Pole-following rotor of rotary motor

A rotating electrical machine, cis-pole technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of low utilization rate of permanent magnets, affecting rotor application, increasing motor output, etc. The effect of low utilization rate, reduction of magnetic flux leakage of magnets, and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

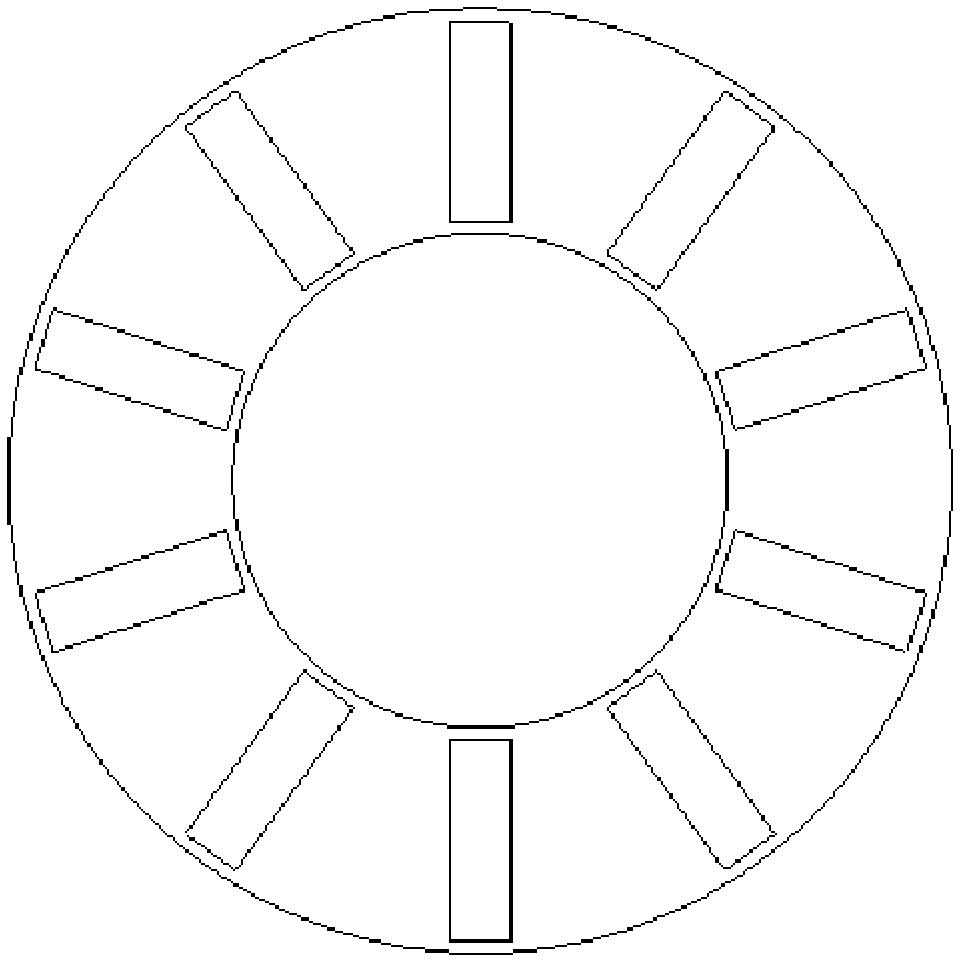

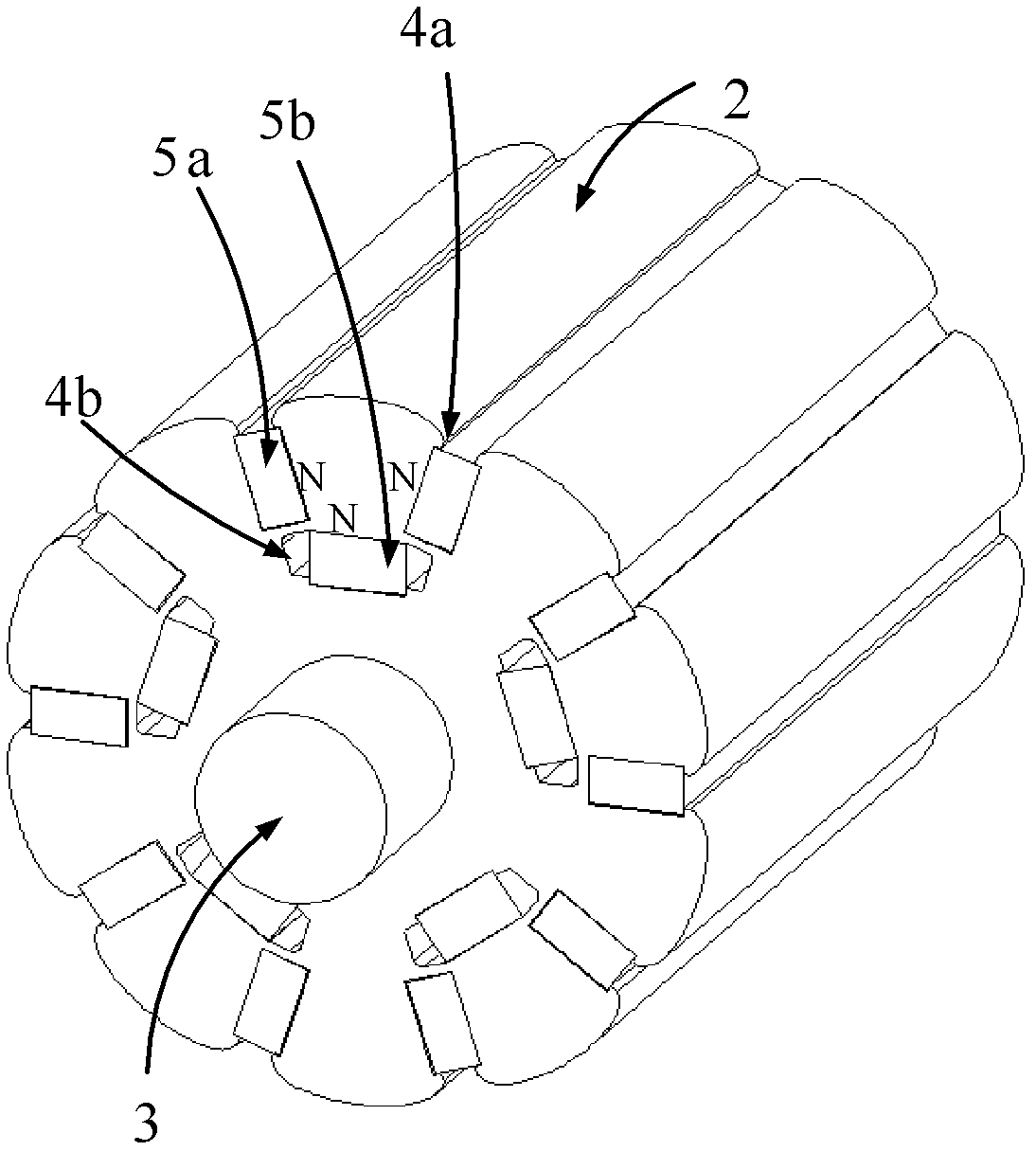

[0016] see image 3 The cis-polar rotor of this rotating electrical machine includes a rotor composed of a rotating shaft 3 and a laminated iron core 2. The laminated iron core 2 is provided with several first permanent magnets that rotate along the axis of the rotating shaft 3 and are magnetized in the circumferential direction of the rotor relative to the axis. The magnetic pole part 5a is also provided with several second permanent magnetic pole parts 5b that rotate along the axis of the rotating shaft 3 and are magnetized in the radial direction of the rotor relative to the axis in the laminated core 2. The number of the second permanent magnetic pole parts 5b is the first 1 / 2 of the number of permanent magnet pole parts 5a.

[0017] In this embodiment, the rotor is a 10-pole rotor, and there are 10 first permanent magnetic pole parts 5a in total. The polarities of each adjacent group of first permanent magnetic pole parts 5a are opposite, and the polarities of the second ...

no. 2 example

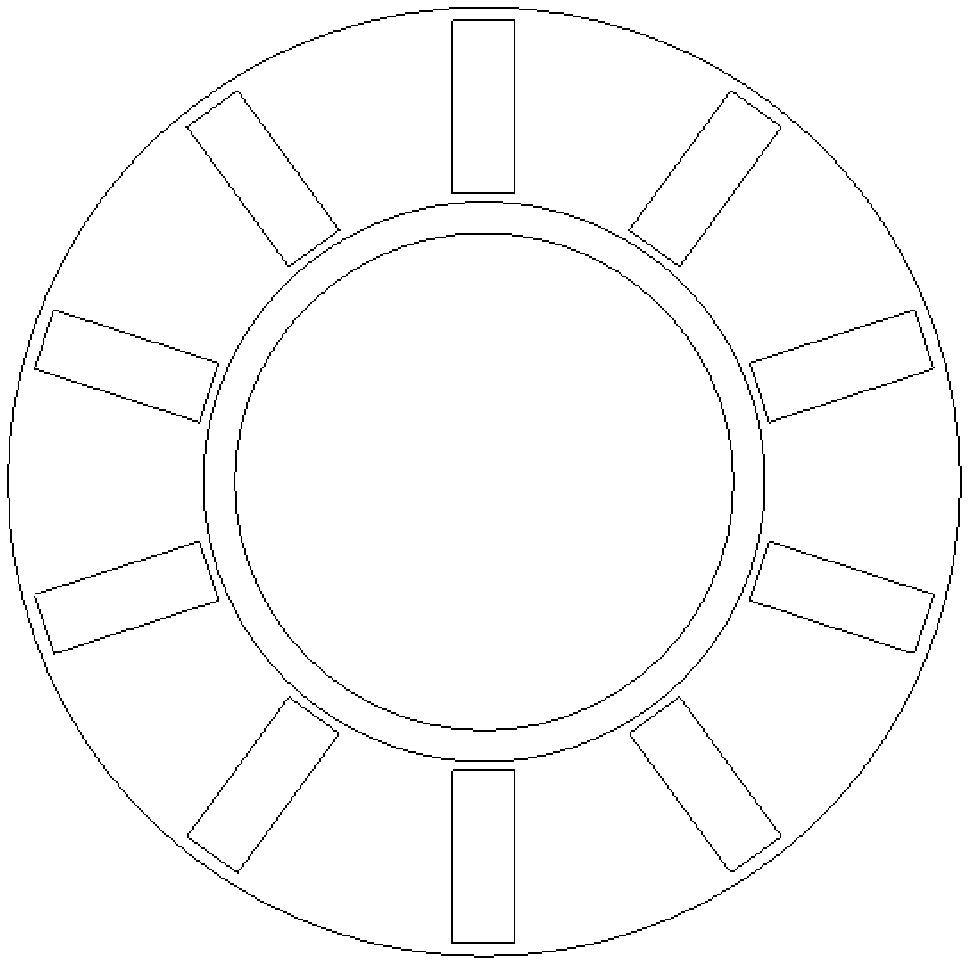

[0020] see Figure 4 , The main difference between the parallel pole rotor of this rotating electrical machine and the first embodiment is that the second permanent magnet groove (no label in the figure) is equivalent to the second permanent magnet pole part 5b, and there is no gap. Other unmentioned parts are the same as the first embodiment and will not be repeated.

no. 3 example

[0022] see Figure 5 The main difference between the parallel pole rotor of this rotating electrical machine and the first embodiment is that the second permanent magnet pole part 5b is embedded in the outer layer of the laminated core 2 through the second permanent magnet slot 4b, that is, the first permanent magnet pole part 5 a is embedded in the inner layer of the laminated core 2 . Other unmentioned parts are the same as the first embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com