Rotating gas-jetting rotor

A technology for rotating jets and rotors, which is used in jet propulsion devices, gas turbine devices, and air inlets of turbine/propulsion devices. and other problems, to achieve the effect of good dynamic balance performance, compact axial structure and large output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

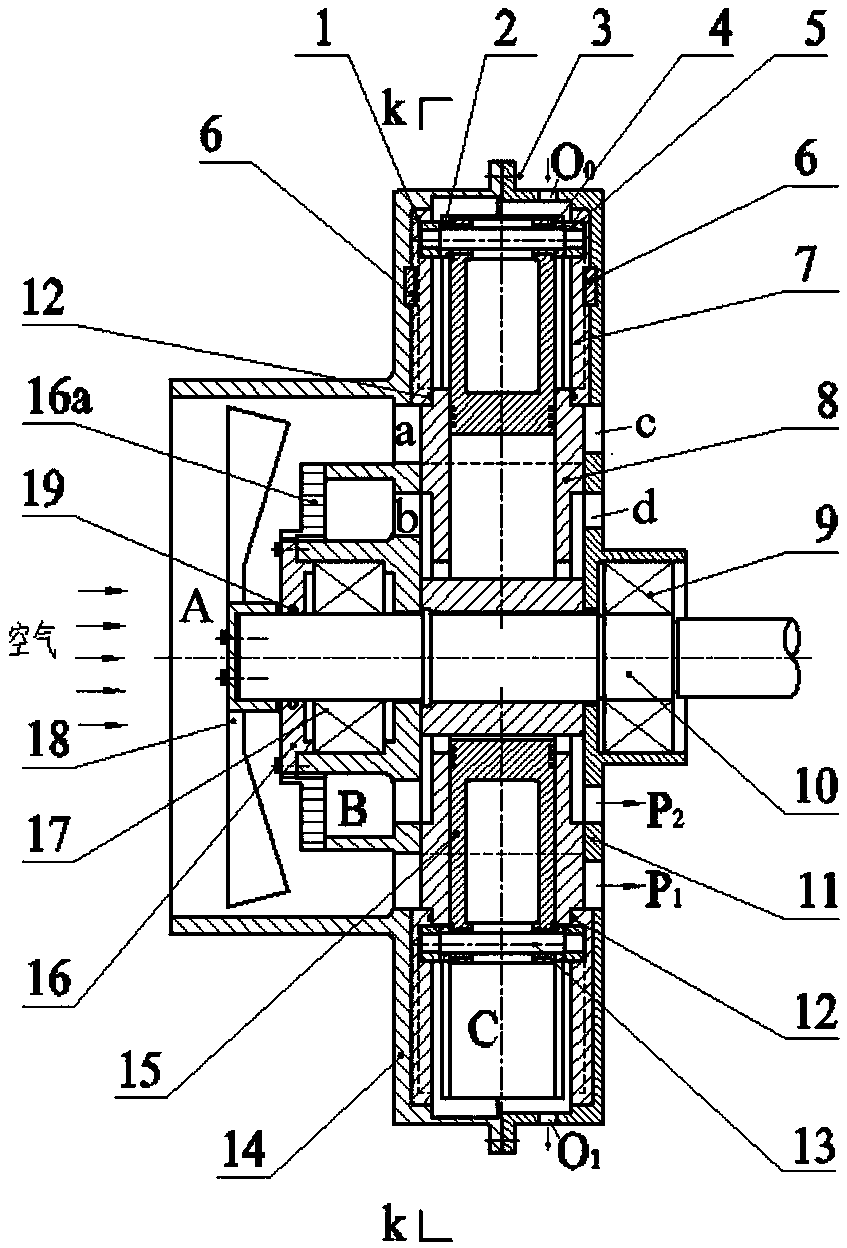

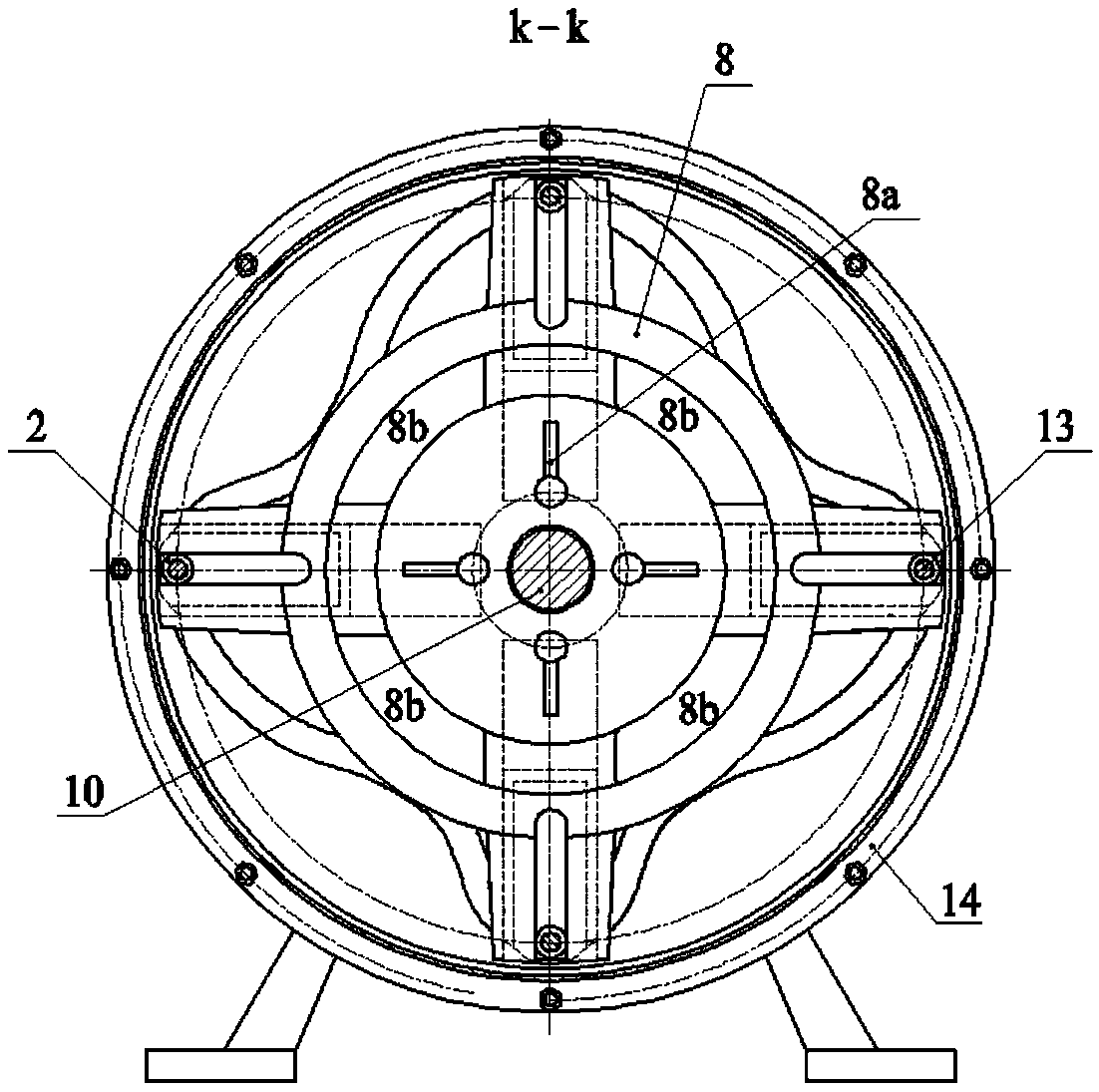

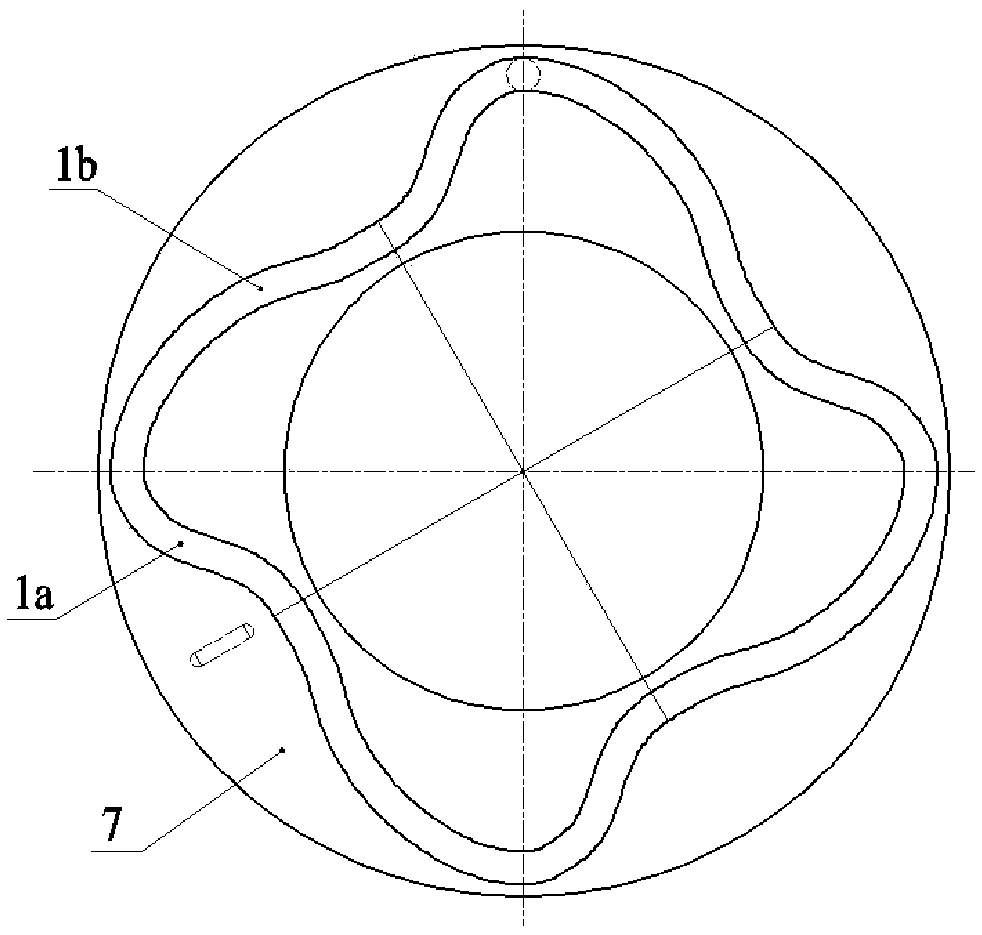

[0019] exist figure 1 Among them, the central shaft 2 sequentially passes through the inner hole of the bearing 3 and the turntable 6 and is axially fixed by the round nut group 7 (including the round nut and the stop washer), wherein the inner ring of the bearing 3 is positioned by the shoulder of the central shaft 2, and the turntable The end surface of the inner hole of 6 is in contact with the end surface of the inner ring of the bearing 3; a key 9 is installed between the central shaft 2 and the turntable 6 for circumferential positioning. Two spark plugs 12 are symmetrical to the axis of the turntable, and are fixedly installed on the right side wall of the main combustion chamber 6d through threaded connection. The valve core 13, spring 14 and guide tube 4 are seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com