Collector ring with double nested structure

A technology of double-layer nesting and confluence rings, which is applied in the direction of current collectors, electrical components, rotating current collectors, etc., can solve the problems of unsatisfactory requirements, wire winding and twisting, large axial size of confluence rings, etc., and achieve convenient and stable Effects of rotation, height reduction, and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

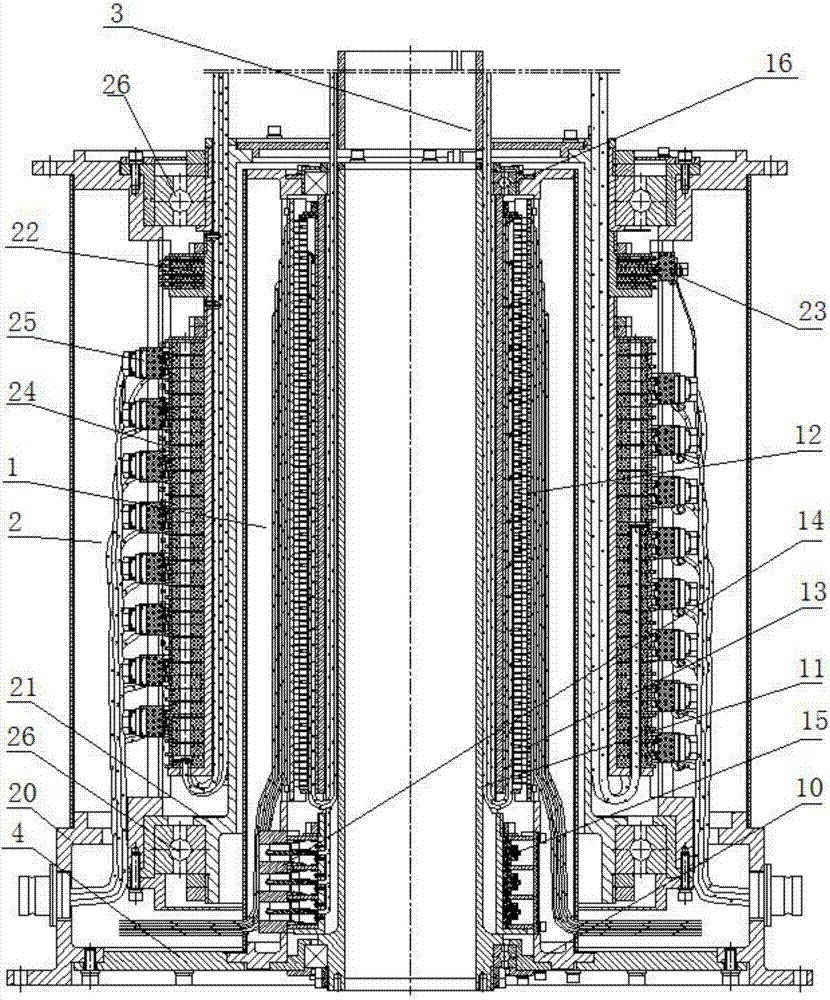

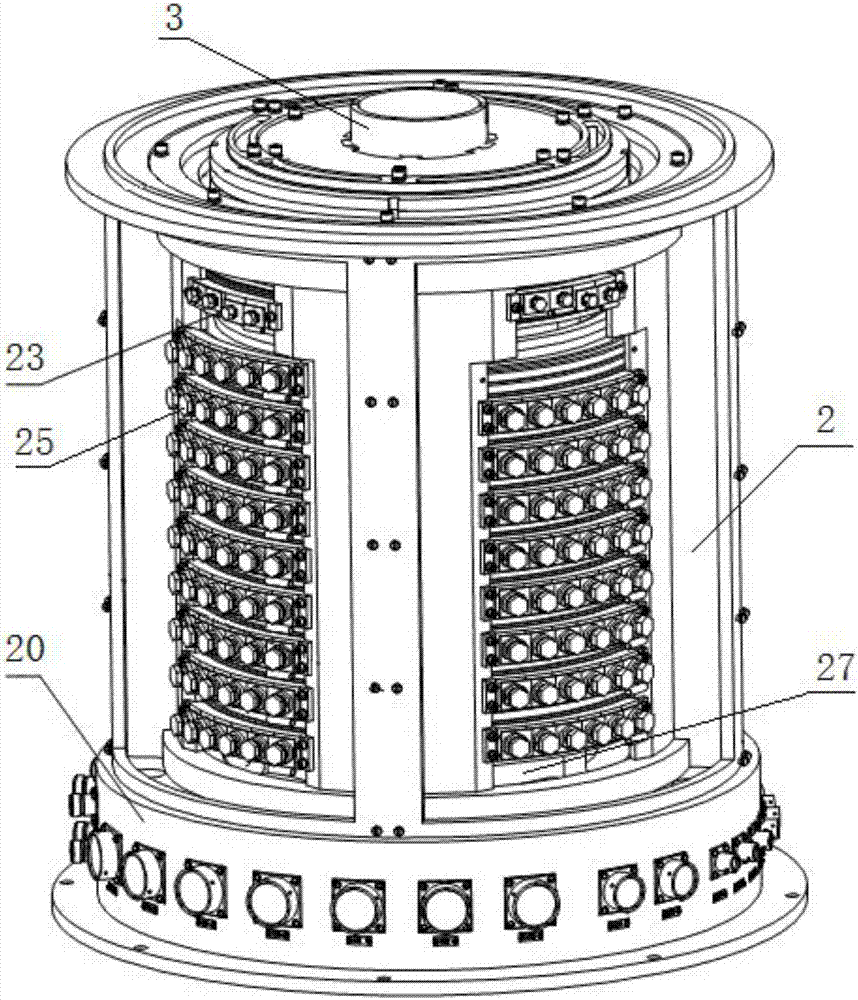

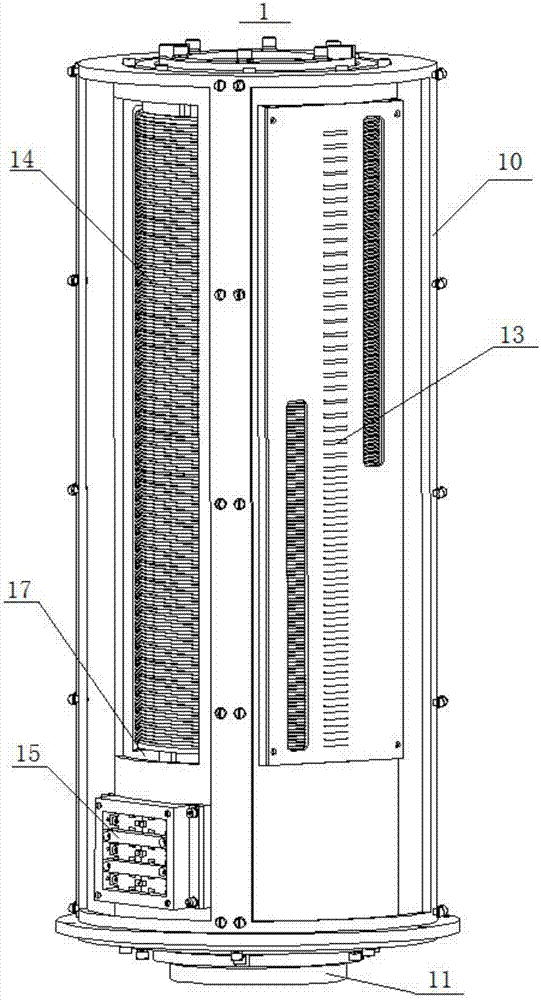

[0024] This embodiment provides a double-layer nested structure of the bus ring, such as Figure 1 to Figure 3 As shown, it includes an inner layer collector ring 1 and an outer layer collector ring 2, and the outer layer collector ring 2 is sleeved on the peripheral side of the inner layer collector ring 1; the inner layer collector ring 1 includes an inner layer shell 10, Inner mandrel 11, the inner mandrel 11 is rotatably arranged on the inner shell 10; the outer slip ring 2 includes the outer shell 20, the outer mandrel 21, the outer mandrel 21 is hollow and surrounds the The inner slip ring 1 is rotatably arranged on the outer shell 20; the middle parts of the inner mandrel 11 and the outer mandrel 21 are fixed with a conductive ring assembly along their axial directions, and the inner shell 10 and the outer shell The housing 20 is respectively fixed with a brush assembly that fits and slidably connects with the conductive ring assembly. Specifically, the inner mandrel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com