Trailer bogie with built-in axle boxe of high-speed motor train unit

A high-speed EMU, built-in technology, applied in the direction of the bogie, the installation of the axle box, the device for lateral relative movement between the underframe and the bogie, etc. High-speed and high-bearing capacity operation requirements, to achieve the effect of strong vertical bearing capacity, less lateral space occupation, and reduced lateral space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

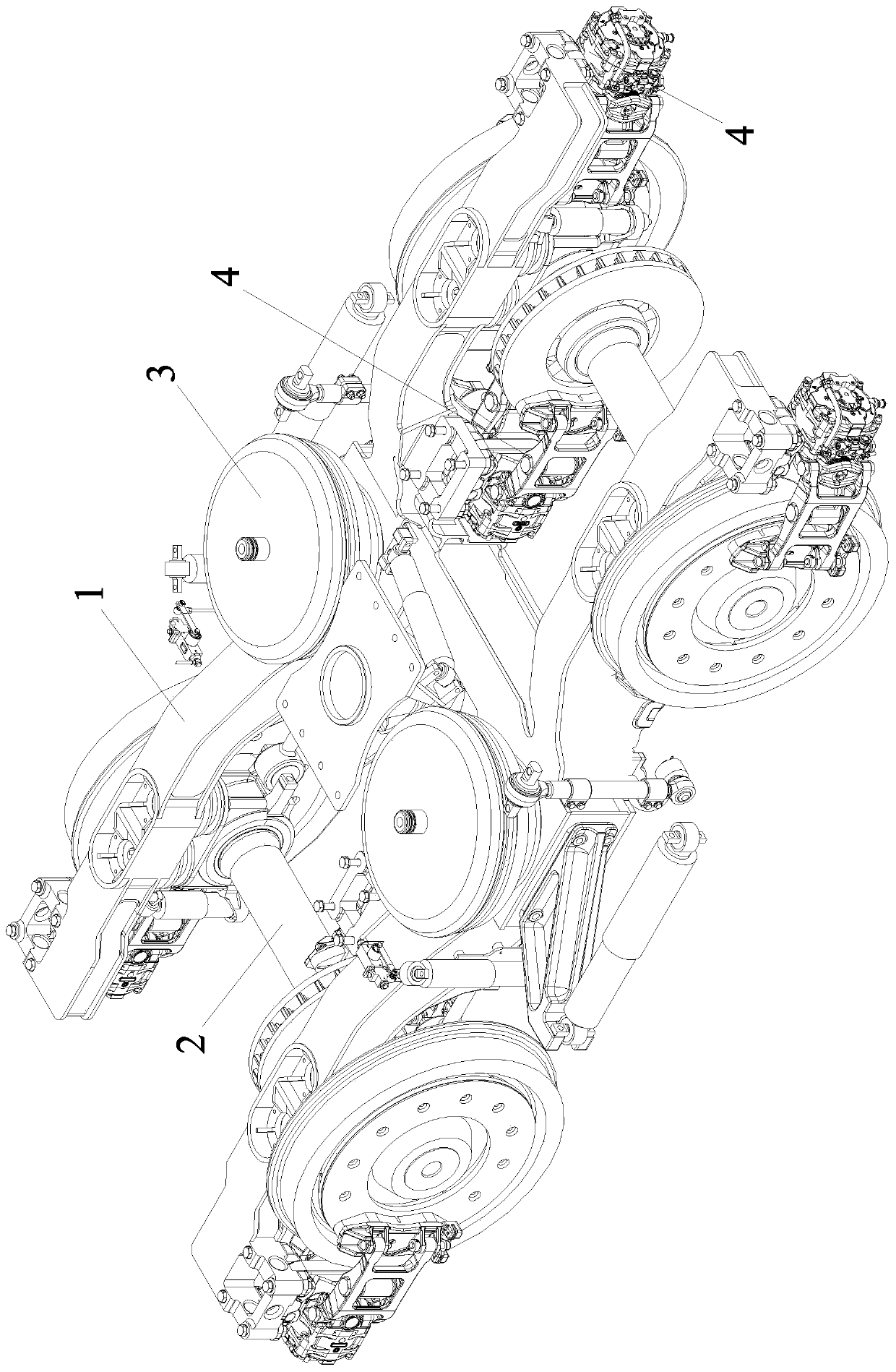

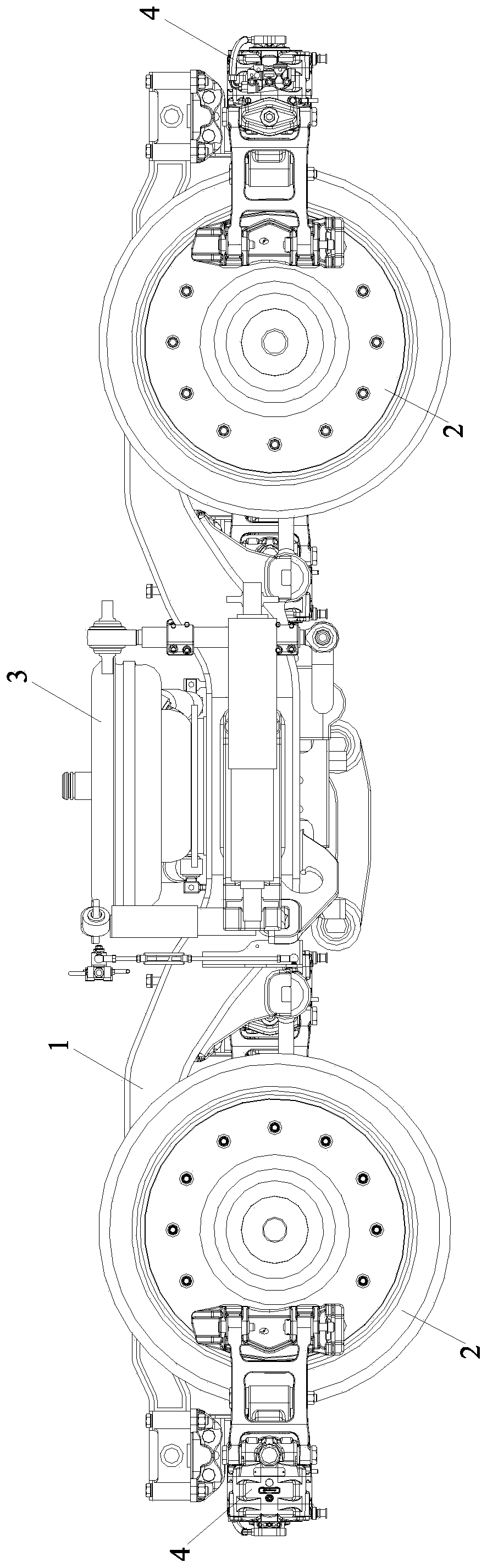

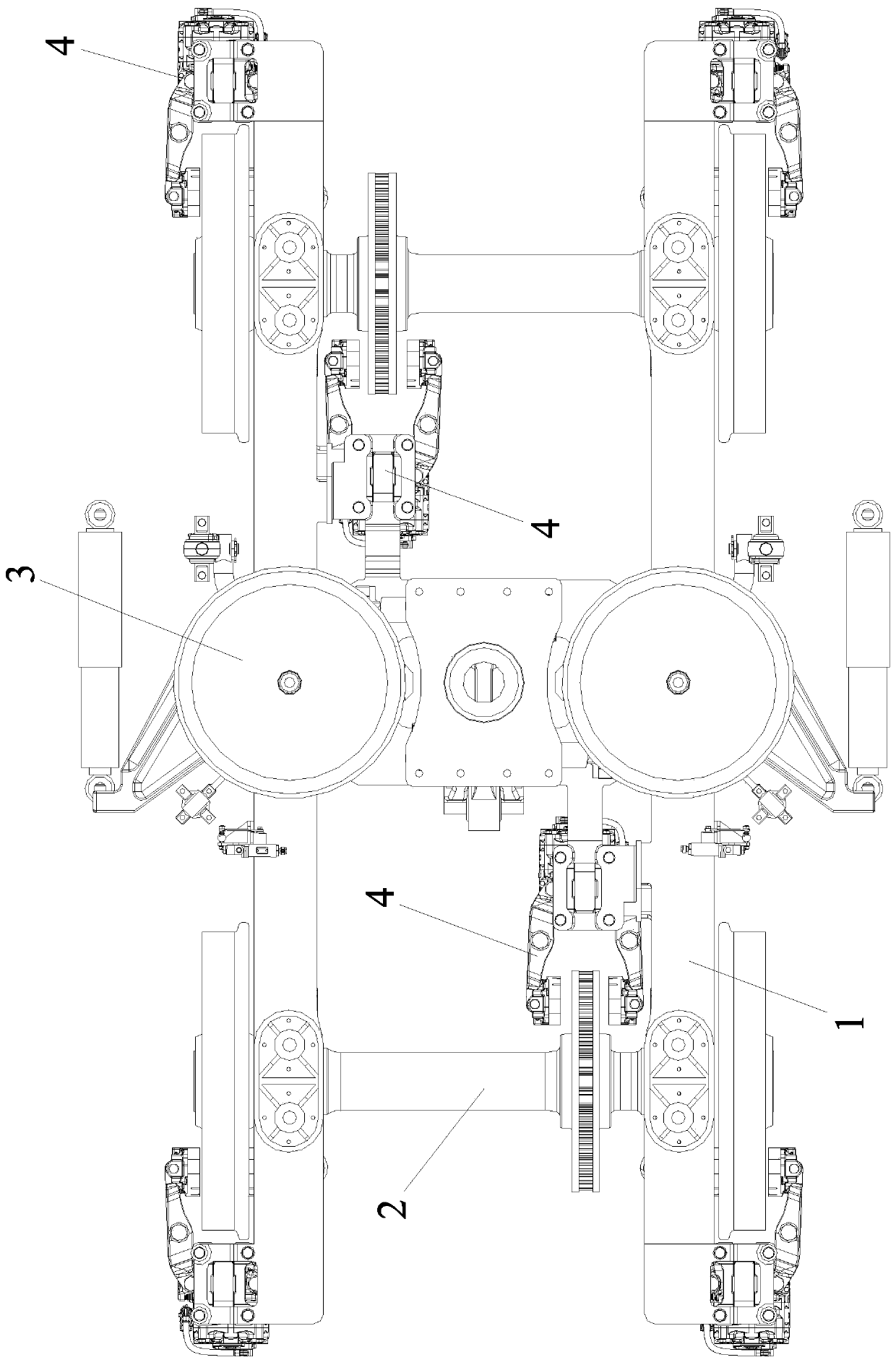

[0040] Such as Figure 1 to Figure 15As shown, the high-speed EMU axle box built-in trailer bogie of the present invention includes: a frame 1, a wheel-to-axle box device 2, a central suspension device 3 and a foundation braking device 4; the frame 1 is a box girder welded structure, The frame 1 is provided with a series of spring seats 6, two air spring seats 7, four disc foundation brake device mounts 8, two shaft disc foundation brake device mounts 9, a traction rod seat 10, four one System positioning seat 11, two anti-rolling torsion bar seats 12, two anti-snaking shock absorber seats 13, two secondary vertical shock absorber seats 14 and two secondary transverse shock absorber seats 15. The wheel-to-axle box device 2 includes a wheel 16, an axle 17, two axle-mounted brake discs 18, four primary vertical hydraulic shock absorbers 19, four primary positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com