Single-drive linear motion robot

A linear motion and robot technology, applied in the direction of manipulators, program control manipulators, manufacturing tools, etc., to achieve the effect of easy integration, compact structure in the axial direction, and save space in the lateral direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

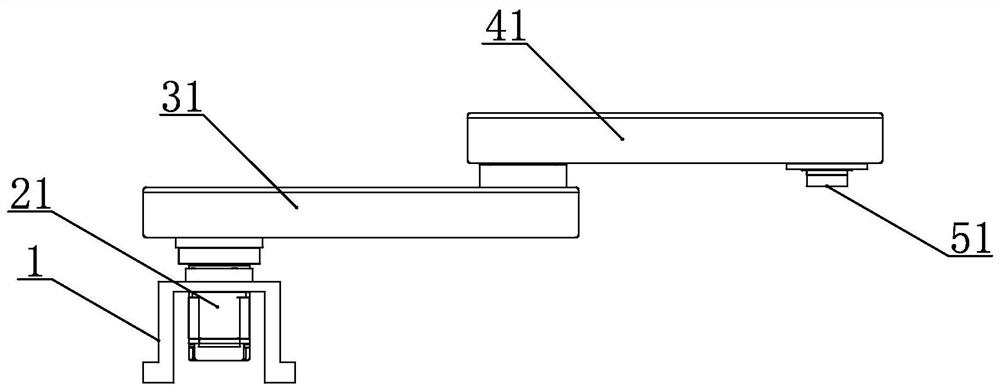

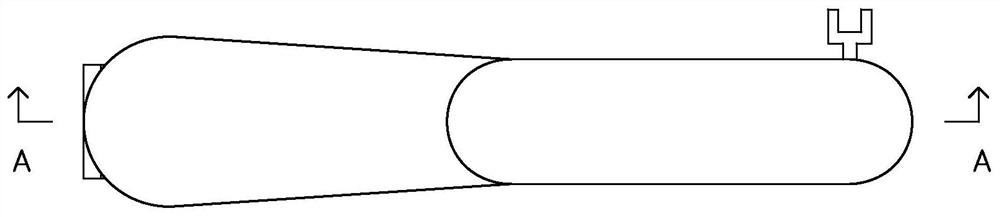

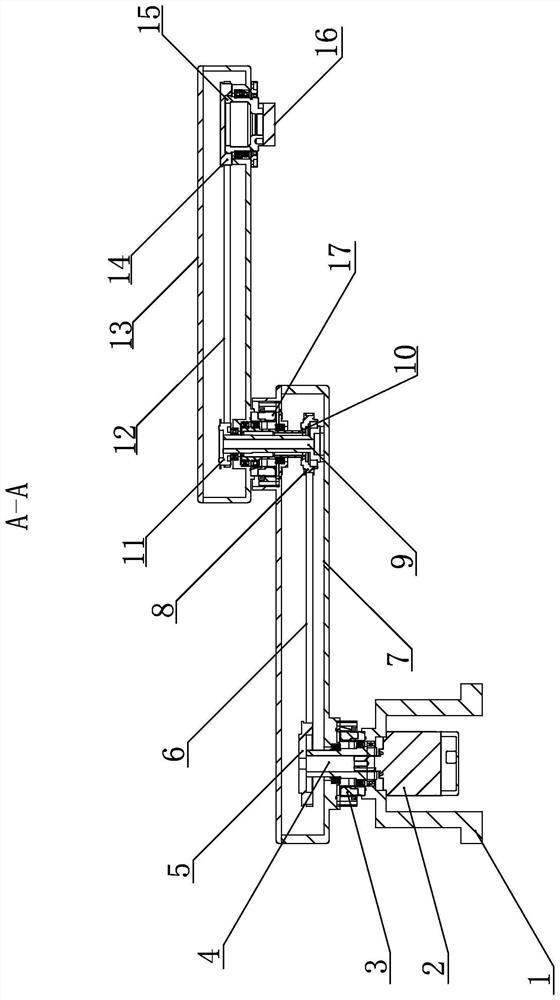

[0033] Such as Figure 1-Figure 3 As shown, the single-drive linear motion robot of the present invention includes a drive assembly 21 , a boom assembly 31 , a small arm assembly 41 and an end tool 51 .

[0034] The drive assembly 21 includes a drive motor 2 and a first reducer 3 , and the drive motor 2 and the first reducer 3 are installed on the frame 1 . The driving motor 2 drives the first transmission shaft 4 to rotate through key transmission. The first transmission shaft 4 drives the first reducer 3 to run. The output end of the first speed reducer 3 is fixedly connected with the main body 7 of the boom, so as to realize the rotation of the main body 7 of the boom.

[0035] The boom assembly 31 includes a first pulley 5 , the first pulley 5 is located inside the boom body 7 , and the first pulley 5 is driven by the first tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com