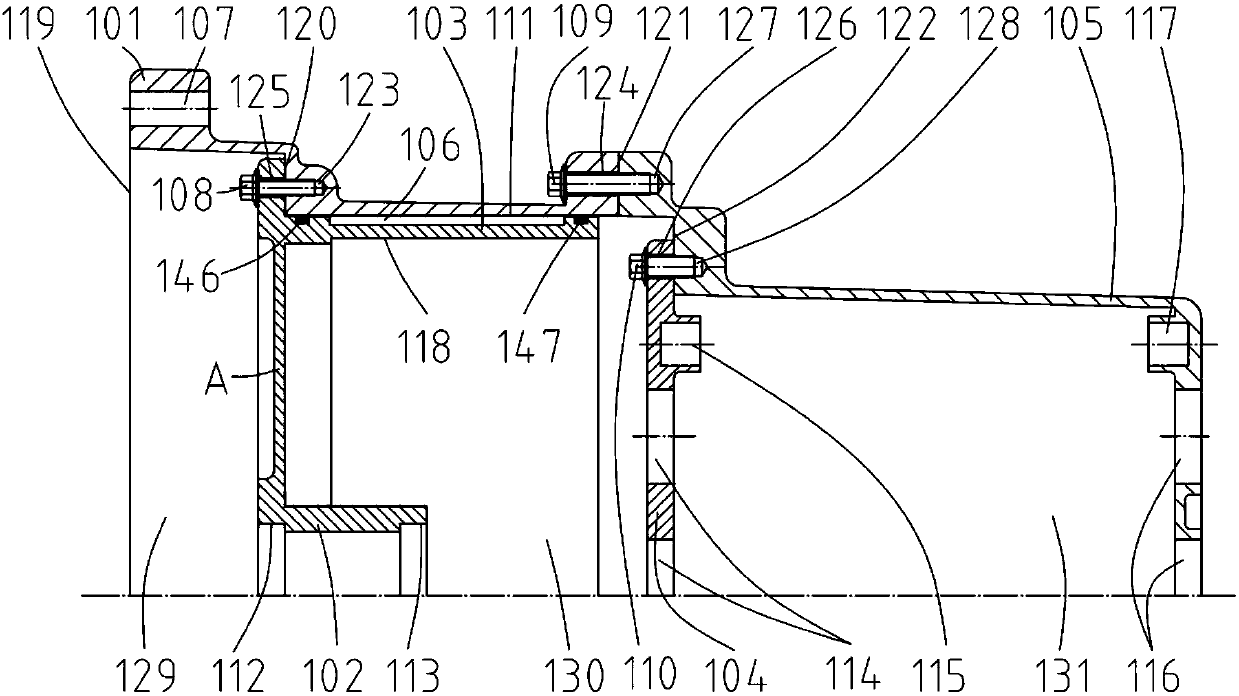

[0140] The difference between the second embodiment and the first embodiment is that the motor end cover 102 and the motor water jacket 103 are integrated into one component—integrated motor end cover A.

[0141] Such as image 3 As shown, the housing for the hybrid driving device provided in this embodiment includes: a front end housing 101, a motor end cover 102, a motor water jacket 103, a supporting hydraulic partition 104 and a rear end housing 105, The motor end cover 102 is connected to the front end housing 101 through a connecting piece, the motor water jacket 103 is arranged in the water jacket installation hole 111 of the front end housing and integrally formed with the motor end cover 102, so The supporting hydraulic diaphragm 104 is connected to the rear end casing 105 through a connecting piece, and the front end casing 101 is connected to the rear end casing 105 through a connecting piece. The internal space formed by the front end housing 101, the motor water ...

no. 3 Embodiment

[0154] The difference between the third embodiment and the second embodiment is that: the supporting hydraulic diaphragm 104 is fixedly connected to the front end casing 101 through a plurality of third connecting bolts 110 .

[0155] Such as Figure 5 As shown, the housing for the hybrid driving device provided in this embodiment includes: a front end housing 101, a motor end cover 102, a motor water jacket 103, a supporting hydraulic partition 104 and a rear end housing 105, The motor end cover 102 is connected to the front end housing 101 through a connecting piece, the motor water jacket 103 is arranged in the water jacket installation hole 111 of the front end housing and integrally formed with the motor end cover 102, so The supporting hydraulic diaphragm 104 is connected to the front end casing 101 through a connecting piece, and the front end casing 101 is connected to the rear end casing 105 through a connecting piece. The internal space formed by the front end housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com