Single-motor coaxial two-gear electric drive axle

A coaxial, single-motor technology, applied in the direction of electric power devices, power devices, control devices, etc., can solve the problems of inability to meet the speed change requirements, the built-in structure is not compact enough, and the comfort of shifting is poor, so as to improve the comfort of shifting , compact structure, and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

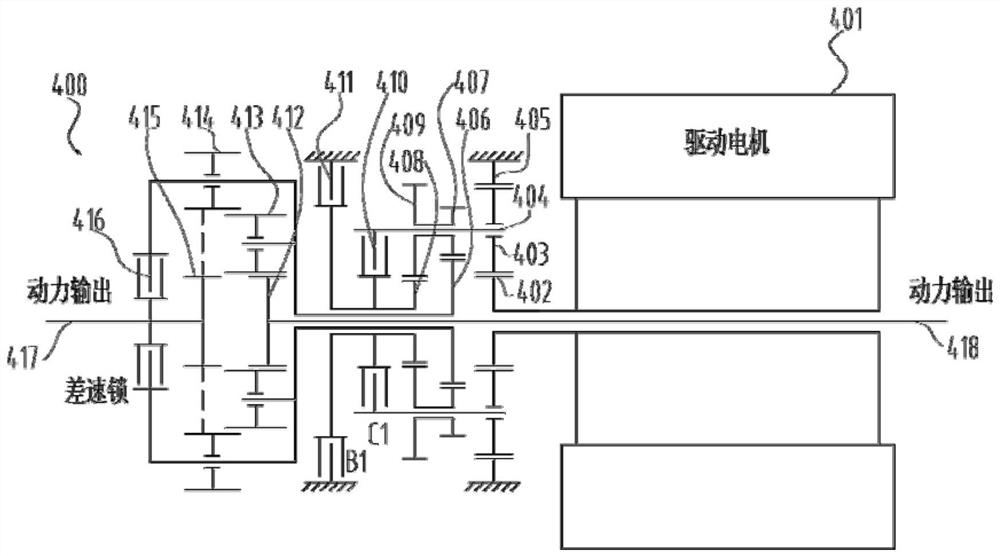

[0027] According to a preferred embodiment of the present invention, see figure 1 , provides a single-motor coaxial two-speed electric drive axle 400, which is characterized in that it includes:

[0028] The driving motor 401 has an output shaft, and the output shaft is a first hollow shaft;

[0029] The two-speed planetary reduction mechanism includes a reduction planetary row, a compound planetary row, a clutch 410 and a brake 411, and the reduction planetary row includes a first sun gear 402, a first planetary gear 403, a first planet carrier and a first ring gear 405, The first sun gear 402 is connected to the first hollow shaft, the first ring gear 405 is connected to the transaxle casing, and the composite planetary row includes the second sun gear 406, the second planetary gear 407, the second planet carrier, the second Three sun gears 408, the third planet gear 409 and the third planet carrier, the second sun gear 406 is larger than the third sun gear 408, the second ...

Embodiment approach

[0033] According to another preferred embodiment of the present invention, the second planetary gear 407 is meshed with the second sun gear 406, the third planetary gear 409 is meshed with the third sun gear 408, and the second planetary gear 407 and the third planetary gear 409 are arranged in parallel and connected to each other.

[0034] According to another preferred embodiment of the present invention, the differential is a compound planetary differential and further includes a fourth sun gear 412, a fourth planetary gear 413, a fifth sun gear 415 and a fifth planetary gear 414, the fourth The sun gear 412 is connected to the first output half shaft 418, the fifth sun gear 415 is connected to the second output half shaft 417, the fourth planetary gear 413 and the fifth planetary gear 414 are connected to the differential case and are externally meshed with each other. The fourth planetary gear 413 is engaged with the fourth sun gear 412 , and the fifth planetary gear 414 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com