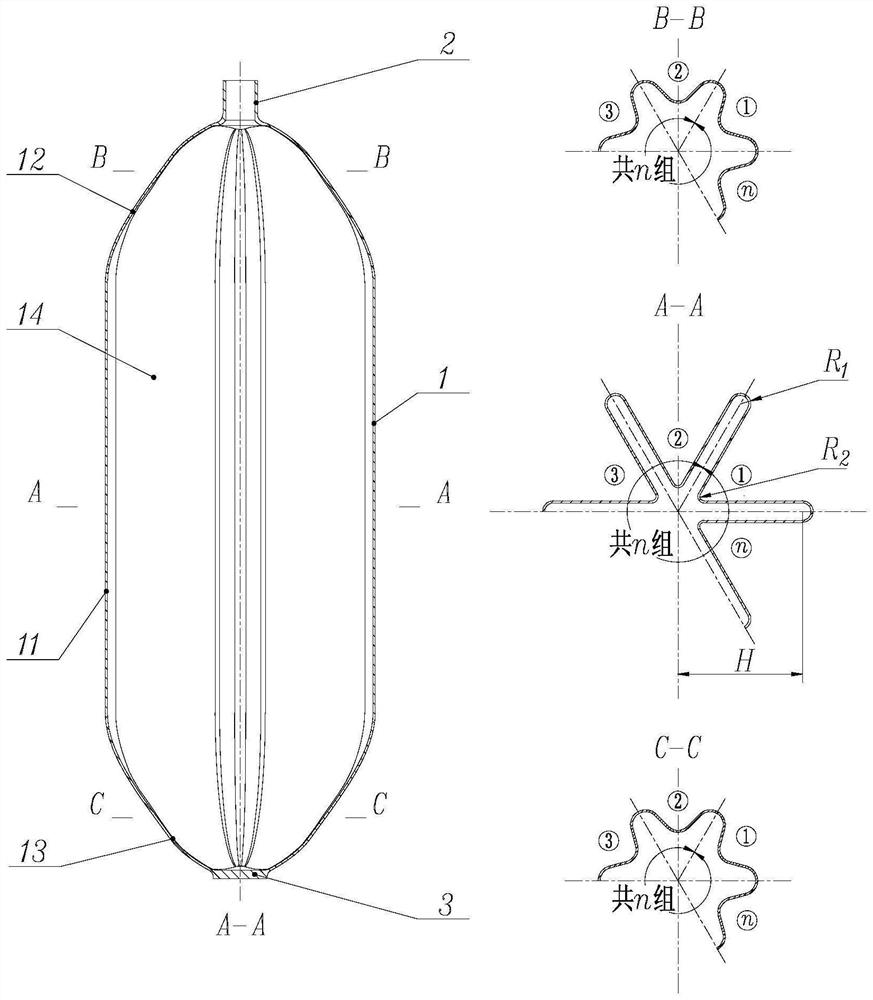

Cylindrical diaphragm

A diaphragm and cylindrical technology, which is applied in the field of aircraft liquid storage and management, can solve the problem that the metal diaphragm tank cannot meet the requirements of cylindrical installation space, etc., and achieve the effects of being beneficial to attitude control, stable center of mass and stable pressure difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

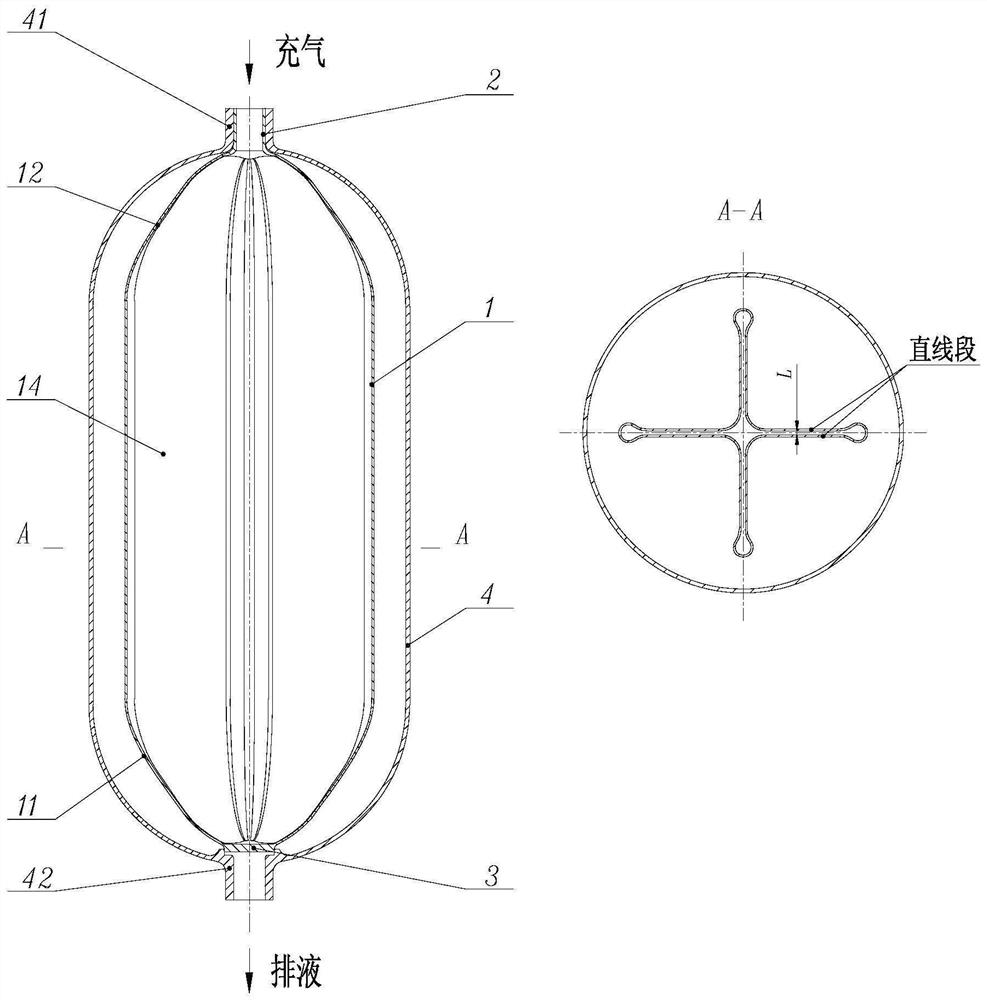

Embodiment 1

[0036] Such as figure 2 As shown, a propellant tank using a cylindrical diaphragm provided by the present invention, the diaphragm cylinder 1 is arranged in the inner cavity of the tank shell 4; The filling and deflation port 41 is sealed and connected, and the assembly joint 3 is fixedly connected with the filling and discharging port 42 of the storage tank shell 4; The inner walls of the tank housing 4 together form a liquid storage chamber 5 .

[0037] Specifically, in this embodiment, the diaphragm cylinder 1 is made of metal material with a wall thickness of 1 mm.

[0038] Specifically, in this embodiment, the number of "∩"-shaped structures of the diaphragm cylinder 1 is four.

[0039] Specifically, in this embodiment, the two straight line segments of the "∩"-shaped structure of the diaphragm cylinder 1 are parallel, and the distance L is 1 mm.

[0040] Specifically, in this embodiment, the diaphragm cylinder 1 is connected to the inflation joint 2 and the installat...

Embodiment 2

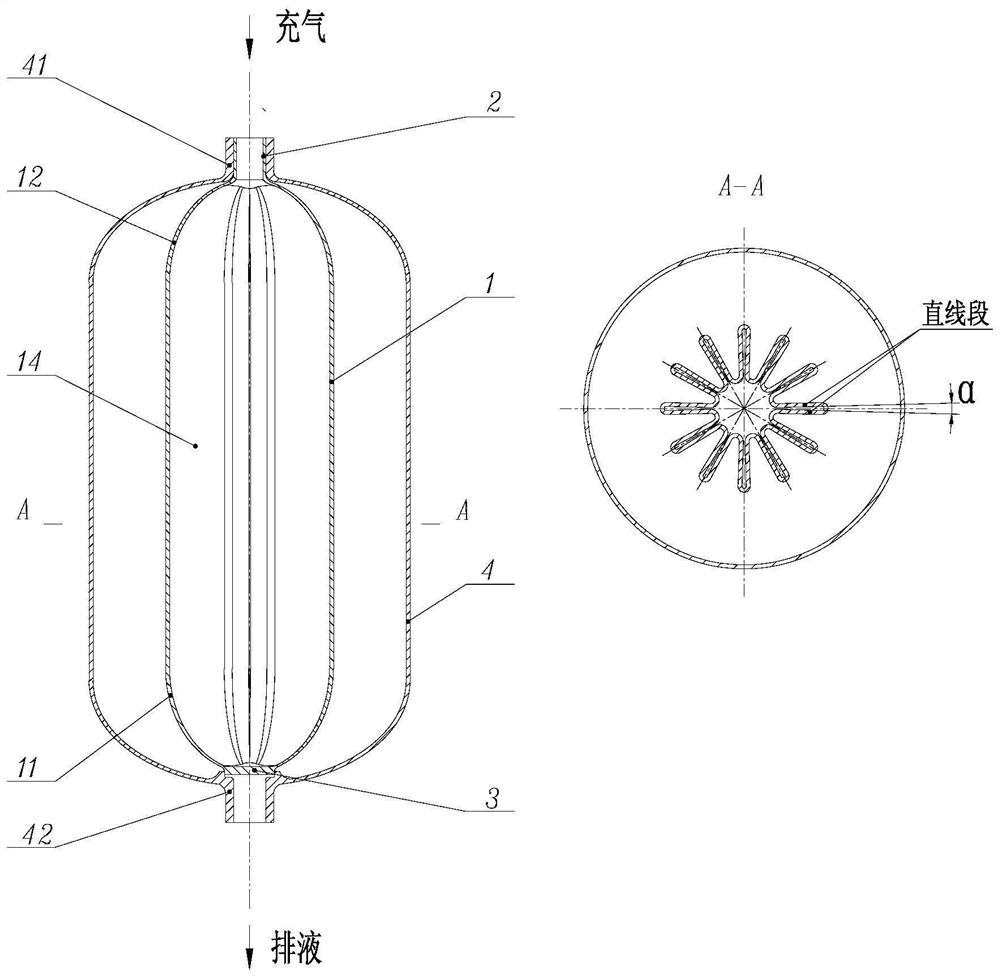

[0045] This embodiment is an improvement based on Embodiment 1, such as image 3 shown.

[0046] Specifically, in this embodiment, the diaphragm cylinder 1 is made of non-metallic material with a wall thickness of 2mm.

[0047] Specifically, in this embodiment, the number of "∩"-shaped structures of the diaphragm cylinder 1 is 12.

[0048] Specifically, in this embodiment, the angle between two straight line segments of the “∩”-shaped structure of the diaphragm cylinder 1 is α=3°.

[0049] Specifically, in this embodiment, the diaphragm cylinder 1 is glued to the inflation joint 2 and the installation joint 3 .

[0050] Specifically, in this embodiment, after the diaphragm cylinder 1 is inflated and fully expanded from the inside to the outside, the profile of the cylinder body 11 is cylindrical, and the profiles of the first head 12 and the second head 13 are both semi-cylindrical. Ellipsoid.

Embodiment 3

[0052] This embodiment is an improved manner based on Embodiment 1 or Embodiment 2.

[0053] Specifically, in this embodiment, after the diaphragm cylinder 1 is inflated and fully expanded from the inside to the outside, the profile of the cylinder body 11 is cylindrical, the profile of the first head 12 is hemispherical, and the profile of the second head 13 is semi-ellipsoidal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com