Patents

Literature

57results about How to "Axial compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

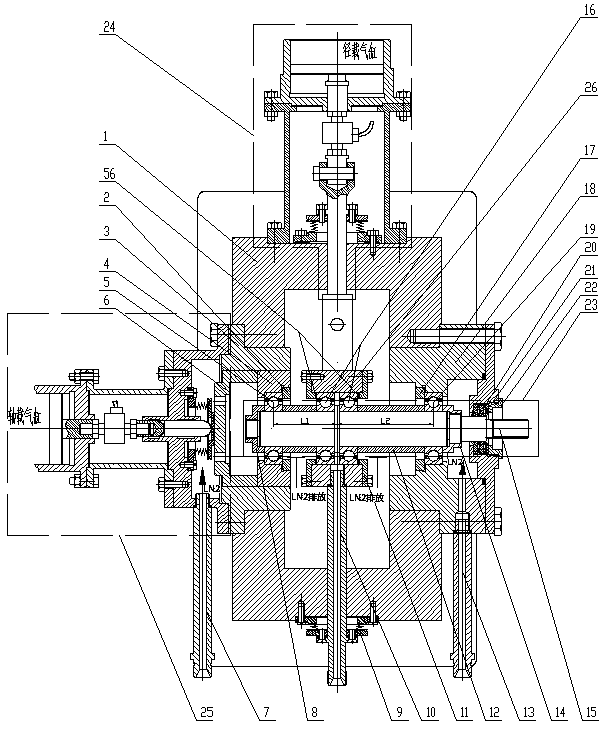

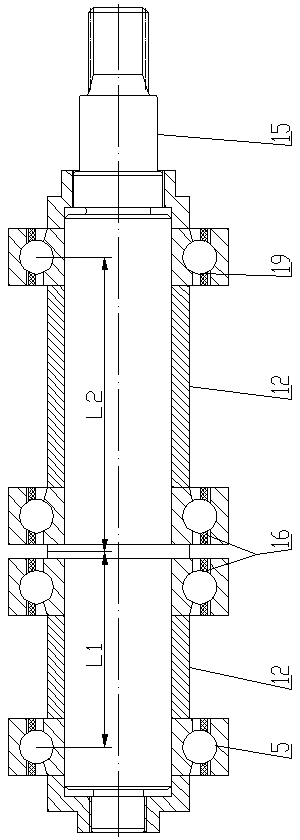

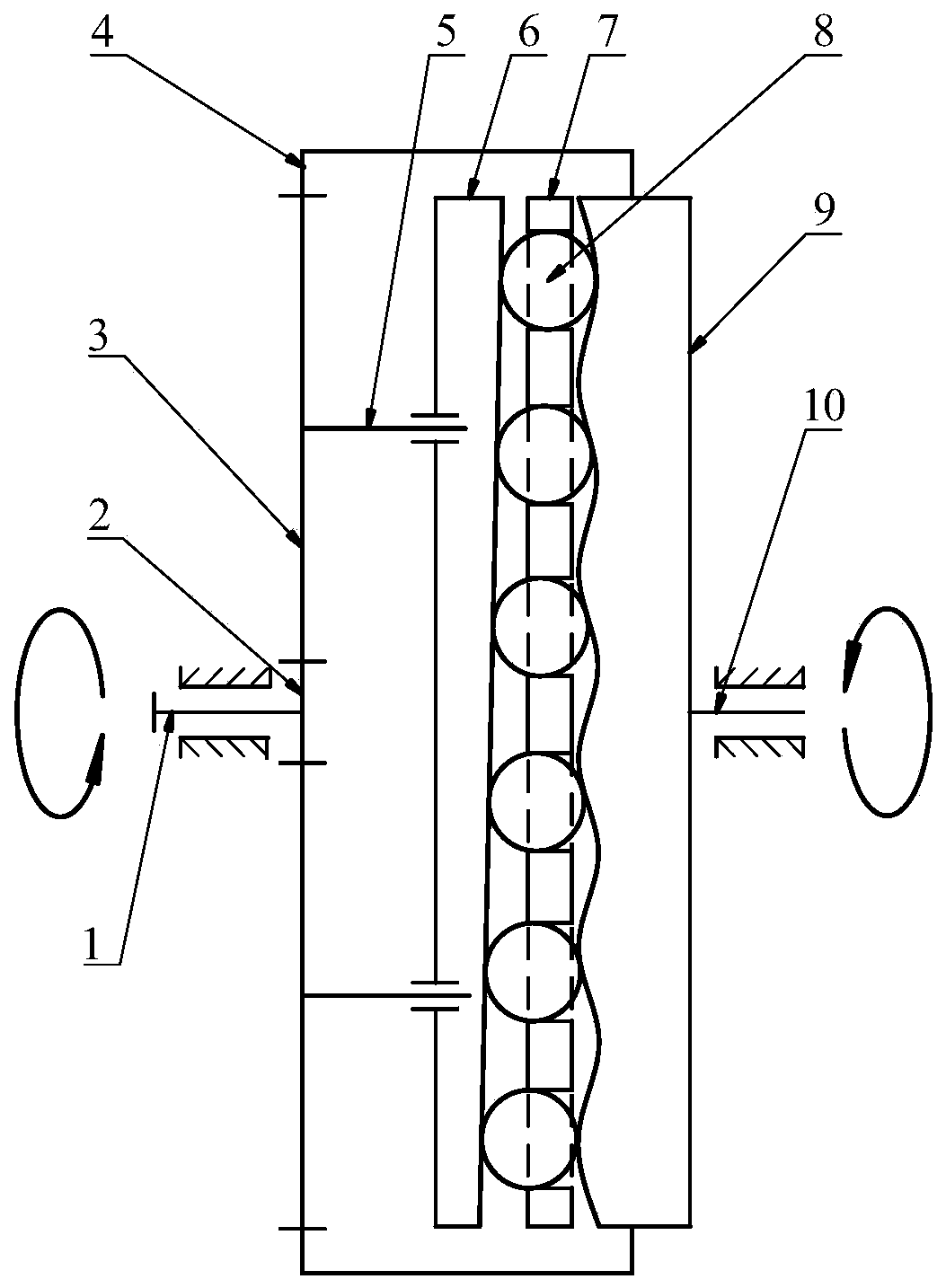

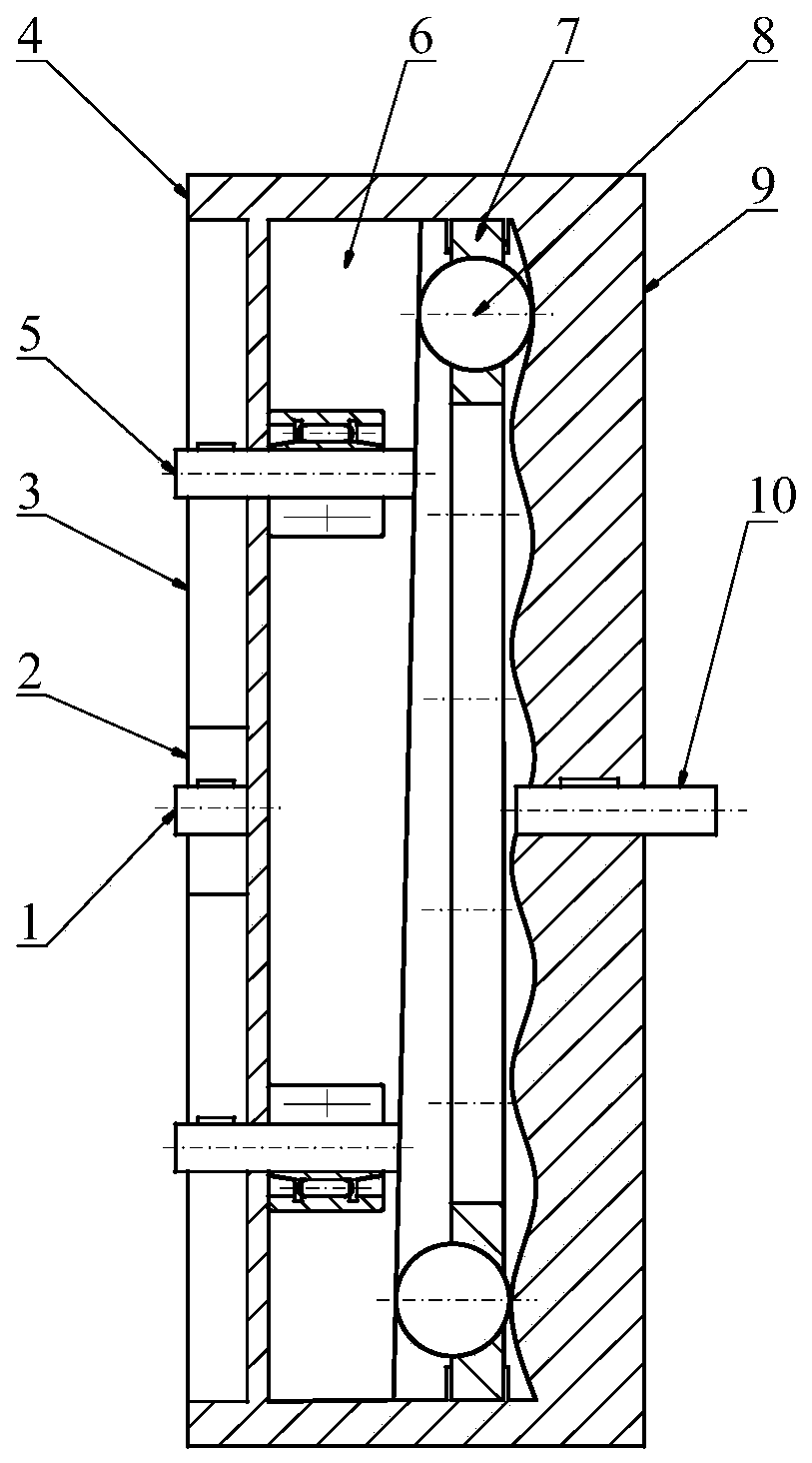

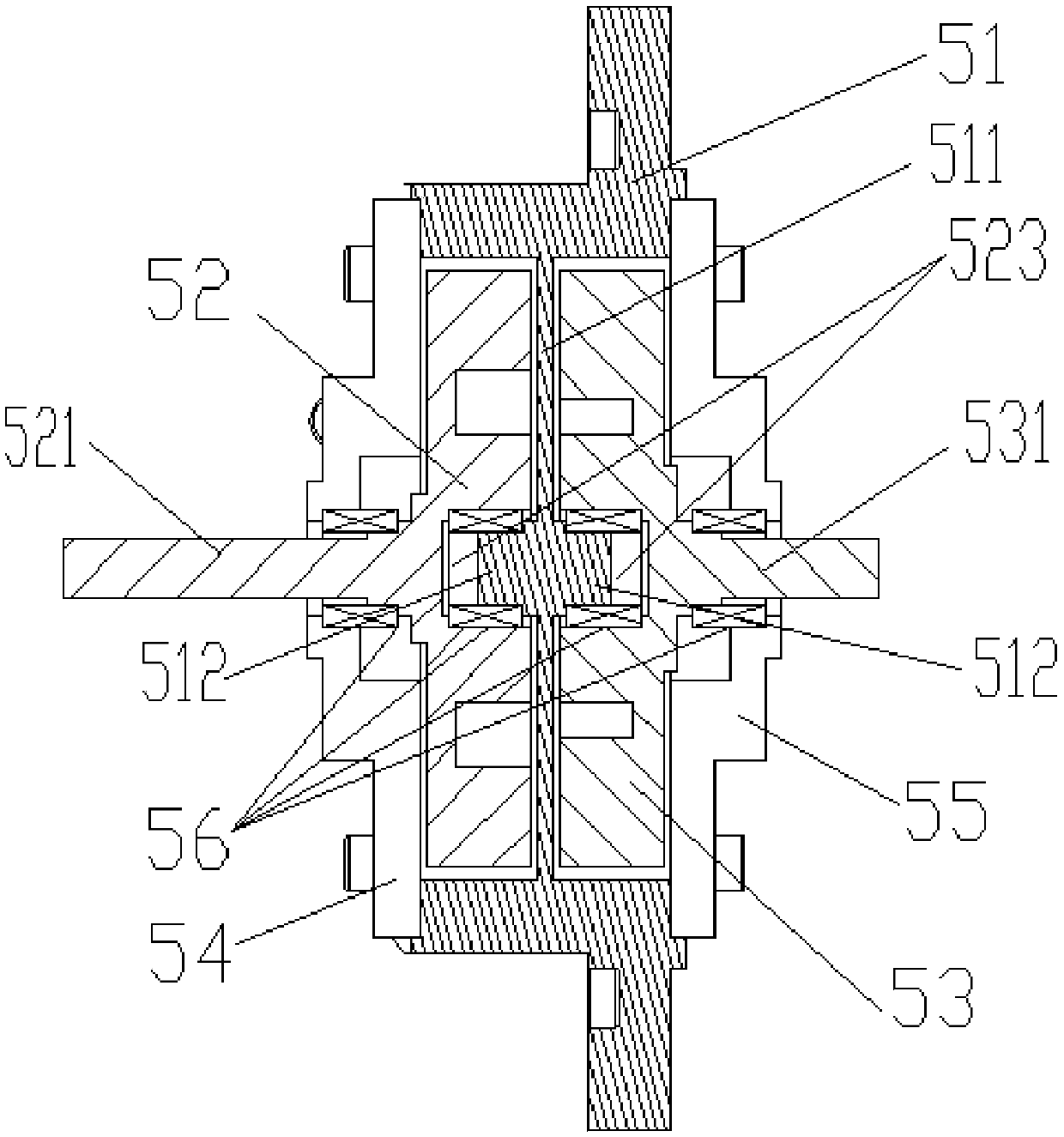

Test device and test method for fatigue life of bearing with ultra-low temperature and high DN value

PendingCN109975022AImprove cooling effectReduce vibrationMachine bearings testingRubber CupEngineering

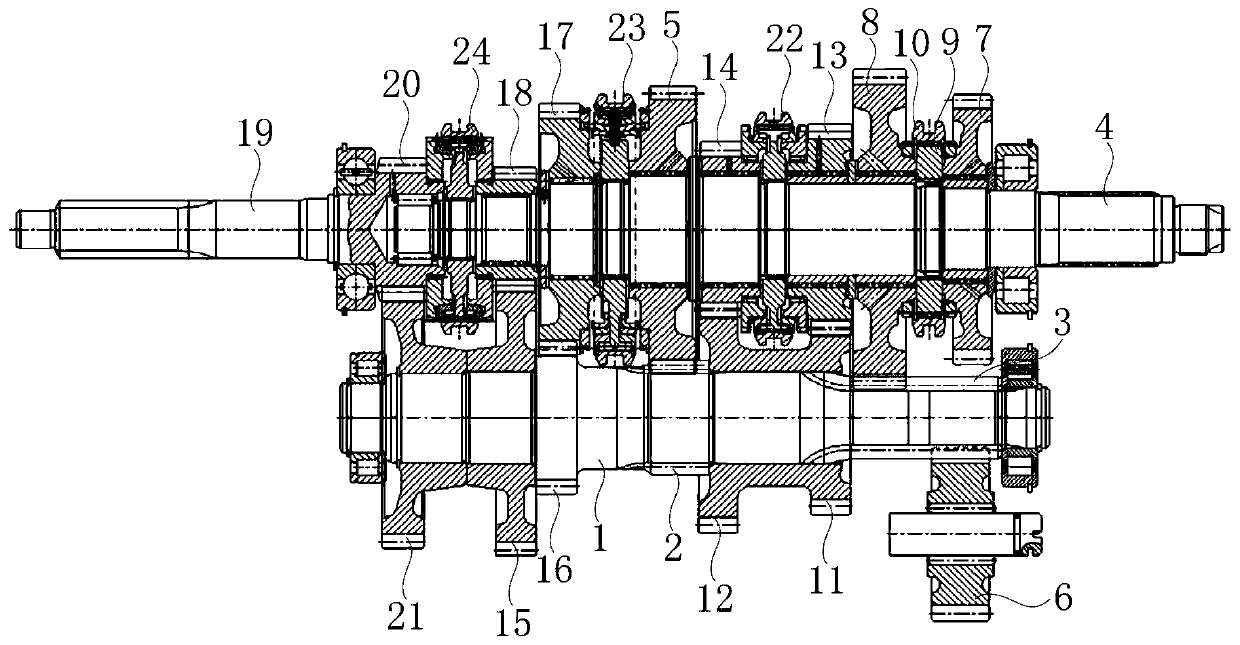

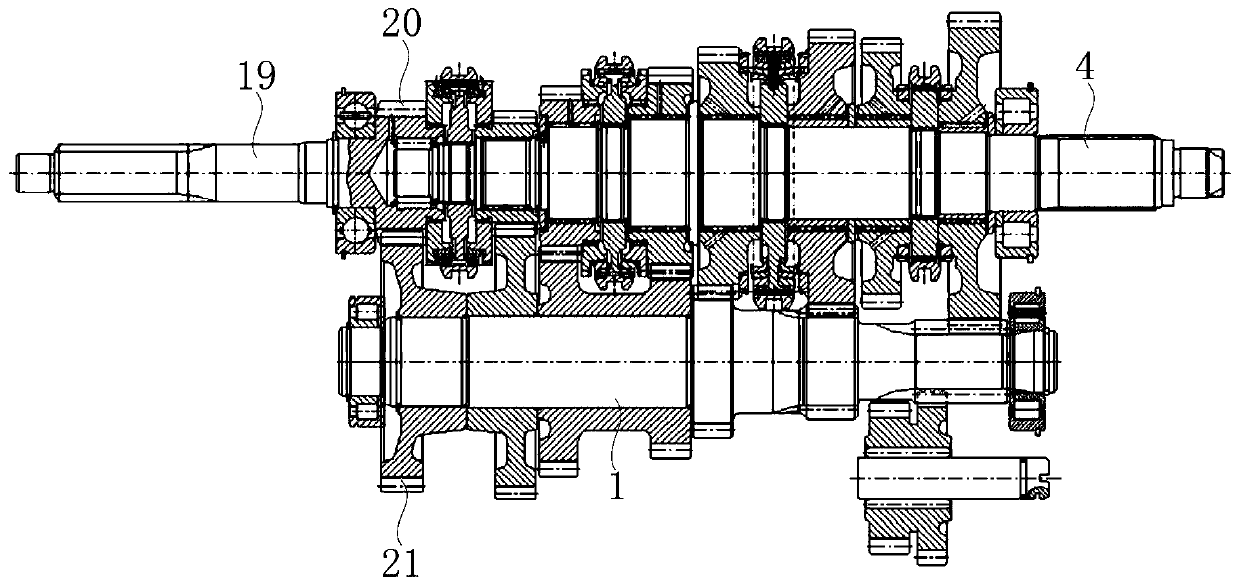

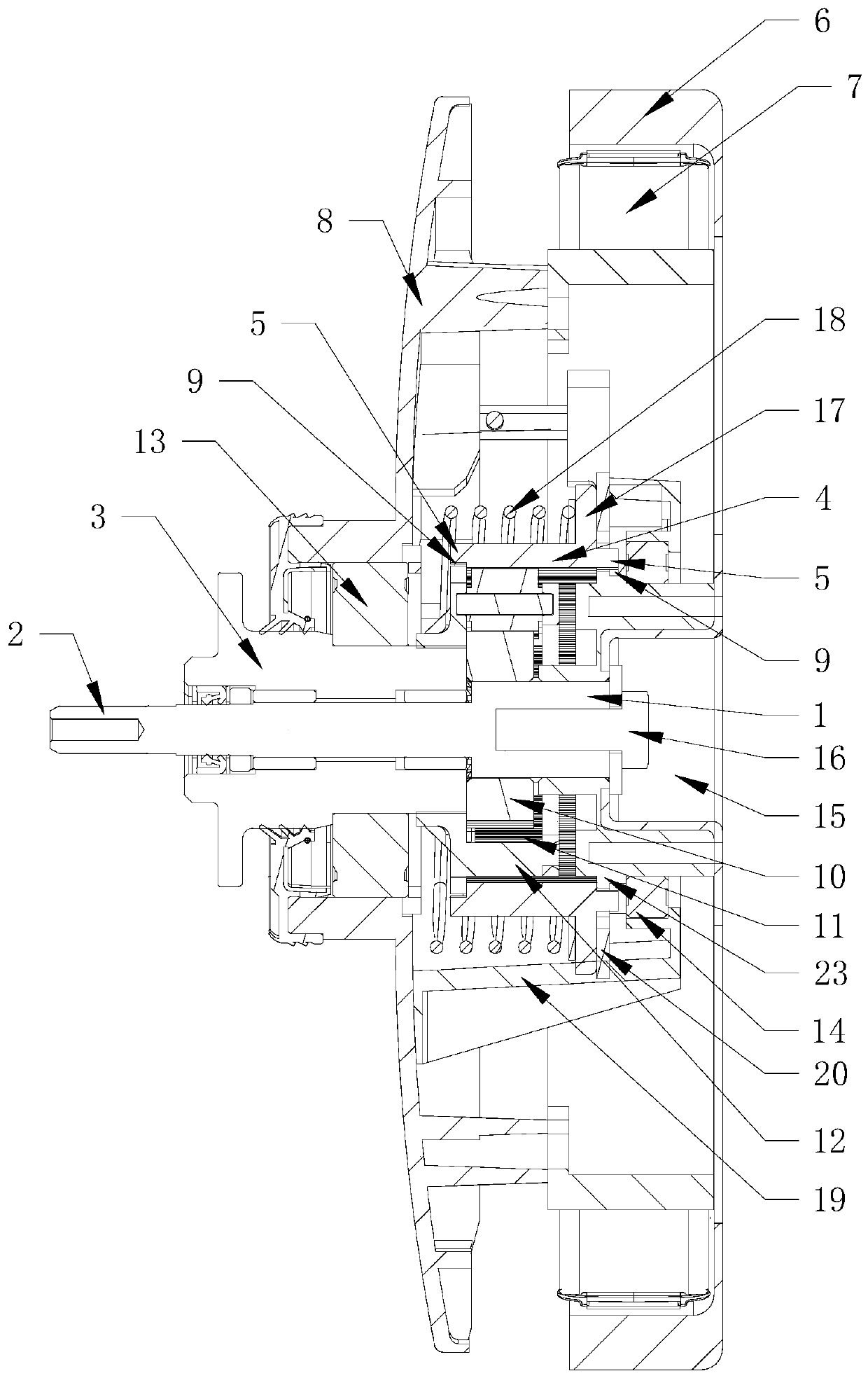

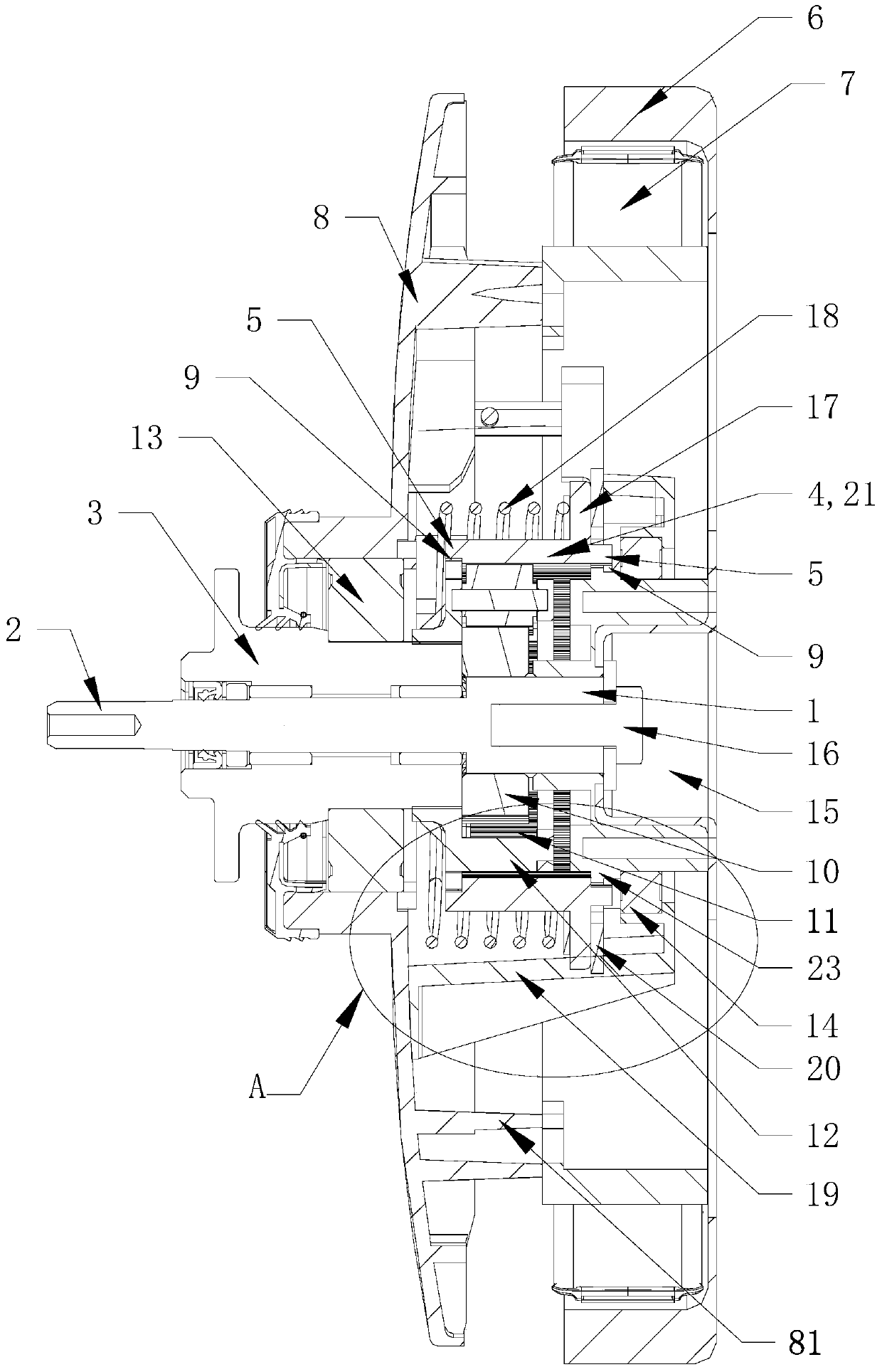

The invention discloses a test device and a test method for fatigue life of a bearing with ultra-low temperature and a high DN value. The test device comprises a device housing, wherein the device housing is connected with an axial flexible loading device and a radial flexible loading device; the axial flexible loading device and the radial flexible loading device are connected with a test rotor respectively; the test rotor comprises a main shaft; a tested bearing, a supporting process bearing, two loading process bearings and a shaft sleeve are installed on the main shaft; the main shaft andend covers are sealed by means of rubber cup sealing pieces; a force transmission sleeve having a through hole is installed between the axial flexible loading device and the radial flexible loading device; and a tested bearing outer sleeve and a front pressing cover fix a tested bearing outer ring through threaded connection, the tested bearing outer sleeve is connected with a front intermediate sleeve, and the front intermediate sleeve is connected with a front positioning cover. The test device and the test method realize the simulation of actual operating conditions of a low-temperature bearing in a turbopump of a low-temperature liquid rocket engine, including the ambient temperature, load, rotational speed and cooling flow rate being consistent or approximated to the actual operatingconditions.

Owner:北京宇航推进科技有限公司

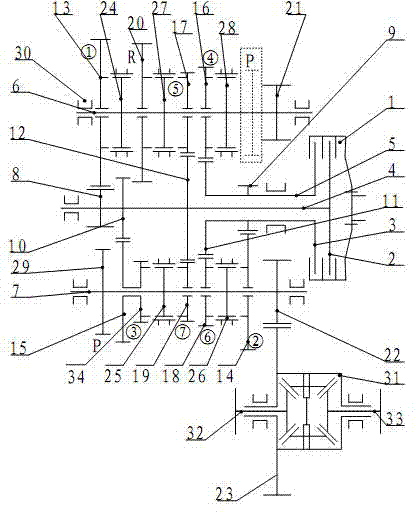

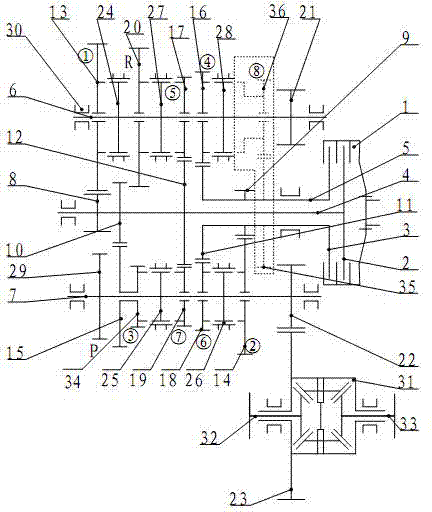

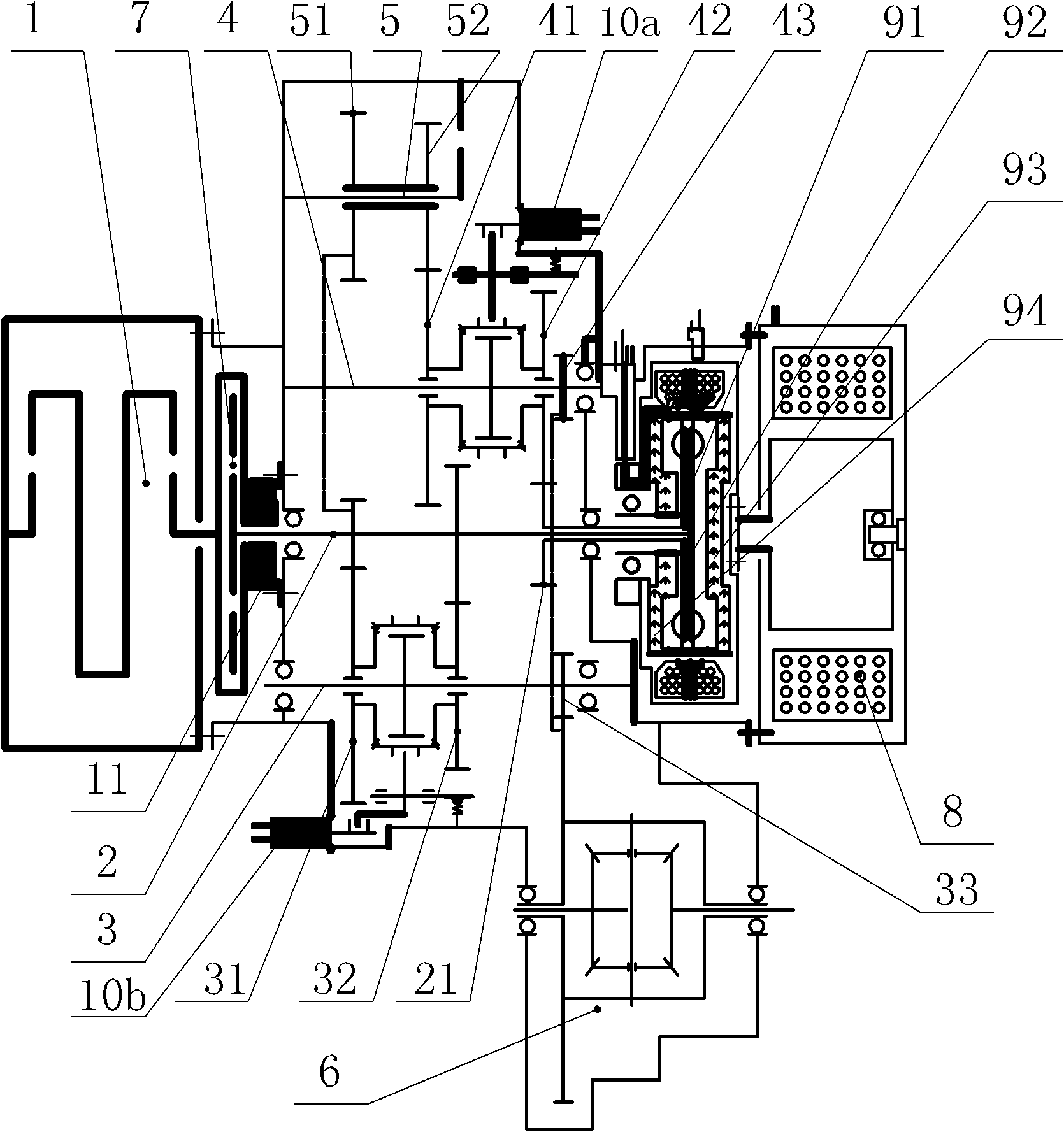

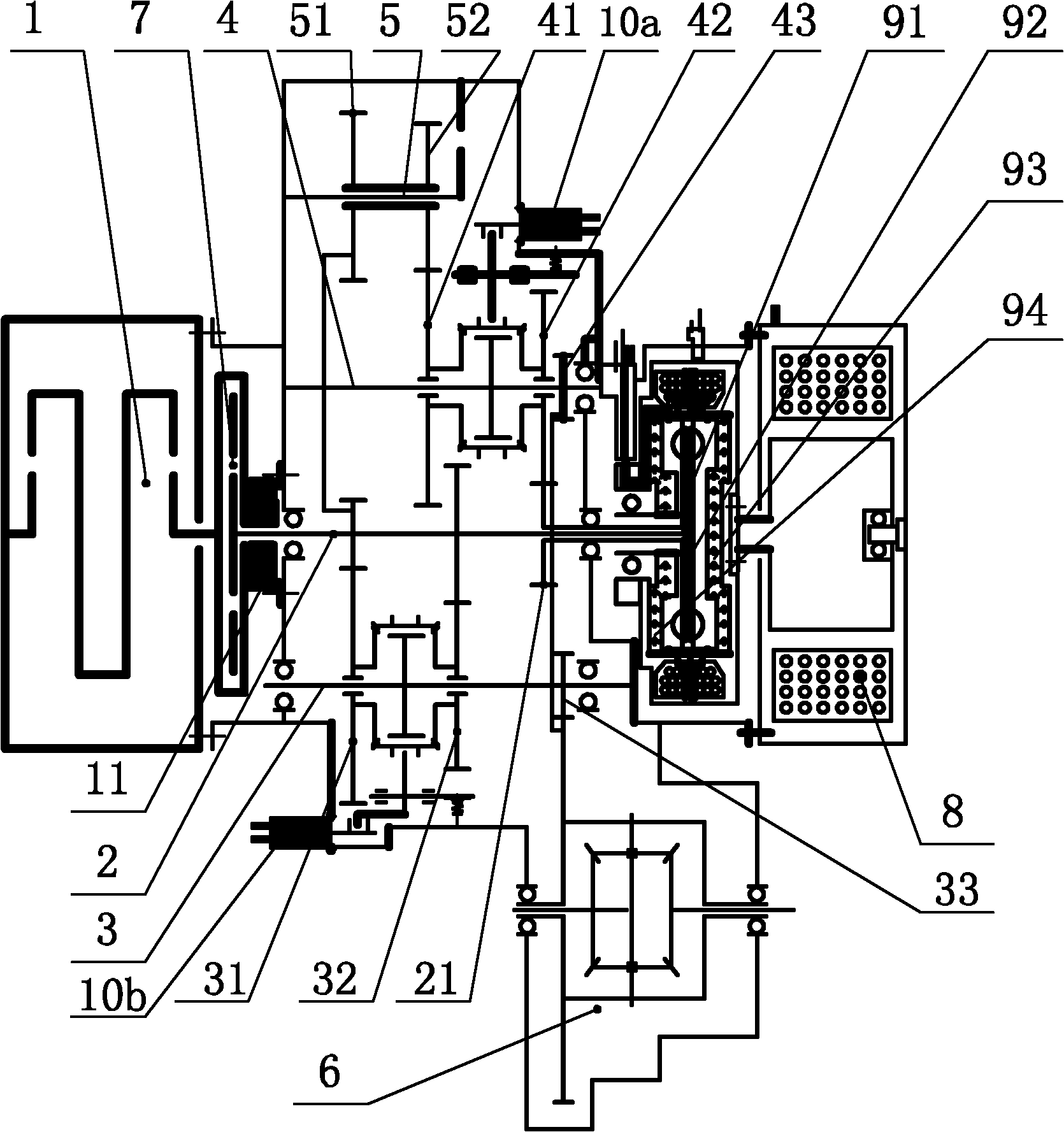

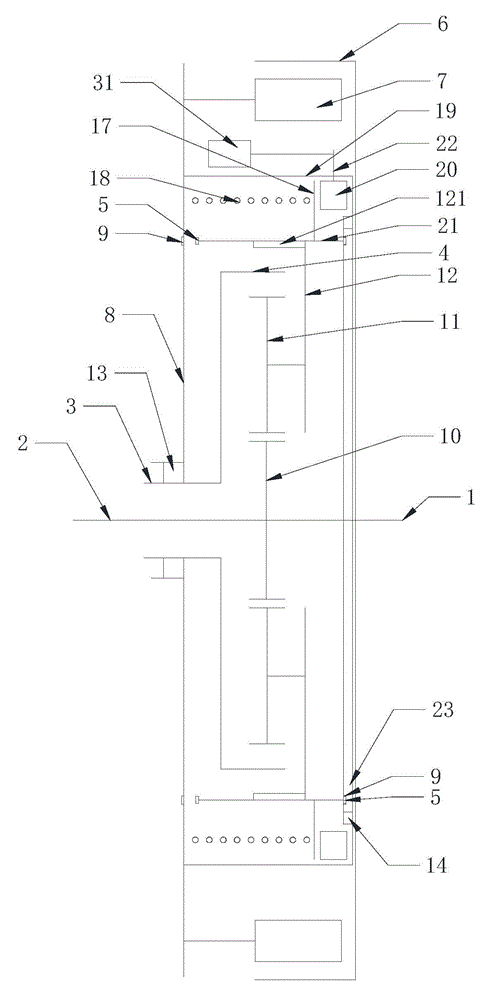

Variable-speed transmission mechanism of double-clutch speed changer

InactiveCN103195880AReduce in quantityReduce consumptionToothed gearingsGearing detailsEngineeringPower performance

The invention provides a variable-speed transmission mechanism of a double-clutch speed changer. The variable-speed transmission mechanism of the double-clutch speed changer is used for solving the problem of vehicle power transmission and comprises a first input shaft, a second input shaft, a first intermediate shaft, a second intermediate shaft and a differential mechanism output assembly. The first input shaft and the second input shaft with a hollow structure are installed in sleeved mode, the first input shaft is an odd-gear and reverse-gear driving gear fixing shaft, the second input shaft is an even-gear driving gear fixing shaft, driven gears at different gears and synchronizers are sleeved on the first intermediate shaft and the second intermediate shaft, and the first intermediate shaft and the second intermediate shaft are respectively connected with the differential mechanism output assembly. The variable-speed transmission mechanism of the double-clutch speed changer is characterized in that a third-gear driven gear and a reverse-gear idle gear are sleeved on the second intermediate shaft and are of a connection tooth structure. The variable-speed transmission mechanism of the double-clutch speed changer is compact in arrangement, smooth in power connection and rapid in gear shifting response and remarkably improves power performance and economic performance of a vehicle.

Owner:GREAT WALL MOTOR CO LTD

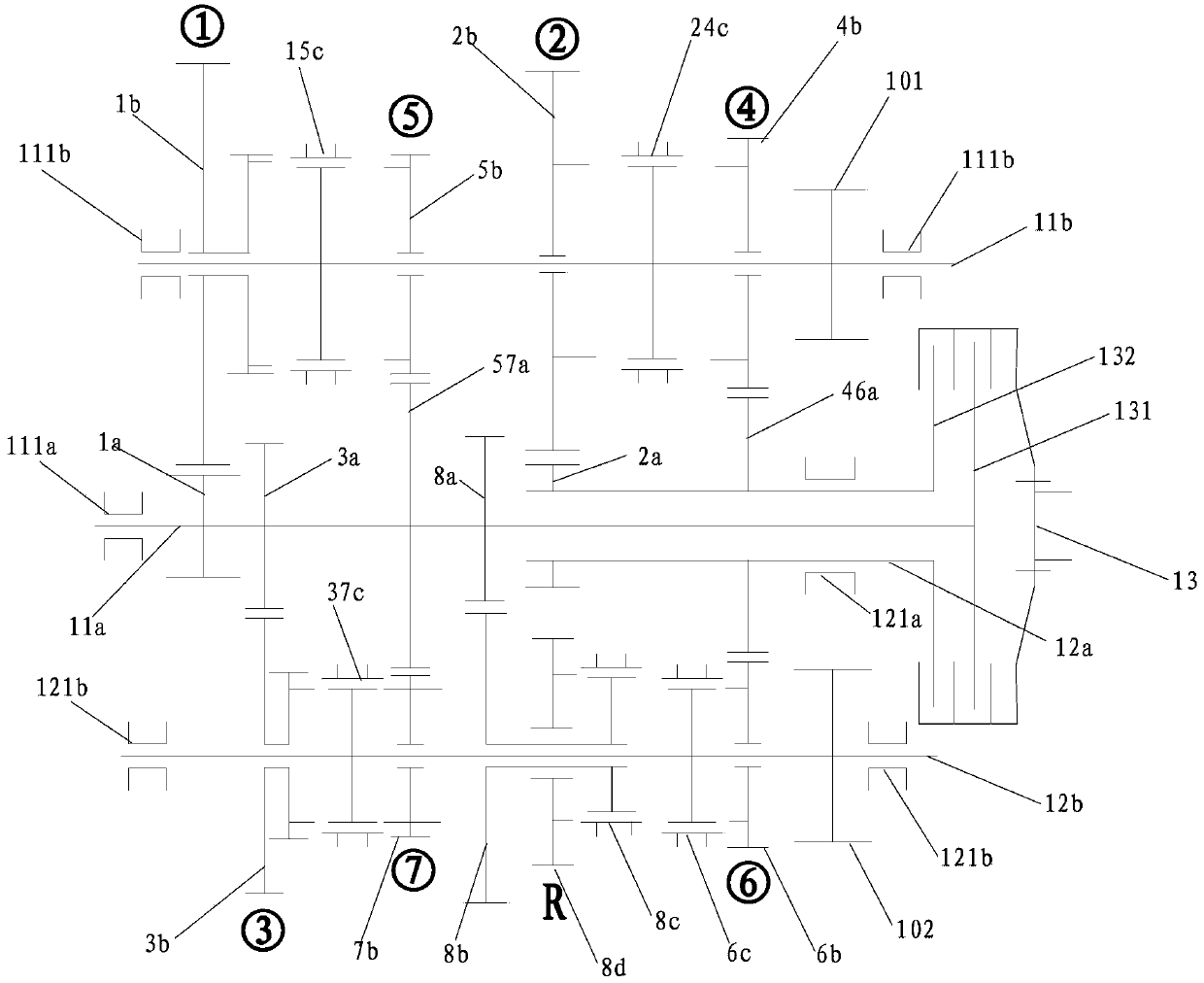

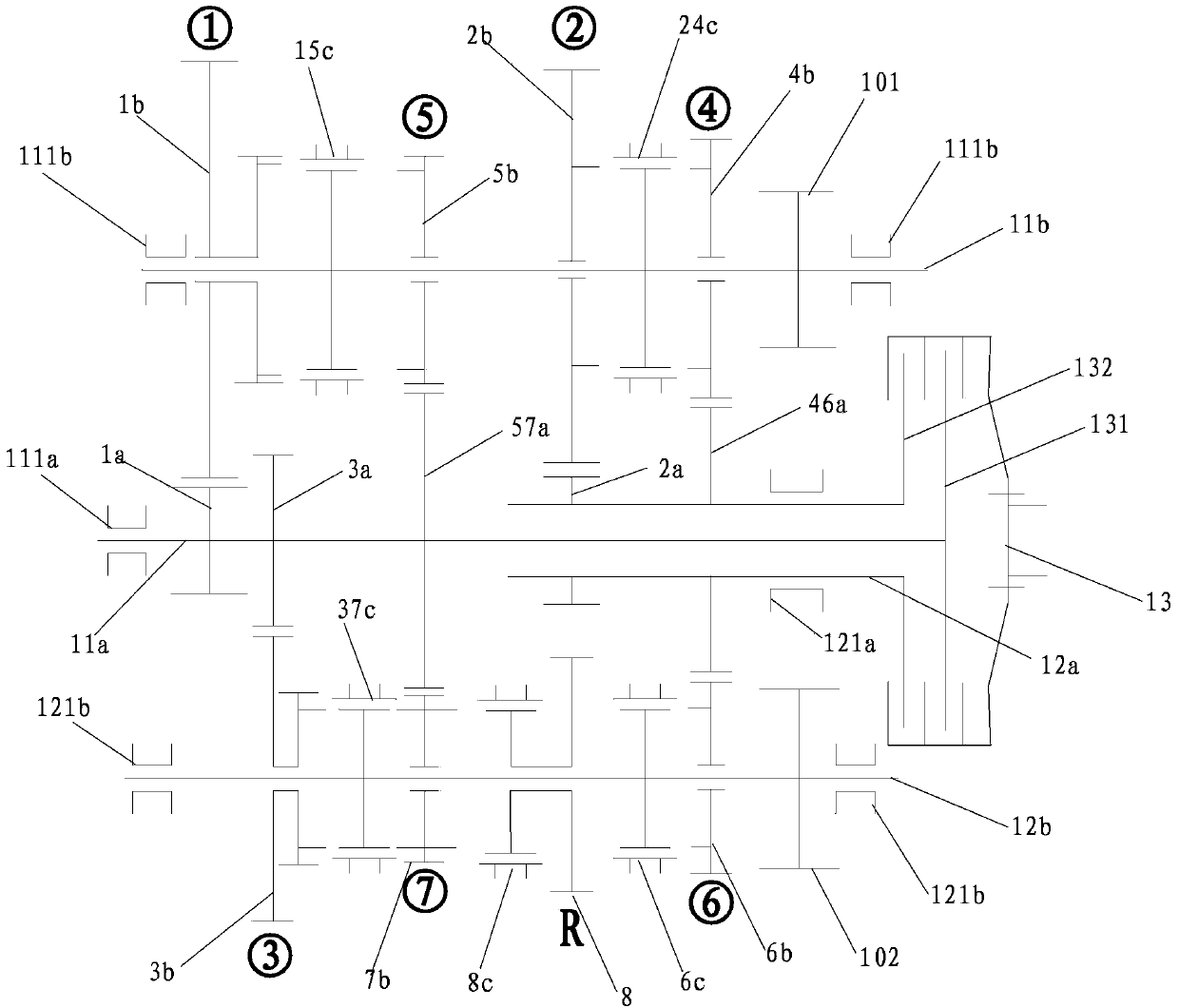

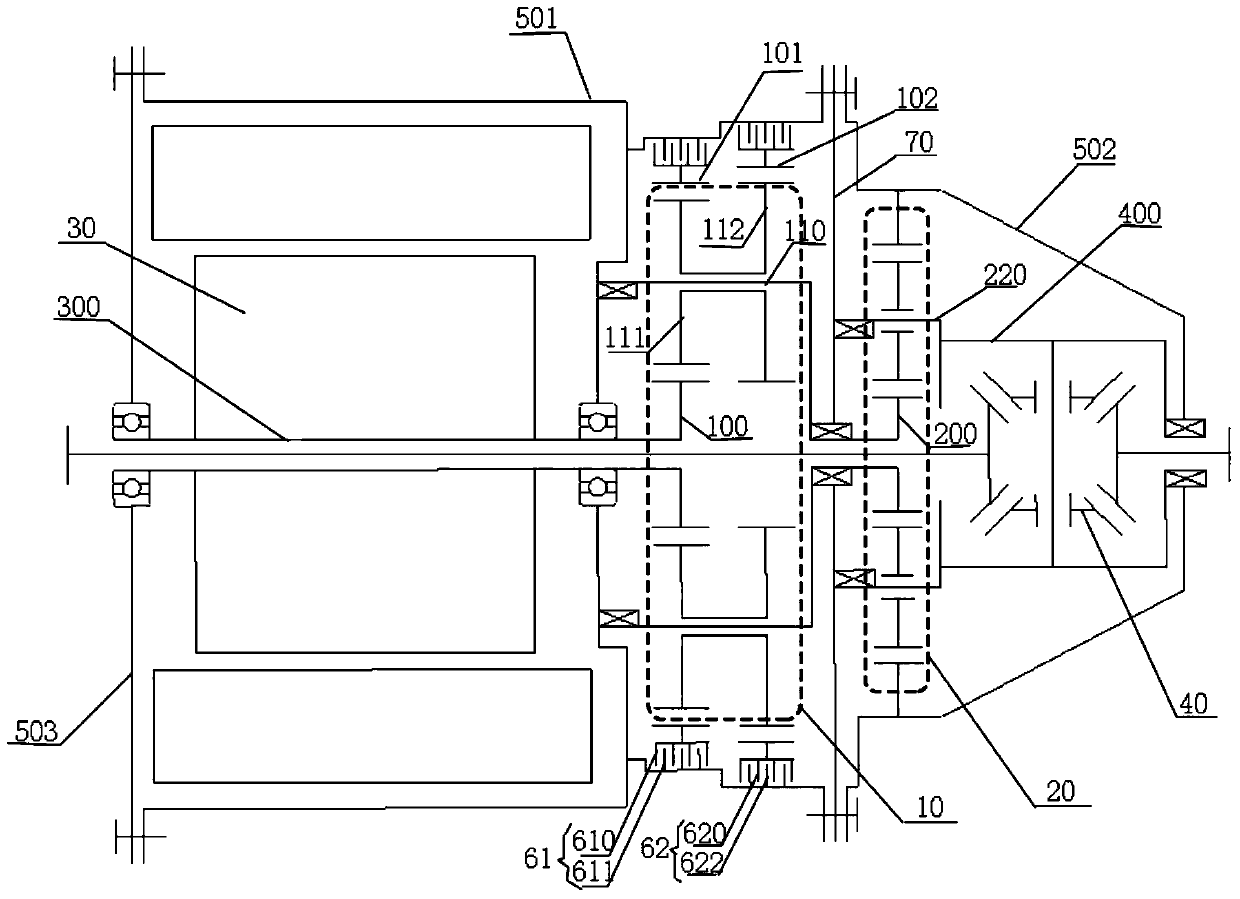

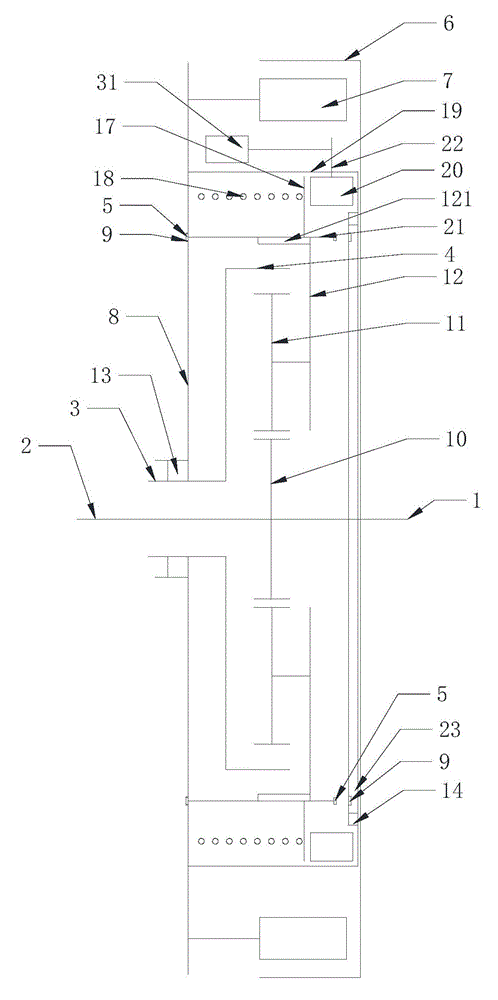

Transmission and vehicle provided with same

The invention discloses a transmission and a vehicle provided with the transmission. The transmission comprises a double clutch, a first input shaft, a second input shaft, a first output shaft, a second output shaft, a first-fifth gear synchronizer, a second-fourth gear synchronizer, a third-seventh gear synchronizer, a sixth gear synchronizer and a reverse gear synchronizer. The double clutch comprises a first clutch plate and a second clutch plate, the first input shaft is connected with the first clutch plate, the first input shaft is fixedly provided with a first-gear driving gear, a third-gear driving gear, a fifth-seventh-gear driving gear and a reverse gear driving gear, the second input shaft is connected with the second clutch plate, the second input shaft is fixedly provided with a second-gear driving gear and a fourth-sixth-gear driving gear, the first output shaft is sleeved with a first-gear driven gear, a fifth-gear driven gear, a second-gear driven gear and a fourth-gear driven gear, the second output shaft is sleeved with a third-gear driven gear, a seventh-gear driven gear, a reverse-gear driven gear, a sixth-gear driven gear and a reverse-gear intermediate gear which is meshed with the second-gear driven gear. According to the transmission disclosed by the invention, the number of driving gears can be reduced, and accordingly the volume of the transmission is reduced.

Owner:HYCET TRANSMISSION TECH HEBEI CO LTD

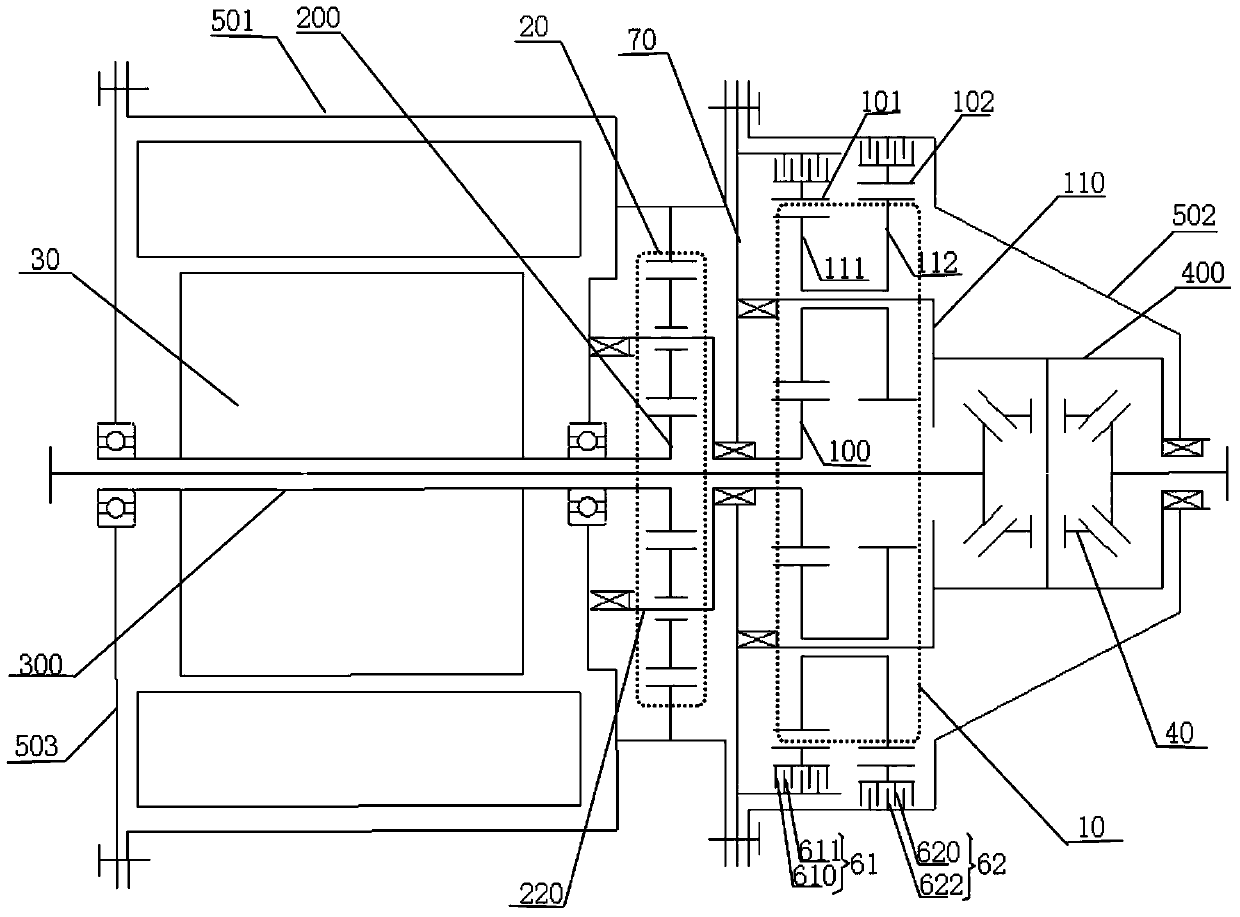

Transmission and vehicle provided with same

The invention discloses a transmission and a vehicle provided with the transmission. The transmission comprises a double clutch, a first input shaft, a second input shaft, a first output shaft, a second output shaft, a first-fifth gear synchronizer, a second-fourth gear synchronizer, a third-seventh gear synchronizer, a sixth gear synchronizer and a reverse gear synchronizer. The double clutch comprises a first clutch plate and a second clutch plate, the first input shaft is connected with the first clutch plate, the first input shaft is fixedly provided with a first-gear driving gear, a third-gear driving gear and a fifth-seventh-gear driving gear, the second input shaft is connected with the second clutch plate, the second input shaft is fixedly provided with a second-gear driving gear and a fourth-sixth-gear driving gear, the first output shaft is sleeved with a first-gear driven gear, a fifth-gear driven gear, a second-gear driven gear and a fourth-gear driven gear, the second output shaft is sleeved with a third-gear driven gear, a seventh-gear driven gear, a sixth-gear driven gear and a reverse-gear gear which is meshed with the second-gear driven gear, and the reverse gear synchronizer is used for connecting the reverse-gear gear with the third-gear driven gear or the seventh-gear driven gear. According to the transmission disclosed by the invention, the number of driving gears can be reduced, and accordingly the volume of the transmission is reduced.

Owner:HYCET TRANSMISSION TECH HEBEI CO LTD

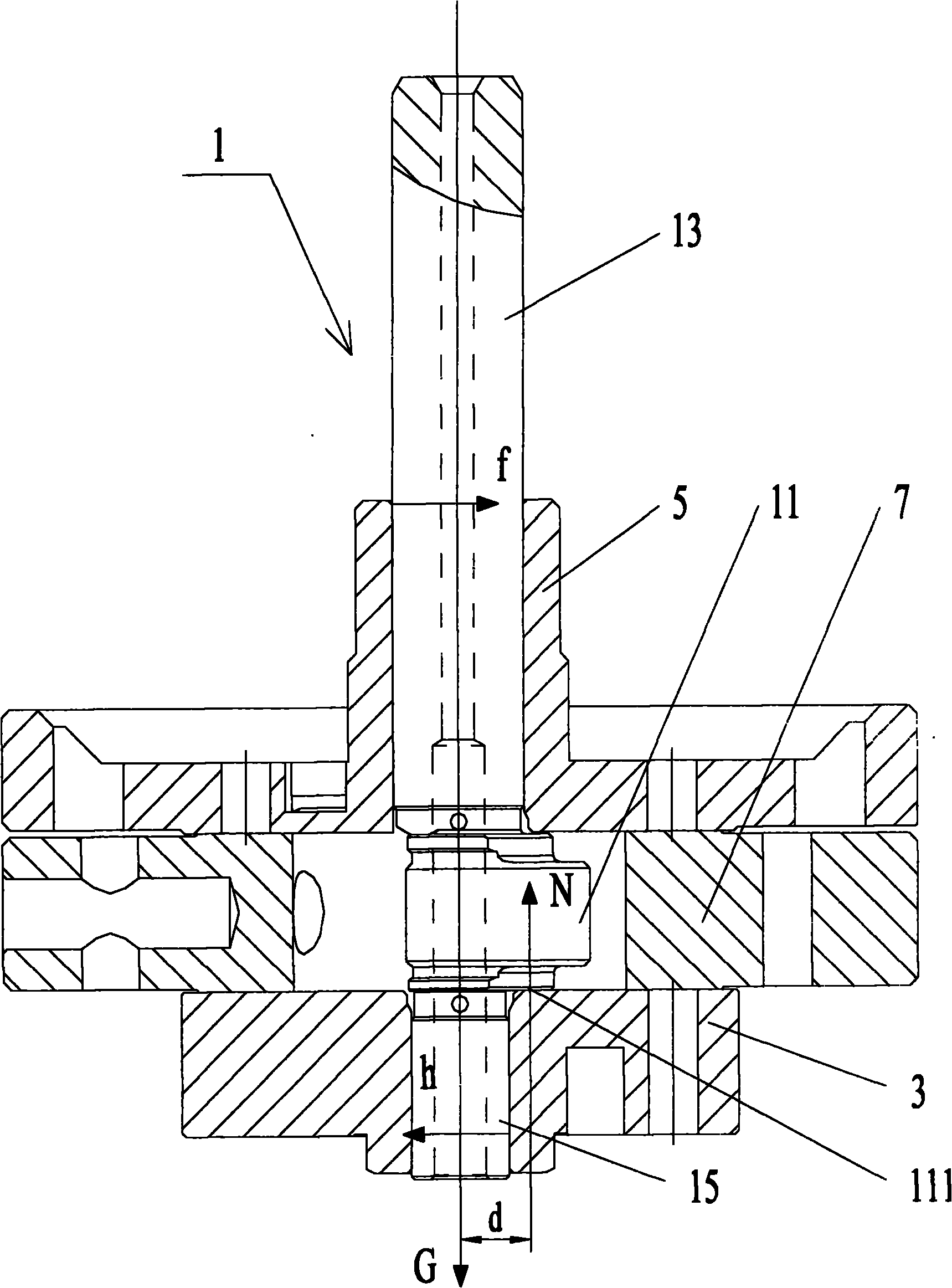

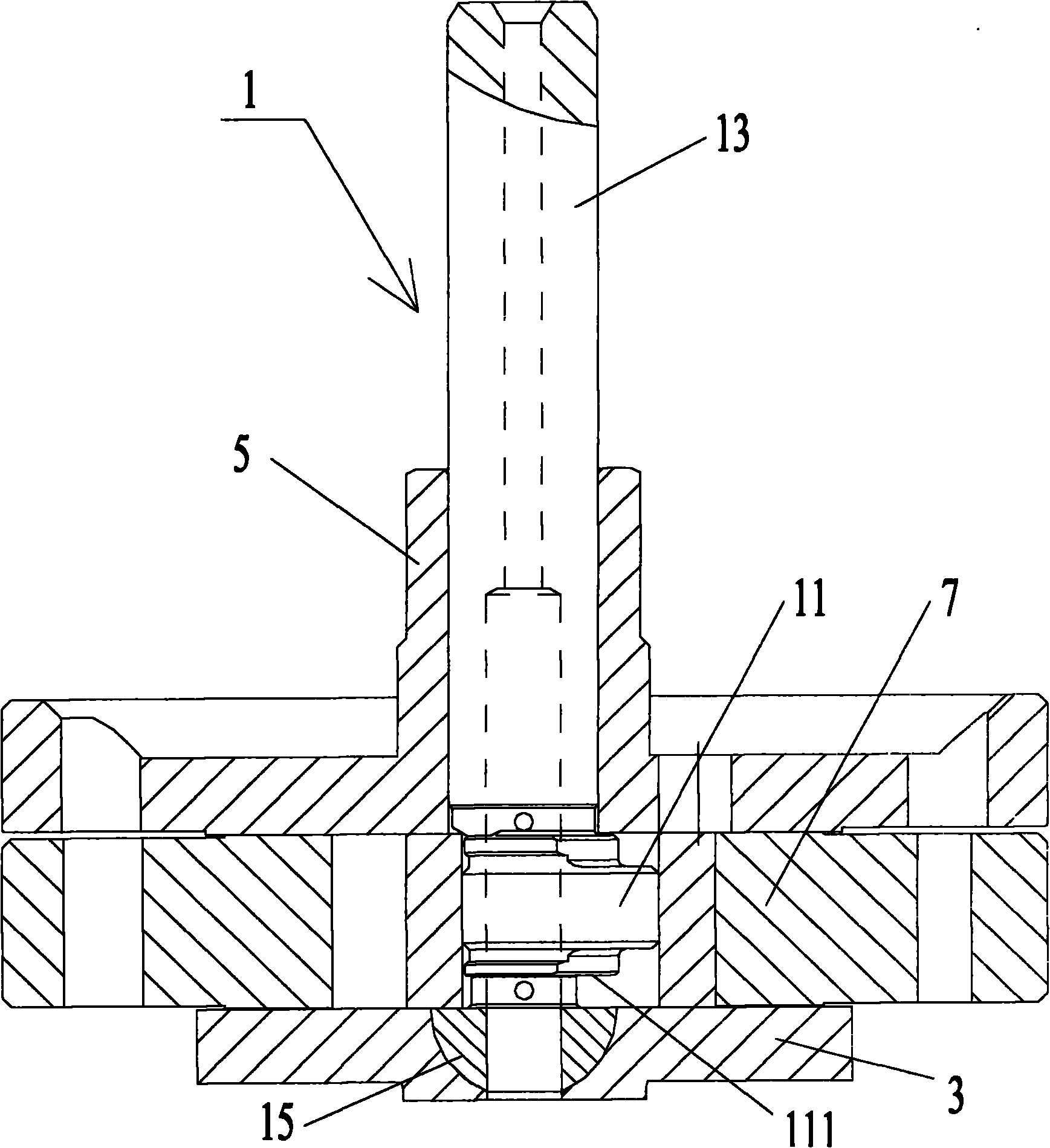

Rear power takeoff for speed changing box

The invention discloses a rear power takeoff for a speed changing box, which comprises a power takeoff gear shaft, wherein one end of the power takeoff gear shaft is provided with a spline section and an output shaft being in coaxial on-off with the power takeoff gear shaft, a shaft circle at one end of the output shaft is provided with a spline section corresponding to the spline section on the power takeoff gear shaft, the spline section of the output shaft is connected with a clutch spline sleeve which is connected with a clutch drive device, and the other end of the output shaft is provided with an output connecting spline hole. The rear power takeoff also comprises a front shell and a rear shell which are connected mutually, the shaft end of the power takeoff gear shaft is provided with a connecting supporting hole, the end part of the output shaft is supported in the connecting supporting hole at the shaft end of the power takeoff gear shaft through a bearing, and the other end of the output shaft is supported between the front shell and the rear shell. The rear power takeoff has compact axial structure and small volume, and can be widely applied to medium and heavy speed changing boxes.

Owner:DONGFENG MOTOR CORP HUBEI

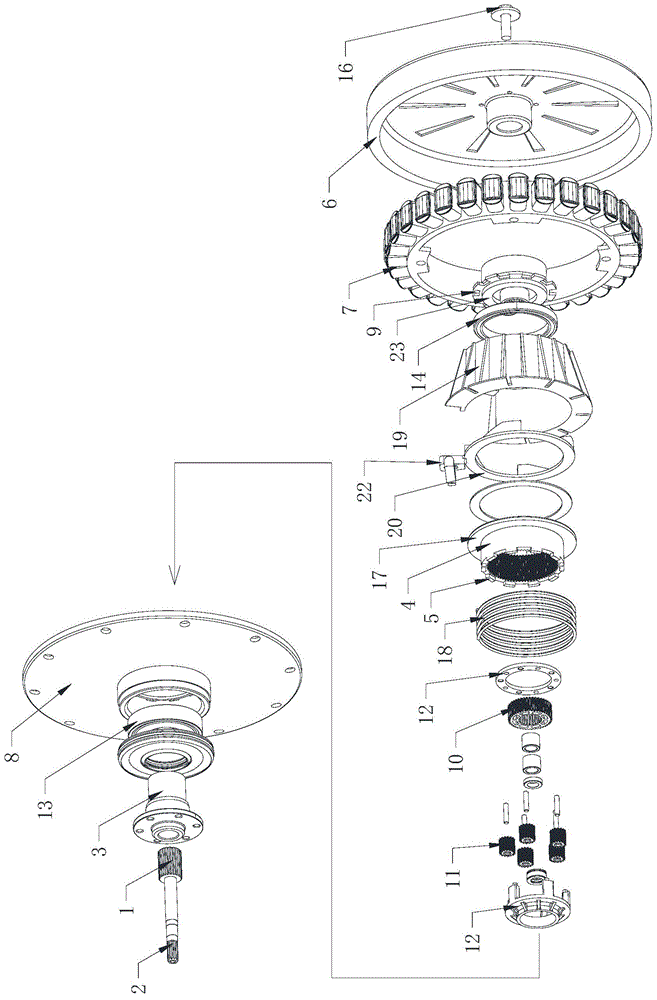

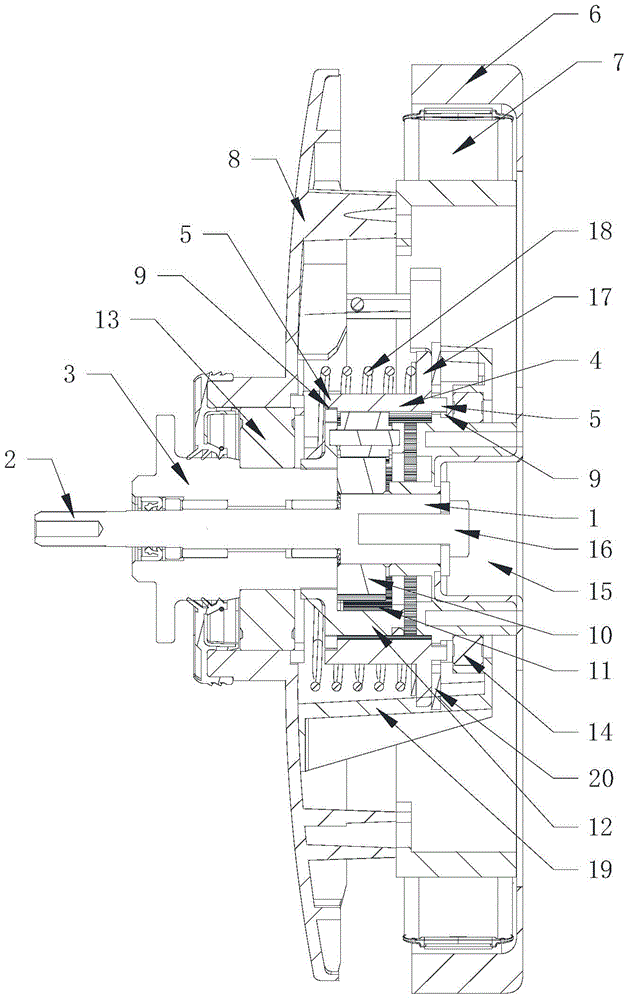

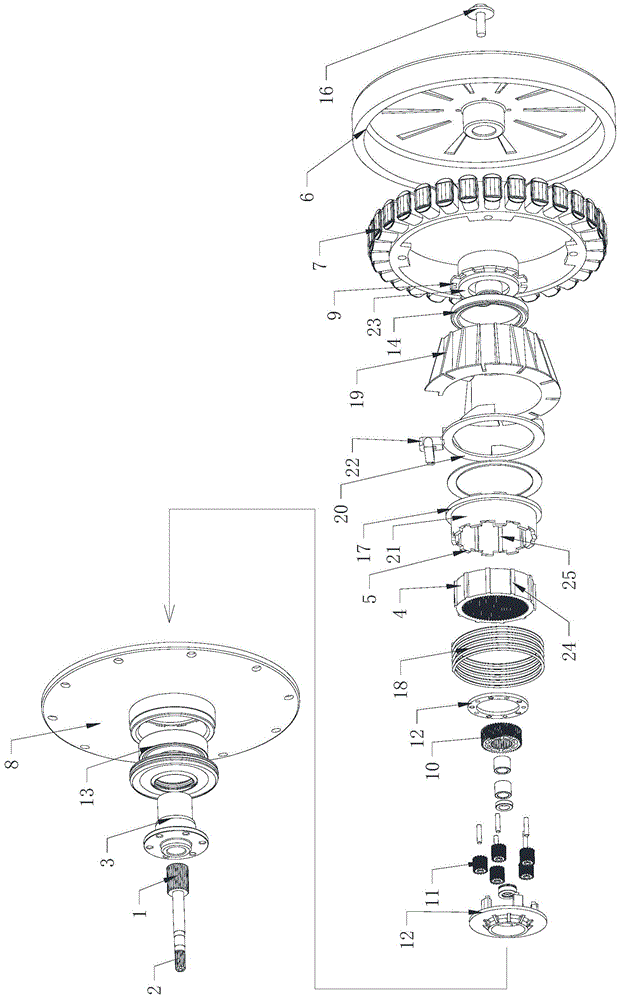

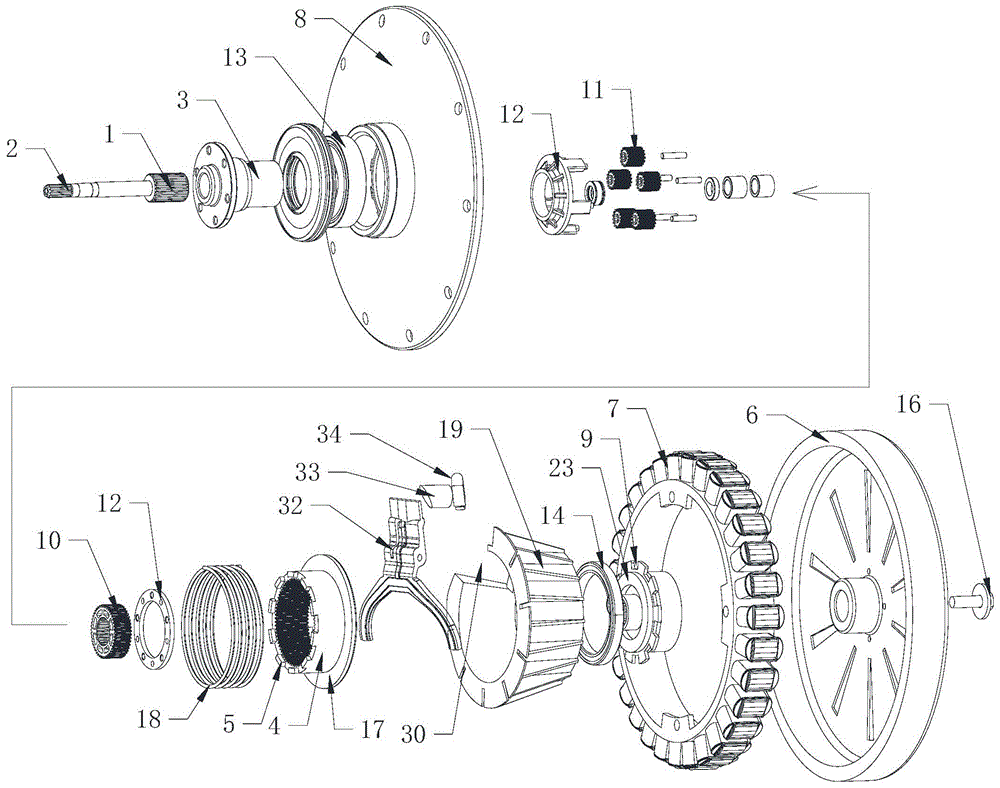

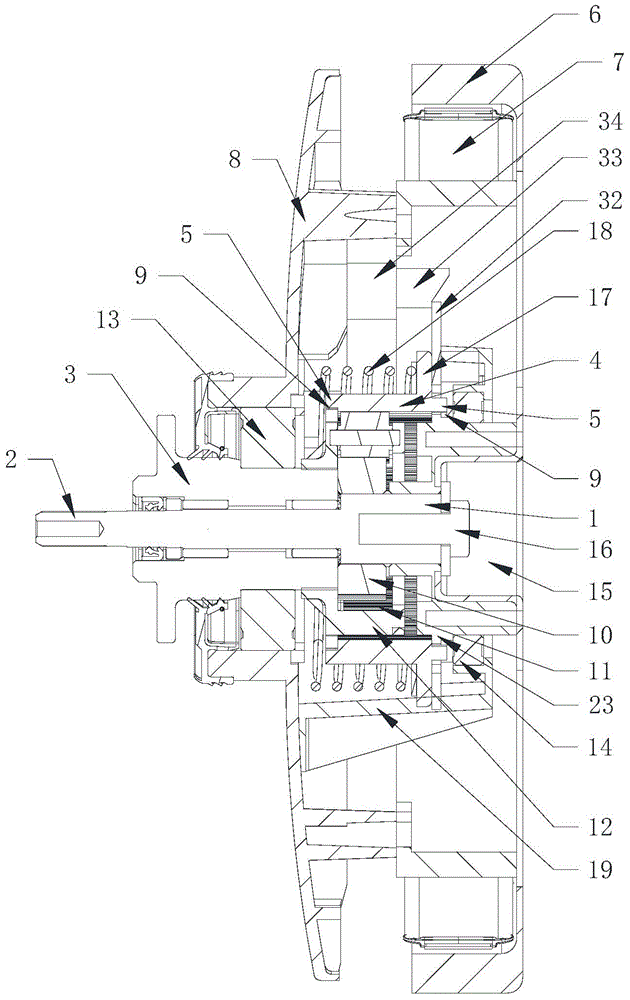

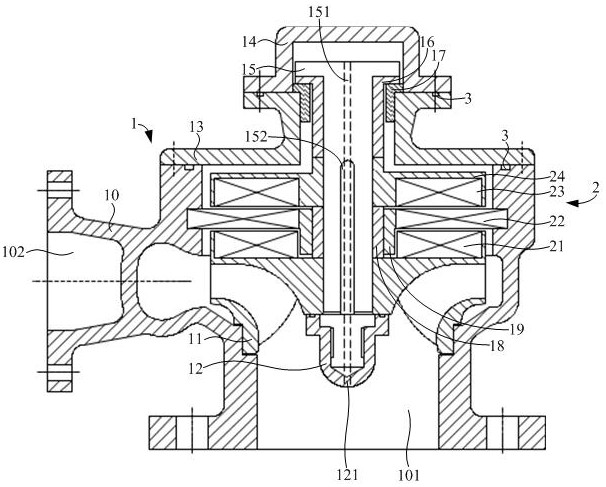

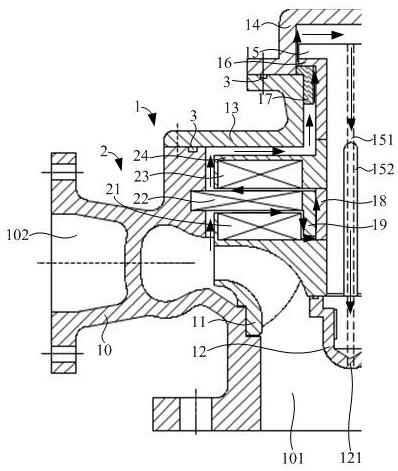

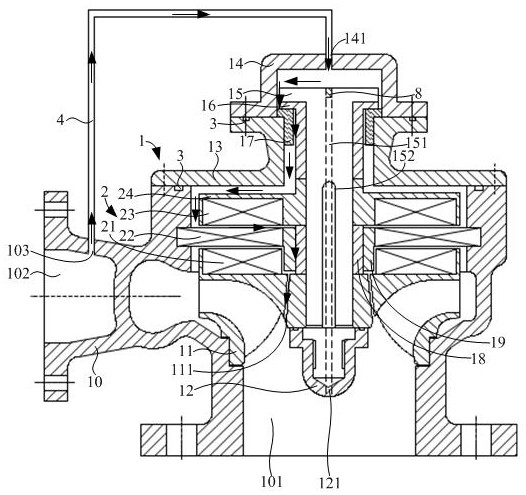

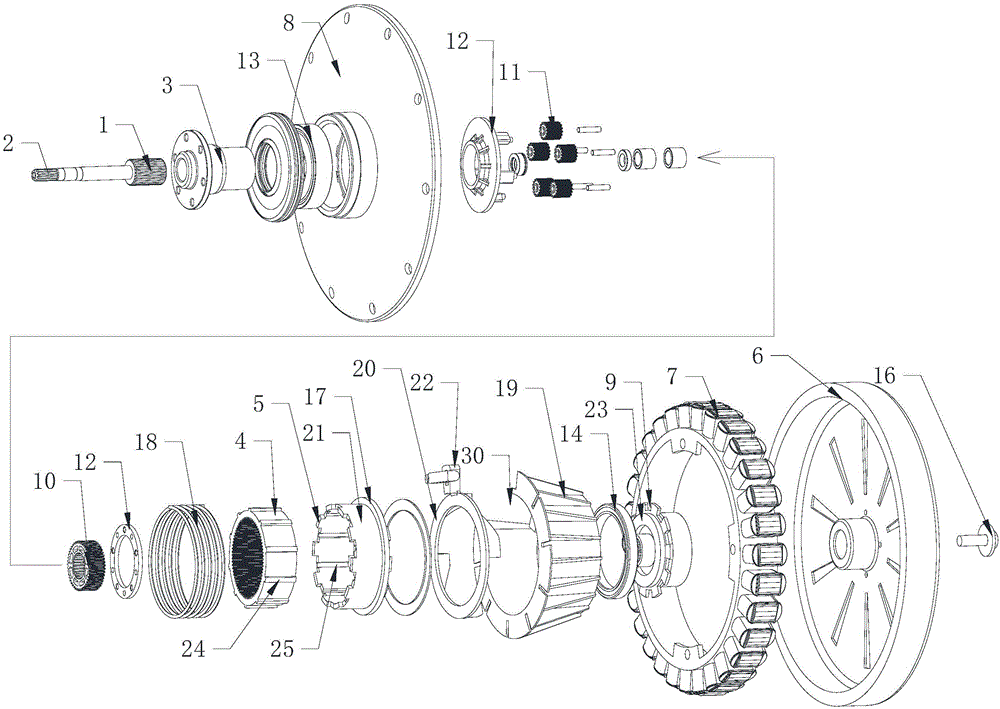

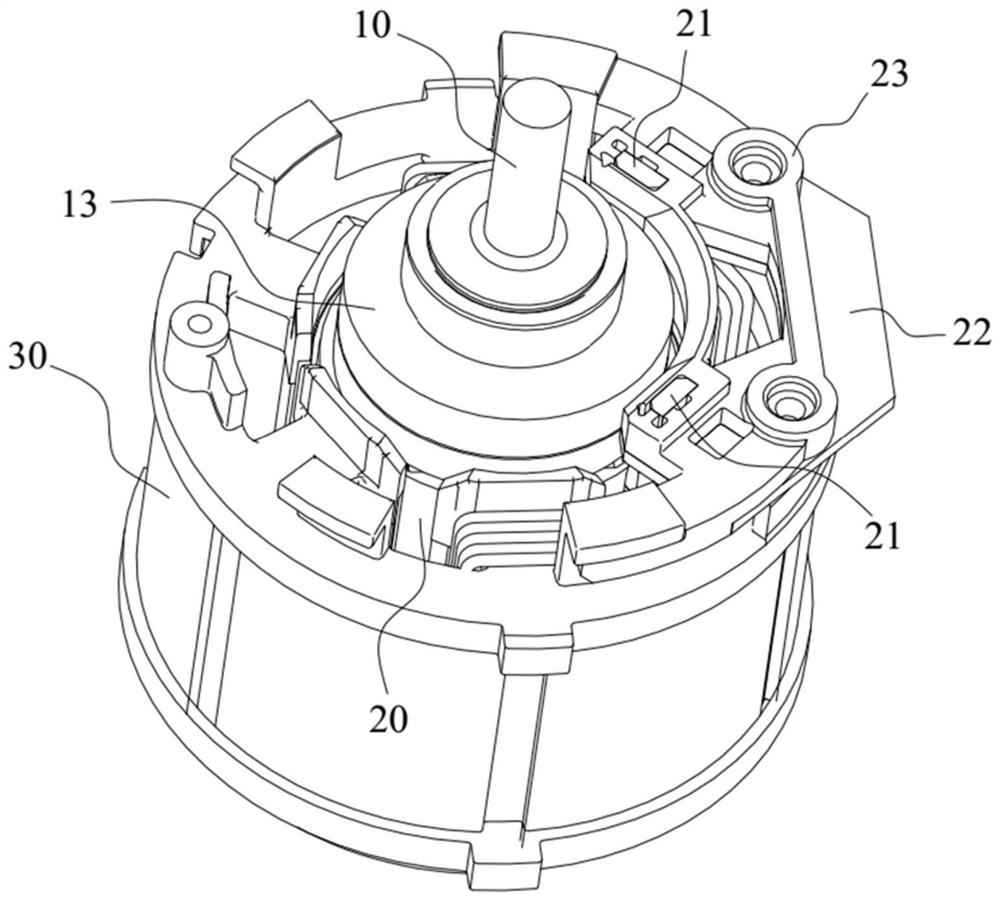

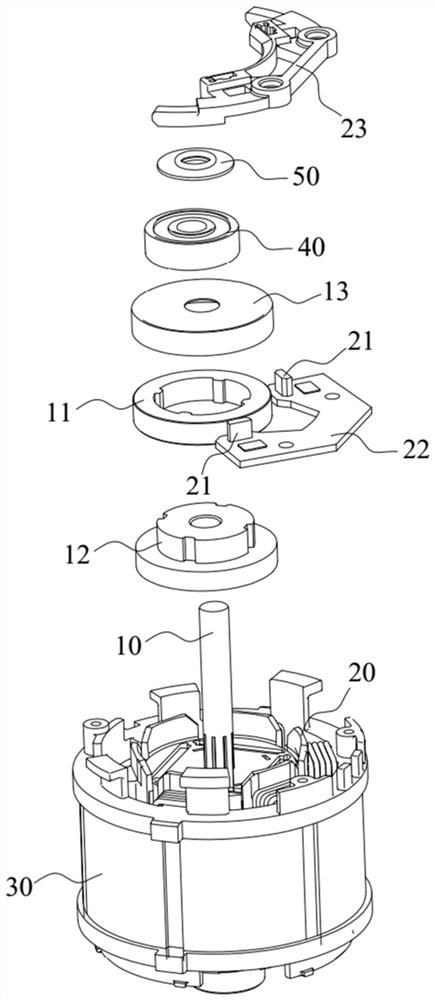

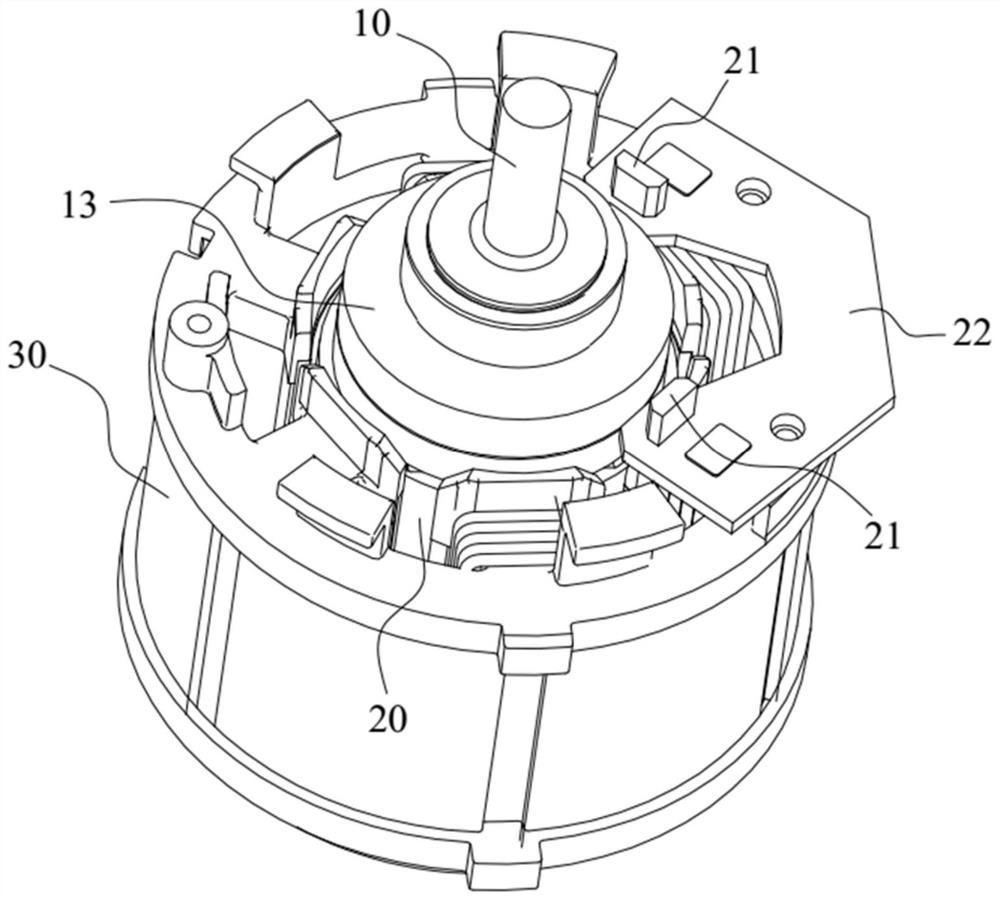

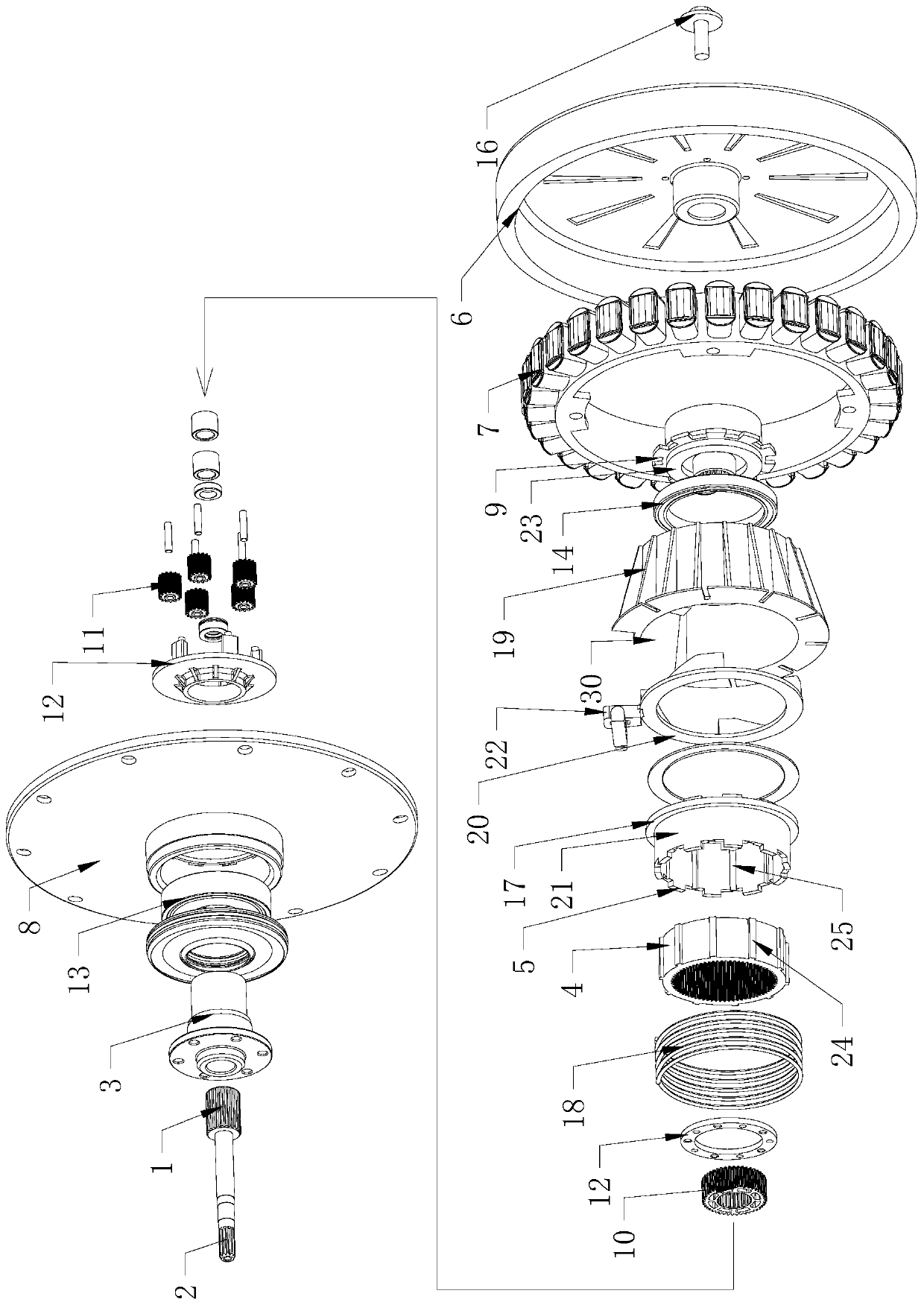

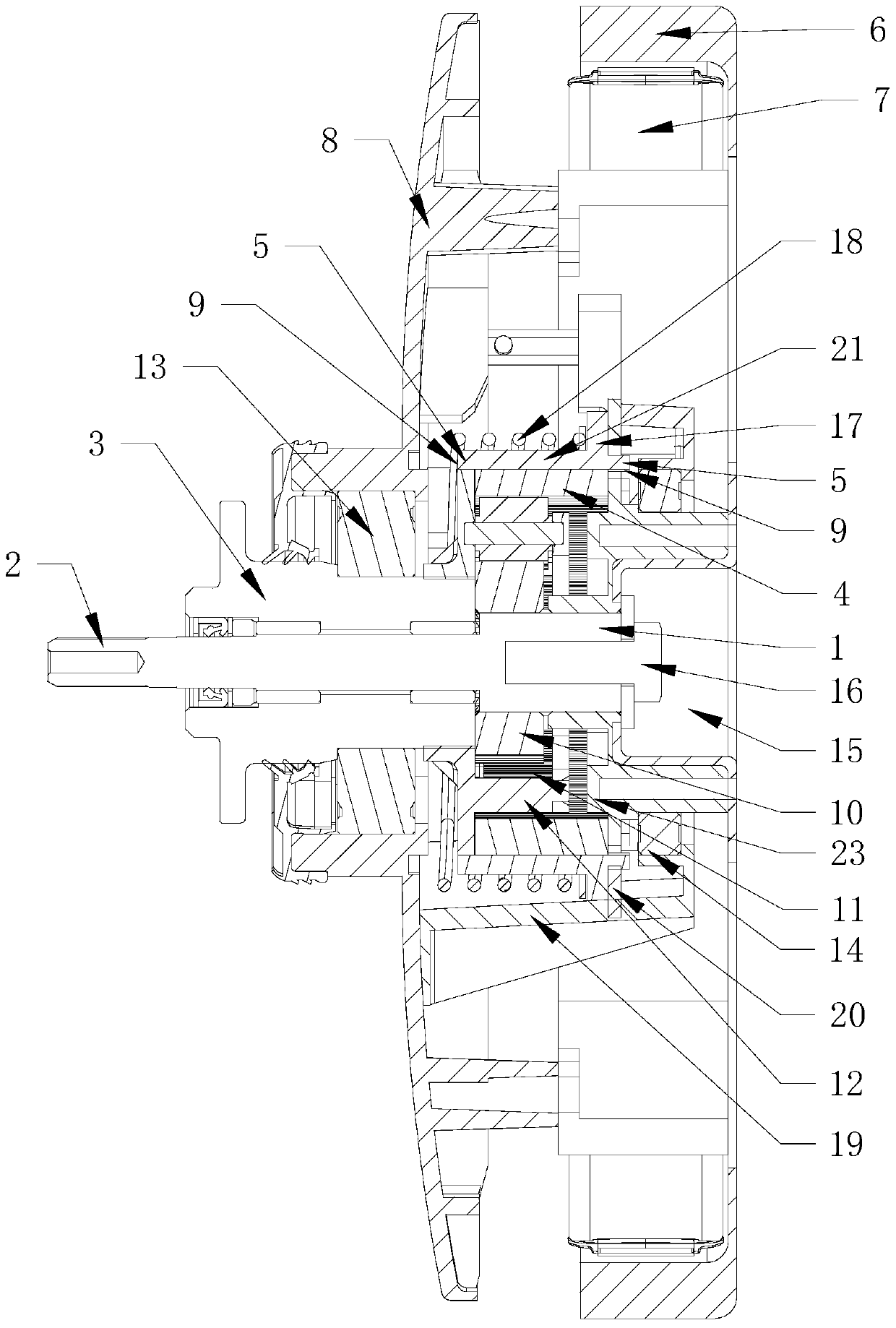

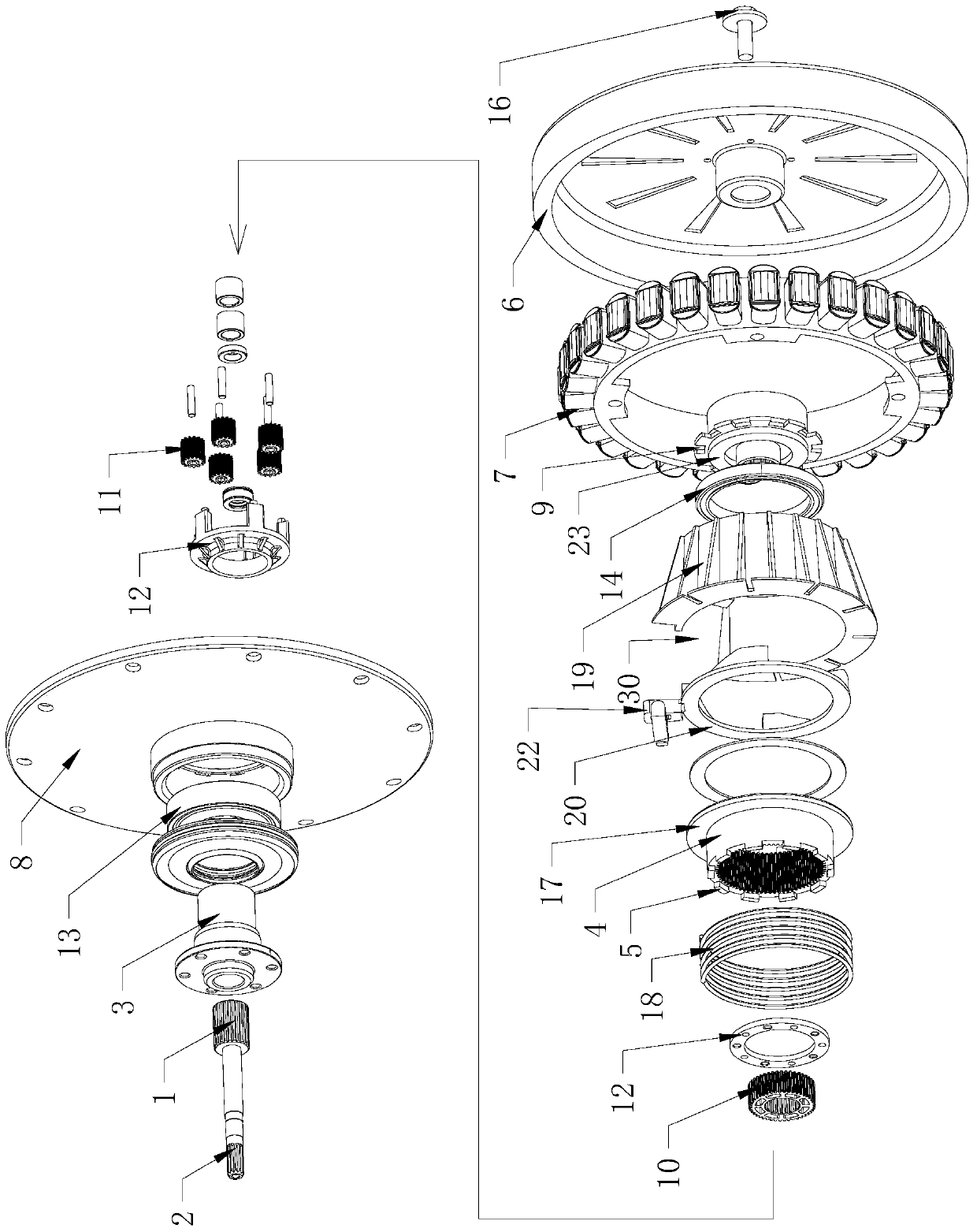

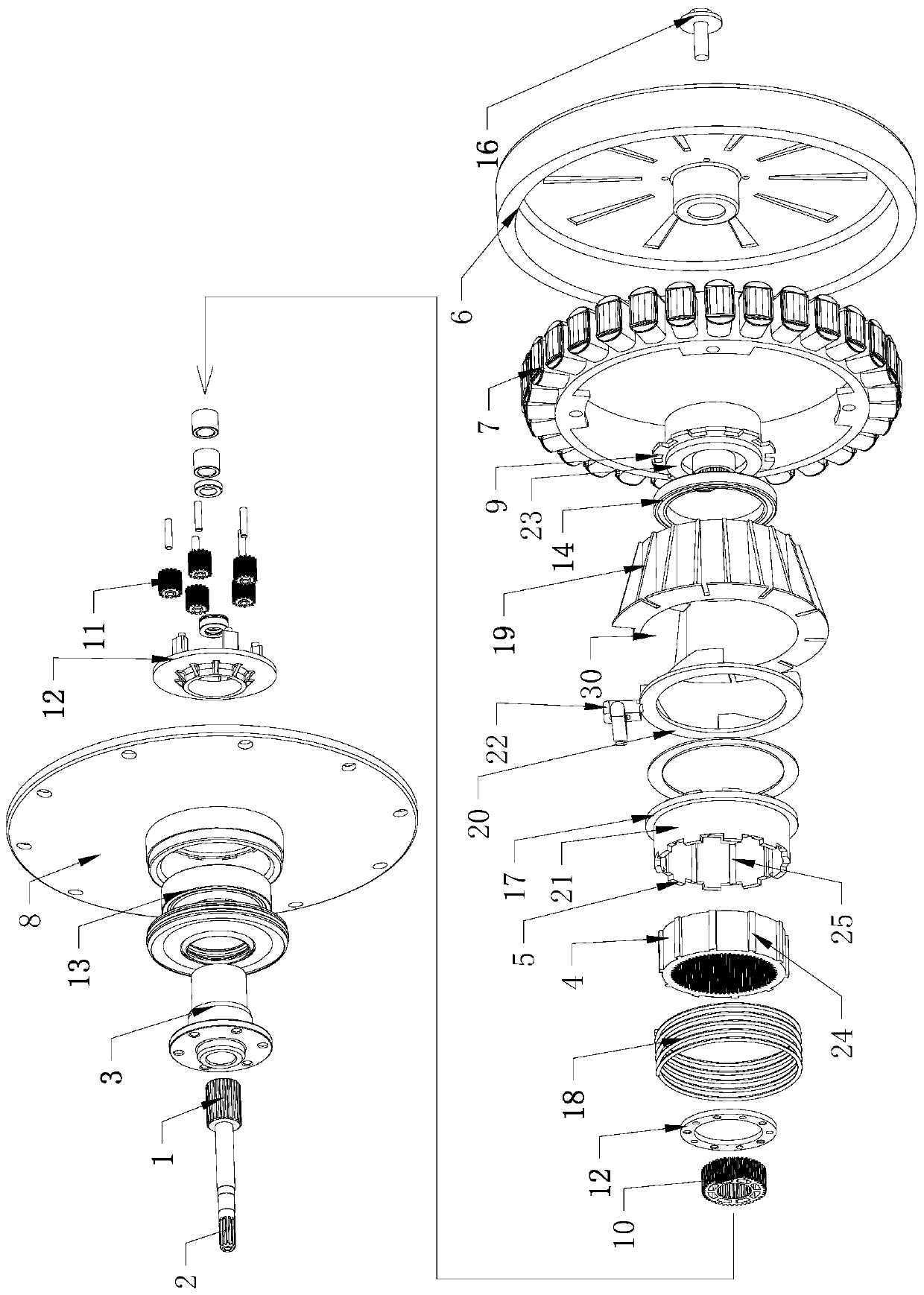

Washing machine deceleration clutch and washing machine

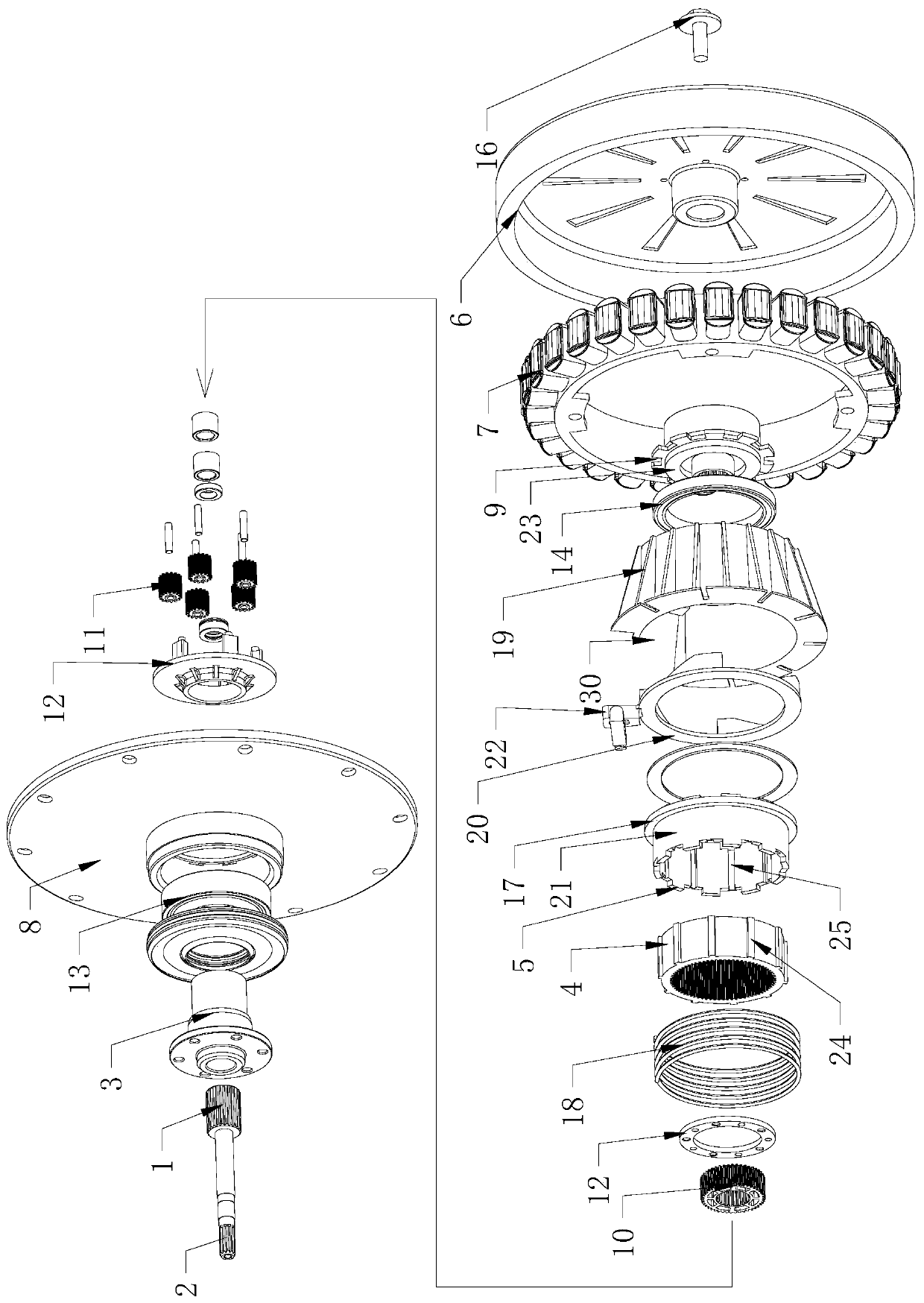

ActiveCN105463769AAxial space savingCompact structure and installationClutchesOther washing machinesEngineeringDrive motor

The invention provides a washing machine deceleration clutch and a washing machine. The washing machine deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is formed by a clutch platen and a clutch shaft sleeve; the clutch shaft sleeve covers the circumferential periphery of the deceleration device; the clutch platen rotationally move surrounding the axis to drive the clutch shaft sleeve to axially move; a first position of the clutch shaft sleeve movement is connected with a fixing device; the fixing device and an external cylinder of the washing machine are relatively fixed, so a washing work condition can be achieved; a second position of the clutch shaft sleeve movement is connected with a rotor of a direct-drive motor, so a dehydrating work condition can be achieved. The clutch device is arranged on the circumferential periphery of the deceleration device, so overall height of the deceleration clutch can be reduced, washing machine size can be reduced with the same of the washing capacity or washing capacity can be increased with the same of the washing machine size.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Three-gear magnetic particle type double-clutch speed changer for hybrid power

ActiveCN102155530AReduce energy conversion lossesReduce shift shockGearboxesToothed gearingsEngineeringHybrid vehicle

The invention provides a three-gear magnetic particle type double-clutch speed changer for hybrid power, belonging to the technical field of automobiles. The speed changer solves the problem that a driving system of an existing hybrid vehicle has high shifting impact performance. The three-gear magnetic particle type double-clutch speed changer for hybrid power comprises an engine, an input shaft, a first output shaft, a second output shaft, a reverse gear shaft and a differential mechanism and a commutator controlling the changing-over of gears; an output shaft of the engine is provided witha single clutch; one end of the input shaft is connected with the single clutch; the other end of the input shaft is provided with a magnetic particle type double-clutch; and the double-clutch is connected with an electric motor which is connected with a storage battery. The speed changer has advantages of compact structure, small shifting impact, less energy conversion loss and the like.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

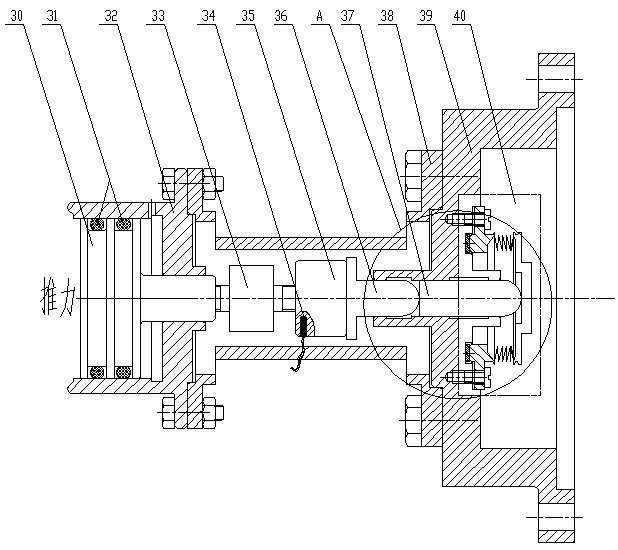

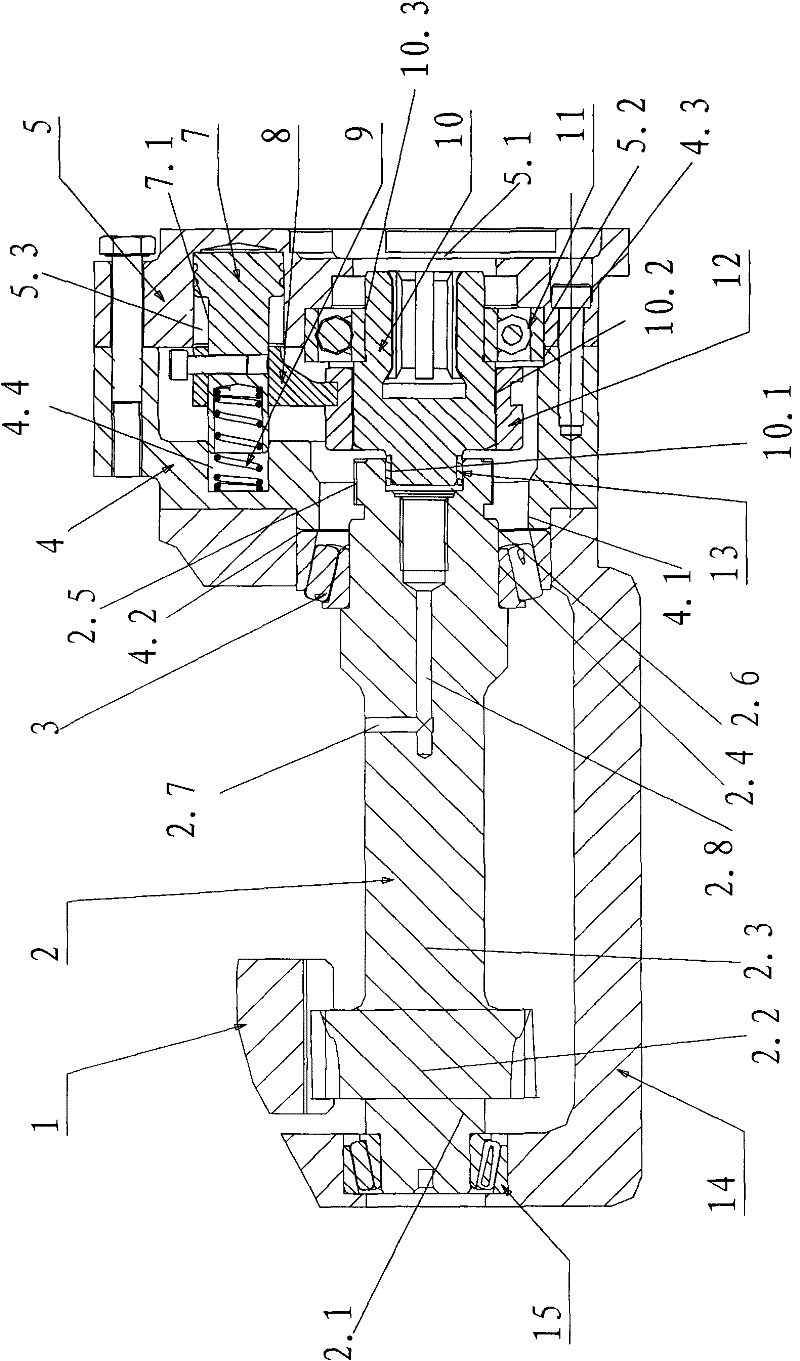

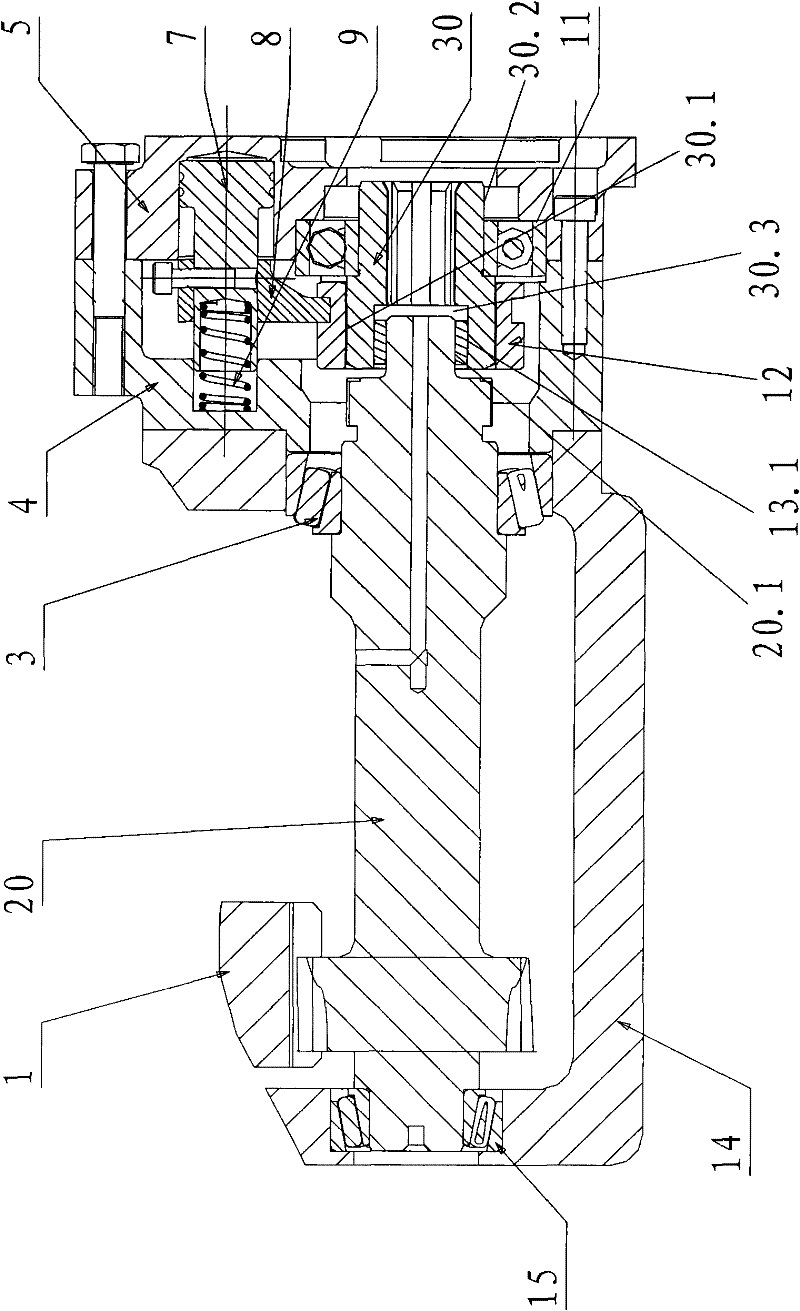

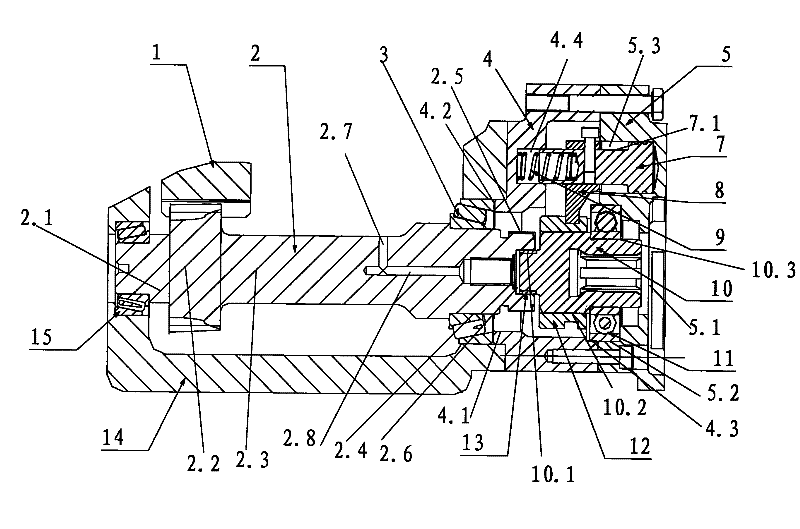

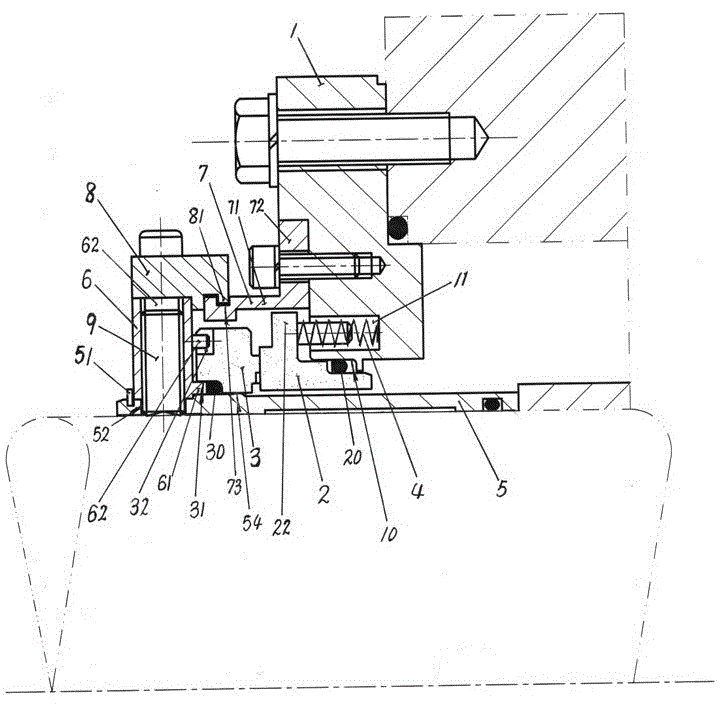

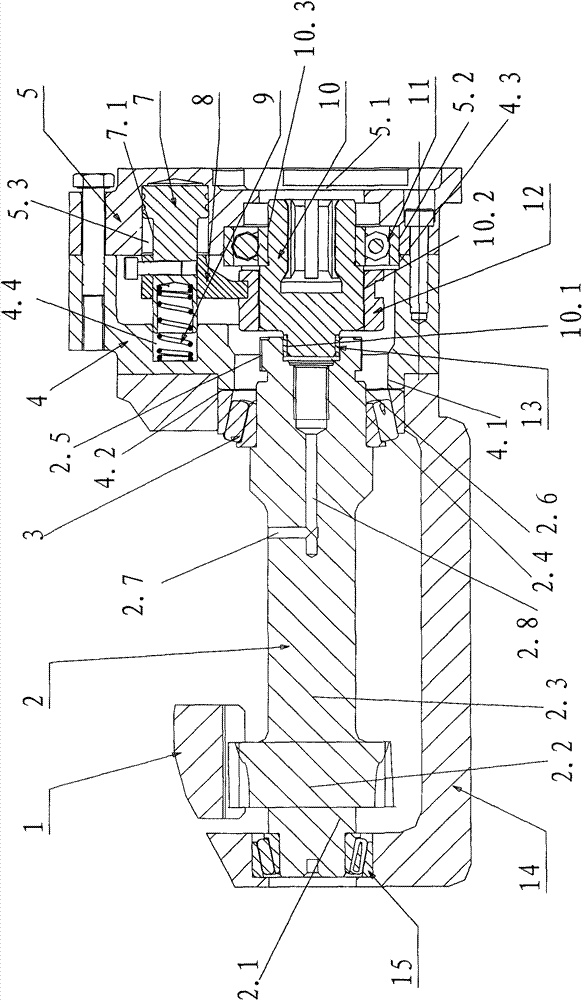

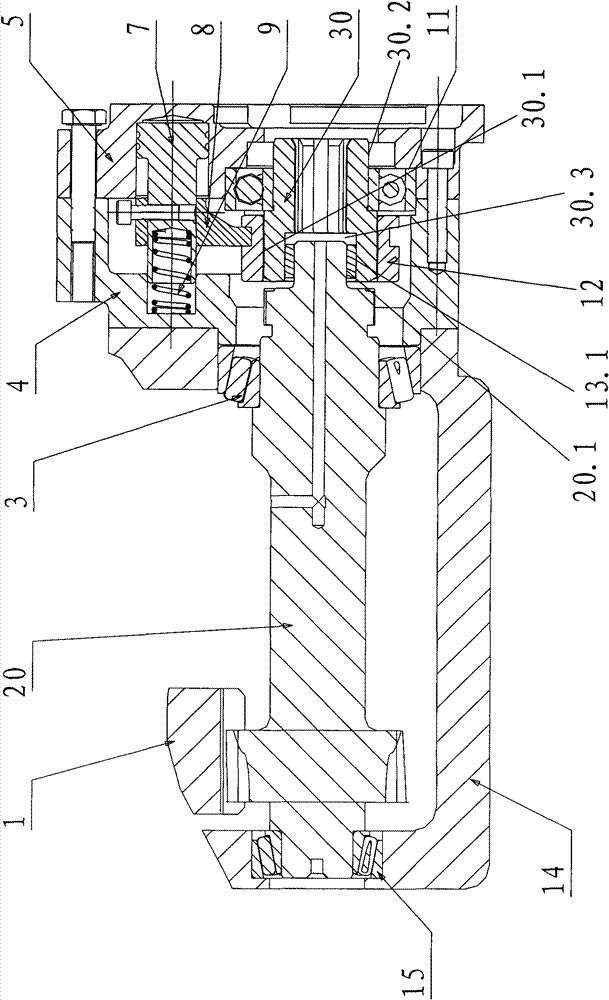

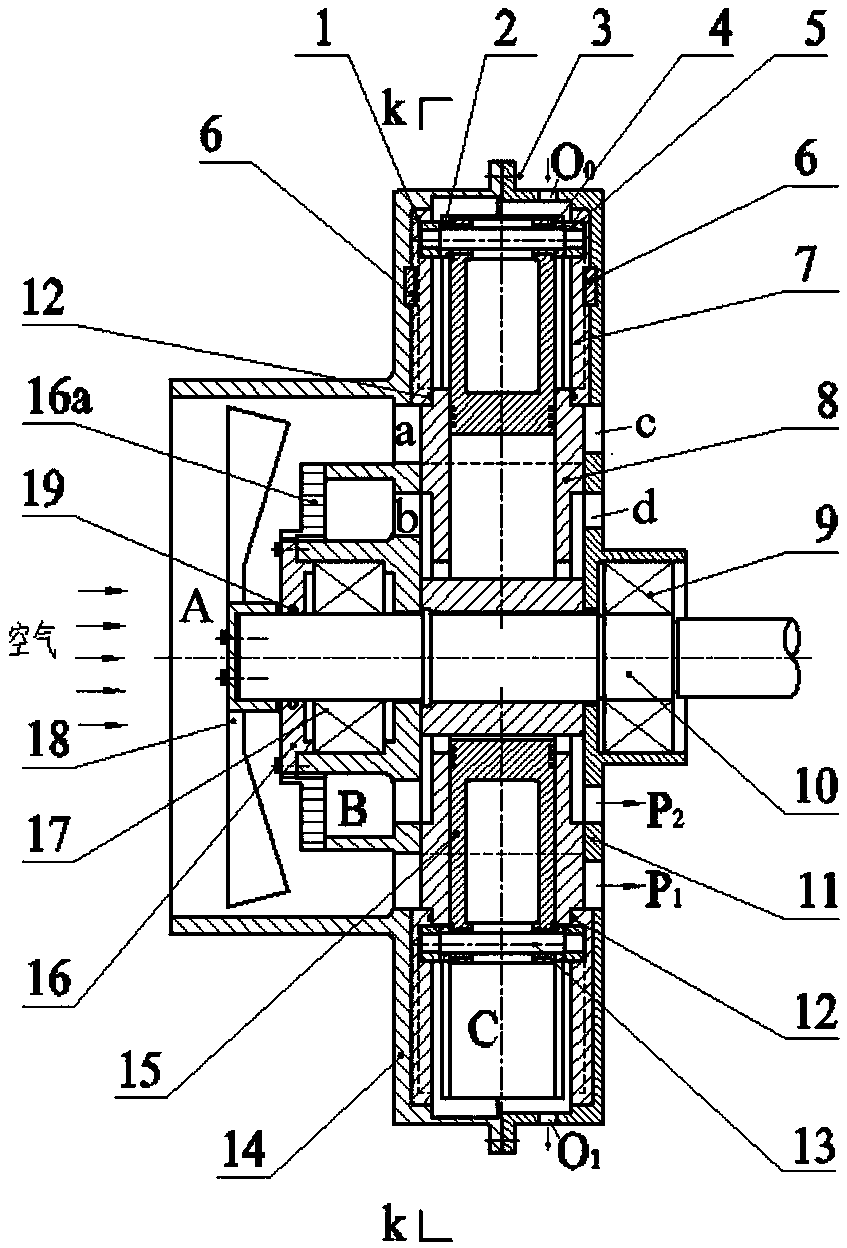

Integrated external spring compensation type mechanical sealing device

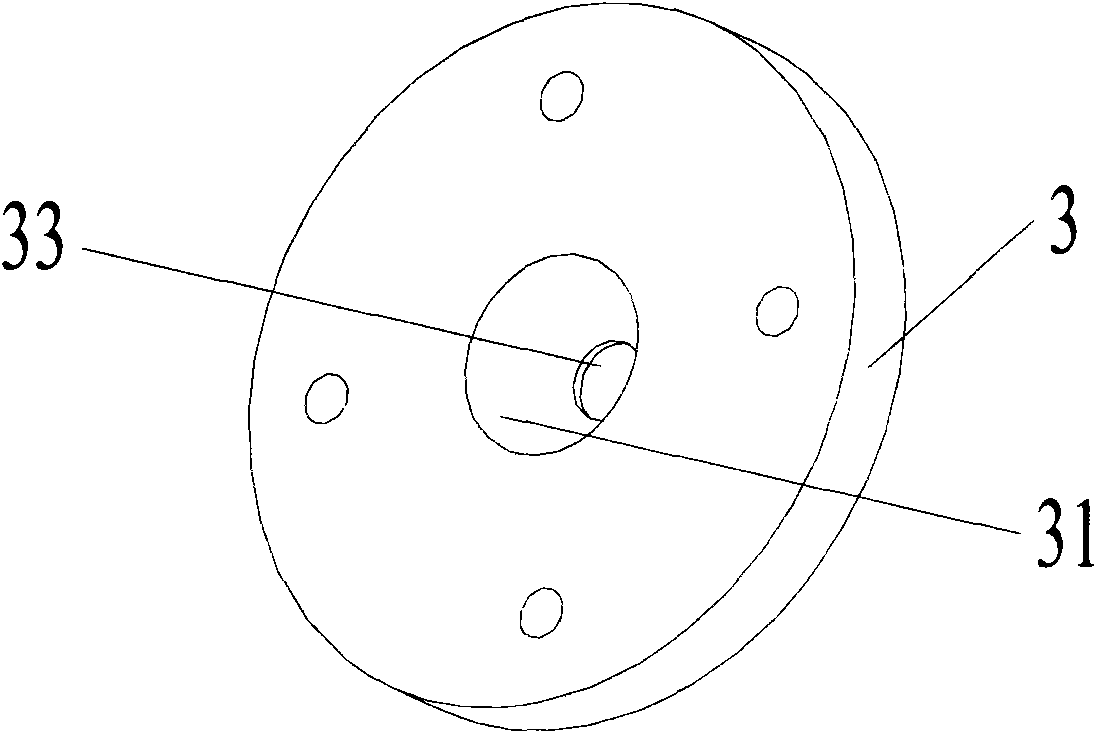

The invention discloses an integrated external spring compensation type mechanical sealing device. The integrated external spring compensation type mechanical sealing device is composed of a gland (1), a fixed ring (2), a moving ring (3), a compensation spring (4), a shaft sleeve (5), a transmission ring (6), a fixed ring auxiliary sealing ring (20), a moving ring sealing ring (30), a limiting ring (7) and locating clamp blocks (8). The components are integrally assembled together in the manner that the locating clamp block (8) fixed to the transmission ring (6) cooperates with the locating clamp block (8) fixed to the gland (1) in a hooked manner, and therefore the external mechanical sealing device is formed. The integrated external spring compensation type mechanical sealing device is compact in structure, convenient to mount, use and maintain and suitable for being used under the conditions that the content of impurity particles in conveying media is large, corrosiveness is high, and the axial mounting size is small.

Owner:DANDONG COLOSSUS GROUP

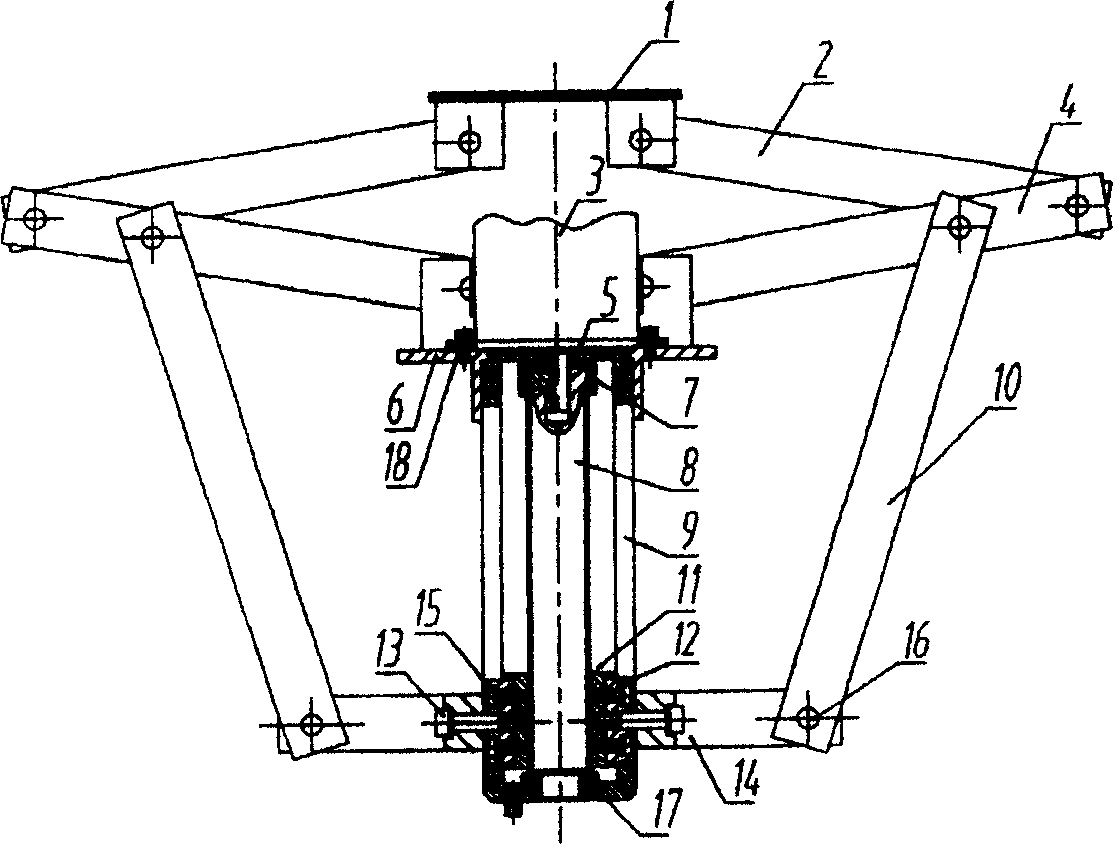

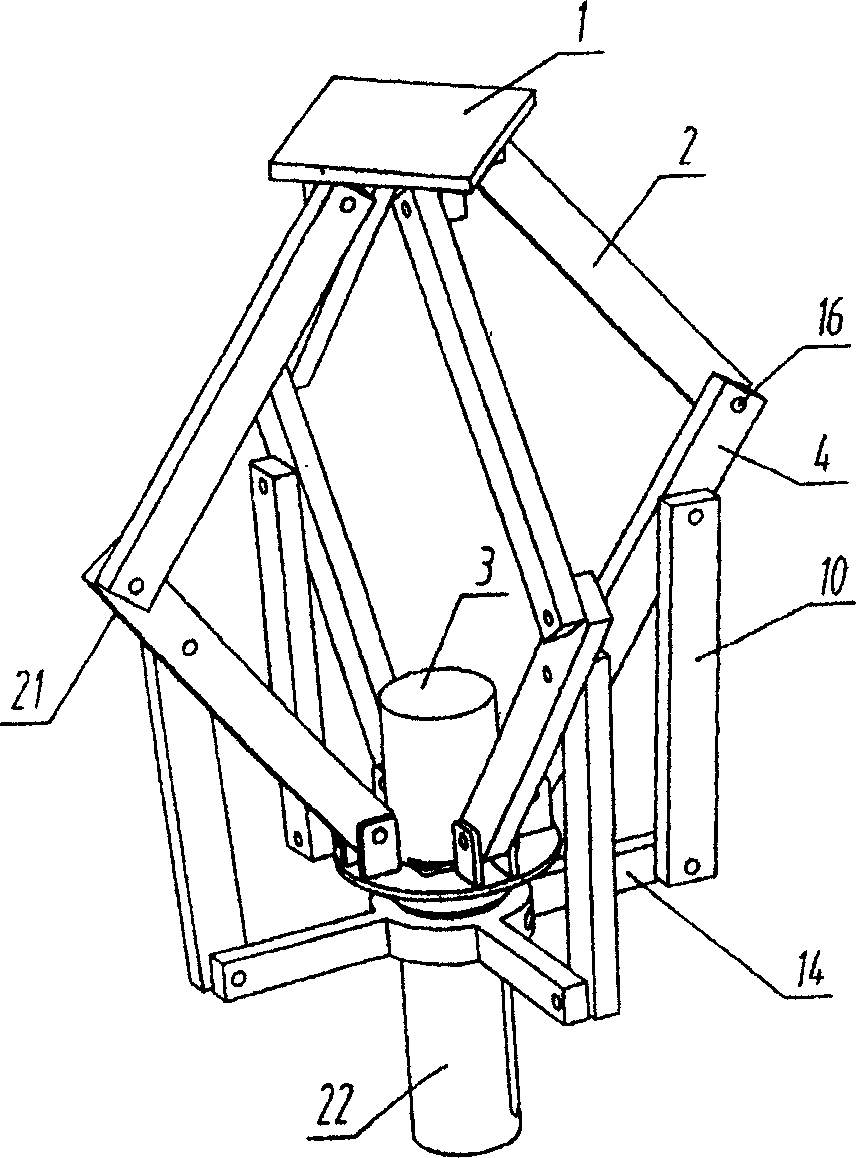

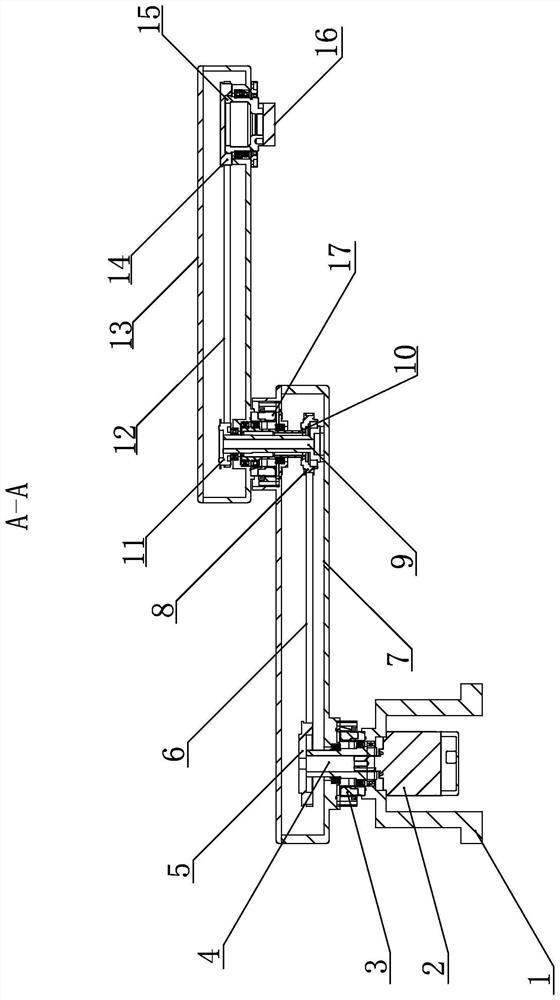

Self-locking compact type vertical lifting mechanism

The present invention discloses one kind of self-locking compact vertical elevating mechanism capable of realizing great stroke vertical elevation within a narrow space and with relatively low production cost. The vertical elevating mechanism consists of a link rod-sliding block mechanism, a screw-nut mechanism and a casing. The screw-nut mechanism is set inside the casing, and the link rod-sliding block mechanism has fixing board connected to the top of the casing and lower sliding board connected to the screw-nut mechanism. The present invention is used mainly in treating bed and other rehabilitative medical equipment, and may be also used in other field needing great stroke vertical elevation in narrow space.

Owner:文德承

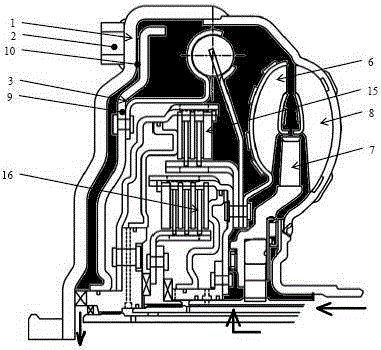

Washing machine deceleration clutch and washing machine

ActiveCN105332239ALower the altitudeReduce volumeClutchesOther washing machinesElectric machineEngineering

The invention relates to a washing machine deceleration clutch and a washing machine. The deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is at least partially arranged on the periphery of the deceleration device; the deceleration clutch axially occupies little space; the clutch device comprises a clutch shaft sleeve capable of axially moving and a driving device driving the clutch shaft sleeve to axially move; the clutch shaft sleeve is an annular gear of the deceleration device; the driving device drives the annular gear to axially move to control different output states of the output shaft and the output shaft sleeve; the driving device comprises at least one shifting fork rod; the shifting fork rod is provided with a fixing part; and one end of the shifting fork rod is provided with a shifting fork controlling the annular gear to axially move and the other end is provided with a driving end in transmission connection with a driving motor. The driving device is simply structured, has reliable control, small stroke, and compact structure and occupies small space; stable and reliable operation and low fault rate can be achieved; and with the compact structure, a modularized structure can be achieved and high component integration degree can be realized.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Rare earth permanent magnet motor driven centrifugal pump and self-lubricating method

ActiveCN113738657AAxial compactRealize functionPump componentsPump installationsPhysicsCentrifugal pump

The invention discloses a rare earth permanent magnet motor driven centrifugal pump and a self-lubricating method, and belongs to the field of centrifugal pumps. The centrifugal pump is sequentially sleeved with an upper shaft sleeve, an upper rotor and a lower shaft sleeve, then an impeller is fixed to the top end of a main shaft through an impeller nut, and an inward-concave mounting chamber is formed in the back face of the impeller; the outer portion of the upper shaft sleeve is sleeved with an upper bearing, and upper magnetic steel is clamped in a containing chamber on the upper rotor; the outer portion of the lower shaft sleeve is sleeved with a lower bearing; the lower bearing is firstly sleeved with a motor stator and then sleeved with lower magnetic steel in the axial direction of the lower bearing, and the lower magnetic steel is clamped in the mounting chamber; the main shaft, the upper / lower shaft sleeve, the upper / lower bearing, the upper rotor, the upper / lower magnetic steel, the motor stator, the impeller and the impeller nut are all located in a containing inner cavity formed by a pump body, a pump cover and an end cover; and a balance through hole is formed in the main shaft, a via hole is formed in the top end of the impeller nut, and the via hole and the balance through hole are coaxial so that an inlet of the pump body can communicate with the top end of the balance through hole. The structure of the rare earth permanent magnet motor driven centrifugal pump structure is light, and self-lubricating can be achieved.

Owner:西安泵阀总厂有限公司

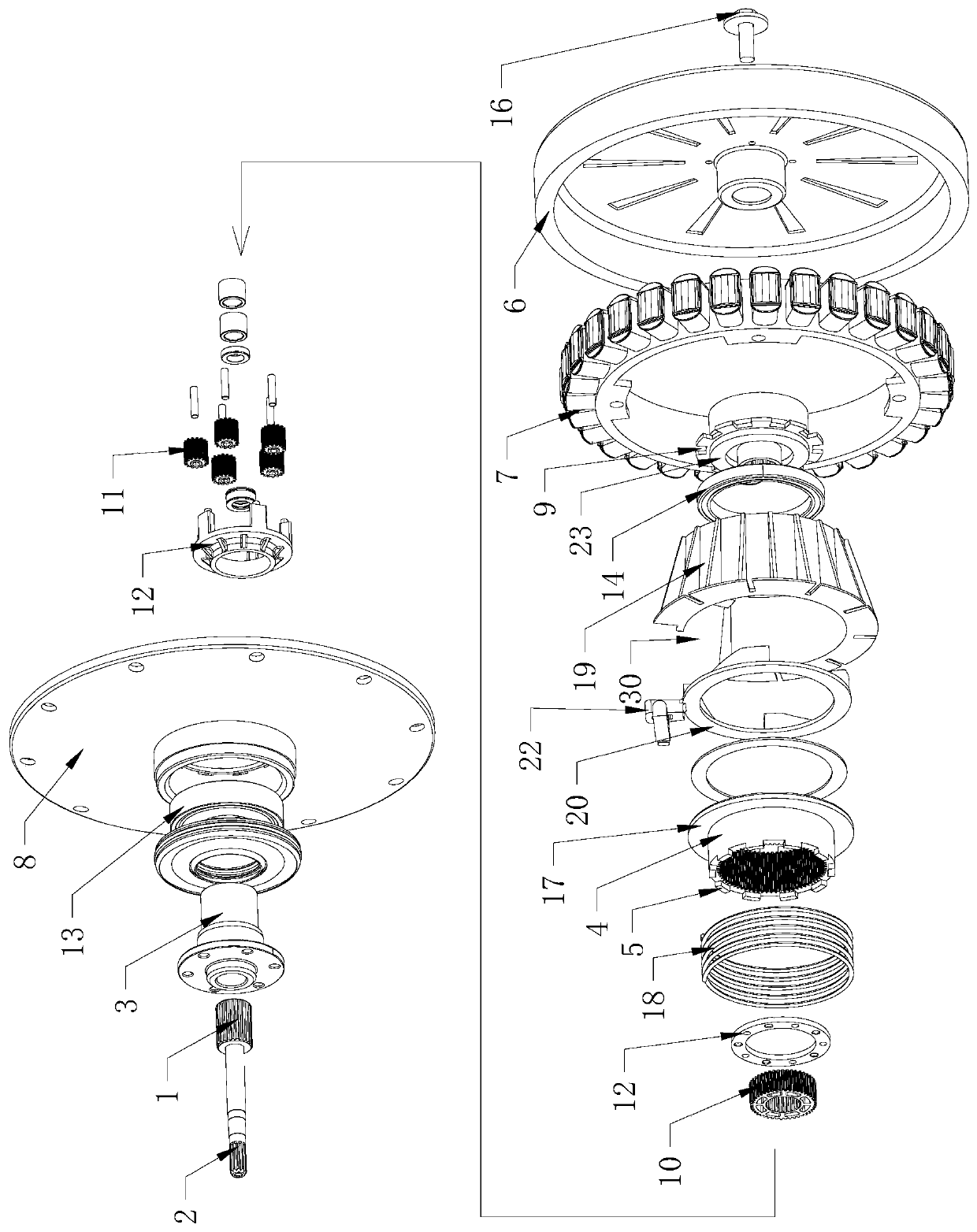

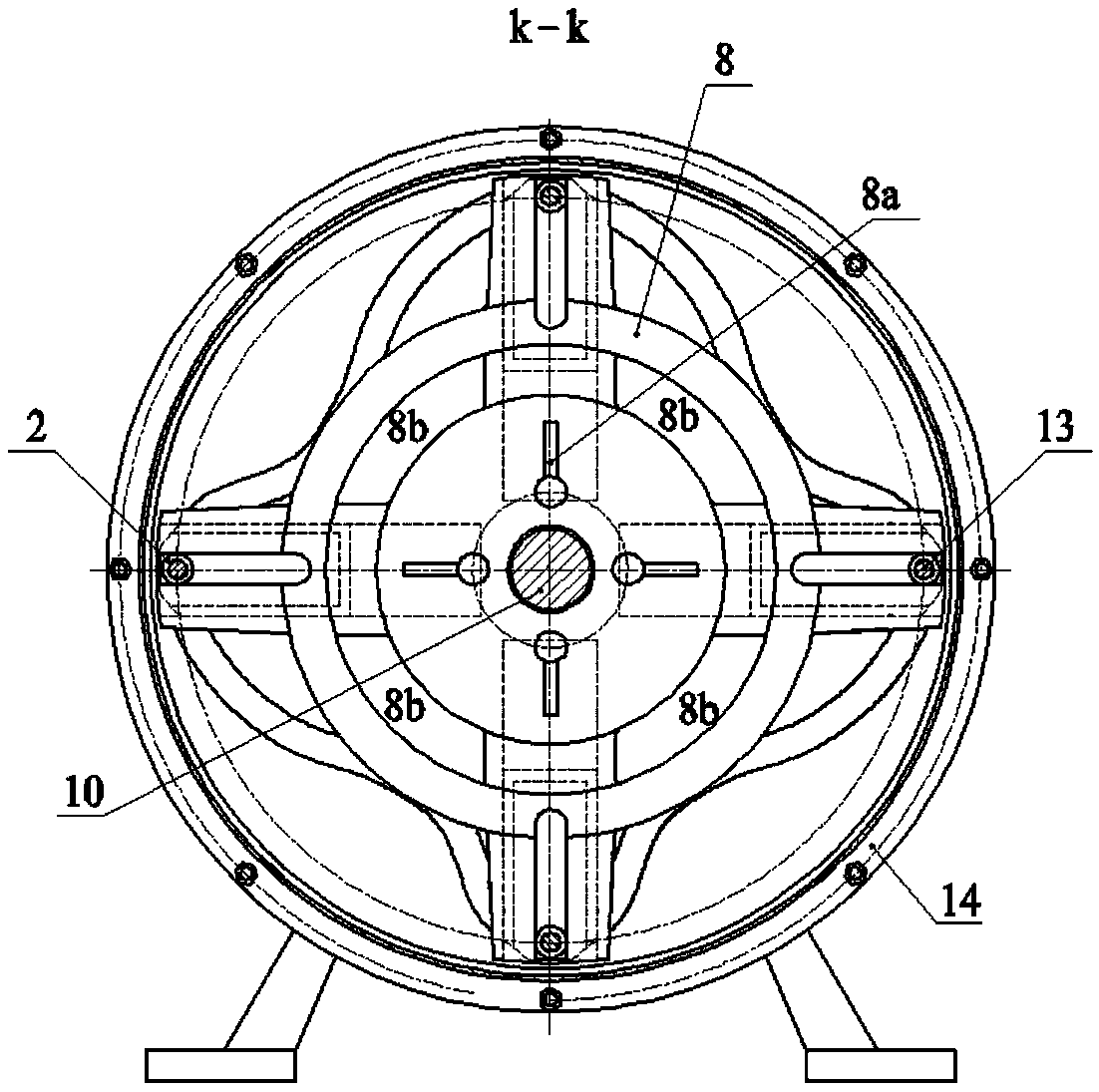

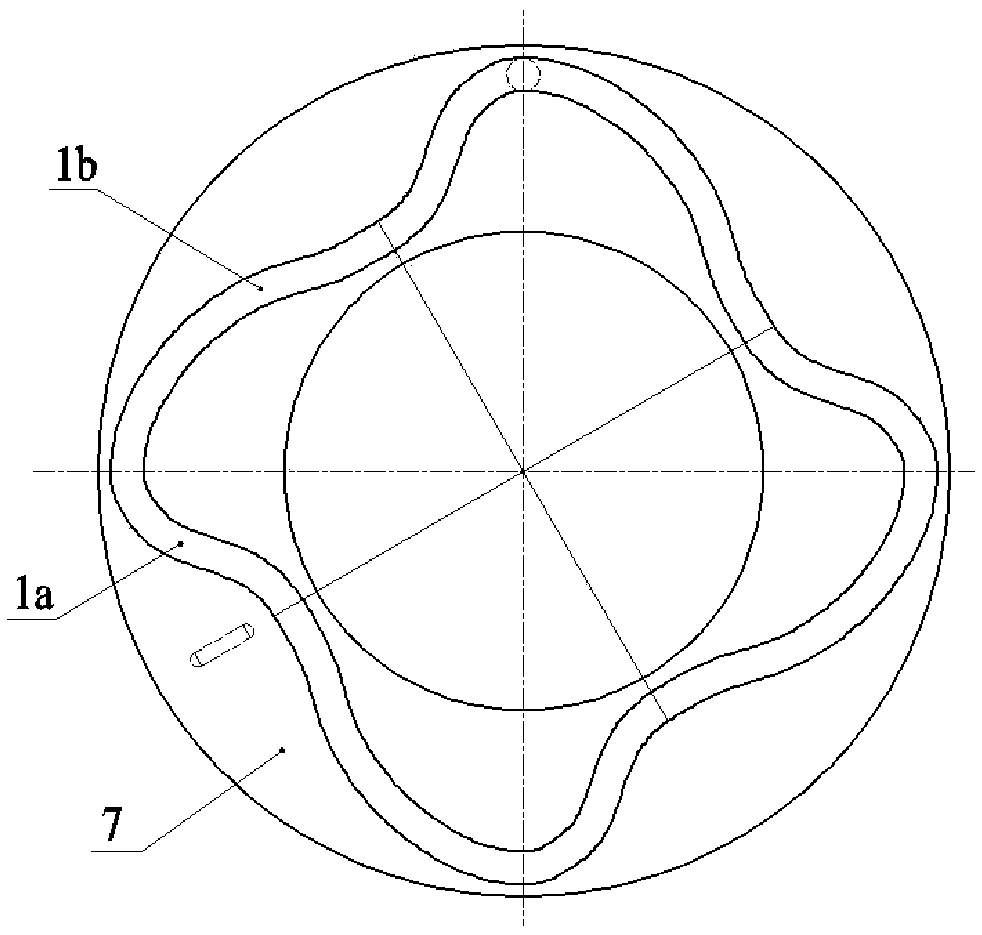

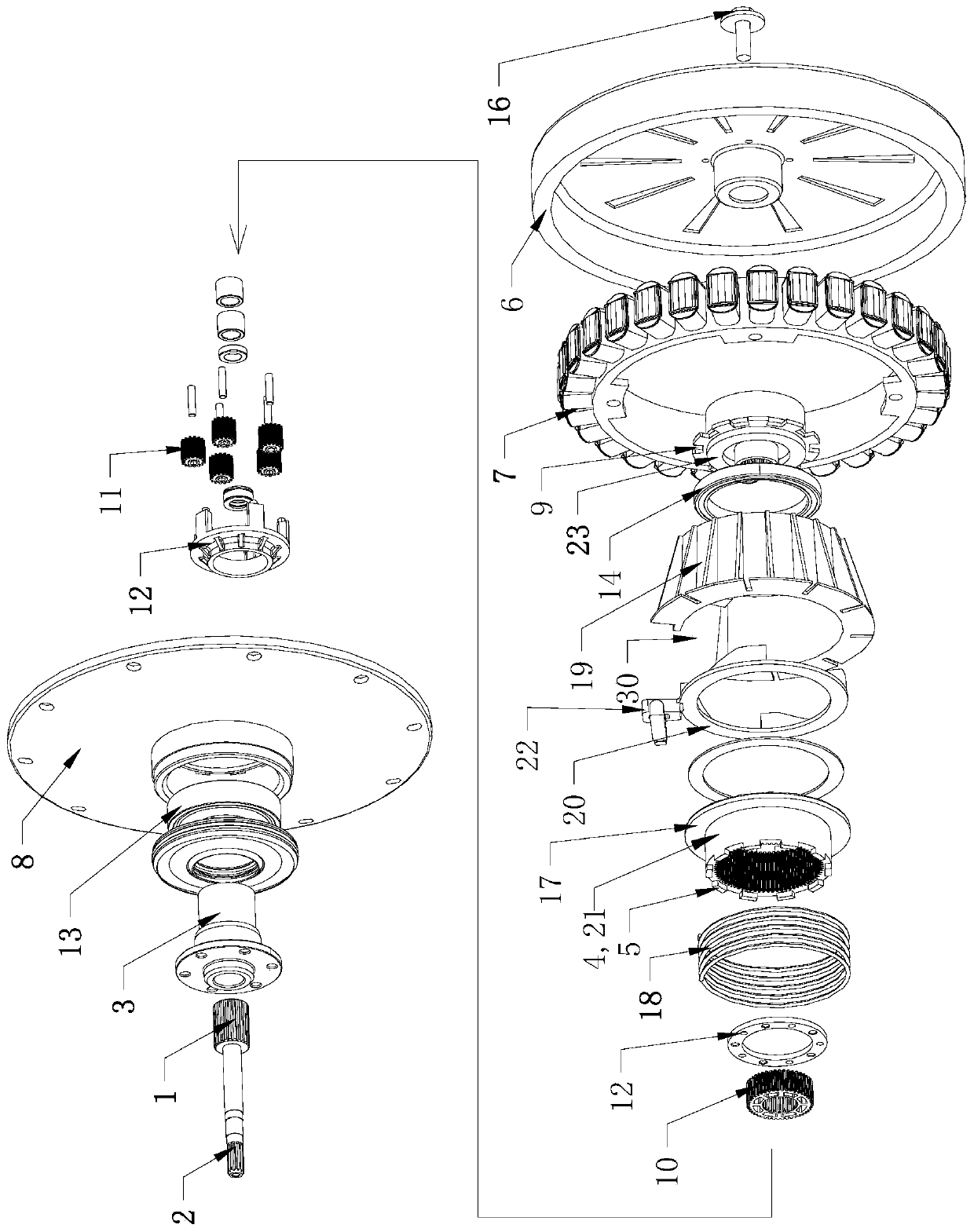

Two-stage closed type cylindrical sine end surface movable teeth reducer

The invention discloses a two-stage closed type cylindrical sine end surface movable teeth reducer. A high-speed stage comprises an input shaft, a center wheel, three planetary gears distributed in aradial direction, a sun gear and three planetary wheel shafts to form a 2K-H type differential gear train. A low-speed stage comprises a shock wave device, a fixed movable tooth frame, movable teeth,a movable gear and an output shaft. The sun gear and the movable gear are fixedly connected into one component, and rotation of the movable gear is fed back to the sun gear as input movement of a high-speed stage differential gear train, so that two-stage closed type planetary transmission is formed. The left ends of the planetary wheel shafts are fixedly connected with the planetary gears respectively, the right ends of the planetary wheel shafts are connected with corresponding pin holes on the shock wave device to form a rotating pair, the autorotation movement of the shock wave device is implemented through revolving movement of the planetary gears, and then an axial shock wave is generated. For the two-stage closed type cylindrical sine end surface movable teeth reducer, a transmission chain is shortened to the maximum, the transmission efficiency and the reliability are improved, the axial structure is compact, the large reduction ratio and multi-tooth engagement are realized, the rigidity is large, the bearing capacity is strong, and transmission is stable; and compared with a common movable gear, the two-stage closed type cylindrical sine end surface movable teeth reducer has the characteristic of the axial shock wave.

Owner:TIANJIN UNIV

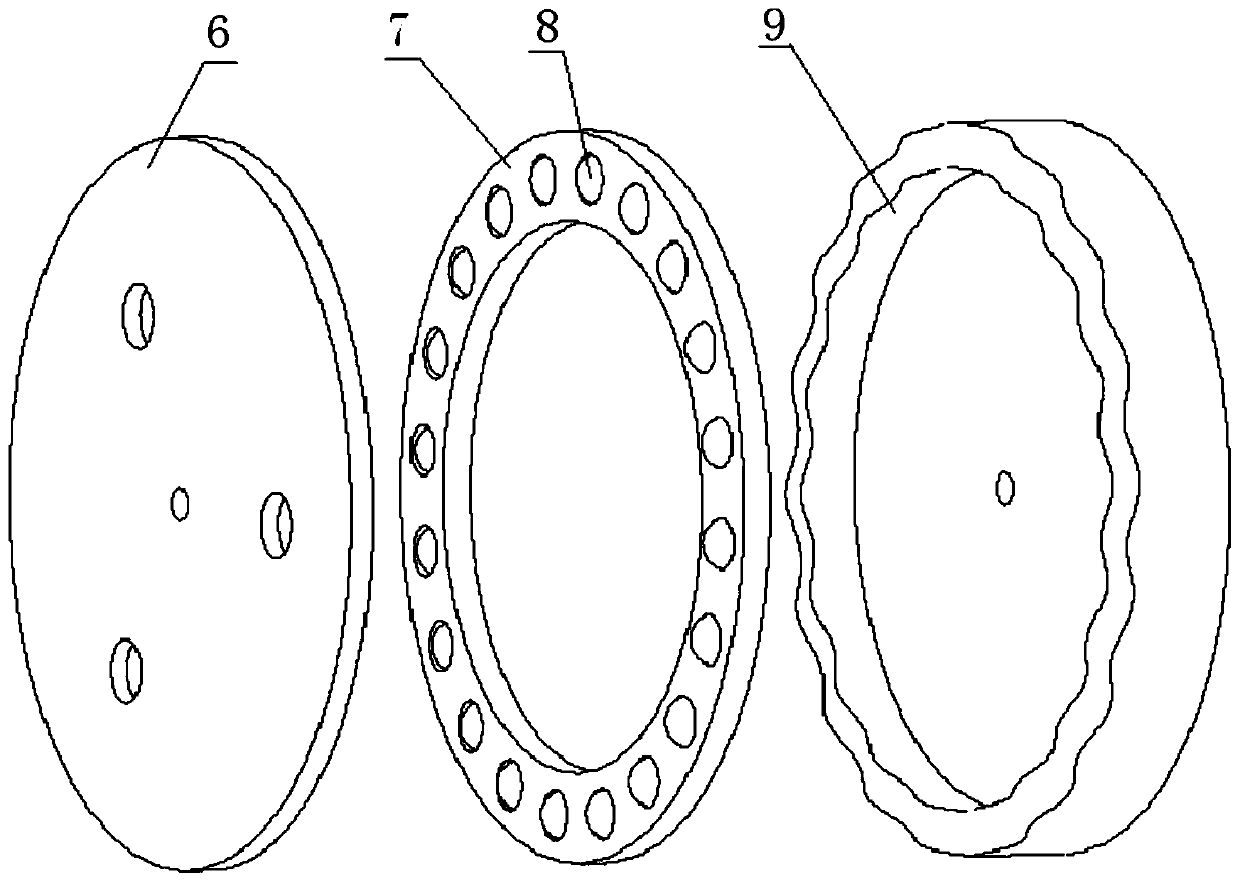

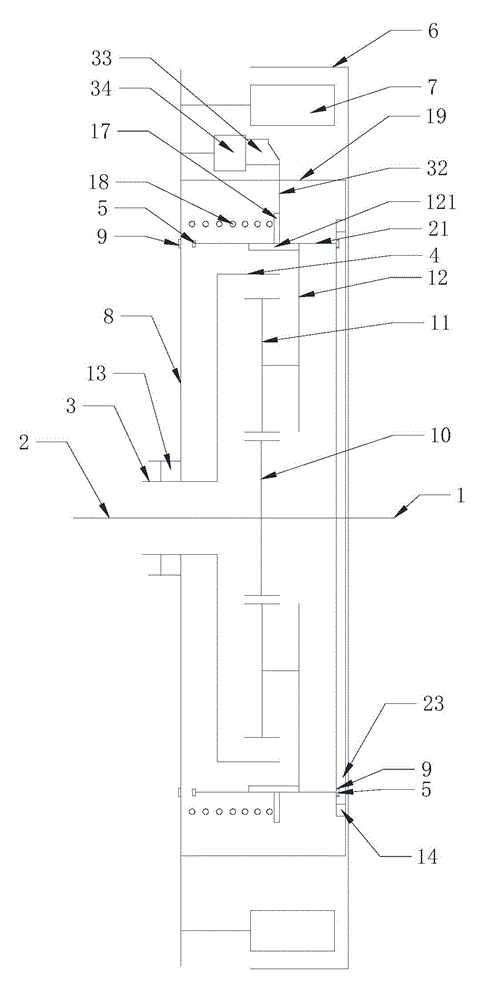

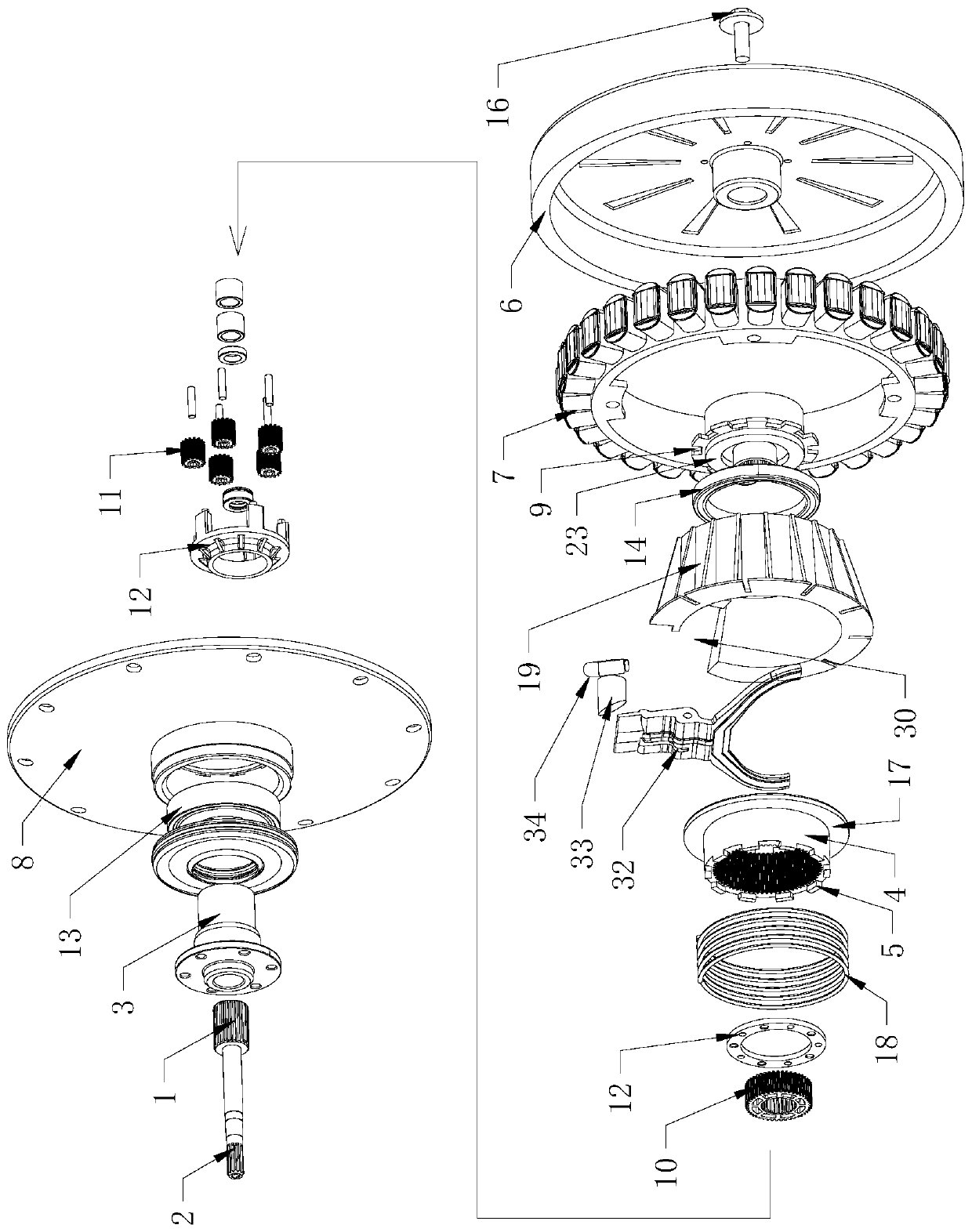

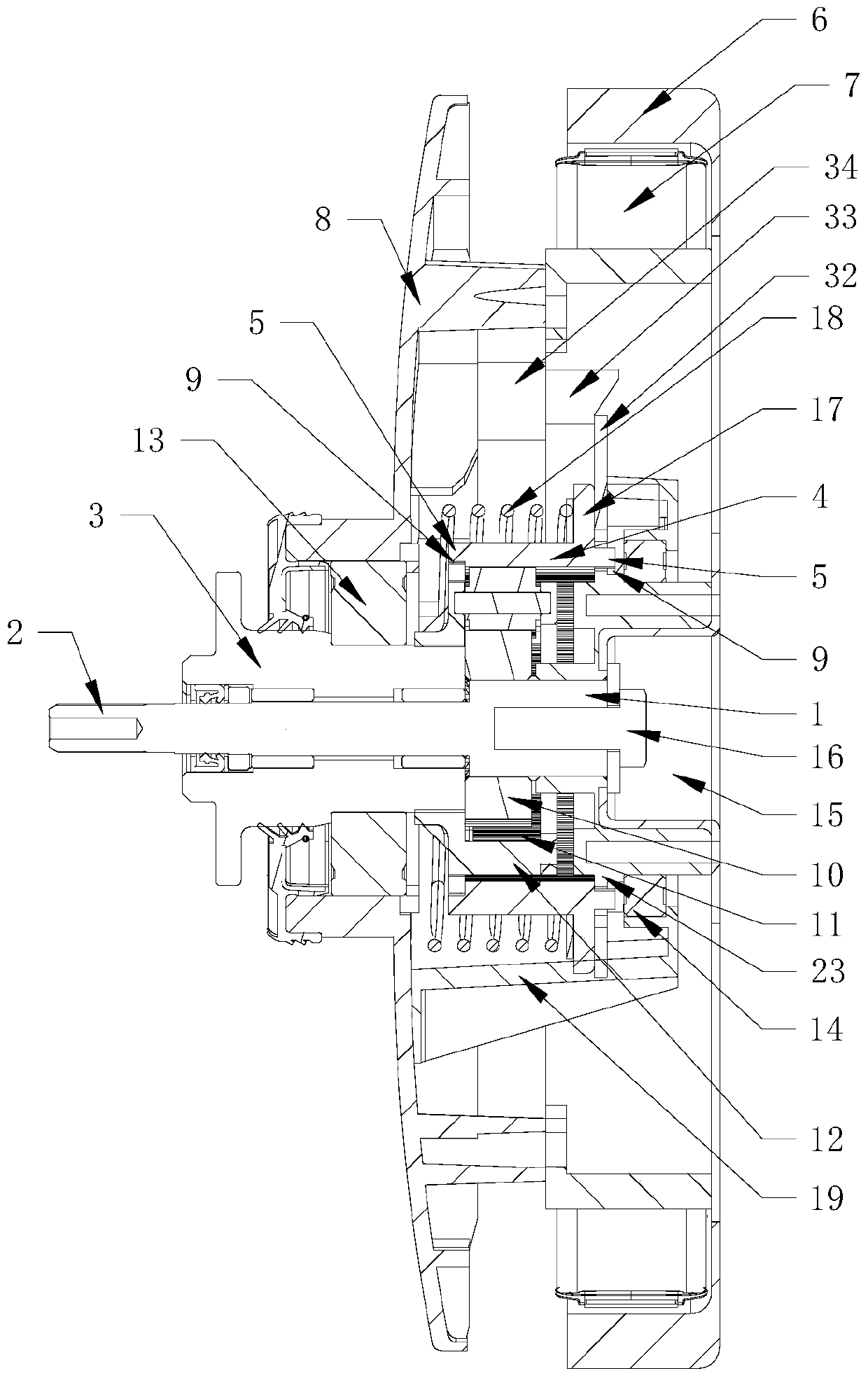

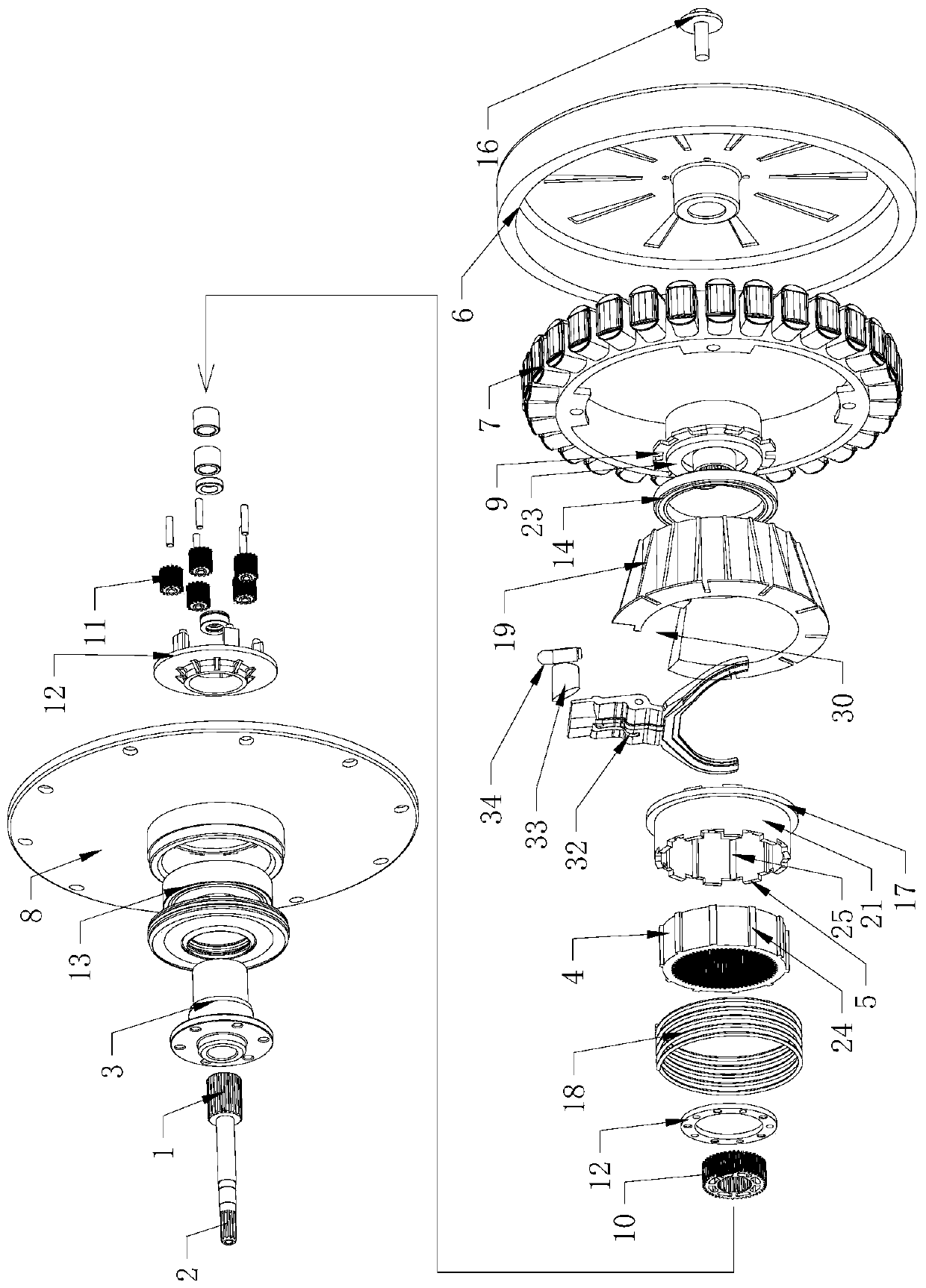

Washing machine deceleration clutch and washing machine

The invention relates to a washing machine deceleration clutch and a washing machine. The deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is at least partially arranged on the periphery of the deceleration device; the clutch device at least comprises a clutch shaft sleeve capable of axially moving and a driving device driving the clutch shaft sleeve to axially move; the clutch shaft sleeve is arranged outside an annular gear of the deceleration device and is in a connection with the annular gear in way of being capable of sliding relative to the annular gear but incapable of rotating relative to the same; the driving device drives the clutch shaft sleeve to axially move to control different output states of the output shaft and the output shaft sleeve; the driving device comprises at least one clutch press plate coaxially arranged with the clutch shaft sleeve; and the clutch press plate can circumferentially rotate to drive the clutch shaft sleeve to axially move. The deceleration clutch is simply structured and axially occupies small space; and overall height of the deceleration height can be reduced and washing capacity can be increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

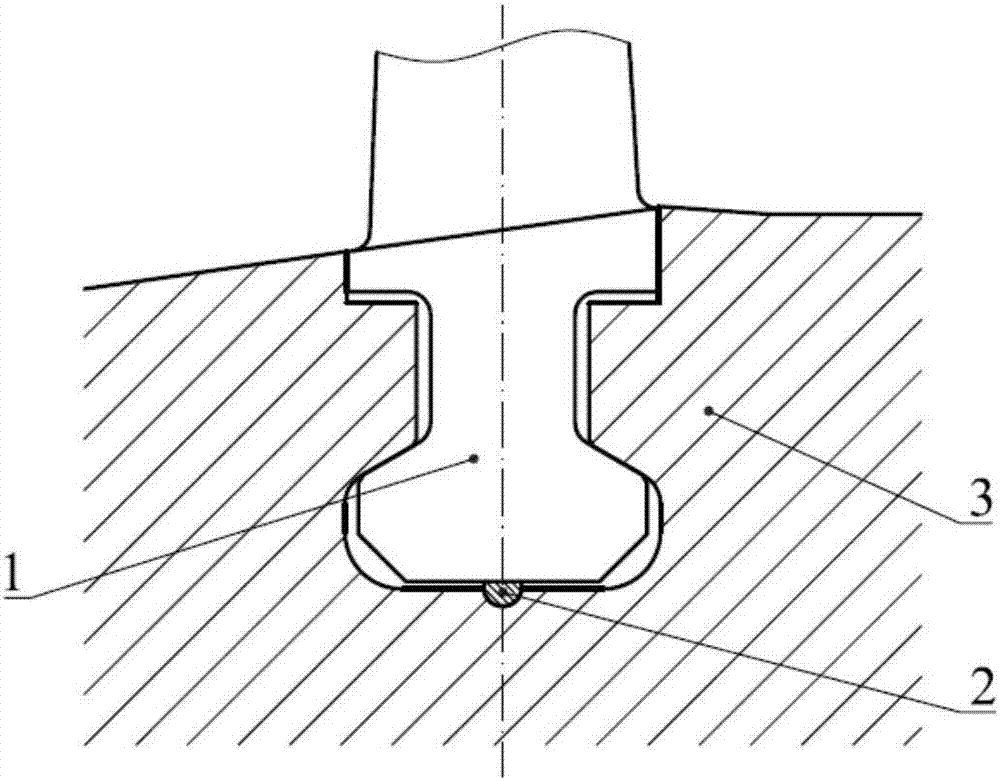

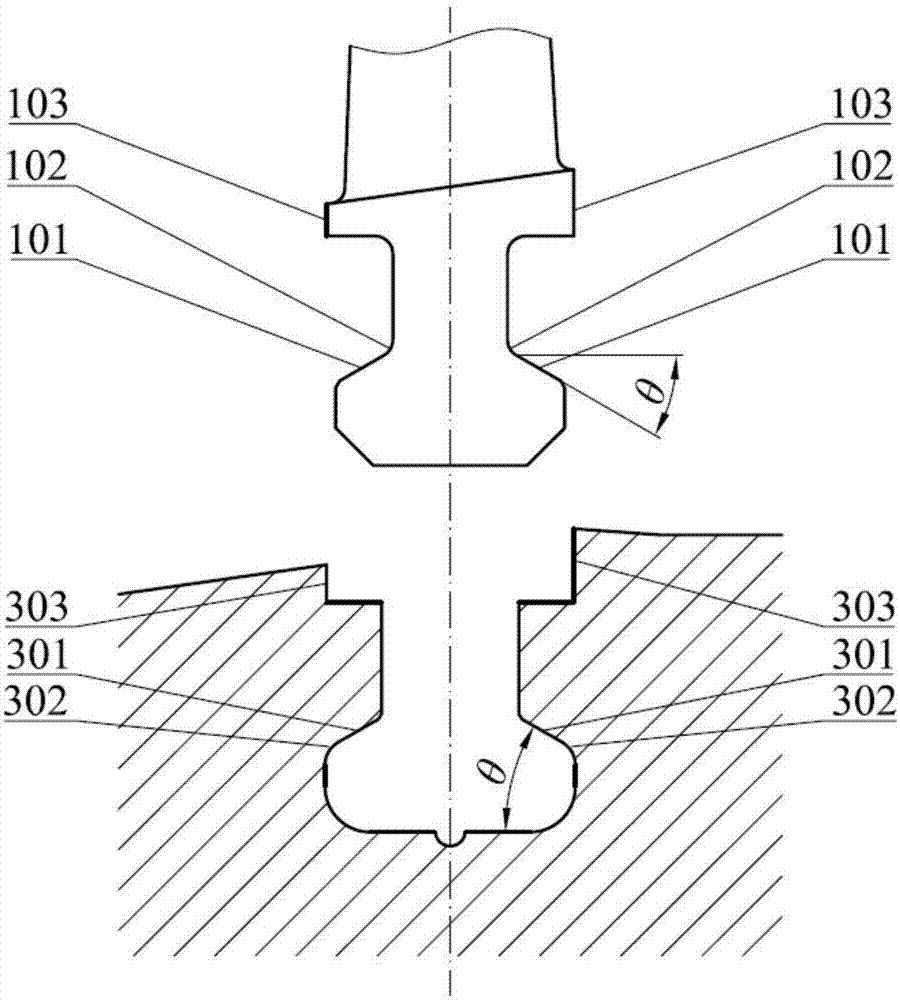

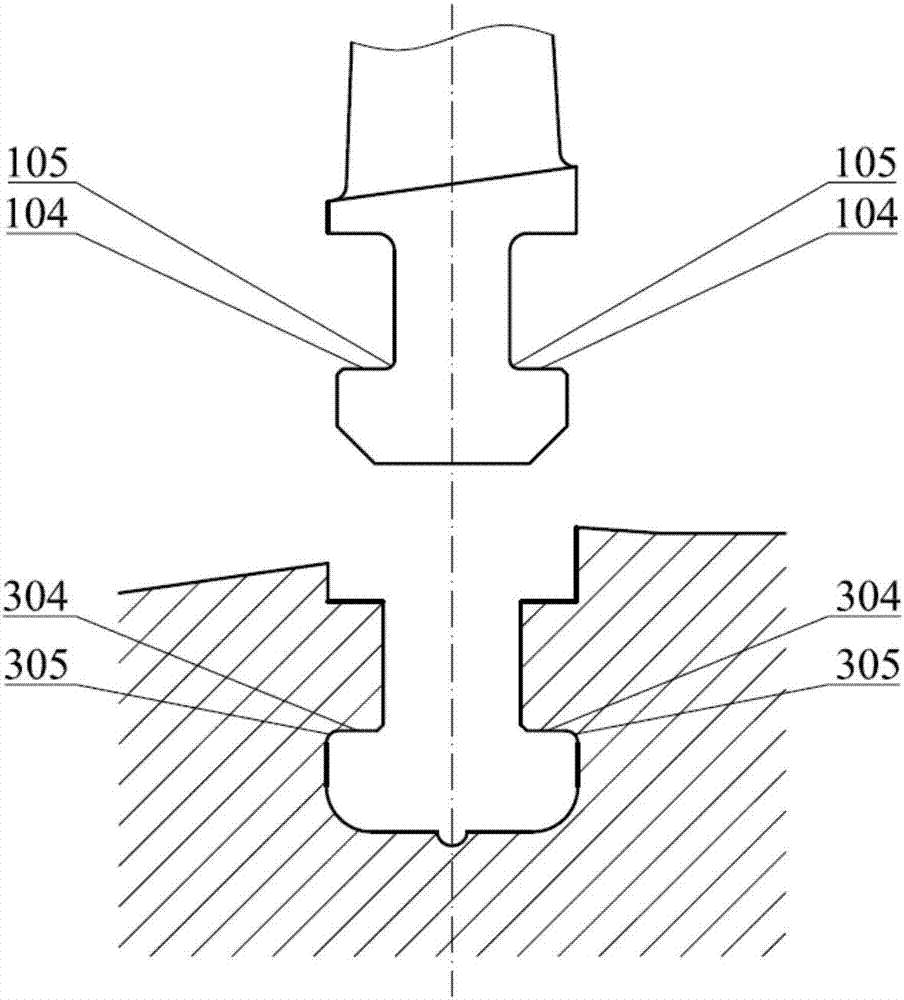

T-shaped blade root of turbine blade and matched flangeway thereof

PendingCN107420135AReduce stress levelsImprove securityBlade accessoriesMachines/enginesSteam turbine bladeNeck parts

The invention relates to a T-shaped blade root of a turbine blade. The T-shaped blade root comprises a T-shaped head part, a neck part, a blade root unit and a blade body connecting section, and is characterized in that observed from a meridian plane section view, a bearing surface, matched with a flangeway, of the T-shaped head part of the blade root is an inclined surface; an included angle theta is formed between the bearing surface of the T-shaped head part of the blade root and the axial direction of a turbine, and an inclined T-shaped head part blade root structure is formed; the bearing surface of the inclined T-shaped head part of the blade root and the neck part of the blade root are in round corner transition; and the value range of the included angle is that delta is larger than or equal to 25 degrees and is smaller than or equal to 30 degrees, and 25 degrees is optimal. Technical defects of a traditional T-shaped blade root are solved, the novel inclined T-shaped blade root of the turbine blade and the matched flangeway thereof are provided, and the novel inclined T-shaped blade root of the turbine blade avoids relatively large stress concentration of a round corner of the T-shaped blade root and a round corner of the flangeway and is relatively high in safety, relatively low in technological difficulty, compact in structure and convenient in assembly.

Owner:HANGZHOU TURBINE POWER GRP

Gearbox and vehicle

PendingCN111043253AImprove rigidityShorten the axial lengthToothed gearingsGearing detailsGear wheelGear tooth

The invention provides a gearbox and a vehicle provided with the same. The gearbox comprises a middle shaft assembly. The middle shaft assembly comprises a middle shaft and an intermediate speed transmission gear assembly arranged on the middle shaft in a sleeving manner. The middle shaft comprises a one-gear tooth and a reversing gear tooth. The intermediate speed transmission gear assembly is located between the one-gear tooth and the reversing gear tooth. A tool withdrawal groove is formed in one side of the reversing gear tooth. A part of the intermediate speed transmission gear assembly is arranged on the tool withdrawal groove. In the scheme, due to the fact that the intermediate speed transmission gear assembly does not need to avoid the tool withdrawal groove, the tool withdrawal groove is buried in the intermediate speed transmission gear assembly, thus the axial length of a shaft body is reduced, rigidity of the middle shaft is improved, the axial structure is more compact, under the circumstance of increasing gears of the gearbox, the size of the gearbox is basically the same as the axial installing size of a gearbox in the related technology, and thus the gearbox with the gears increased can fit multiple vehicles beneficially.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

Magnetic coupling component and magnetic coupling steering device thereof

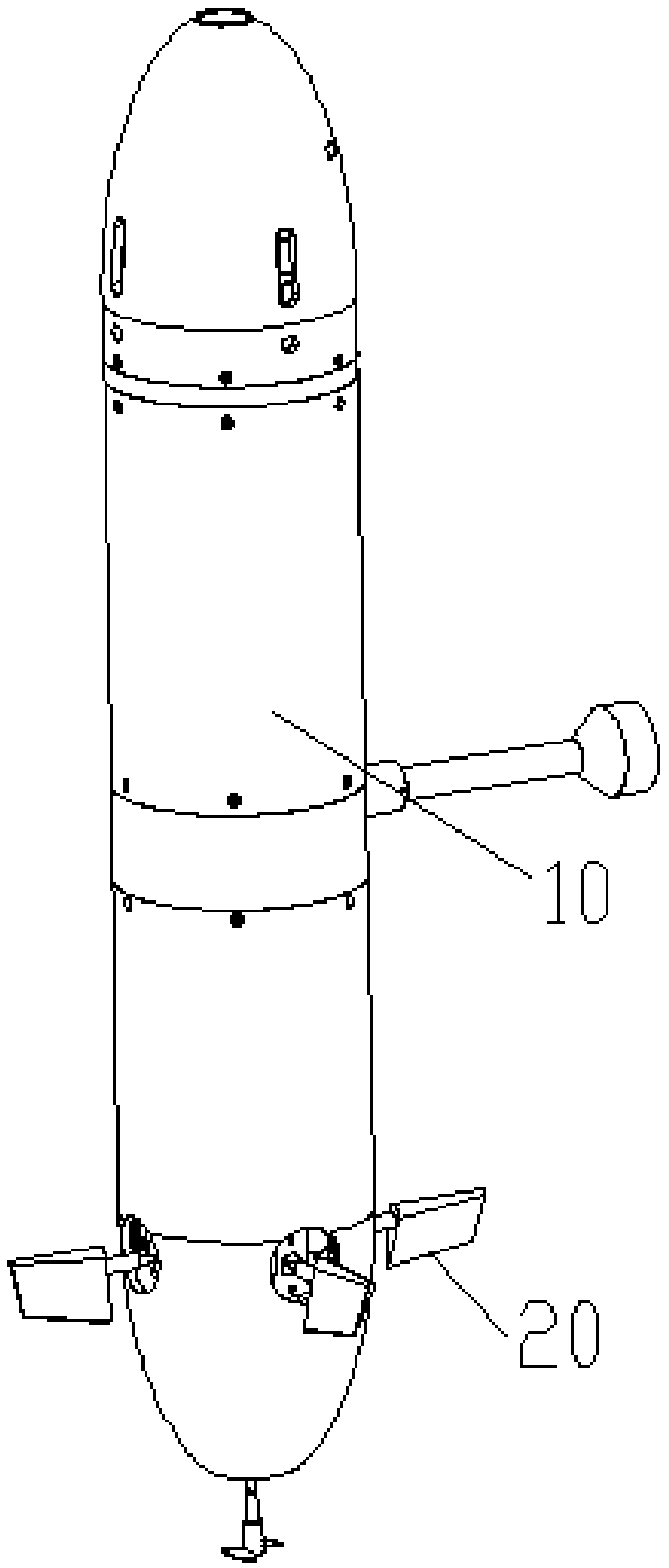

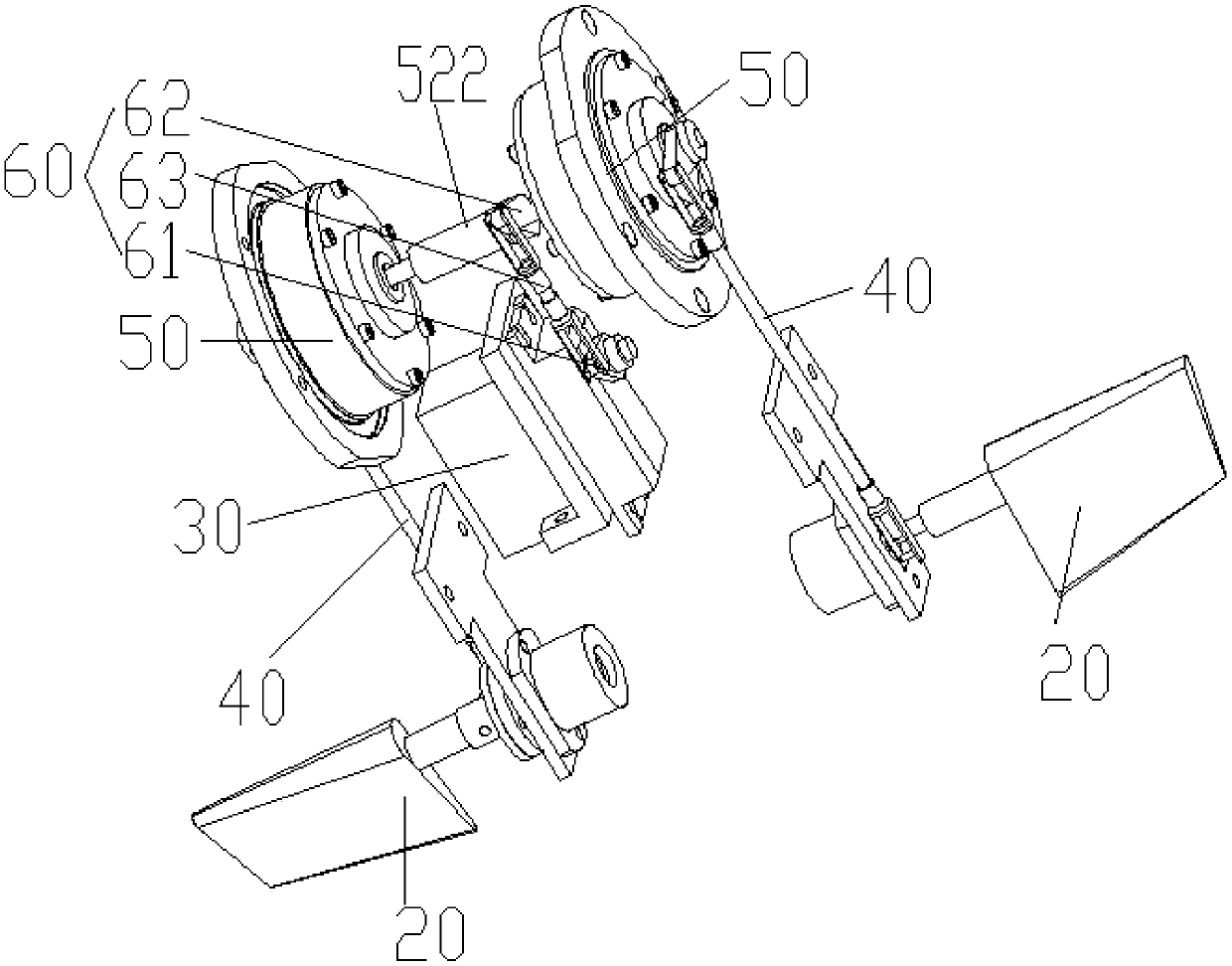

InactiveCN107719617AIncrease torqueIncrease output powerDynamo-electric brakes/clutchesSteering ruddersCouplingEngineering

The invention relates to a magnetic coupling component and a magnetic coupling steering device thereof, wherein the magnetic coupling component comprises a shell, a front cover and a rear cover whichare both arranged on the two ends of the shell. The shell forms two relative chambers from the intro-radial direction, which are defined as an inner cavity and an external chamber respectively. The inner cavity of the shell is provided with an inputting rotator, wherein the input axis of the inputting rotator extends out the front cover; the external cavity of the shell is provided with an outputting rotator, wherein the output axis of the outputting rotator extends out the rear cover; the inputting rotor and the outputting rotor are respectively embedded with a plurality of magnetic parts ontheir respective relative surfaces. Compared with the prior art, the magnetic coupling component and the magnetic coupling steering device thereof have the advantages that the magnetic induction of the interaction between the inputting and outputting of the rotors is enhanced, which effectively improves the torque when the magnetic coupling steering device drives the outputting rotor to rotate bythe inputting rotor; at the same time, the axial structure of the magnetic coupling component becomes more compact.

Owner:HANGZHOU DIANZI UNIV

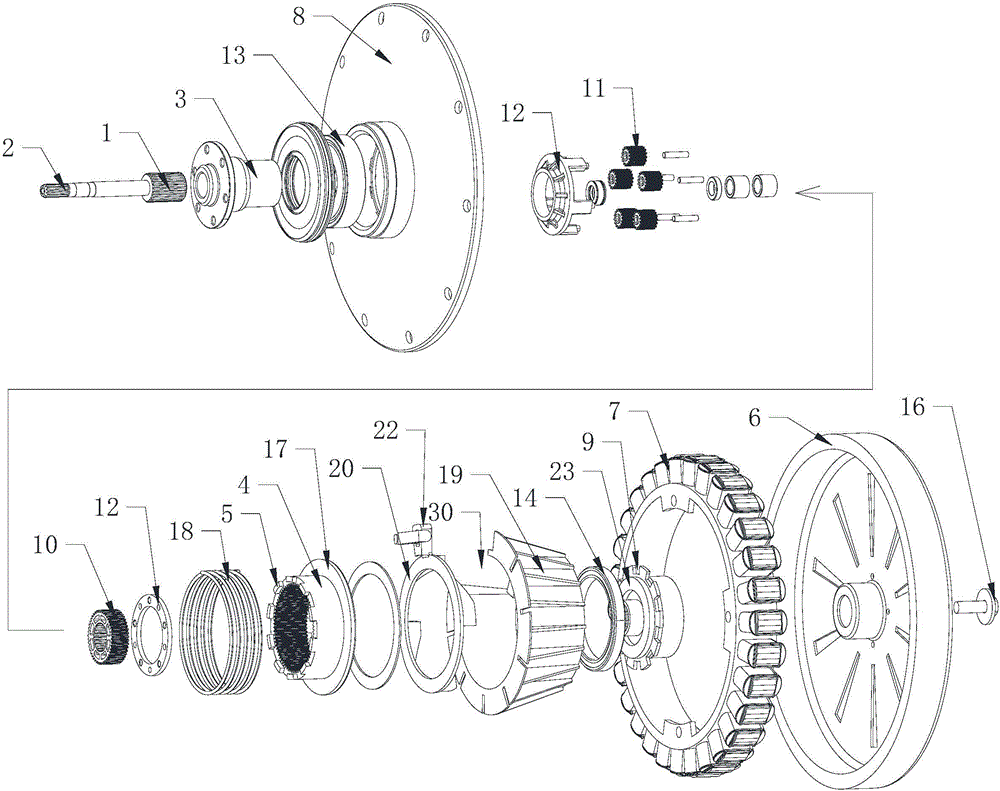

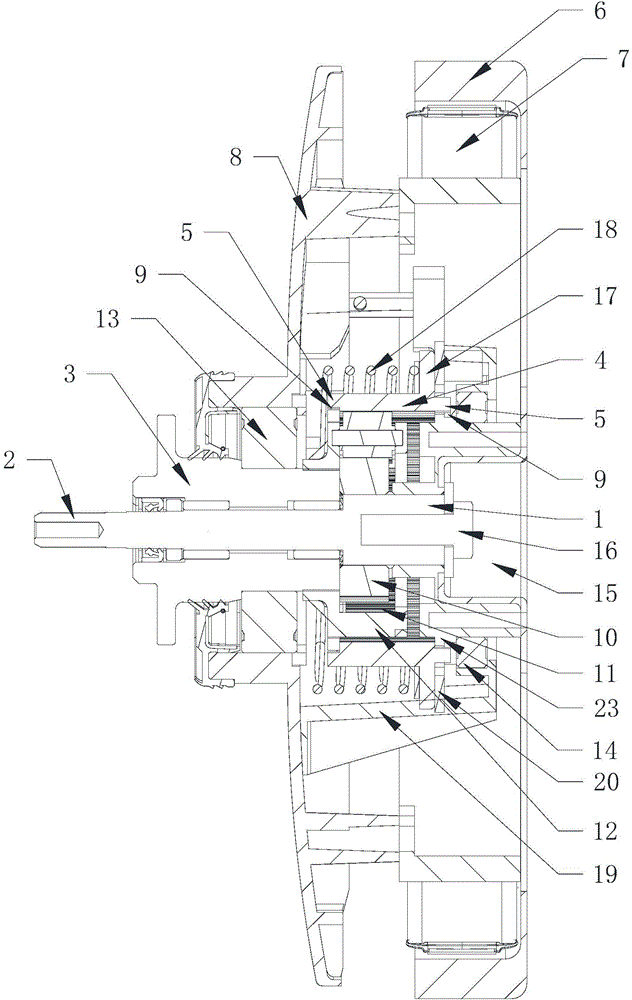

Hydraulic torque converter integrated with double radially nested type gear shifting clutches

The invention discloses a hydraulic torque converter integrated with double radially nested type gear shifting clutches. The double gear shifting clutches arranged in the hydraulic torque converter are disposed in the hydraulic torque converter in a radially nested mode. The hydraulic torque converter has the advantages that the double gear shifting clutches are integrated in the hydraulic torque converter in the radially nested mode, so that the structure is simplified, the cost is lowered, and the axial structure of the hydraulic torque converter is more compact; starting is smoother, the comfort level is high, and the defect of obvious abrupt sense during low-gear low-speed forward moving is overcome.

Owner:华域动力总成部件系统(上海)有限公司

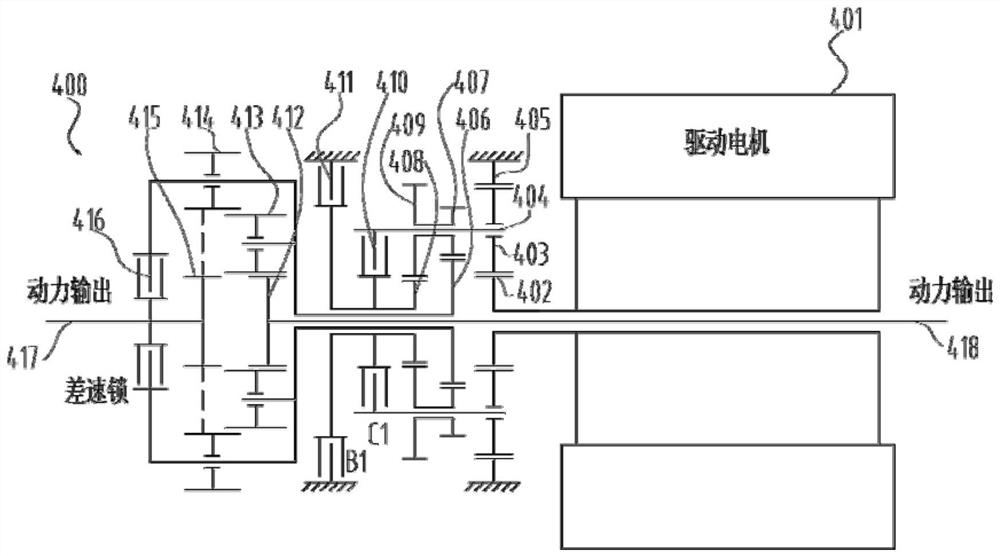

Single-motor coaxial two-gear electric drive axle

PendingCN113928101ASmall space requirementRealize independent distributed driveElectric propulsion mountingControl devicesElectric machineryEngineering

The invention provides a single-motor coaxial two-gear electric drive axle which comprises a drive motor, a two-gear planetary speed reduction mechanism which comprises a speed reduction planetary row, a composite planetary row, a clutch and a brake; and a differential which comprises a differential shell, a first output half shaft and a second output half shaft, and the second output half shaft and the first output half shaft are coaxial and opposite in output direction. The speed reduction planet row and the composite planet row share the frame, and the structure is more compact; due to the structural design of the compound planet row, the transmission ratio between a high gear and a low gear is reduced, and the economical efficiency and the gear shifting comfort of the vehicle are improved after the two gears are arranged behind the speed reduction planet row.

Owner:江苏华永复合材料有限公司

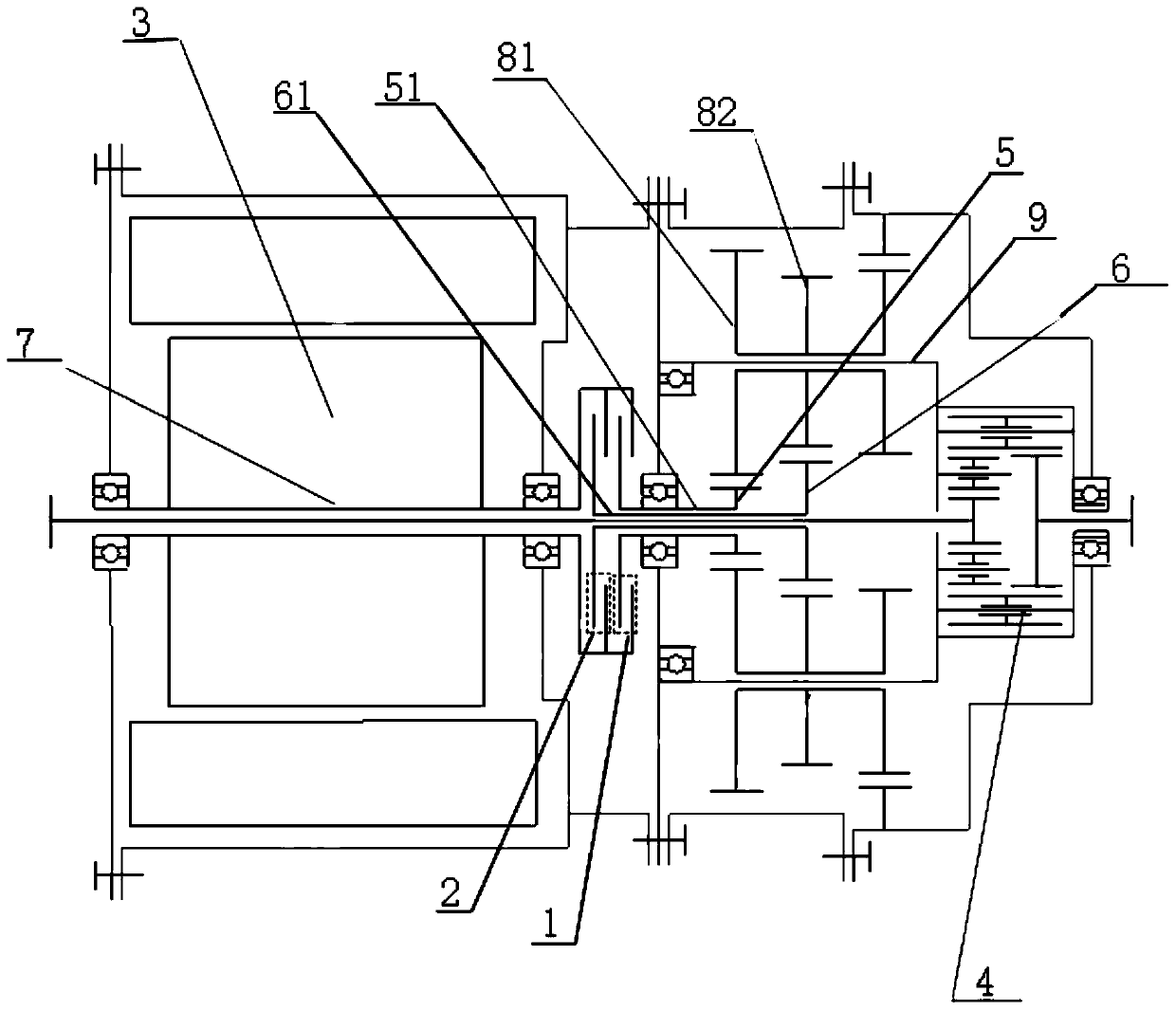

Automobile and electric axis driving system

InactiveCN110758095AMake full use of radial spaceSmall structureElectric propulsion mountingToothed gearingsElectric machineGear wheel

The embodiment of the invention provides an electric axis driving system and an automobile. The electric axis driving system comprises a box body, a differential, a motor, a first multi-linkage planetary gear set, a first clutch and a second clutch, wherein the differential comprises a differential shell; the motor comprises a motor output shaft; the first multi-linkage planetary gear set comprises a first sun gear, a first planet carrier, a first gear ring and a second gear ring, wherein the cross sections of the first gear ring and the second gear ring are mutually in parallel, the first sungear and the motor output shaft are in anti-torque connection, and the first planet carrier and the differential shell are in the anti-torque connection; the first clutch comprises a first steel sheet and a first friction sheet, wherein the first steel sheet and the first friction sheet have an on-off function, the first steel sheet is fixed on the box body, and the first friction sheet is fixedly connected with the first gear ring; and the second clutch comprises a second steel sheet and a second friction sheet, wherein the second steel sheet and the second friction sheet have an on-off function, the second steel sheet is fixed on the box body, and the second friction sheet is fixedly connected with the second gear ring. By use of the electric axis driving system provided by the embodiment of the invention, an axial occupation space is reduced, and the structural compactness of the whole system is improved.

Owner:SCHAEFFLER TECH AG & CO KG

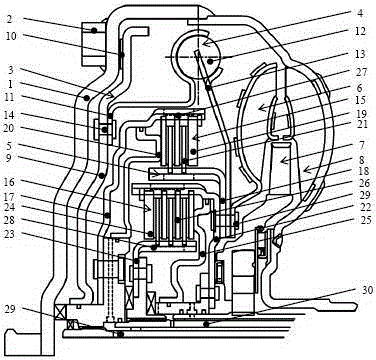

Washing machine deceleration clutch and washing machine

ActiveCN105463771ALower the altitudeReduce volumeOther washing machinesTextiles and paperEngineeringHeight difference

The invention relates to a washing machine deceleration clutch comprising an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve. The deceleration device is at least formed by a central gear, a transmission gear, a transmission gear rack and an internal gear ring; the clutch device at least comprises a clutch shaft sleeve and a driving device driving a clutch shaft sleeve to axially move; the clutch shaft sleeve is mounted on the circumferential periphery of the deceleration device; the clutch shaft sleeve and the transmission gear rack can axially slide to each other, but cannot be circumferentially rotationally connected; the internal gear ring is connected with the output shaft sleeve; the driving device comprises at least one clutch platen coaxially arranged with the clutch shaft sleeve; the end surface of the clutch platen has height difference in an axial direction; the clutch platen circumferentially drives the clutch shaft sleeve to axially move to control different output states of the output shaft and the output shaft sleeve. The washing machine deceleration clutch is simply structured and occupies little space in an axial direction; and overall height of the deceleration clutch can be reduced and washing capacity can be increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Rotating body position detection device

PendingCN113364217AOptimize space layoutAxial compactStructural associationConverting sensor outputMagnetic field magnitudeMagnetic loop

The invention discloses a rotating body position detection device, which belongs to the technical field of detection, and comprises a magnetic ring, a calculation unit and at least two Hall sensors, wherein the magnetic ring is fixed on a rotating body, the magnetic ring comprises at least one pair of magnetic poles, and the magnetic poles are distributed along the radial direction of the magnetic ring; the at least two Hall sensors are arranged around the peripheral surface of the magnetic ring at intervals or are arranged opposite to the end surface of the magnetic ring, and are used for detecting the magnetic field intensity of the magnetic ring; and the calculation unit is used for calculating the position of the rotating body according to the magnetic field intensity detected by each Hall sensor. When the rotating body rotates around the central axis, the magnetic ring is driven to rotate, the Hall sensor can detect the magnetic field intensity of the magnetic ring, any position of the rotating body can be detected through the calculation unit, and comprehensive detection is achieved. The Hall sensor does not occupy space, space layout is facilitated, and the axial structure is compact.

Owner:NANJING CHERVON IND

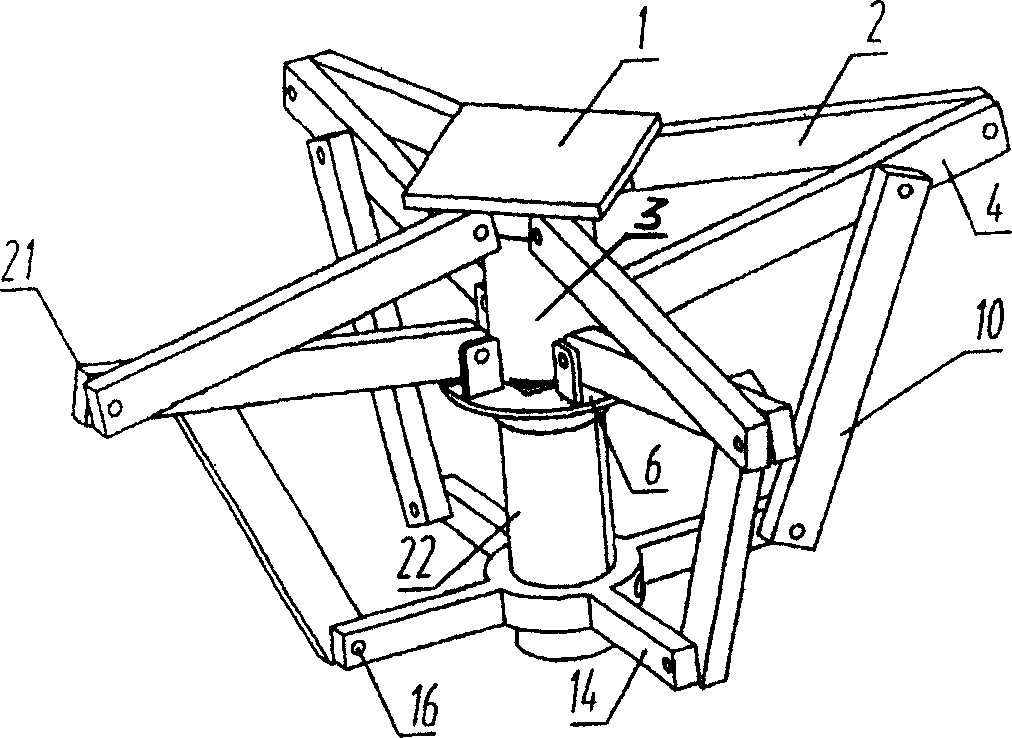

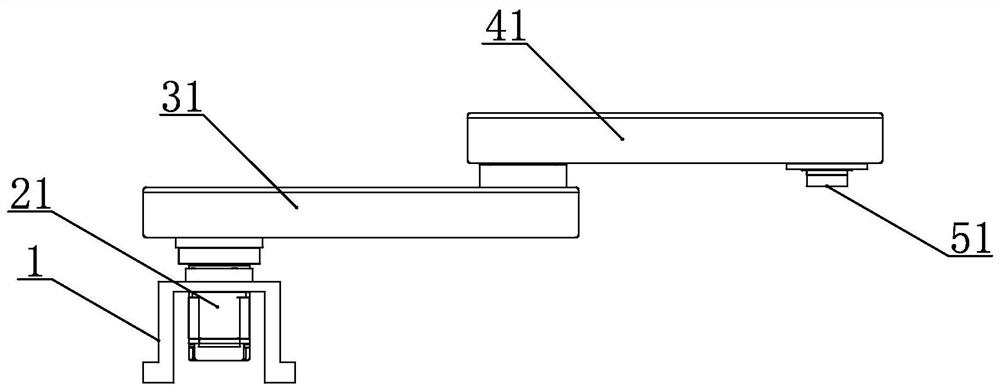

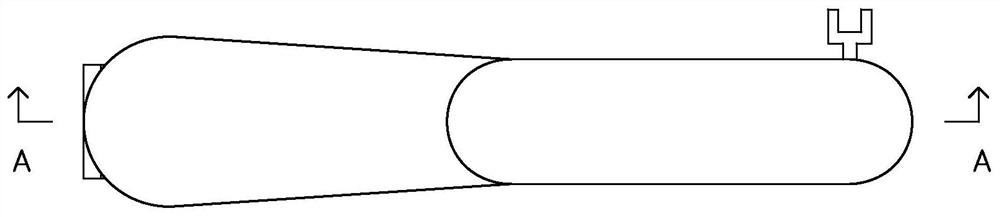

Single-drive linear motion robot

ActiveCN113043253AReduce energy consumptionReduce weightProgramme-controlled manipulatorLinear motionReduction drive

The invention discloses a single-drive linear motion robot, and relates to an industrial robot. The single-drive linear motion robot is flexible in structure and small in occupied space. The single-drive linear motion robot comprises a driving assembly, an upper arm assembly, a forearm assembly and a tail end tool; the driving assembly comprises a driving motor, the driving motor is connected with a first transmission shaft, the first transmission shaft is connected with a first speed reducer, and the output end of the first speed reducer is connected with an upper arm body; the upper arm assembly comprises a first belt wheel, a second belt wheel and a second transmission shaft, the second transmission shaft is connected with a second speed reducer, the output end of the second speed reducer is connected with a forearm body, and a third transmission shaft is connected between the upper arm body and the forearm body; the forearm assembly comprises a third belt wheel and a fourth belt wheel, the fourth belt wheel is connected with an output shaft, and the output shaft is provided with a tool installation hole used for installing a tail end tool. The distance between the first transmission shaft and the second transmission shaft is equal to the distance between the third transmission shaft and the output shaft.

Owner:珞石(北京)科技有限公司

Rear power takeoff for speed changing box

ActiveCN101746265BAxial compactReduce volumeAuxillary drivesGear lubrication/coolingEngineeringPower take-off

The invention discloses a rear power takeoff for a speed changing box, which comprises a power takeoff gear shaft, wherein one end of the power takeoff gear shaft is provided with a spline section and an output shaft being in coaxial on-off with the power takeoff gear shaft, a shaft circle at one end of the output shaft is provided with a spline section corresponding to the spline section on the power takeoff gear shaft, the spline section of the output shaft is connected with a clutch spline sleeve which is connected with a clutch drive device, and the other end of the output shaft is provided with an output connecting spline hole. The rear power takeoff also comprises a front shell and a rear shell which are connected mutually, the shaft end of the power takeoff gear shaft is provided with a connecting supporting hole, the end part of the output shaft is supported in the connecting supporting hole at the shaft end of the power takeoff gear shaft through a bearing, and the other end of the output shaft is supported between the front shell and the rear shell. The rear power takeoff has compact axial structure and small volume, and can be widely applied to medium and heavy speed changing boxes.

Owner:DONGFENG MOTOR CORP HUBEI

A washing machine deceleration clutch and washing machine

The invention relates to a washing machine deceleration clutch and a washing machine. The deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is at least partially arranged on the periphery of the deceleration device; the clutch device at least comprises a clutch shaft sleeve capable of axially moving and a driving device driving the clutch shaft sleeve to axially move; the clutch shaft sleeve is arranged outside an annular gear of the deceleration device and is in a connection with the annular gear in way of being capable of sliding relative to the annular gear but incapable of rotating relative to the same; the driving device drives the clutch shaft sleeve to axially move to control different output states of the output shaft and the output shaft sleeve; the driving device comprises at least one clutch press plate coaxially arranged with the clutch shaft sleeve; and the clutch press plate can circumferentially rotate to drive the clutch shaft sleeve to axially move. The deceleration clutch is simply structured and axially occupies small space; and overall height of the deceleration height can be reduced and washing capacity can be increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Pump body structure of compressor and compressor with same

ActiveCN102251953BAxial compactImprove performancePositive displacement pump componentsPositive-displacement liquid enginesKinematic pairEngineering

The invention provides a pump body structure of a compressor and a compressor with the same, wherein the pump body structure of the compressor comprises a crankshaft and a lower flange. The crankshaft comprises a long shaft, a short shaft and an eccentric shaft, the eccentric shaft is connected between the long shaft and the short shaft, the short shaft is provided with a first matching surface, the lower flange is provided with a second matching surface matched with the first matching surface, and the first matching surface is a rotating surface capable of bearing an axial load. The invention further provides a compressor comprising the pump body structure. Through the pump body structure and the compressor, problems of mechanical loss, noises, vibrations and the like are solved by the elimination of capsizing moment and the realization of automatic alignment; on the foundation, an oil pipeline is designed, thus the lubrication between kinematic pairs is increased, the abrasion is reduced, and the axial structure of the compressor is more compact; therefore, the effect of improving the reliability and the performances of the compressor is achieved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

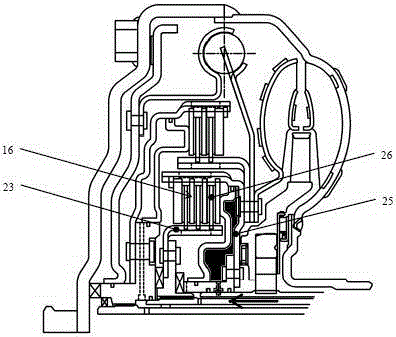

A washing machine deceleration clutch and washing machine

ActiveCN105332241BLower the altitudeReduce volumeOther washing machinesTextiles and paperDrive motorEngineering

The invention relates to a washing machine deceleration clutch and a washing machine. The deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is at least partially arranged on the periphery of the deceleration device; the clutch device at least comprises a clutch shaft sleeve capable of axially moving and a driving device driving the clutch shaft sleeve to axially move; the clutch shaft sleeve is arranged outside an annular gear of the deceleration device and can slide relative to the annular gear in an axial way but cannot rotate relative to the same in the circumferential way; the driving device drives the clutch shaft sleeve to axially move to control different output states of the output shaft and the output shaft sleeve; the driving device comprises at least one shifting fork rod; the shifting fork rod is provided with a fixing part; and one end of the shifting fork rod is provided with a shifting fork controlling the clutch shaft sleeve to axially move and the other end is provided with a driving end in a transmission connection with a driving motor. The deceleration clutch is simply structured, has reliable control, small stroke, and compact structure and occupies small space; stable and reliable operation and low fault rate can be achieved; and overall height of the deceleration height can be reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

A washing machine deceleration clutch and washing machine

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Rotating gas-jetting rotor

ActiveCN109139292AImproved torque stabilityIncrease thrustGas turbine plantsTurbine/propulsion air intakesCombustion chamberHigh energy

The invention discloses a rotating gas-jetting rotor, and belongs to the technical field of jet engine equipment. The rotating gas-jetting rotor comprises a box, a box cover, a center shaft, a rotating disc, a conductive ring, a spark plug, a flow guiding pipe, a valve core and a spring; the box and the box cover are fixedly connected to form a machine base, the conductive ring is fixedly connected with the box cover, the center shaft and the rotating disc are fixedly connected to form an axisymmetric rotating body, and the rotating disc is provided with a main combustion chamber and a C-shaped gas channel; and high-pressure mixed gas enters the main combustion chamber, high-pressure gas generated by ignition combustion of the spark plug is jet from the front end of the valve core to be mixed or combusted with air sucked by the flow guiding pipe or combustible mixed gas in the C-shaped gas channel to form high-energy gas, the gas is jet from a spraying nozzle on the rotating disc to generate thrust, the rotating body is pushed to rotate at the high speed, and rotating moment is output. The rotating gas-jetting rotor has the characteristics that output power and the self-weight ratio are large, the axial structure is compact, the manufacturing cost is low, and dynamic balance performance is good.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

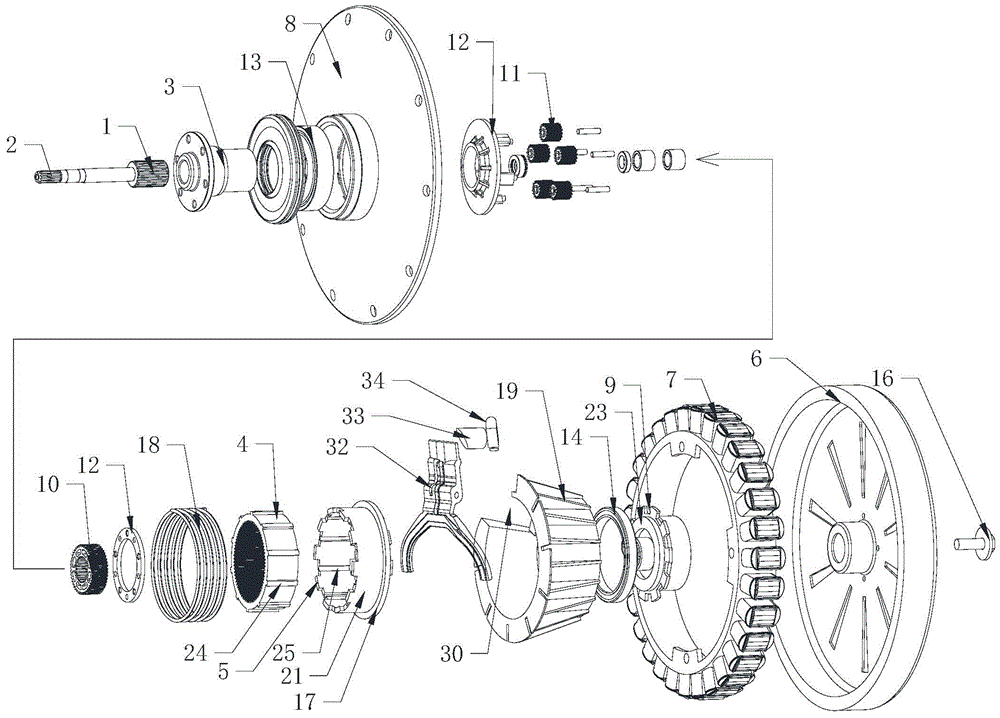

A wheel-side reducer installation structure and a wheel-side reduction bridge assembly

ActiveCN112677759BAxial compactReduce manufacturing costGearing detailsControl devicesReduction driveEngineering

The invention relates to the technical field of vehicle axles, and discloses an installation structure of a wheel-side reducer and a wheel-side reduction axle assembly. The wheel side reducer installation structure is used to connect the planetary reducer and the axle housing, the planetary reducer is connected to one end of the half shaft, the axle housing is rotatably sleeved on the half shaft, and the axle housing is arranged on the end face of the planetary reducer. The limit boss is provided with an external thread on the outer peripheral surface of the limit boss. The installation structure of the wheel side reducer also includes a ring gear bracket and a locking nut. The ring gear bracket is used to connect with the planetary reducer, and the ring gear bracket is provided with There are installation holes, the installation holes are sleeved on the limit boss, the side of the ring gear bracket away from the planetary reducer is in contact with the end face, the lock nut is matched with the external thread, and the lock nut and the ring gear bracket are close to the side of the planetary reducer Abut. The mounting structure of the wheel-side reducer has a compact structure along the axial direction and low manufacturing cost. The wheel-side reduction axle assembly is provided with the above-mentioned wheel-side reducer installation structure, and the axial structure is compact and the space occupied is small.

Owner:FAW JIEFANG AUTOMOTIVE CO

A washing machine deceleration clutch and washing machine

ActiveCN105316906BLower the altitudeReduce the overall heightOther washing machinesTextiles and paperElectric machineryEngineering

The invention relates to a washing machine decelerating clutch and a washing machine. The decelerating clutch comprises an input shaft, a decelerating device, a clutch device, an output shaft and an output shaft sleeve, and is characterized in that the clutch device at least comprises a clutch shaft sleeve capable of moving axially and a clutch driving device for driving the clutch shaft sleeve to move axially; the clutch shaft sleeve is arranged at the outer part of an inner gear ring of the decelerating device; the clutch driving device drives the clutch shaft sleeve to move axially and control different output states of the output shaft and the output shaft sleeve; the clutch driving device is close to a decelerating clutch shell for arranging an upper cover of a penetrating-out end of the output shaft. According to the washing machine decelerating clutch, the clutch driving device is arranged at a position close to an installation plate, so that partial components of the clutch device can be formed by using the thickness of the upper cover; meanwhile, at least part of the decelerating device and / or the clutch device extends into a cavity of a motor, the overall height of the decelerating clutch is further reduced, and a larger space is provided for a wash bucket.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com