Semi-automatic anti-rust agent coating device for special-shaped metal sheet

A technology of special-shaped metal and anti-rust agent, which is applied to the device and coating of the surface coating liquid, which can solve the problem that the clutch assembly cannot meet the assembly requirements, affect the service life of the clutch assembly, and consume too much anti-rust agent. and other problems, to achieve the effect of saving antirust agent, improving assembly quality, and uniformity of antirust agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

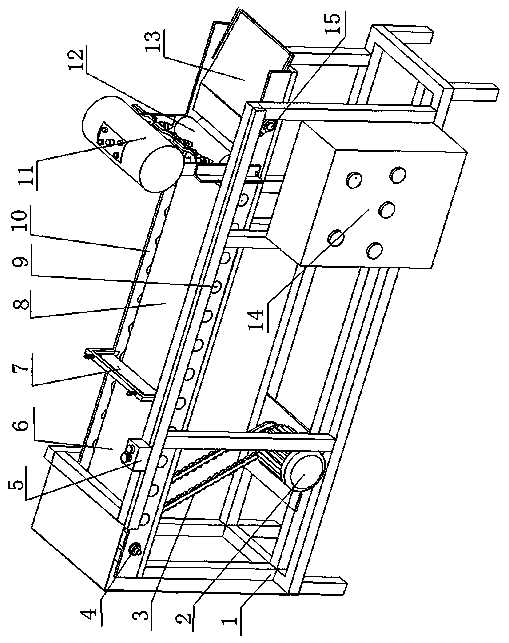

[0015] The present invention is equipped with conveyer belt 8 on frame 1 through power input roller 4, transmission roller 9 and tension roller 15, adjusts tension roller 15, must Bangzheng conveyer belt 8 smooth, and power input roller 4 passes transmission chain 3 and motor 2 shaft connection; the frame 1 on both sides of the conveyor belt 8 is equipped with a baffle plate 10, the front end of the conveyor belt 8 is a loading station 6, and other auxiliary feeding equipment can be used to prevent the workpiece from the loading station 6. Workpieces can be placed manually, and a separation and screening mechanism 7 is installed on the baffle plate 10 on the rear side of the loading station 6, and an electric control box 14 and control buttons 5 are installed on the frame 1, and the electric control box 14 and control buttons 5. Existing electronic equipment is used to adjust the speed of the conveyor belt, etc.; on the frame 1, a dripping grease mechanism is installed through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com