Modified silane sealant for LED backlight and preparation method thereof

A technology of LED backlight source and sealant, applied in the field of sealant, can solve the problems of increased viscosity of silane-terminated polyether sealant, limited product process operation performance, poor applicability of light bar bonding, etc., and achieves good compatibility. , Avoid the thickening or even gel of the rubber compound, the effect of good process operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

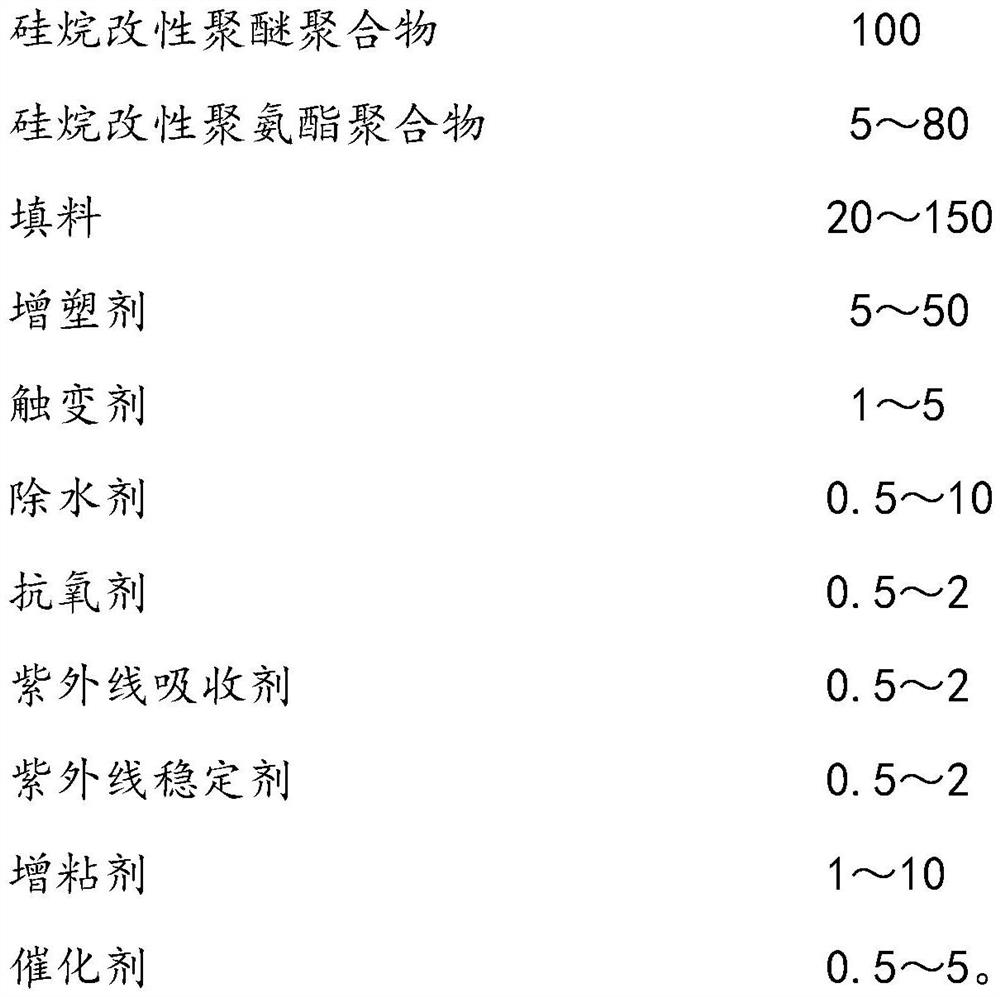

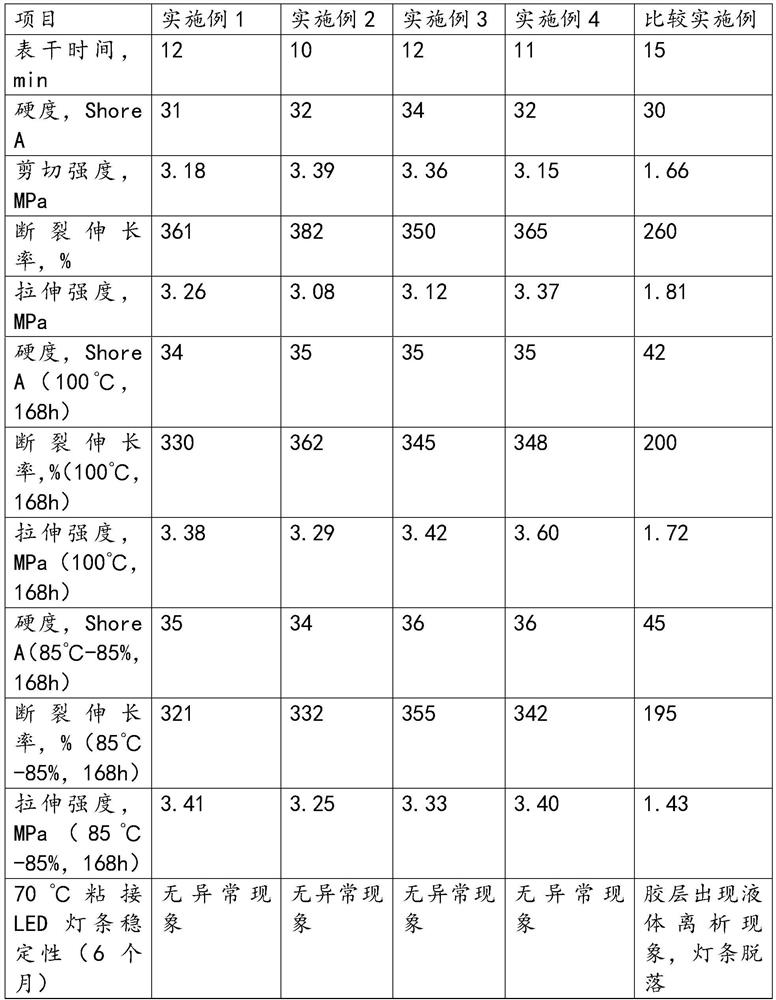

[0033] In parts by weight, 100 parts of methyldimethoxysilyl-modified polyether, 5 parts of trimethoxysilane-terminated silane-modified polyurethane, 20 parts of cyclohexane 1,2-dicarboxylic acid di Add the isononyl ester into the mixer, stir and mix for 30 minutes at room temperature and vacuum degree of 0 MPa; add 50 parts of nano-calcium carbonate and 20 parts of alumina and stir and mix for 55 minutes; then add 2 parts of β-(3,5- Di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, 0.5 parts of 2-[2-hydroxy-5-tert-octylphenyl)benzotriazole, 0.5 parts of bis(2,2,6 , 6-tetramethyl-4-piperidinyl) sebacate and 1 part of fumed silica were dehydrated and blended for 120 minutes at a temperature of 120°C and a vacuum of -0.08MPa; the temperature was lowered to below 50°C, and the pumping was stopped. Vacuum and stir, add 10 parts of vinyltrimethoxysilane, 5 parts of tackifier, 5 parts of bis(acetylacetonate) dibutyltin, and stir and mix for 60 minutes under the condition of vac...

Embodiment 2

[0035] In parts by weight, 100 parts of methyldimethoxysilyl-modified polyether, 80 parts of trimethoxysilane-terminated silane-modified polyurethane, 20 parts of cyclohexane 1,2-dicarboxylic acid di Add the isononyl ester into the mixer, stir and mix for 20 minutes at room temperature and vacuum degree of -0.09MPa; add 30 parts of alumina and 30 parts of silicon micropowder and stir and mix for 30 minutes; add 1 part of β-(3,5 - Di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, 1 part of 2-[2-hydroxy-5-tert-octylphenyl) benzotriazole, 1 part of bis(2,2, 6,6-Tetramethyl-4-piperidinyl) sebacate and 5 parts of fumed silica were dehydrated and blended for 180 minutes at a temperature of 100°C and a vacuum of -0.09MPa; the temperature was lowered to below 50°C, and the process was stopped. Vacuumize and stir, add 8 parts of vinyltrimethoxysilane, 10 parts of tackifier, 3 parts of bis(acetylacetonate) dibutyltin, and stir and mix for 30 minutes under the condition of vacuum de...

Embodiment 3

[0037]In parts by weight, 100 parts of trimethoxysilyl-modified polyether, 20 parts of triethoxysilane-terminated silane-modified polyurethane, 30 parts of cyclohexane 1,2-diisononyl dicarboxylate Add the base ester into the mixer, stir and mix for 10 minutes at room temperature and vacuum degree of 0 MPa; add 30 parts of nano-calcium carbonate and 60 parts of kaolin and stir and mix for 60 minutes; add 1 part of β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) n-octadecanyl propionate, 2 parts of 2-[2-hydroxy-5-tert-octylphenyl)benzotriazole, 2 parts of bis(2,2,6,6- Tetramethyl-4-piperidinyl) sebacate and 2 parts of polyamide wax were dehydrated and blended for 90 minutes at a temperature of 110°C and a vacuum of -0.1MPa; the temperature was lowered to below 50°C, and the vacuuming and stirring were stopped. Add 10 parts of vinyltrimethoxysilane, 3 parts of tackifier, and 3 parts of dibutyltin dilaurate, and stir and mix for 45 minutes under the condition of vacuum degree -0.1MPa t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com