Pump body structure of compressor and compressor with same

A compressor and pump body technology, applied in the direction of machines/engines, pump components, mechanical equipment, etc., can solve the problems of heavy crankshaft load and severe wear, and achieve the effects of improving performance, eliminating overturning moment, and enhancing lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

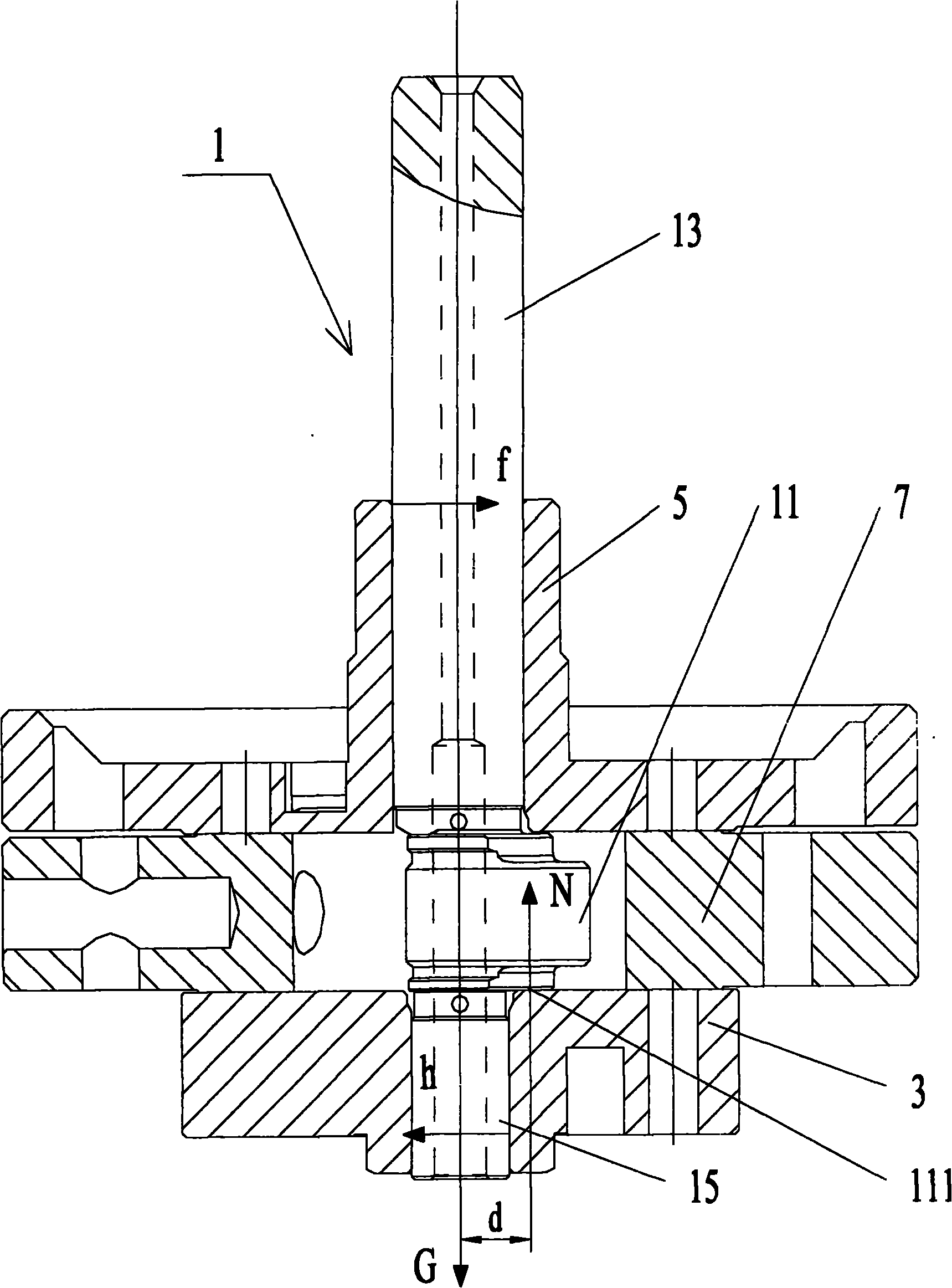

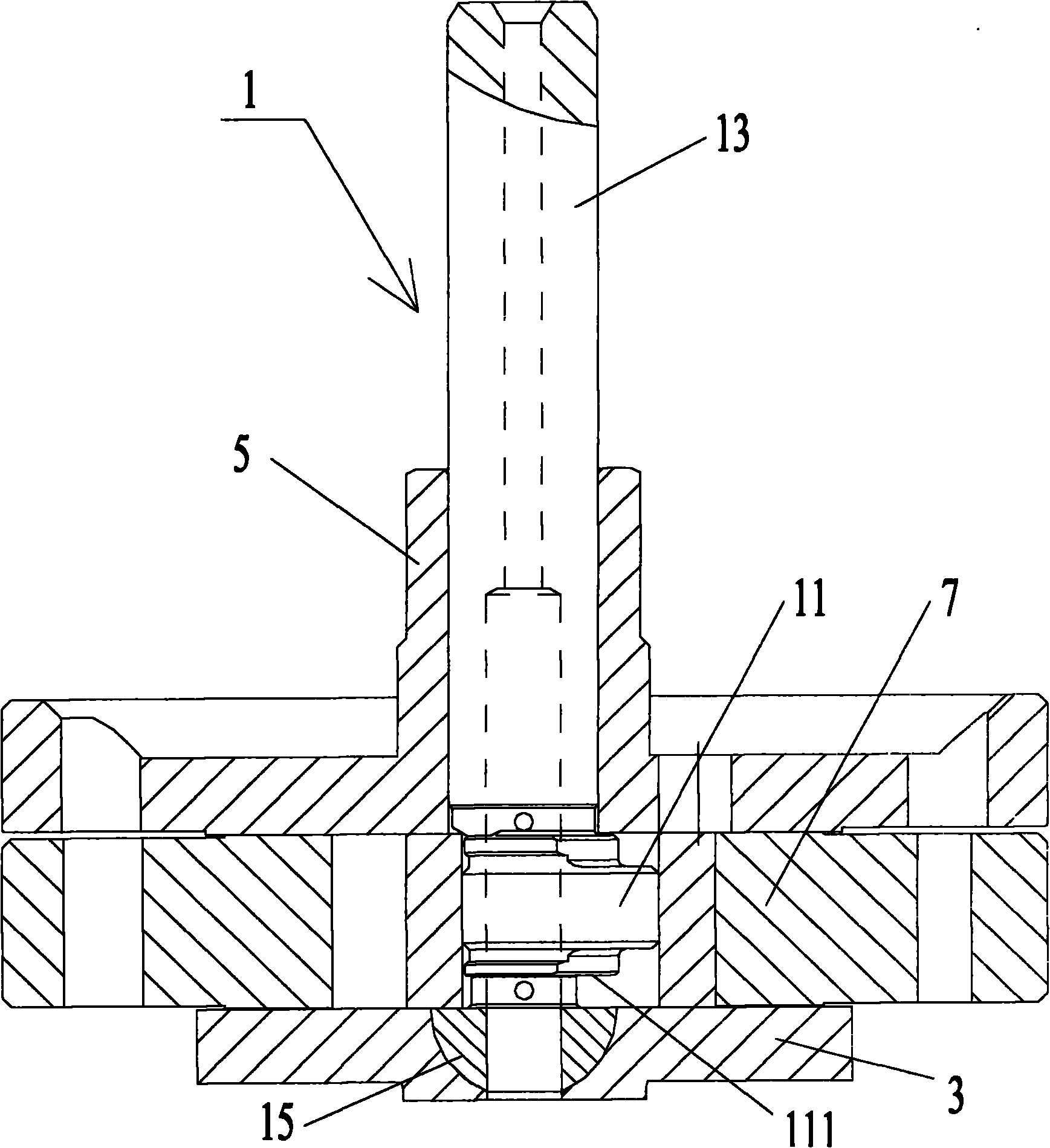

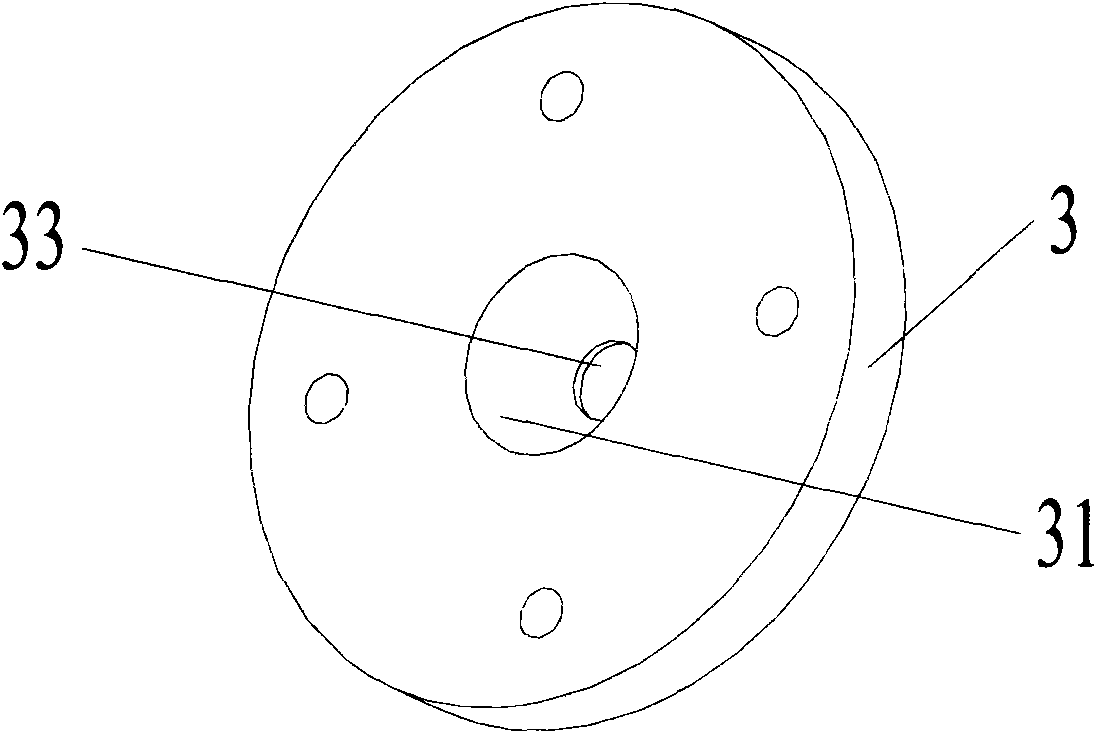

[0025] Such as figure 2 , image 3 As shown, the compressor pump body structure according to the embodiment of the present invention includes: a crankshaft 1 , an upper flange 5 , a lower flange 3 and a cylinder 7 . The cylinder 7 is installed between the upper flange 5 and the lower flange 3 . Crankshaft 1 passes through upper flange 5 , lower flange 3 and cylinder 7 . The crankshaft 1 includes: a long shaft 13, a short shaft 15 and an eccentric shaft 11 connected between them. Cooperating with the lower flange 3, the short shaft 15 has a first mating surface, which is a rotating surface capable of carrying axial loads. The rotating surface can be in various suitable shapes, including spherical surfaces, conical surfaces, and various regular and The irregular rotating surface only needs to be able to have axial contact with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com