Self-locking compact type vertical lifting mechanism

A vertical lifting mechanism, compact technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of occupying a large space, not being able to go straight up and down, high cost, etc., to achieve compact structure in the axial direction, safe lifting process, and stress-resistant reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail by the following examples.

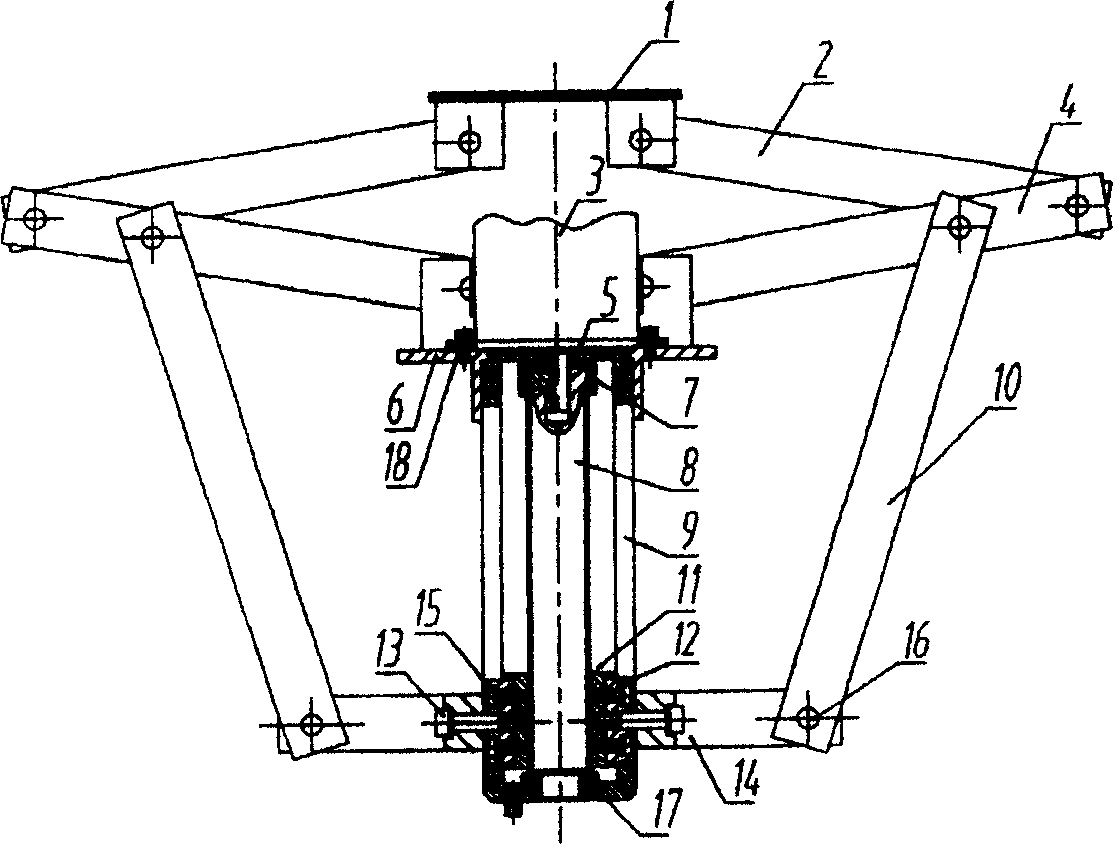

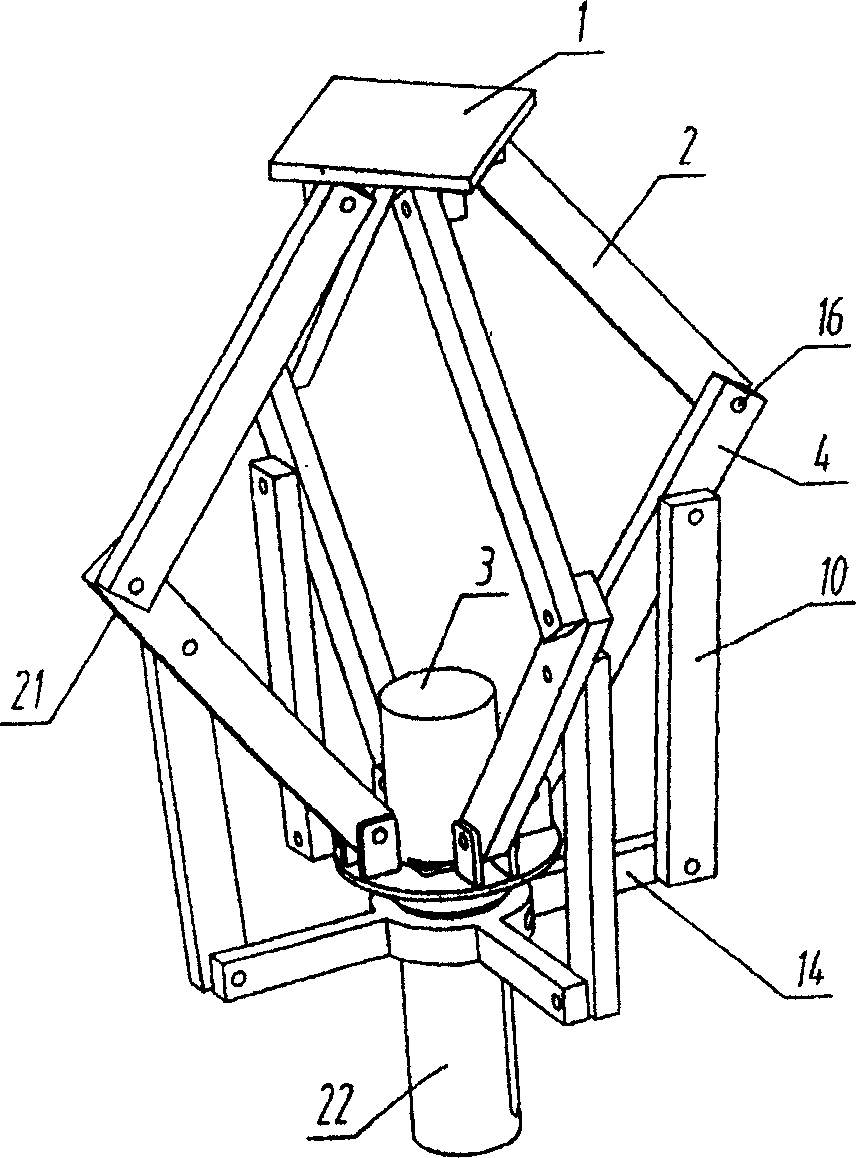

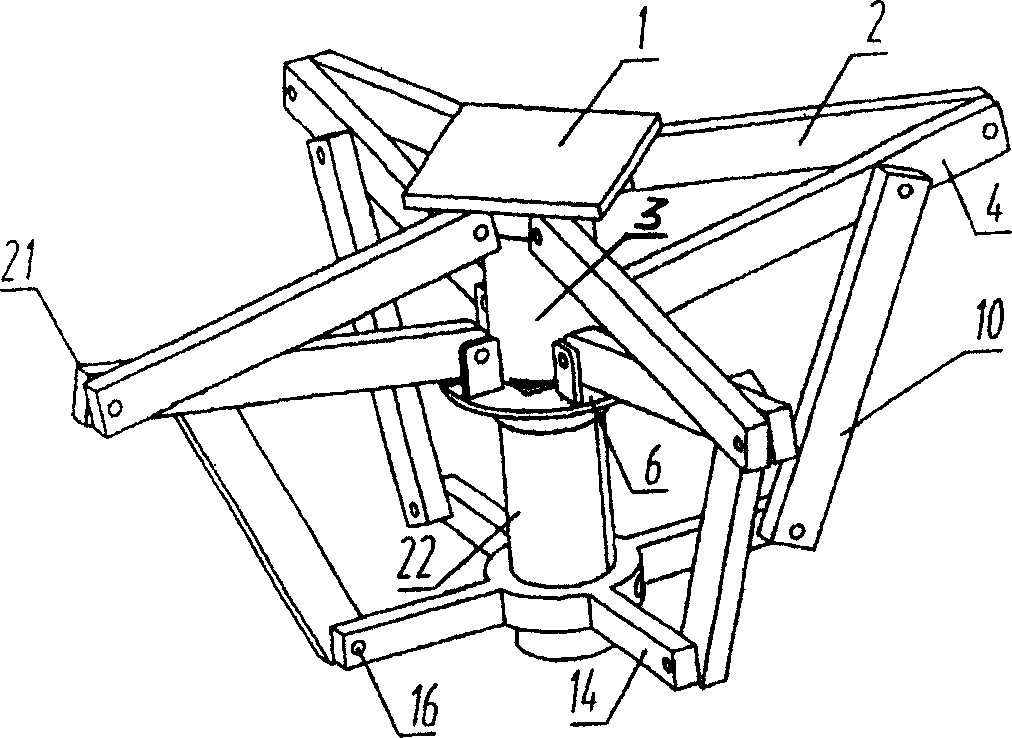

[0013] see figure 1 , figure 2 , image 3 As shown, a self-locking compact vertical lifting mechanism of the present invention includes a link slider mechanism 21 , a screw nut mechanism 22 and a housing 9 . Described link slider mechanism 21 is made up of fixed plate 6, upper slider 1, lower slider 14 and four groups of rods, each group of rods includes upper connecting rod 2, lower connecting rod 10 and swing rod 4, each rod Both ends of the parts are provided with holes, and the upper and lower sliders 1, 14 and the fixed plate 6 are provided with corresponding hinge seats, and each hinge seat is correspondingly provided with a pin hole, which is hinged to each other through the pin shaft 16: the upper connecting rod The top of 2 is hinged to the bottom of upper slider 1, the bottom of upper connecting rod 2 is hinged to the top of swing rod 4, the top of lower connecting rod 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com