A disk-type double-cross-link magnetism-concentrating transverse field motor

It is a transverse magnetic field and magnetic concentrating technology, which is applied to synchronous motors, magnetic circuits, and synchronous machines with static armatures and rotating magnets. , to achieve the effect of ensuring installation accuracy and installation reliability, accurate positioning, and improving torque stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

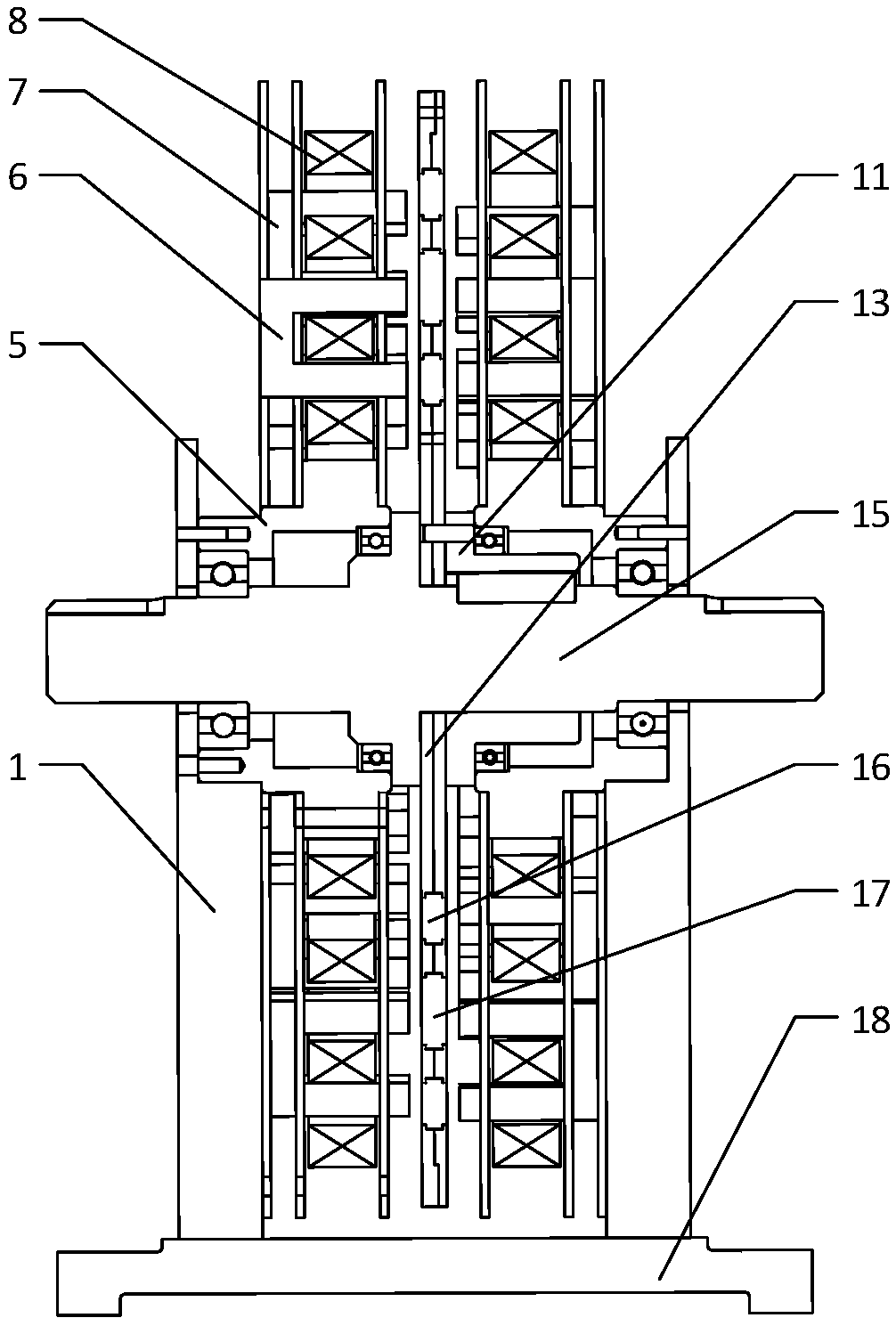

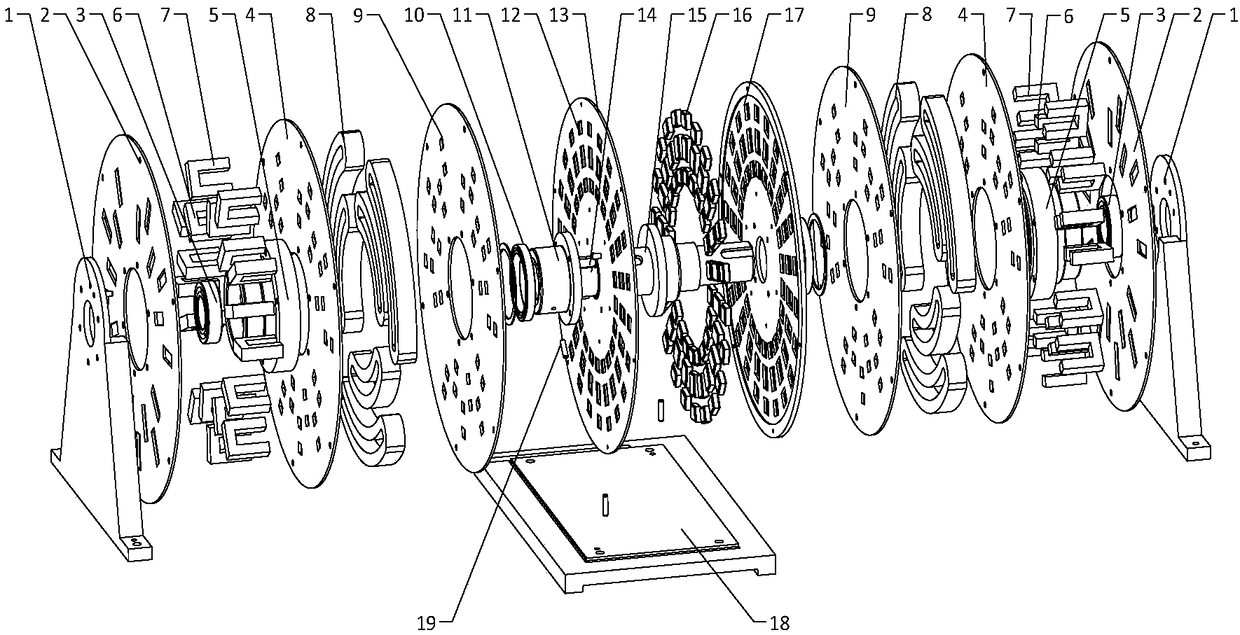

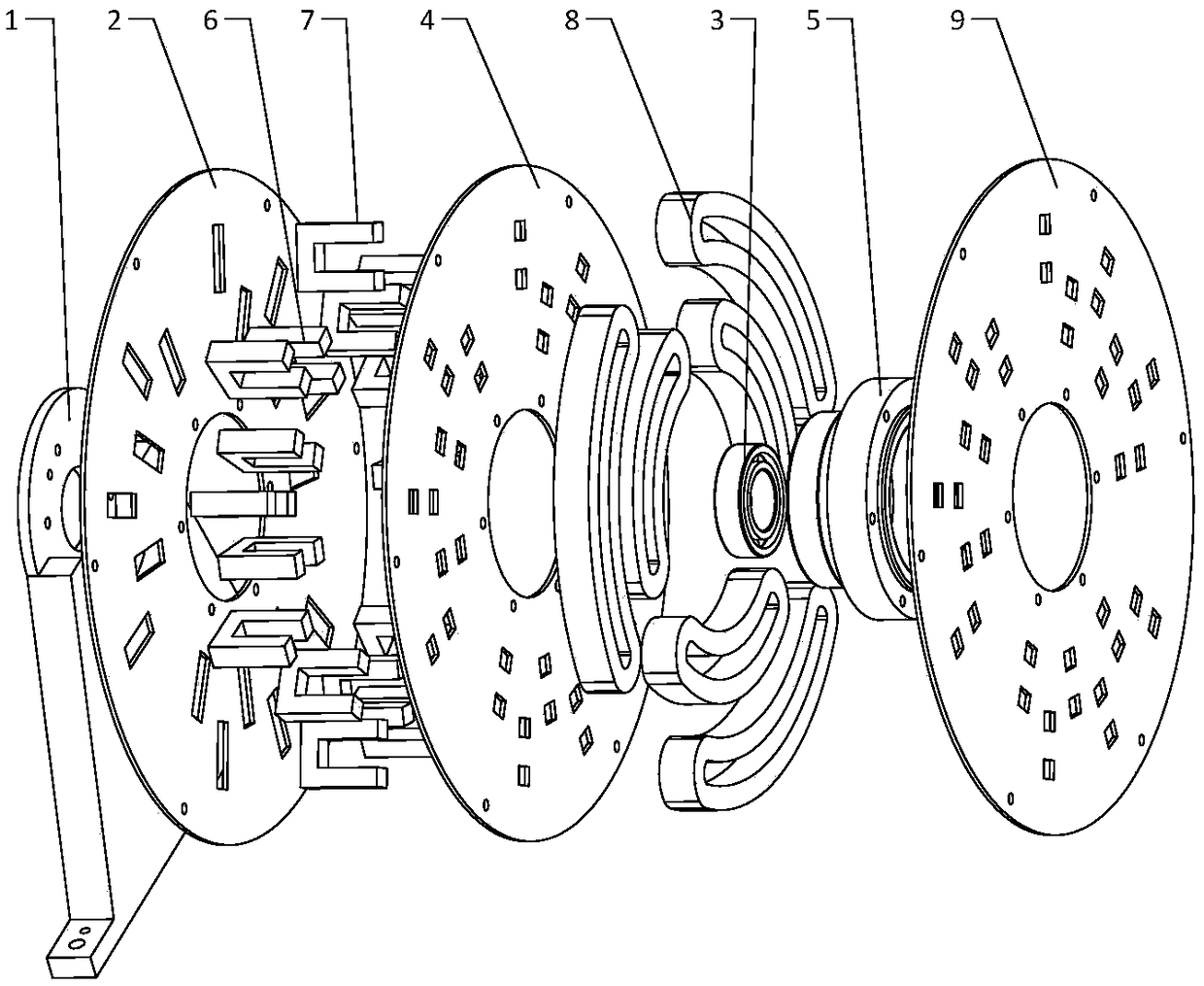

[0020] This embodiment is a disk-type double-cross-linkage magnetism-concentrating transverse field motor.

[0021] refer to Figure 1 to Figure 5 In this embodiment, the disk-type double-cross-link magnetic-gathering transverse field motor is composed of a rotor, a stator on both sides, a support 1, and a machine base 18. The two supports 1 and the machine base 18 are positioned and fixed by pins. The two supports 1 and the machine The seat 18 is installed vertically and symmetrically; the stators on each side are connected to the bracket 1 by pins, the stators on both sides differ in the circumferential direction by 360 / 2P mechanical angle, P is the number of pole pairs of the motor, and the axial length of the gap between the rotor and the stators on both sides is equal. Among them, the stator consists of a stator disc 2, a pay-off disc 4, a crimping disc 9, a primary C-type silicon steel lamination 6, a secondary C-type silicon steel lamination 7, an armature winding 8, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com