Rear power takeoff for speed changing box

A technology of gearbox and power take-off, applied in the direction of gear transmission, gear lubrication/cooling, belt/chain/gear, etc. The effect of improving the force condition and the compact structure in the axial direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

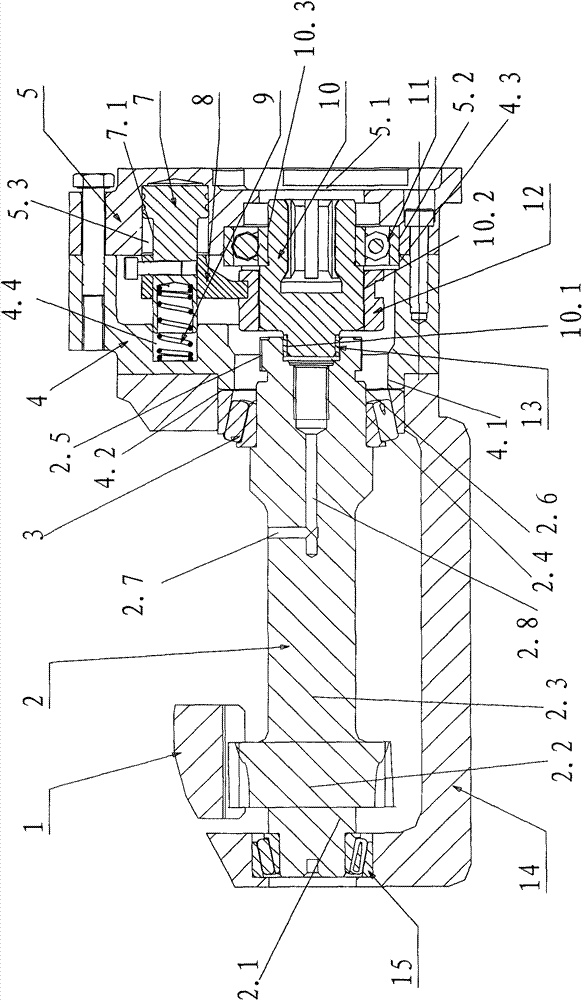

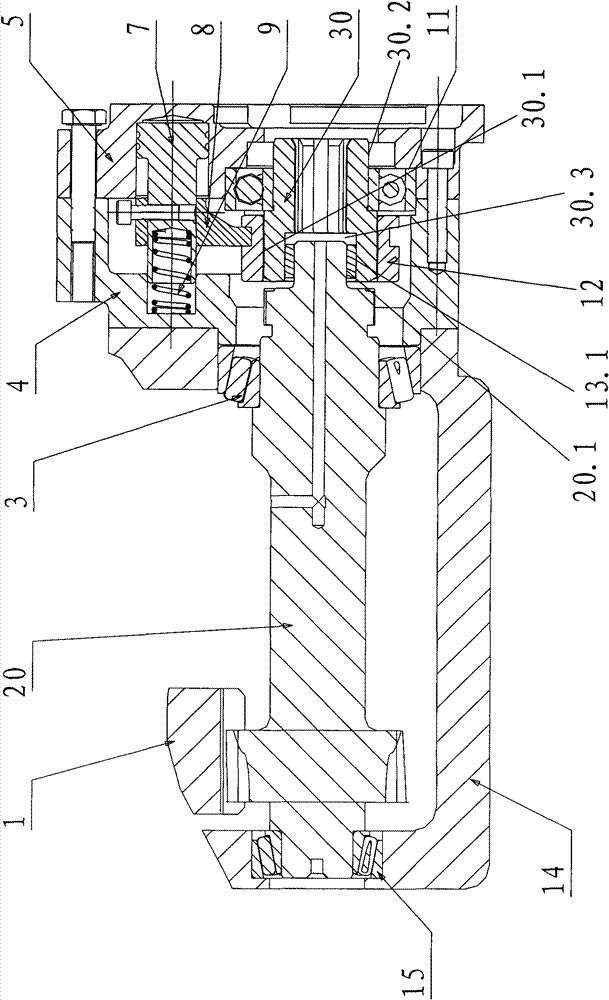

[0026] It has some structural differences with the embodiment, such as figure 2 As shown, the power take-off gear shaft 20 in this embodiment has at least 6 sections, that is, the support section 20.1 connected with the output shaft 30 is added on the basis of the five sections of Embodiment 1. The output shaft 30 in this embodiment is at least composed of Two sections, that is, only the spline section 30.1 and the support section 30.2 connected by the clutch spline sleeve, the spline section 30.1 is provided with a connection support hole 30.3 at the end, and the support section 20.1 of the power take-off gear shaft 20 extends into the connection In the support hole 30.3, a bearing 13.1 is provided between the support section 20.1 and the connecting support hole 30.3, so as to support the output shaft 30. Other structures of the power take-off in this embodiment are the same as those of the power take-off in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com