Automobile and electric axis driving system

A drive system, electric shaft technology, applied in the direction of electric power unit, power unit, transmission device, etc., can solve the problem of occupying a lot of axial space and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It can be seen from the background art that the structural arrangement of the existing electric shaft drive system occupies a large axial space.

[0035] Combined with an electric shaft drive system, the reasons for the above problems are analyzed.

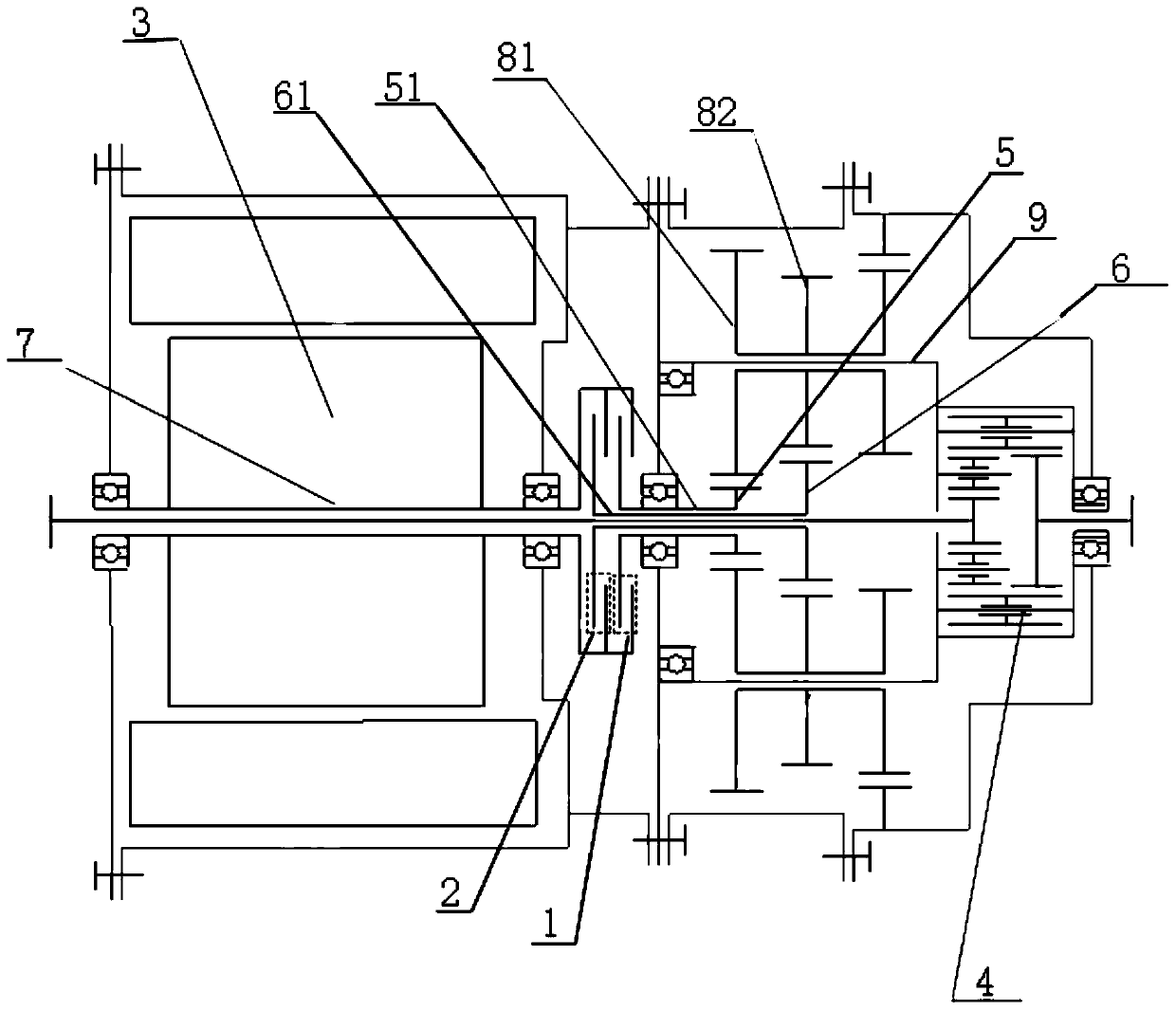

[0036] Please refer to figure 1 , figure 1 It is a structural schematic diagram of an electric shaft drive system.

[0037] Such as figure 1 As shown, an electric shaft drive system includes: a motor 3, a double clutch, a triple planetary gear set and a differential 4, the first clutch 1 in the double clutch and the hollow shaft 51 of the first sun gear of the triple planetary gear set The second clutch 2 of the double clutch is connected with the hollow shaft 61 of the second sun gear of the triple planetary gear set, and the motor output shaft 7 of the motor is connected with the housing of the double clutch. When the first clutch 1 is working, the power transmission path is as follows: the power is transmitted to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com